Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (6): 717-723.DOI: 10.15541/jim20190285

Special Issue: 2020年能源材料论文精选(二):超级电容器

• RESEARCH PAPER • Previous Articles Next Articles

JIANG Hao,WU Hao,HOU Chengyi,LI Yaogang,XIAO Ru,ZHANG Qinghong( ),WANG Hongzhi(

),WANG Hongzhi( )

)

Received:2019-06-12

Revised:2019-09-02

Published:2020-06-20

Online:2019-09-20

Supported by:CLC Number:

JIANG Hao,WU Hao,HOU Chengyi,LI Yaogang,XIAO Ru,ZHANG Qinghong,WANG Hongzhi. Sawing Angles on Property of Lithium-sulfur Battery Interlayer Prepared with Birch Derived Orientedly Microchannel Biochar[J]. Journal of Inorganic Materials, 2020, 35(6): 717-723.

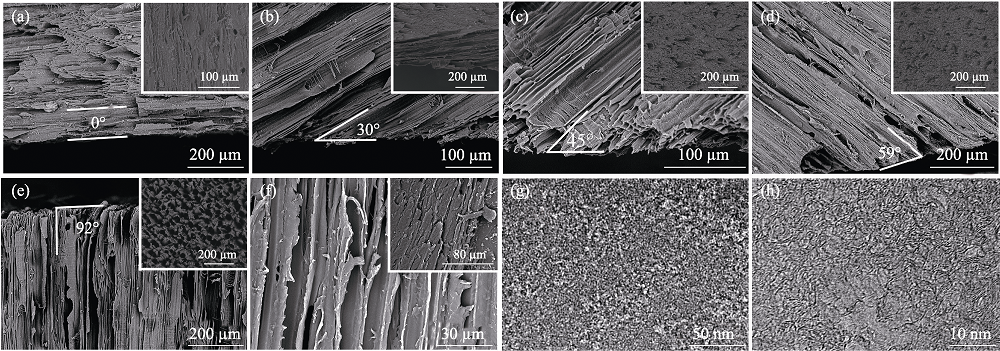

Fig. 2 Cross-sectional and longitudinal (inserts) SEM images of the of biochar saw along varying angles: 0°(a), 30° (b), 45° (c), 60° (d), and 90° (e); SEM images of wood before (insert in (f)) and after (f) delignification; TEM (g) and HRTEM(h) images of biochar oriented at 45°

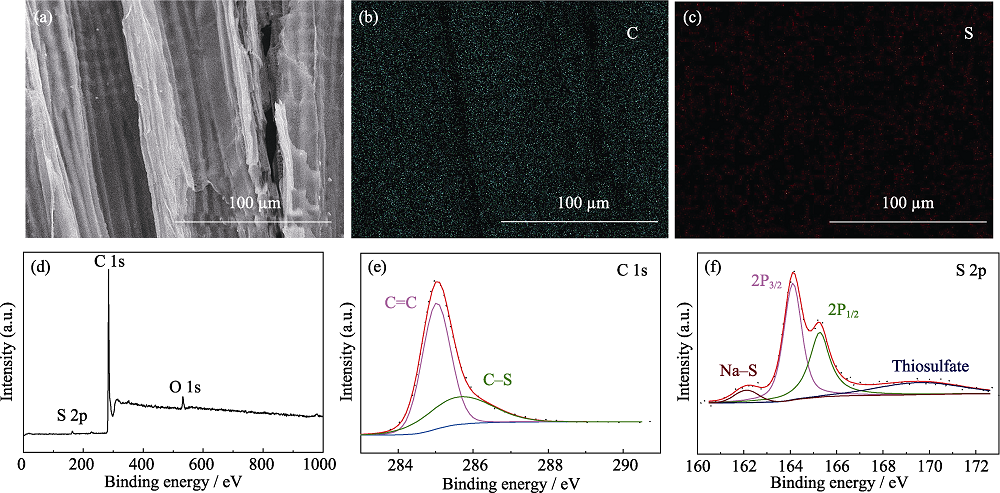

Fig. 3 SEM image (a), corresponding C (b) and S (c) elements distribution mappings of biochar oriented at 45°, XPS spectra of biochar oriented at 45°, survey spectrum (d), C1s (e), and S2p (f)

