Journal of Inorganic Materials ›› 2015, Vol. 30 ›› Issue (4): 432-438.DOI: 10.15541/jim20140618

• Orginal Article • Previous Articles Next Articles

HUANG Ping, LI Peng, ZHAO Jun-Sheng, QU Shu-Xin, FENG Bo, WENG Jie

Received:2014-11-27

Revised:2015-01-08

Published:2015-04-29

Online:2015-03-26

About author:HUANG Ping. E-mail: huangping135515@163.com

Supported by:CLC Number:

HUANG Ping, LI Peng, ZHAO Jun-Sheng, QU Shu-Xin, FENG Bo, WENG Jie. Mechanical Activation Reinforced Porous Calcium Phosphate Cement[J]. Journal of Inorganic Materials, 2015, 30(4): 432-438.

| Samples | (L/P ratio)/ (mL·g-1) | CH2O2/% | pH | T/℃ |

|---|---|---|---|---|

| BCPC-S | 1.0 | 25 | 8.0 | 60 |

| CPC-S | 0.4 | 25 | 8.0 | 60 |

| Control-S | 1.0 | 0 | 8.0 | 60 |

Table 1 The optimal parameter combinations of orthogonal test for CPC-S, BCPC-S and Control-S

| Samples | (L/P ratio)/ (mL·g-1) | CH2O2/% | pH | T/℃ |

|---|---|---|---|---|

| BCPC-S | 1.0 | 25 | 8.0 | 60 |

| CPC-S | 0.4 | 25 | 8.0 | 60 |

| Control-S | 1.0 | 0 | 8.0 | 60 |

| Samples | d/(g·cm-3) | dB/(g·cm-3) | dC/(g·cm-3) | SSA/(m2·g-1) |

|---|---|---|---|---|

| BCPC | 2.430 ± 0.138a | 0.498 ± 0.098b | 1.937 ± 0.106c | 15.100 |

| CPC | 2.871 ± 0.112a | 0.891 ± 0.127b | 2.135 ± 0.114c | 8.616 |

Table. 2 Apparent densities, bulk densities, compact densities and specific surface areas of BCPC-P and CPC-P(n=6)

