Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (12): 1358-1364.DOI: 10.15541/jim20220249

Previous Articles Next Articles

CHENG Ziqiu1,2( ), WANG Yanbin1,3, LIU Xin1,2, DAI Zhengfa1,2, CHEN Haohong1,2, TIAN Feng1,2, CHEN Penghui1,2, LI Jiang1,2(

), WANG Yanbin1,3, LIU Xin1,2, DAI Zhengfa1,2, CHEN Haohong1,2, TIAN Feng1,2, CHEN Penghui1,2, LI Jiang1,2( )

)

Received:2022-04-26

Revised:2022-05-18

Published:2022-12-20

Online:2022-08-26

Contact:

LI Jiang, professor. E-mail: lijiang@mail.sic.ac.cnAbout author:CHENG Ziqiu (1998-), male, Master candidate. E-mail: chengziqiu20@mails.ucas.ac.cn

Supported by:CLC Number:

CHENG Ziqiu, WANG Yanbin, LIU Xin, DAI Zhengfa, CHEN Haohong, TIAN Feng, CHEN Penghui, LI Jiang. Component Regulation and Performance Optimization of Al2O3-YAG:Ce Composite Ceramic Phosphors for High-power Laser Lighting[J]. Journal of Inorganic Materials, 2022, 37(12): 1358-1364.

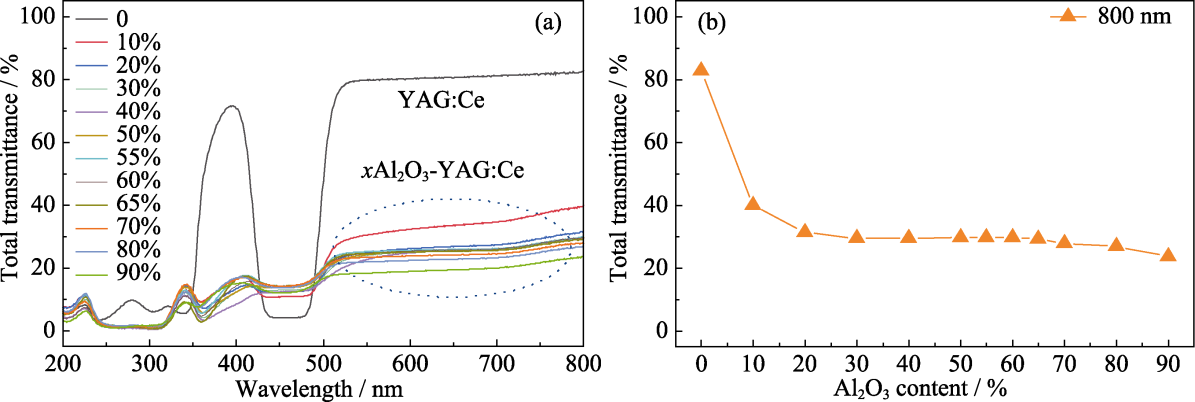

Fig. 4 Total transmittance of xAl2O3-YAG:Ce ceramic phosphors (a) Total transmittance curves; (b) Total transmittance at 800 nmColor figures can be obtained from online edition