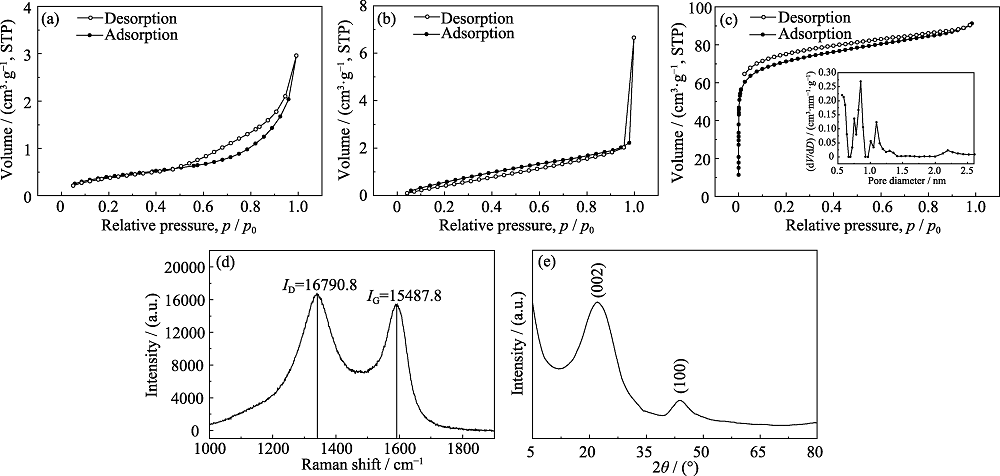

Fig. 4 (a-c) N2 adsorption-desorption isotherms of the untreated birch (a), lignin-free birch (b), biochar sawing along 45°(c) and pore size distribution curve (insert in (c)) of biochar sawing along 45°; Raman spectrum (d) and XRD pattern (e) of biochar oriented at 45°

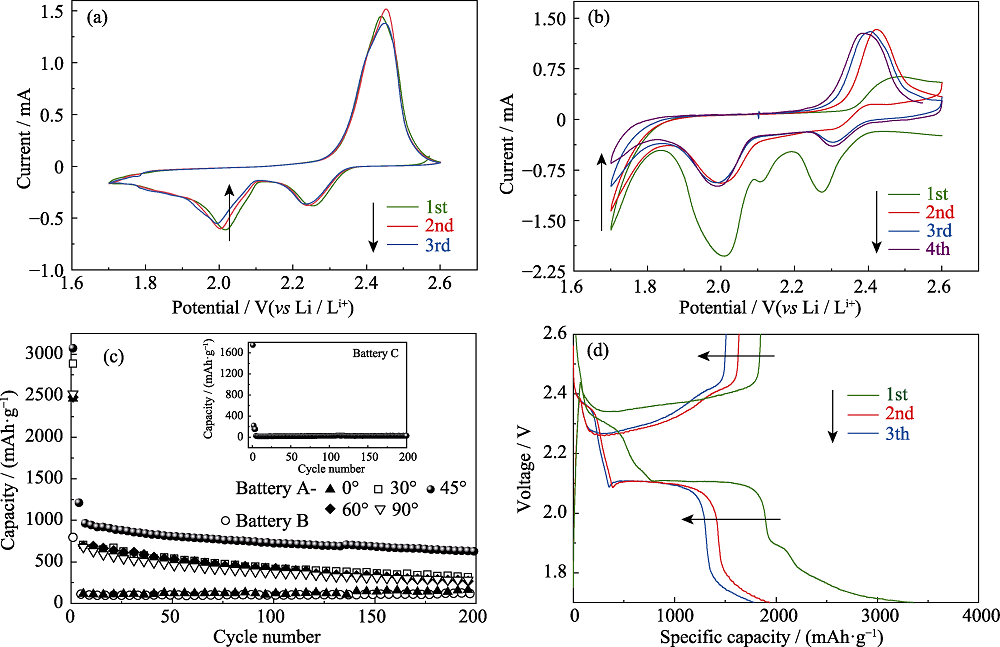

Fig. 5 Cyclic voltammograms of battery B (a) and battery A-45° (b) between 1.7-2.6 V at 0.1 mV/s; (c) Cycling performances of batteries A with different cutting orientation biochar interlayers and battery B with insert showing the cycling performance of battery C; (d) Charging-discharging profiles of battery A-45° at 0.05C