| Samples | d/(g·cm-3) | dB/(g·cm-3) | dC/(g·cm-3) | SSA/(m2·g-1) |

|---|---|---|---|---|

| BCPC | 2.430 ± 0.138a | 0.498 ± 0.098b | 1.937 ± 0.106c | 15.100 |

| CPC | 2.871 ± 0.112a | 0.891 ± 0.127b | 2.135 ± 0.114c | 8.616 |

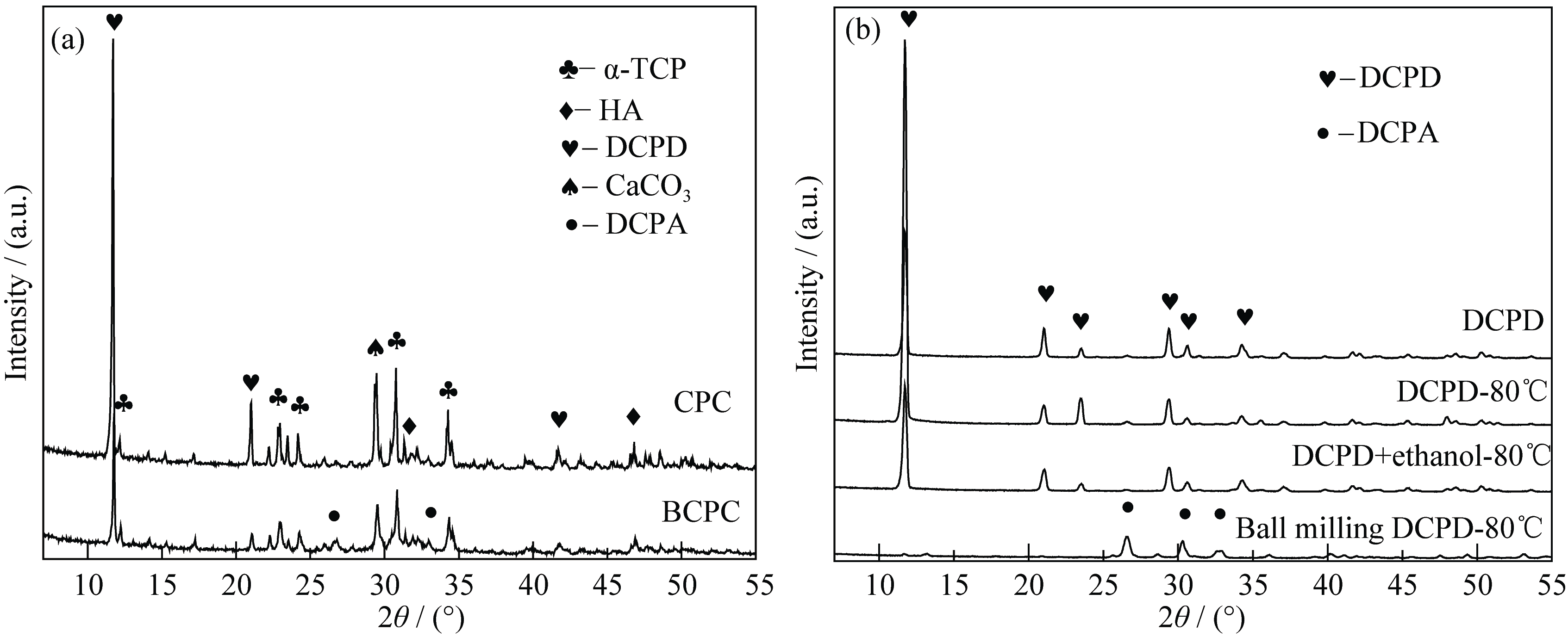

Fig. 2 XRD patterns of BCPC-P and CPC-P (a) and XRD patterns of DCPD with different treatments (b) DCPD: Drying at 37℃; DCPD-80℃: Drying at 80℃; DCPD + ethanol - 80℃: Drying at 80℃ after adding 50 mL ethanol; Ball milling DCPD-80℃: Drying at 80℃ after ball milling

