Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (10): 1153-1162.DOI: 10.15541/jim20240493

Special Issue: 【结构材料】陶瓷基复合材料(202512)

Previous Articles Next Articles

LIN Yuanwei1( ), JING Zhao2, CHEN Hetuo1(

), JING Zhao2, CHEN Hetuo1( ), LI Jiaheng1,4, QIN Xianpeng1, ZHOU Guohong1,3(

), LI Jiaheng1,4, QIN Xianpeng1, ZHOU Guohong1,3( ), WANG Shiwei1,3

), WANG Shiwei1,3

Received:2024-11-26

Revised:2025-02-19

Published:2025-10-20

Online:2025-02-25

Contact:

CHEN Hetuo, associate professor. E-mail: chenhetuo@mail.sic.ac.cn;About author:LIN Yuanwei (1997-), male, Master. E-mail: linyuanwei19@mails.ucas.ac.cn

Supported by:CLC Number:

LIN Yuanwei, JING Zhao, CHEN Hetuo, LI Jiaheng, QIN Xianpeng, ZHOU Guohong, WANG Shiwei. Ablative Properties of SiCp Doped Cf/Li2O-Al2O3-SiO2 Composites[J]. Journal of Inorganic Materials, 2025, 40(10): 1153-1162.

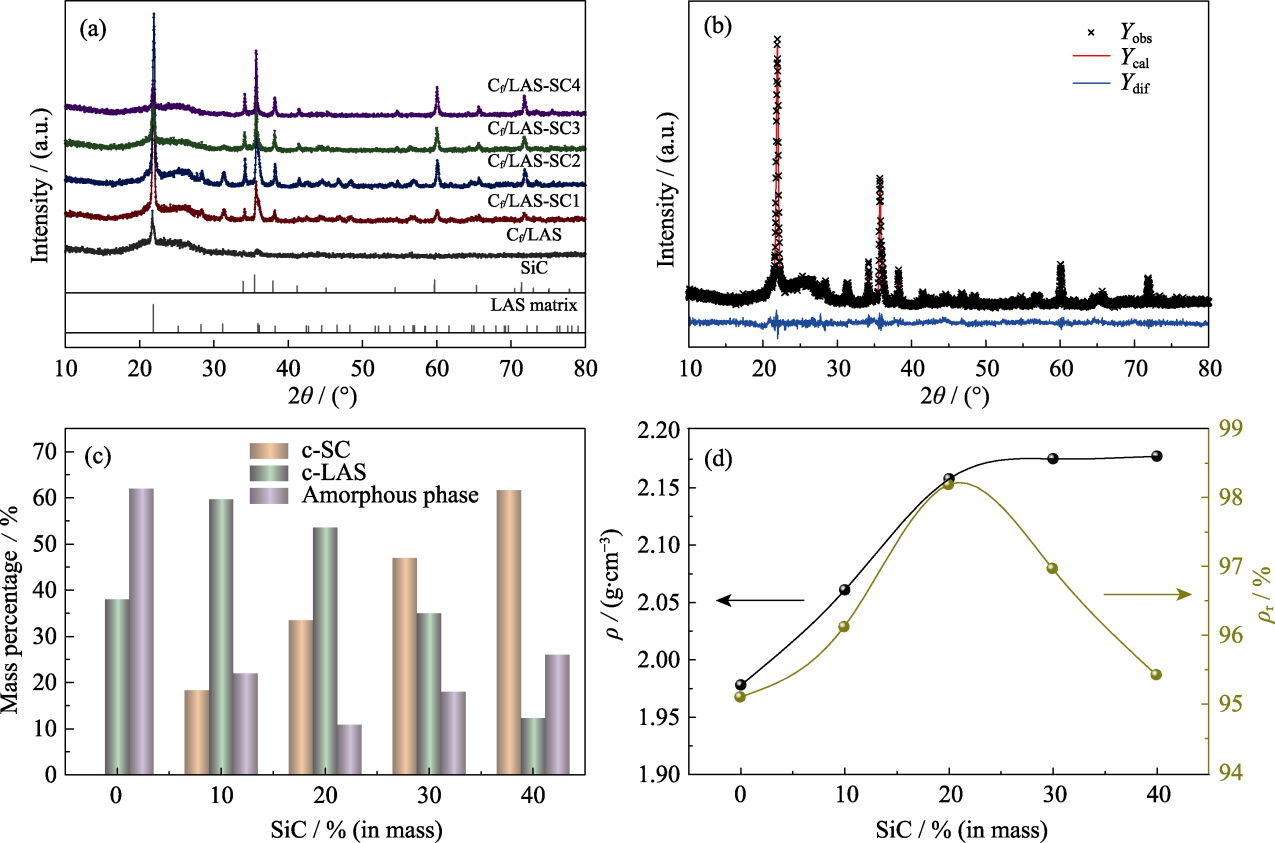

Fig. 1 Characterizations of Cf/LAS-SC composites (a) XRD patterns; (b) XRD refined patterns of Cf/LAS-SC3; (c) Mass percentages of different phases obtained by XRD refinement (c-SC indicates crystalline SiC and c-LAS indicates crystalline LAS); (d) Density (ρ) and relative density (ρr)

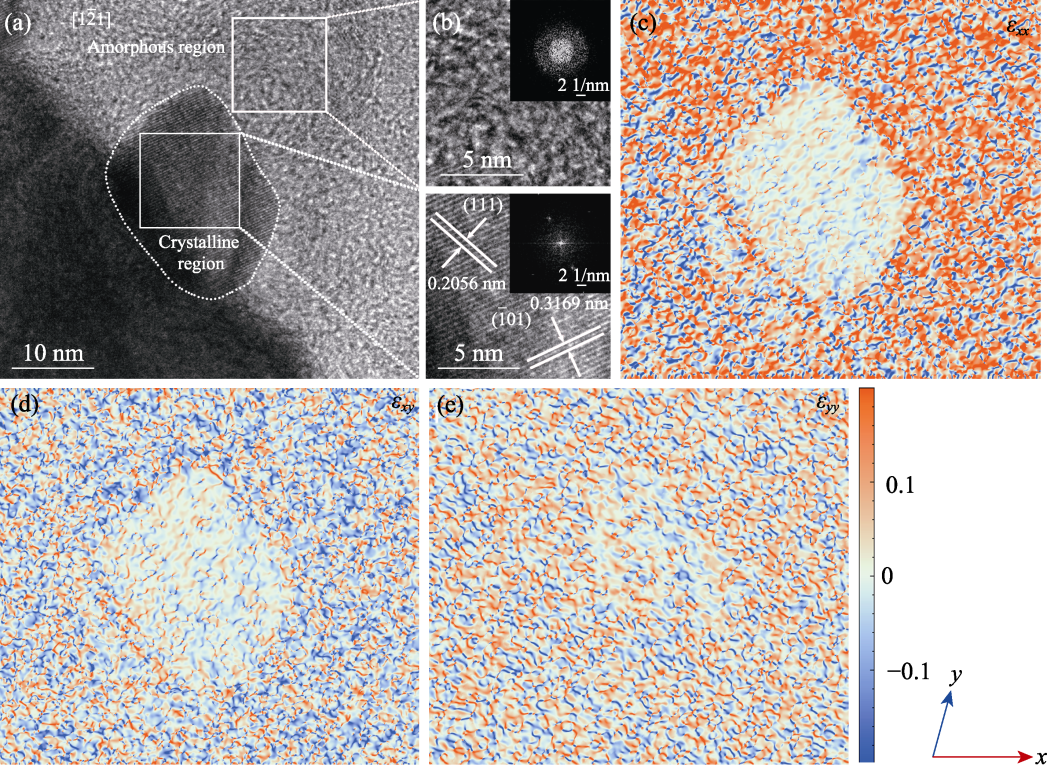

Fig. 5 TEM characterizations of Cf/LAS composite material along the [$1\bar{2}1$] zone axis (a) High-resolution transmission electron microscopy (HRTEM) image; (b) Images for selected regions obtained locally enlarged after the corresponding region’s fast Fourier transform (FFT); (c-e) Strain distribution obtained by geometric phase analysis (GPA) of FFT