| [1] |

ARMAND M, TARASCON J M . Building better batteries. Nature, 2008,451(7179):652-657.

DOI URL |

| [2] |

BRUCE P G, FREUNBERGER S A, HARDWICK L J , et al. LiO2 and Li-S batteries with high energy storage. Nature Materials, 2012,11(1):19-29.

DOI URL |

| [3] |

SEH Z W, SUN Y M, ZHANG Q F , et al. Designing high-energy lithium-sulfur batteries. Chemical Society Reviews, 2016,45(20):5605-5634.

DOI URL |

| [4] | FANG R P, ZHAO S Y, SUN Z H, et al. More reliable lithium- sulfur batteries: status, solutions and prospects. Advanced Materials, 2017, 29(48): 1606823-1-25. |

| [5] |

JI X L, LEE K T, NAZAR LINDA F . A highly ordered nanostructured carbon-sulphur cathode for lithium-sulphur batteries. Nature Materials, 2009,8(6):500-506.

DOI URL |

| [6] |

MANTHIRAM A, CHUNG S H, ZU C X . Lithium-sulfur batteries: progress and prospects. Advanced Materials, 2015,27(12):1980-2006.

DOI URL |

| [7] |

CHENG X B, YAN C, CHEN X , et al. Implantable solid electrolyte interphase in lithium-metal batteries. Chem., 2017,2(2):258-270.

DOI URL |

| [8] | YE H, XIN S, YIN Y X , et al. Advanced porous carbon materials for high-efficient lithium metal anodes. Advanced Energy Materials, 2017,7(23): 1700530-1-9. |

| [9] |

CHEN J J, YUAN R M, FENG J M , et al. Conductive Lewis base matrix to recover the missing link of Li2S8 during the sulfur redox cycle in Li-S battery. Chemistry of Materials, 2015,27(6):2048-2055.

DOI URL |

| [10] |

YU S, FENG X R, ZHANG N , et al. Understanding conversion- type electrodes for lithium rechargeable batteries. Accounts of Chemical Research, 2018,51(2):273-281.

DOI URL |

| [11] |

EVERS S, NAZAR L F . New approaches for high energy density lithium-sulfur battery cathodes. Accounts of Chemical Research, 2013,46(5):1135-1143.

DOI URL |

| [12] |

JI L W, RAO M M, ZHENG H M , et al. Graphene oxide as a sulfur immobilizer in high performance lithium/sulfur cells. Journal of The American Chemical Society, 2011, 133( 46):18522-18525.

DOI URL |

| [13] |

QIN F R, WANG X W, ZHANG K , et al. High areal capacity cathode and electrolyte reservoir render practical Li-S batteries. Nano Energy, 2017,38:137-146.

DOI URL |

| [14] |

FU Y Z, SU Y S, MANTHIRAM A . Highly reversible lithium/ dissolved polysulfide batteries with carbon nanotube electrodes. Angewandte Chemie-International Edition, 2013,52(27):6930-6935.

DOI URL |

| [15] | CHUNG S H, HAN P, SINGHAL R , et al. Electrochemically stable rechargeable lithium-sulfur batteries with a microporous carbon nanofiber filter for polysulfide. Advanced Energy Materials, 2015, 5(18): 1500738-1-11. |

| [16] | LI Z, WU H B, LOU X W . Rational designs and engineering of hollow micro-/nanostructures as sulfur hosts for advanced lithium- sulfur batteries. Energy & Environmental Science, 2016,9(10):3061-3070. |

| [17] |

LUO S W, YAO M J, LEI S , et al. Freestanding reduced graphene oxide-sulfur composite films for highly stable lithium-sulfur batteries. Nanoscale, 2017,9(14):4646-4651.