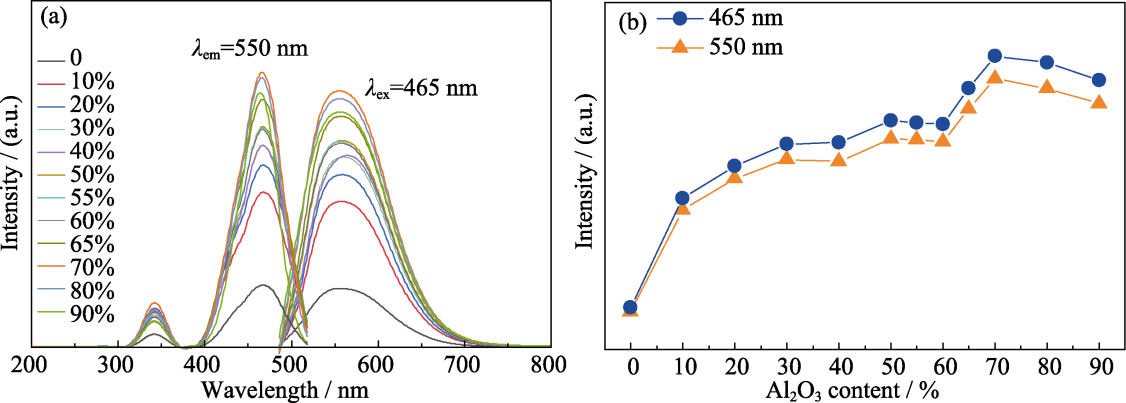

Fig. 5 PL and PLE spectra of xAl2O3-YAG:Ce ceramic phosphors (a) PL and PLE spectra; (b) PL and PLE spectra intensity at 465 and 550 nmColor figures can be obtained from online edition