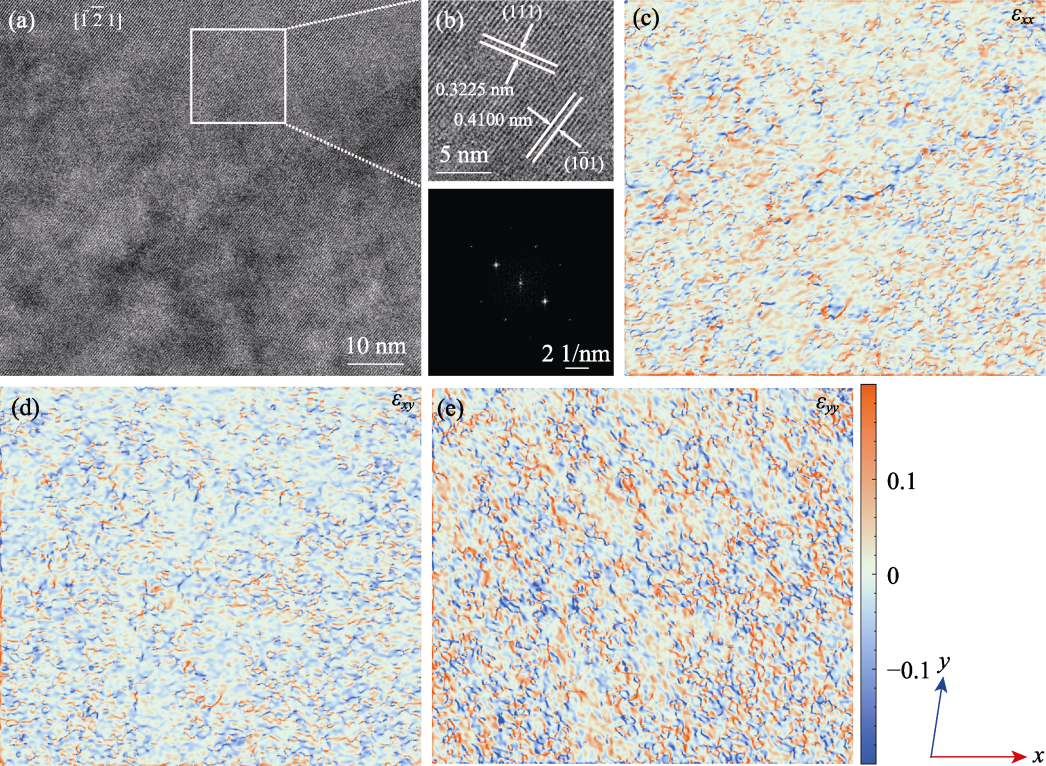

Fig. 6 TEM characterizations of Cf/LAS-SC1 composite material along the [$1\bar{2}1$] zone axis (a) HRTEM image; (b) Images for selected regiosn obtained locally enlarged after the corresponding region’s FFT; (c-e) Strain distribution obtained by GPA of FFT