DOI URL |

| [18] |

WANG H L, YANG Y, LIANG Y Y , et al. Graphene-wrapped sulfur particles as a rechargeable lithium-sulfur battery cathode material with high capacity and cycling stability. Nano Letters, 2011,11(7):2644-2647.

DOI URL |

| [19] |

CAO J, CHEN C, ZHAO Q , et al. A flexible nanostructured paper of a reduced graphene oxide-sulfur composite for high-performance lithium-sulfur batteries with unconventional configurations. Advanced Materials, 2016,28(43):9629-9636.

DOI URL |

| [20] | JEONG Y C, KIM J H, NAM S , et al. Rational design of nanostructured functional interlayer/separator for advanced Li-S batteries. Advanced Functional Materials, 2018, 28(38): 1707411-1-32. |

| [21] |

WANG P, ZHANG Z A, HONG B , et al. Multifunctional porous VN nanowires interlayer as polysulfides barrier for high performance lithium sulfur batteries. Journal of Electroanalytical Chemistry, 2019,832:475-479.

DOI URL |

| [22] |

XU G Y, YAN Q B, WANG S T , et al. A thin multifunctional coating on a separator improves the cyclability and safety of lithium sulfur batteries. Chemical Science, 2017,8(9):6619-6625.

DOI URL |

| [23] |

LAI Y Q, WANG P, QIN F R , et al. A carbon nanofiber@mesoporous δ-MnO2 nanosheet-coated separator for high-performance lithium- sulfur batteries. Energy Storage Materials, 2017,9:179-187.

DOI URL |

| [24] | PARK J, KIM E T, KIM C , et al. The importance of confined sulfur nanodomains and adjoining electron conductive pathways in subreaction regimes of Li-S batteries. Advanced Energy Materials, 2017, 7(19): 1700074-1-10. |

| [25] |

LIANG G M, WU J X, QIN X Y , et al. Ultrafine TiO2 decorated carbon nanofibers as multifunctional interlayer for high-performance lithium-sulfur battery. ACS Applied Materials & Interfaces, 2016,8(35):23105-23113.

DOI URL |

| [26] |

REHMAN S, GUO S J, HOU Y L . Rational design of Si/SiO2@hierarchical porous carbon spheres as efficient polysulfide reservoirs for high-performance Li-S battery. Advanced Materials, 2016,28(16):3167-3172.

DOI URL |

| [27] |

HUANG J Q, ZHANG Q, WEI F . Multi-functional separator/ interlayer system for high-stable lithium-sulfur batteries: progress and prospects. Energy Storage Materials, 2015,1:127-145.

DOI URL |

| [28] |

LIU M C, KONG L B, ZHANG P , et al. Porous wood carbon monolith for high-performance supercapacitors. Electrochimica Acta, 2012,60:443-448.

DOI URL |

| [29] |

ZHANG S, WU C L, WU W , et al. High performance flexible supercapacitors based on porous wood carbon slices derived from Chinese fir wood scraps. Journal of Power Sources, 2019,424:1-7.

DOI URL |

| [30] |

MA F W, SONG S J, WU G , et al. Facile selt-template large scale preparation of biomass-derived 3D hierarchical porous carbon for advanced supercapacitors. J. Mater. Chem. A, 2015,3(35):18154-18162.

DOI URL |

| [31] |

YUAN X Q, WU L S, HE X L , et al. Separator modified with N, S co-doped mesoporous carbon using egg shell as template for high performance lithium-sulfur batteries. Chemical Engineering Journal, 2017,320:178-188.

DOI URL |

| [32] |

ROSENMAN A, MARKEVICH E, SALITRA G , et al. Facile synthesis and very stable cycling of polyvinylidene dichloride derived carbon: sulfur composite cathode. Journal of The Electrochemical Society, 2016,163(9):A1829-A1835.