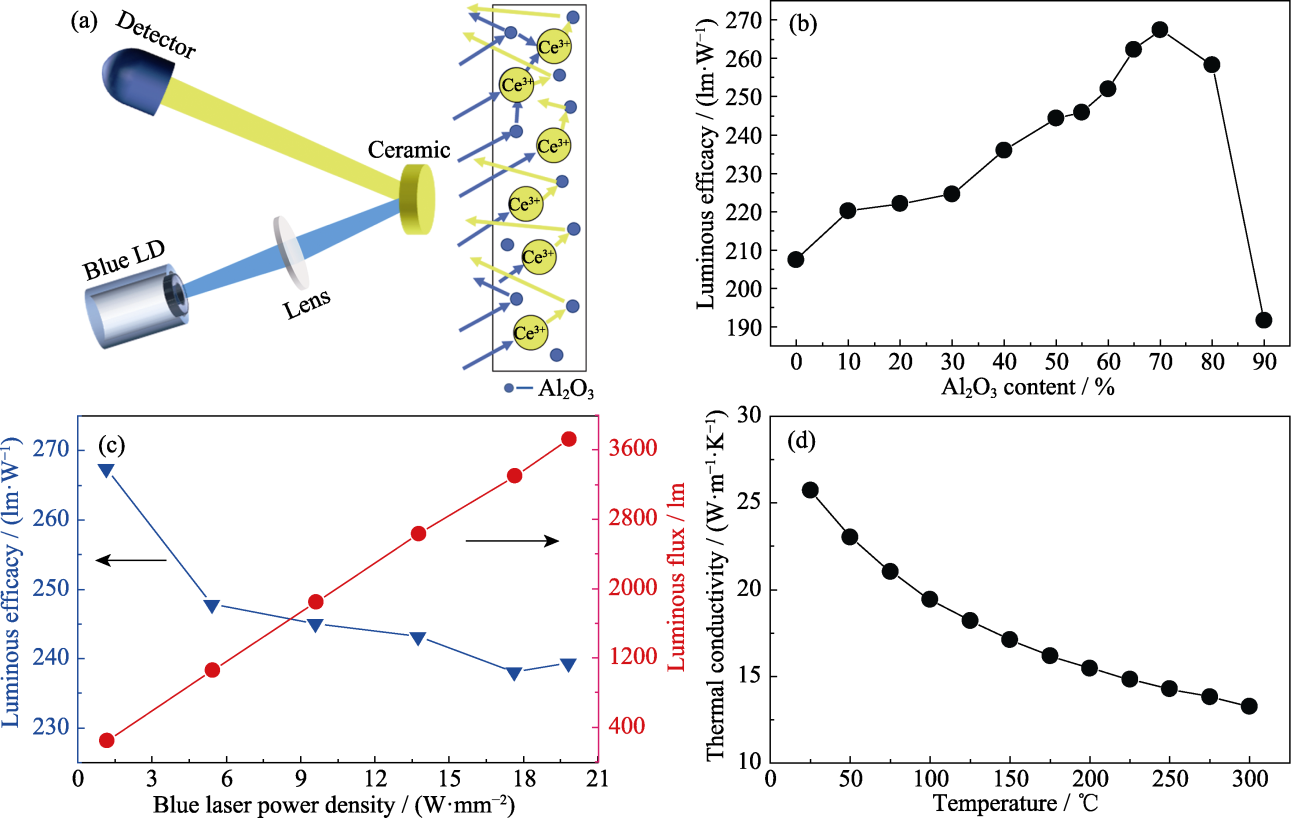

Fig. 6 Light propagation path, luminous efficacy, luminous flux and thermal conductivity of xAl2O3-YAG:Ce ceramic phosphors (a) Diagram of reflection mode to measure luminous properties and light propagation; (b) Luminous efficacy of the ceramics with different Al2O3 contents under 1 W·mm-2 blue laser irradiation; (c) Luminous efficacy and luminous flux of 70% Al2O3-YAG:Ce as a function of blue laser power density; (d) Thermal conductivity of 70% Al2O3-YAG:Ce as a function of temperature from 25 ℃ to 300 ℃

| [1] |

NAKAMURA S. The roles of structural imperfections in InGaN-based blue light-emitting diodes and laser diodes. Science, 1998, 281(5379): 956-961.

DOI URL |

| [2] | HAITZ R, TSAO J Y. Solid-state lighting: 'the case' 10 years after and future prospects. Physica Status Solidi (A) Applications and Materials Science, 2011, 208(1): 17-29. |

| [3] |

PIMPUTKAR S, SPECK J S, DENBAARS S P, et al. Prospects for LED lighting. Nature Photonics, 2009, 3(4): 179-181.

DOI URL |

| [4] |

LING J, ZHOU Y, XU W, et al. Red-emitting YAG:Ce,Mn transparent ceramics for warm WLEDs application. Journal of Advanced Ceramics, 2020, 9(1): 45-54.

DOI URL |

| [5] | WIERER J J, TSAO J Y, SIZOV D S. Comparison between blue lasers and light-emitting diodes for future solid-state lighting. Laser & Photonics Reviews, 2013, 7(6): 963-993. |

| [6] |

CANTORE M, PFAFF N, FARRELL R M, et al. High luminous flux from single crystal phosphor-converted laser-based white lighting system. Optics Express, 2016, 24(2): 215-221.

DOI PMID |

| [7] | LI S X, WANG L, HIROSAKI N, et al. Color conversion materials for high-brightness laser-driven solid-state lighting. Laser & Photonics Reviews, 2018, 12(12): 173-202. |

| [8] |

DING H, HU P, LIU Y F, et al. Recent progress of LuAG:Ce3+ for white laser diode lighting application. Chinese Journal of Luminescence, 2021, 42(10): 1531-1548.

DOI URL |

| [9] |

KURITZKY L Y, Speck J S. Lighting for the 21st century with laser diodes based on non-basal plane orientations of GaN. MRS Communications, 2015, 5(3): 463-473.

DOI URL |

| [10] |

PENG X L, LI S X, LIU Z H, et al. Phosphor ceramics for high-power solid-state lighting. Journal of Inorganic Materials, 2021, 36(8): 807-819.

DOI |

| [11] |

XIA Z G, MEIJERINK A. Ce3+-doped garnet phosphors: composition modification, luminescence properties and applications. Chemical Society Reviews, 2017, 46(1): 275-299.

DOI URL |

| [12] |

DU A C, DU Q Y, LIU X, et al. Ce:YAG transparent ceramics enabling high luminous efficacy for high-power LEDs/LDs. Journal of Inorganic Materials, 2021, 36(8): 883-892.

DOI |

| [13] | ZHANG R, LIN H, YU Y L, et al. A new-generation color converter for high-power white LED: transparent Ce3+:YAG phosphor-in-glass. Laser & Photonics Reviews, 2014, 8(1): 158-164. |

| [14] |

SOMMER C, HARTMANN P, PACHLER P, et al. A detailed study on the requirements for angular homogeneity of phosphor converted high power white LED light sources. Optical Materials, 2009, 31(6): 837-848.

DOI URL |

| [15] |

SONG Y H, JI E K, JEONG B W, et al. Design of laser-driven high-efficiency Al2O3/YAG:Ce3+ ceramic converter for automotive lighting: fabrication, luminous emittance, and tunable color space. Dyes and Pigments, 2017, 139: 688-692.