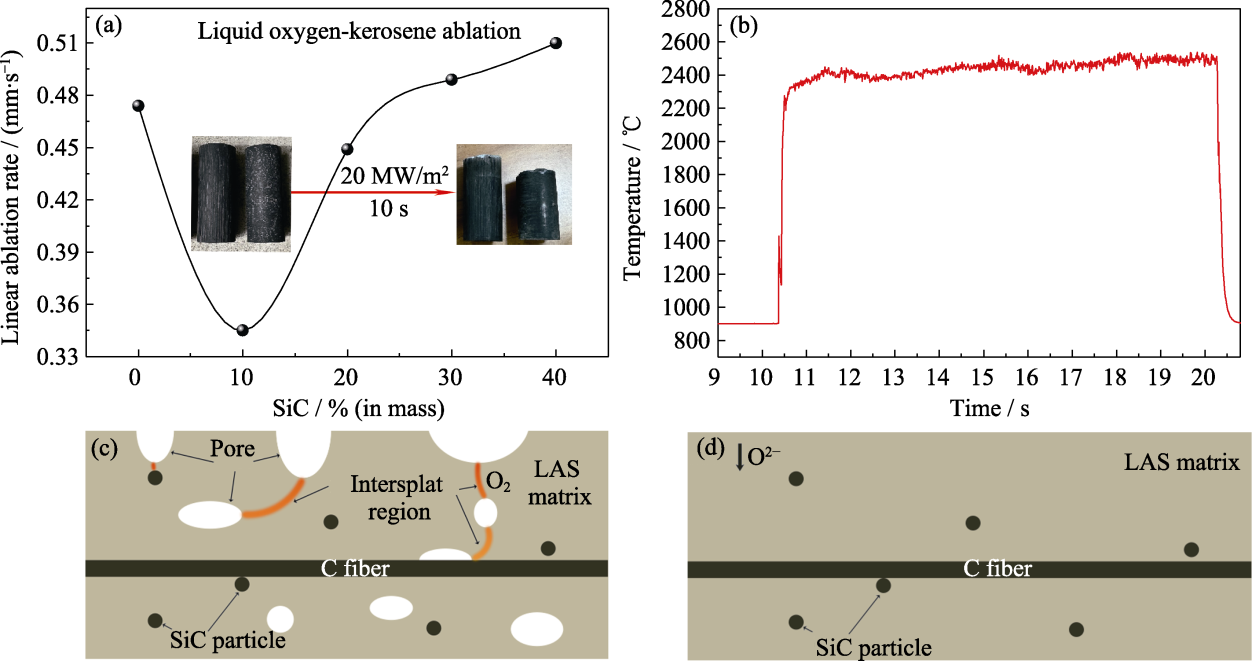

Fig. 8 (a) Average linear ablation rate with insets showing photographs of Cf/LAS-SC1 (left) and Cf/LAS (right)); (b) Surface temperature of Cf/LAS-SC; (c, d) Schematic diagrams of (c) oxygen molecule direct contact ablation and (d) oxygen ion diffusion ablation mechanism, respectively

| Composition | ρ/ (g·cm-3) | λ/ (W·m-1·K-1) | Ablation at high heat flux | Ref. | ||

|---|---|---|---|---|---|---|

| Ablation rate/ (mm·s-1) | Test environments | Ablation time/s | ||||

| Cf/C | 1.85 | 45-68 (25-800 ℃) | - | Oxyacetylene torch with a heat flux of 3.9 MW/m2 | 60 | [ |

| 1.80 | - | 1.2-1.4 | Stagnation ablation by high temperature air ionization jet | 3 | [ | |

| - | 0.114 | Nitrogen plasma jet with a heat flux of ~25 MW/m2 | 20 | [ | ||

| 1.80 | - | 0.699 | Stagnation ablation by air plasma flame with a heat flux of 22.1 MW/m2 | 3 | [ | |

| - | - | 0.245 | Liquid oxygen-kerosene, and the heat flux at 30 MW/m2 | 10 | This work | |

| Cf/LAS-SiC1 | 2.03 | 2.2-3.4 (25-1000 ℃) | 0.35 | Liquid oxygen-kerosene, and the heat flux at 20 MW/m2 | 10 | This work |

| 0.70 | Liquid oxygen-kerosene, and the heat flux at 30 MW/m2 | 10 | ||||

Table 1 Properties of Cf/C and Cf/LAS ablative composites[29-31]

| Composition | ρ/ (g·cm-3) | λ/ (W·m-1·K-1) | Ablation at high heat flux | Ref. | ||

|---|---|---|---|---|---|---|

| Ablation rate/ (mm·s-1) | Test environments | Ablation time/s | ||||

| Cf/C | 1.85 | 45-68 (25-800 ℃) | - | Oxyacetylene torch with a heat flux of 3.9 MW/m2 | 60 | [ |

| 1.80 | - | 1.2-1.4 | Stagnation ablation by high temperature air ionization jet | 3 | [ | |

| - | 0.114 | Nitrogen plasma jet with a heat flux of ~25 MW/m2 | 20 | [ | ||

| 1.80 | - | 0.699 | Stagnation ablation by air plasma flame with a heat flux of 22.1 MW/m2 | 3 | [ | |

| - | - | 0.245 | Liquid oxygen-kerosene, and the heat flux at 30 MW/m2 | 10 | This work | |

| Cf/LAS-SiC1 | 2.03 | 2.2-3.4 (25-1000 ℃) | 0.35 | Liquid oxygen-kerosene, and the heat flux at 20 MW/m2 | 10 | This work |