DOI URL |

| [33] | LIANG X, HART C, PANG Q , et al. A highly efficient polysulfide mediator for lithium-sulfur batteries. Nature Communications, 2015, 6: 5682-1-8. |

| [34] |

MALARD L M, PIMENTA M A, DRESSELHAUS G , et al. Raman spectroscopy in graphene. Physics Reports, 2009,473(5):51-87.

DOI URL |

| [35] |

WALLE M D, ZHANG Z, ZHANG M , et al. Hierarchical 3D nitrogen and phosphorous codoped graphene/carbon nanotubes- sulfur composite with synergistic effect for high performance of lithium-sulfur batteries. Journal of Materials Science, 2018,53(4):2685-2696.

DOI URL |

| [36] |

FERRARI A, ROBERTSON J . Interpretation of Raman spectra of disordered and amorphous carbon. Physical Review B (Condensed Matter), 2000,61(20):14095-14107.

DOI URL |

| [37] |

YANG S J, KIM T, IM J H , et al. MOF-derived hierarchically porous carbon with exceptional porosity and hydrogen storage capacity. Chemistry of Materials, 2012,24(3):464-470.

DOI URL |

| [38] |

OAKES L, CARTER R, PINT C L . Nanoscale defect engineering of lithium-sulfur battery composite cathodes for improved performance. Nanoscale, 2016,8(46):19368-19375.

DOI URL |

| [39] |

ZHU Z Q, CHENG F Y, CHEN J . Investigation of effects of carbon coating on the electrochemical performance of Li4Ti5O12/C nanocomposites. Journal of Materials Chemistry A, 2013,1(33):9484-9490.

DOI URL |

| [40] | LI Z, ZHANG J T, GUAN B Y , et al. A sulfur host based on titanium monoxide@carbon hollow spheres for advanced lithium- sulfur batteries. Nature Communications, 2016, 7: 13065-1-11. |

| [41] |

HUANG J Q, LIU X F, ZHANG Q , et al. Entrapment of sulfur in hierarchical porous graphene for lithium-sulfur batteries with high rate performance from -40 to 60 ℃. Nano Energy, 2013,2(2):314-321.

DOI URL |

| [42] | FU X, YANG R, LIU L , et al. Preparation of cellular 3-D graphite and its application in Li-S battery. New Chemical Materials, 2019,47(2):85-89. |

| [43] |

YANG S Y, YAN C, CAO Z X , et al. Preparation of hierarchical porous carbon/sulfur composite based on lotus-leaves and its property for Li-S batteries. Journal of Inorganic Materials, 2016,31(2):135-140.

DOI URL |

| [44] |

ZHU J D, GE Y Q, KIM D , et al. A novel separator coated by carbon for achieving exceptional high performance lithium-sulfur batteries. Nano Energy, 2016,20:176-184.

DOI URL |

| [45] |

FANG X, PENG H S . Revolution in electrodes: recent progress in rechargeable lithium-sulfur batteries. Small, 2015,11(13):1488-1511.

DOI URL |

| [46] |

SONG J, SU D, XIE X , et al. Immobilizing polysulfides with MXene-functionalized separators for stable lithium-sulfur batteries. ACS Appl. Mater. Interfaces, 2016,8(43):29427-29433.

DOI URL |

| [1] | WANG Xinling, ZHOU Na, TIAN Yawen, ZHOU Mingran, HAN Jingru, SHEN Yuansheng, HU Zhiyi, LI Yu. SnS2/ZIF-8 Derived Two-dimensional Porous Nitrogen-doped Carbon Nanosheets for Lithium-sulfur Batteries [J]. Journal of Inorganic Materials, 2023, 38(8): 938-946. |

| [2] | LI Tao, CAO Pengfei, HU Litao, XIA Yong, CHEN Yi, LIU Yuejun, SUN Aokui. NH4+ Assisted Interlayer-expansion of MoS2: Preparation and Its Zinc Storage Performance [J]. Journal of Inorganic Materials, 2023, 38(1): 79-86. |

| [3] | XIAO Meixia, LI Miaomiao, SONG Erhong, SONG Haiyang, LI Zhao, BI Jiaying. Halogenated Ti3C2 MXene as High Capacity Electrode Material for Li-ion Batteries [J]. Journal of Inorganic Materials, 2022, 37(6): 660-668. |