DOI URL |

| [16] | COZZAN C, LHEUREUX G, O'DEA N, et al. Stable, heat-conducting phosphor composites for high-power laser lighting. ACS Applied Materials & Interfaces, 2018, 10(6): 5673-5681. |

| [17] |

WANG J C, TANG X Y, ZHENG P, et al. Thermally self-managing YAG:Ce-Al2O3 color converters enabling high-brightness laser- driven solid-state lighting in a transmissive configuration. Journal of Materials Chemistry C, 2019, 7(13): 3901-3908.

DOI URL |

| [18] |

PADTURE N P, KLEMENS P G. Low thermal conductivity in garnets. Journal of the American Ceramic Society, 1997, 80(4): 1018-1020.

DOI URL |

| [19] |

KLEIN P H, CROFT W J. Thermal conductivity diffusivity and expansion of Y2O3, Y3Al5O12 and LaF3 in the range 77-300 K. Journal of Applied Physics, 1967, 38(4): 1603-1607.

DOI URL |

| [20] | BERMAN R, FOSTER E L, ZIMAN J M. Thermal conduction in artificial sapphire crystals at low temperatures. Proceedings of the Royal Society of London Series A: Mathematical and Physical Sciences, 1955, 231(1184): 130-144. |

| [21] |

GUPTA T K, VALENTICH J. Thermal expansion of yttrium aluminum garnet. Journal of the American Ceramic Society, 1971, 54(7): 355-356.

DOI URL |

| [22] |

CAI P Z, GREEN D J, MESSING G L. Constrained densification of alumina/zirconia hybrid laminates experimental observations of processing defects. Journal of the American Ceramic Society, 1997, 80(8): 1929-1939.

DOI URL |

| [23] |

LI S X, ZHU Q Q, TANG D M, et al. Al2O3-YAG:Ce composite phosphor ceramic: a thermally robust and efficient color converter for solid state laser lighting. Journal of Materials Chemistry C, 2016, 4(37): 8648-8654.

DOI URL |

| [24] |

LIU Z H, LI S X, HUANG Y H, et al. Composite ceramic with high saturation input powder in solid-state laser lighting: microstructure, properties, and luminous emittances. Ceramics International, 2018, 44(16): 20232-20238.

DOI URL |

| [25] |

XU M, CHANG J, WANG J, et al. Al2O3-YAG:Ce composite ceramics for high-brightness lighting. Optics Express, 2019, 27(2): 872-885.

DOI URL |

| [26] |

LIU X, QIAN X, ZHENG P, et al. Composition and structure design of three-layered composite phosphors for high color rendering chip-on-board light-emitting diode devices. Journal of Advanced Ceramics, 2021, 10(4): 729-740.

DOI URL |

| [27] |

MA X, LI X, LI J, et al. Pressureless glass crystallization of transparent yttrium aluminum garnet-based nanoceramics. Nature Communications, 2018, 9: 1175.

DOI PMID |

| [28] |

ZHAO H, LI Z, ZHANG M, et al. High-performance Al2O3-YAG:Ce composite ceramic phosphors for miniaturization of high-brightness white light-emitting diodes. Ceramics International, 2020, 46(1): 653-662.

DOI URL |

| [29] |

UEDA J, TANABE S, NAKANISHI T. Analysis of Ce3+ luminescence quenching in solid solutions between Y3Al5O12 and Y3Ga5O12 by temperature dependence of photoconductivity measurement. Journal of Applied Physics, 2011, 110(5): 053102.

DOI URL |

| [30] |

ZHENG P, DING G Z, XIE R J. Research progress on optical quenching of Ce3+- and Eu2+-doped luminescent materials. Chinese Journal of Luminescence, 2021, 42(10): 1447-1457.

DOI URL |

| [1] | ZHANG Rui, Wang Bo-Yang, WANG Hai. Advances in Phosphor-in-Glass for White LED [J]. Journal of Inorganic Materials, 2017, 32(4): 337-345. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||