| 0.70 | Liquid oxygen-kerosene, and the heat flux at 30 MW/m2 | 10 | ||||

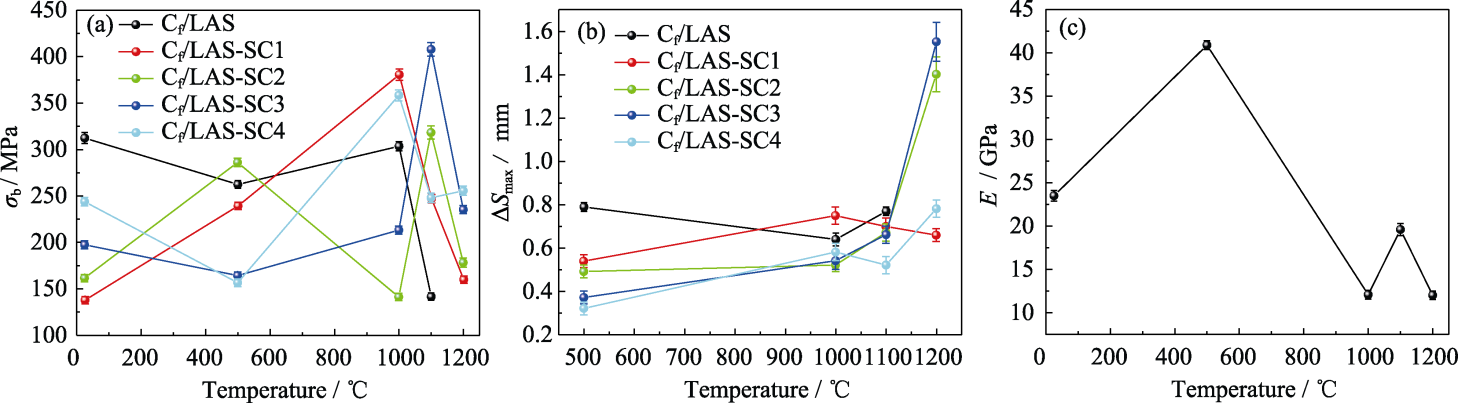

Fig. 10 Mechanical properties of Cf/LAS-SC (a) Curves of temperature-bending strength relationship; (b) Curves of temperature-maximum displacement relationship; (c) Curve of temperature-elastic modulus relationship for Cf/LAS-SC1

| [1] | YE Z M, ZENG Y, XIONG X, et al. Elucidating the role of preferential oxidation during ablation: insights on the design and optimization of multicomponent ultra-high temperature ceramics. Journal of Advanced Ceramics, 2022, 11(12): 1956. |

| [2] | LYU Y, HAN Z H, ZHAO G D, et al. Efficient fabrication of light Cf/SiHfBOC composites with excellent thermal shock resistance and ultra-high-temperature ablation up to 1800 ℃. Journal of Advanced Ceramics, 2023, 12(11): 2062. |

| [3] | FAN Q G, CUI H, YAN L S, et al. Ablation resistance properties of ultra-high temperature composites C/C-SiC-ZrB2 by slurry impregnation method. Journal of Inorganic Materials, 2013, 28(9): 1014. |

| [4] | KUMAR C V, KANDASUBRAMANIAN B. Advances in ablative composites of carbon based materials: a review. Industrial & Engineering Chemistry Research, 2019, 58(51): 22663. |

| [5] | XU L, LI X C, NI L Y, et al. Ablation behavior of functional gradient ceramic coating for porous carbon-bonded carbon fiber composites. Corrosion Science, 2018, 142: 145. |

| [6] | XU X T, PAN X H, NIU Y R, et al. Difference evaluation on ablation behaviors of ZrC-based and ZrB2-based UHTCs coatings. Corrosion Science, 2021, 180: 109181. |

| [7] | SUI H, ZHANG H, GAO L F, et al. Boron and nitrogen doping in fused silica ceramics: structural, high-temperature mechanical and long-term ablation resistance properties of Si-B-O-N ceramics. Silicon, 2024, 16(12): 5147. |

| [8] | QUINTAL C C, CORMONT P, GALLAIS L. Experimental and numerical investigation of CO2 laser ablation of fused silica with sub- microsecond pulses. Journal of Applied Physics, 2021, 130(9): 093106. |

| [9] | FARHAN S, WANG R M, LI K Z, et al. Sublimation and oxidation zone ablation behavior of carbon/carbon composites. Ceramics International, 2015, 41(10): 13751. |