| [4] | LI Tingting, ZHANG Yang, CHEN Jiahang, MIN Yulin, WANG Jiulin. Flexible Binder for S@pPAN Cathode of Lithium Sulfur Battery [J]. Journal of Inorganic Materials, 2022, 37(2): 182-188. |

| [5] | LI Gaoran, LI Hongyang, ZENG Haibo. Recent Progress of Boron-based Materials in Lithium-sulfur Battery [J]. Journal of Inorganic Materials, 2022, 37(2): 152-162. |

| [6] | YE Wenhao, WEI Qiang, LIANG Jiamin, ZHOU Jie, MENG Fanping, EKLUND Per, HUANG Qing. Zr2Al3C4 Coatings on Zirconium-alloy Substrates with Enhanced Adhesion and Diffusion Barriers by Al/Mo-C Interlayers [J]. Journal of Inorganic Materials, 2021, 36(5): 541-546. |

| [7] | TAN Shilin,YIN Shunda,OUYANG Gang. Size Effect on the Interface Modulation of Interlayer and Auger Recombination Rates in MoS2/WSe2 van der Waals Heterostructures [J]. Journal of Inorganic Materials, 2020, 35(6): 682-688. |

| [8] | Ya-Dong LI, Wei-Ping LI, Qin WANG, Dao-Guang ZHENG, Jian-Xin WANG. Flexible Carbon-fiber Supported Carbon-sulfur Electrode: Preparation, Physical Property and Electrochemical Performance [J]. Journal of Inorganic Materials, 2019, 34(4): 373-378. |

| [9] | WANG Yu-Hui, JIN Jun, GUO Zhan-Sheng, WEN Zhao-Yin. Direct View for the Deformation Evolution of Sulfur Electrode during Li-S Battery Cycling [J]. Journal of Inorganic Materials, 2017, 32(3): 247-251. |

| [10] | CHAI Er-Ya, PAN Jun-An, YUAN Guo-Long, CHENG Hao, AN Feng, XIE Shu-Hong. Preparation and Electrochemical Property of Polyaniline Coated Opal Shale/Sulfur Composite [J]. Journal of Inorganic Materials, 2017, 32(11): 1165-1170. |

| [11] | SONG Bo, ZHAO Li-Li, CHEN Xiao-Ying, YOU Li-Jun, SONG Li-Xin. Effects of HfO2 Interlayer on Microstructure and Mechanical Property of Al2O3 Thin Film on MgF2 Substrate [J]. Journal of Inorganic Materials, 2016, 31(7): 779-784. |

| [12] | MA Guo-Qiang, WEN Zhao-Yin, WANG Qing-Song, JIN Jun, WU Xiang-Wei, ZHANG Jing-Chao. Effects of CeO2 Nano-crystal on Electrochemical Properties of Lithium/Sulfur Batteries [J]. Journal of Inorganic Materials, 2015, 30(9): 913-918. |

| [13] | CHEN Fei-Biao, WANG Ying-Nan, WU Bo-Rong, XIONG Yun-Kui, LIAO Wei-Ling, WU Feng, SUN Zhe. Preparation and Electrochemical Performance of Activation Graphene/Sulfur Complex Cathode Material for Lithium-sulfur Batteries [J]. Journal of Inorganic Materials, 2014, 29(6): 627-632. |

| [14] | HU Jing-Jing, LI Guo-Ran, GAO Xue-Ping. Current Status, Problems and Challenges in Lithium-sulfur Batteries [J]. Journal of Inorganic Materials, 2013, 28(11): 1181-1186. |

| [15] | REN Xiao-Bin, LI He-Jun, LU Jin-Hua, GUO Ling-Jun, WANG Jie, SONG Xin-Rui. Influence of Interlayer’s Thickness on Strength of Joints between LAS Glass-ceramic and Carbon/Carbon Composites [J]. Journal of Inorganic Materials, 2011, 26(8): 847-851. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||