| [10] | ZHANG W Z, TAN M Y, CHEN D M, et al. Sugar-derived nanocrystalline graphite matrix C/C composites with excellent ablative resistance at 3000 ℃. Advanced Materials, 2024, 36(7): 2309899. |

| [11] | CHENG L F, XU Y D, ZHANG L T, et al. Oxidation behavior of carbon-carbon composites with a three-layer coating from room temperature to 1700 ℃. Carbon, 1999, 37(6): 977. |

| [12] | FERREIRA J R, COPPINI N L, NETO F L. Characteristics of carbon-carbon composite turning. Journal of Materials Processing Technology, 2001, 109(1/2): 65. |

| [13] | HAN X, ZHANG S Y, LI W, et al. Preparation and thermal conductivity of C/C composites filled with diamond particles. Diamond and Related Materials, 2018, 88: 85. |

| [14] | WANG P P, LI H J, JIA Y J, et al. Ablation resistance of HfB2-SiC coating prepared by in-situ reaction method for SiC coated C/C composites. Ceramics International, 2017, 43(15): 12005. |

| [15] | ZHAO J J, CAI R, MA Z K, et al. Preparation and properties of C/SiC composites reinforced by high thermal conductivity graphite films. Diamond and Related Materials, 2021, 116: 108376. |

| [16] | HE Z J, LI C, YANG B, et al. Interfacial reaction and brazing behaviour of SiCf/SiC with Cf/C composites using Si-10Zr alloy at high temperatures. Journal of the European Ceramic Society, 2021, 41(2): 1142. |

| [17] | ZOU C R, LI B, MENG X J, et al. Ablation behavior and mechanism of SiO2f/SiO2, SiO2f/BN and Si3N4f/BN radar wave transparent composites. Corrosion Science, 2018, 139: 243. |

| [18] | ZHOU G H, WANG S W, HUANG X X, et al. Unidirectional carbon fiber and SiC particulate co-reinforced fused silica composite. Ceramics International, 2007, 33(7): 1395. |

| [19] | VENKATESWARAN C, SREEMOOLANADHAN H, VAISH R. Lithium aluminosilicate (LAS) glass-ceramics: a review of recent progress. International Materials Reviews, 2022, 67(6): 620. |

| [20] | CHEN F, XU X R, XIA W W, et al. Practical nucleator agents for lithium aluminum silicate glass-ceramics. Glass, 2023, 50(11): 32. |

| [21] | ZHANG Y Y, ZHANG X M, GUO L X, et al. Effect of temperature-dependent nano SiC on the ablation resistance of ZrC coating. Journal of the European Ceramic Society, 2024, 44(12): 6875. |

| [22] | SCHERER G. W. Sintering of low-density glasses: I, theory. Journal of the American Ceramic Society, 1977, 60(5/6): 236. |

| [23] | YANG X, SU X L, YAN Y G, et al. Structures and thermoelectric properties of (GeTe)nBi2Te3. Journal of Inorganic Materials, 2021, 36(1): 75. |

| [24] | LI T, ZHANG Y L, ZHANG J, et al. Improved antioxidative and mechanical properties of SiC coated C/C composites via a SiO2-SiC reticulated layer. Journal of the European Ceramic Society, 2021, 41(13): 6151. |

| [25] | XIE W Q, ZHANG B, GE B Z, et al. Exceptionally low ablation rates realized in the cellular-structured MCMB@WC composites via biomimetic design. Composites Part A: Applied Science and Manufacturing, 2024, 179: 108035. |

| [26] | YUAN X B, LI R, XIONG Z, et al. Synergistic crystallization modulation and defects passivation via additive engineering stabilize perovskite films for efficient solar cells. Advanced Functional Materials, 2023, 33(24): 2215096. |

| [27] | DING Y S, DONG S M, HUANG Z R, et al. Fabrication of short C fiber-reinforced SiC composites by spark plasma sintering. Ceramics International, 2007, 33(1): 101. |

| [28] | ZAMAN W, LI K Z, IKRAM S, et al. Residual compressive and thermophysical properties of 4D carbon/carbon composites after repeated ablation under oxyacetylene flame of 3000 ℃. Transactions of Nonferrous Metals Society of China, 2013, 23(6): 1661. |

| [29] | YIN J, XIONG X, ZHANG H B, et al. Microstructure and ablation performances of dual-matrix carbon/carbon composites. Carbon, 2006, 44(9): 1690. |

| [30] | SHEN X T, SHI Z Q, ZHAO Z G, et al. Study of the ablation of a carbon/carbon composite at -25 MW/m2 with a nitrogen plasma torch. Journal of the European Ceramic Society, 2020, 40(15): 5085. |

| [31] | YIN J, ZHANG H B, XIONG X, et al. Ablation properties of C/C-SiC composites tested on an arc heater. Solid State Sciences, 2011, 13(11): 2055. |

| [32] | ZHOU W X, CHENG Y, CHEN K Q, et al. Thermal conductivity of amorphous materials. Advanced Functional Materials, 2020, 30(8): 1903829. |

| [33] | TAKAMORI T, ROY R. Rapid crystallization of SiO2-Al2O3 glasses. Journal of the American Ceramic Society, 1973, 56(12): 639. |

| [34] | SKORODUMOVA O B, SEMCHENKO G D, GONCHARENKO Y N, et al. Crystallization of SiO2 from ethylsilicate-based gels. Glass and ceramics, 2001, 58: 31. |

| [1] | LI Wei, XU Zhiming, GOU Yanzi, YIN Senhu, YU Yiping, WANG Song. Preparation and Performance of Sintered SiC Fiber-bonded Ceramics [J]. Journal of Inorganic Materials, 2025, 40(2): 177-183. |

| [2] | ZHANG Yachen, MENG Jia, CAI Kun, SHENG Xiaochen, LE Jun, SONG Lixin. Bending Failure Mechanism Study of Si-Cr-Ti High Temperature Oxidation Resistance Coating via Acoustic Emission Technique [J]. Journal of Inorganic Materials, 2021, 36(11): 1185-1192. |

| [3] | ZHU Zhao-Xian,WANG Fei,YAO Hong-Jun,DONG Jin-Xin,LONG Dong-Hui. High-temperature Insulation Property of Opacifier-doped Al2O3-SiO2 Aerogel/Mullite Fiber Composites [J]. Journal of Inorganic Materials, 2018, 33(9): 969-975. |

| [4] | WANG Jun-Kai, ZHANG Yuan-Zhuo, LI Jun-Yi, ZHANG Hai-Jun, LI Fa-Liang, HAN Lei, SONG Shu-Peng. Low Temperature Catalytic Synthesis of β-SiC Powders via Microwave Heating [J]. Journal of Inorganic Materials, 2017, 32(7): 725-730. |

| [5] | LI Ya-Jing, ZHANG Yue. Pyrolysis Mechanism of SiBCN Polymer Precursor [J]. Journal of Inorganic Materials, 2014, 29(3): 321-326. |

| [6] | YAN Jian-Hui, TANG Si-Wen, ZHANGHou-An. Preparation of Spraying Powders and Microstructureof MolybdenumDisilicide Coating [J]. Journal of Inorganic Materials, 2011, 26(2): 203-208. |

| [7] | LI Tian-Bao, LIANG Jian, XU Bing-She, WANG Jin. Preparation and Characteristic of One-dimensional Magnesium Borate Nanomaterials [J]. Journal of Inorganic Materials, 2010, 25(9): 947-951. |

| [8] | WANG Pei,LIN Li,ZHU Yue-Xiang,XIE You-Chang. Preparation of Fine γ-Al2O3 Powders by Calcining Carbon-covered α-Al2O3 in Oxygen [J]. Journal of Inorganic Materials, 2008, 23(5): 996-1000. |

| [9] | LI Ya-Wei,LI Nan,WANG Bin-Yao,LIU Jing,CHEN Fang-Yu. β-Sialon/Corundum Composite Refractories by Nitridation Sintering Process [J]. Journal of Inorganic Materials, 2000, 15(4): 612-618. |

| [10] | GONG Huan, ZHANG Xu, ZHANG Xiaofeng, LI Bei, LIU Kai. Machine Learning Potential Development and High-Temperature Property Calculation for High-Entropy Boride Ceramics [J]. Journal of Inorganic Materials, 0, (): 250929-. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||