| Grain size/nm | DCPD | α-TCP | CaCO3 | HA |

|---|---|---|---|---|

| BCPC-P | 59.42 | 29.48 | 33.16 | 42.59 |

| CPC-P | 74.26 | 51.65 | 51.85 | 47.15 |

Table 3 Grain sizes of different calcium phosphates of BCPC-P and CPC-P

| Grain size/nm | DCPD | α-TCP | CaCO3 | HA |

|---|---|---|---|---|

| BCPC-P | 59.42 | 29.48 | 33.16 | 42.59 |

| CPC-P | 74.26 | 51.65 | 51.85 | 47.15 |

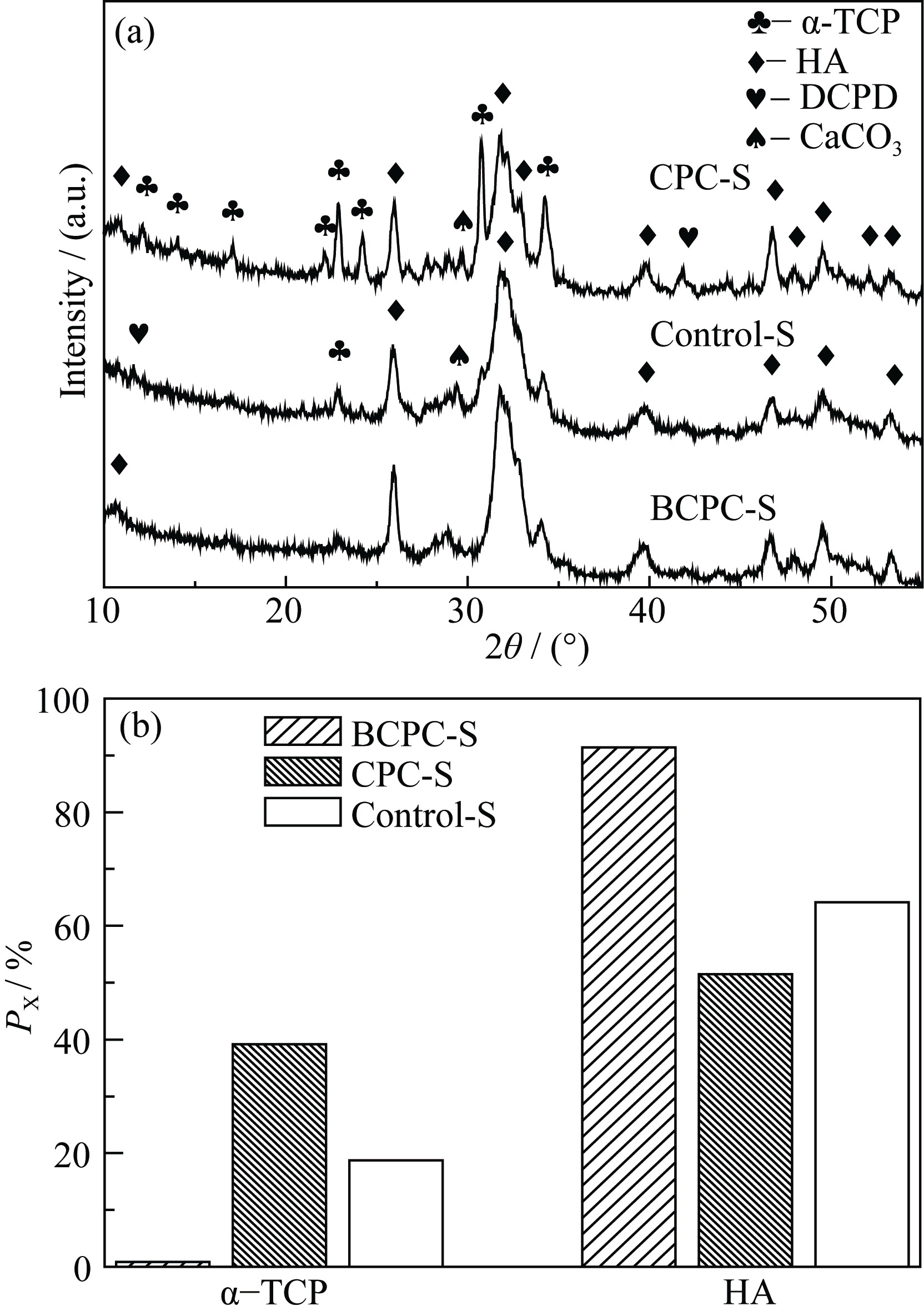

Fig. 4 XRD patterns of CPC-S, BCPC-S and Control-S after hydration for 24 h (a) and relative quantity of α-TCP and HA in BCPC-S, CPC-S and Control-S (b)

| [1] | DOROZHKIN S V, EPPLE M.Biological and medical significance of calcium phosphates.Angewandte Chemie International Edition, 2002, 41(17): 3130-3146. |

| [2] | NANDI S K, ROY S, MUKHERJEE P, et al.Orthopaedic applications of bone graft and graft substitutes: a review.Indian Journal of Medical Research, 2010, 132: 15-30. |

| [3] | FELIX LANAO R P, HOEKSTRA J W, WOLKE J G, et al. Porous calcium phosphate cement for alveolar bone regeneration.Journal of Tissue Engineering and Regenerative Medicine, 2014, 8: 473-482. |

| [4] | DALL'OCA C, MALUTA T, CAVANI F, et al. The biocompatibility of porous vs non-porous bone cements: a new methodological approach.European Journal of Histochemistry, 2014, 58(2): 95-102. |

| [5] | DONG H, YE J D, WANG X P, et al.Preparation of calcium phosphate cement tissue engineering scaffold reinforced with chitin fiber.Journal of Inorganic Materials, 2007, 22(5): 1007-1010. |

| [6] | THEIN-HAN W, XU H H.Collagen-calcium phosphate cement scaffolds seeded with umbilical cord stem cells for bone tissue engineering.Tissue Engineering Part A, 2011, 17(23/24): 2943-2954. |

| [7] | QI X P, YE JIAN-DONG, WANG YING-JING.Alginate/poly (lactic- co-glycolic acid)/calcium phosphate cement scaffold with oriented pore structure for bone tissue engineering.Journal of Biomedical Materials Research Part A, 2009, 89(4): 980-987. |

| [8] | LODE A, MEISSNER K, LUO Y, et al.Fabrication of porous scaffolds by three-dimensional plotting of a pasty calcium phosphate bone cement under mild conditions.Journal of Tissue Engineering and Regenerative Medicine, 2014, 8(9): 682-693. |

| [9] | CHEN W, ZHOU H, TANG M, et al.Gas-foaming calcium phosphate cement scaffold encapsulating human umbilical cord stem cells. Tissue Engineering Part A, 2012, 18(7/8): 816-827. |

| [10] | ALMIRALL A, LARRECQ G, DELGADO J A, et al.Fabrication of low temperature macroporous hydroxyapatite scaffolds by foaming and hydrolysis of an alpha-TCP paste.Biomaterials, 2004, 25(17): 3671-3680. |

| [11] | ZHANG J, LIU W, SCHNITZLER V, et al.Calcium phosphate cements for bone substitution: chemistry, handling and mechanical properties. Acta Biomaterialia, 2014, 10(3): 1035-1049. |

| [12] | LIU W, ZHANG J, RETHORE G, et al.A novel injectable, cohesive and toughened Si-HPMC (silanized-hydroxypropyl methylcellulose) composite calcium phosphate cement for bone substitution. Acta Biomaterialia, 2014, 10(7): 3335-3345. |

| [13] | DAI H L, LI S P, HE J H, et al.Carbon fiber reinforced α-TCP/ TTCP bone cement.Journal of Inorganic Materials, 2004, 19(5): 1025-1030. |

| [14] | SCHUMACHER M, HENSS A, ROHNKE M, et al.A novel and easy-to-prepare strontium(II) modified calcium phosphate bone cement with enhanced mechanical properties. Acta Biomaterialia, 2013, 9(7): 7536-7544. |

| [15] | RENNO A C, NEJADNIK M R, VAN DE WATERING F C, et al. Incorporation of bioactive glass in calcium phosphate cement: material characterization and in vitro degradation. Journal of Biomedical Materials Research Part A, 2013, 101(8): 2365-2373. |

| [16] | MULAK W, BALAŽ P, CHOJNACKA M.Chemical and morphological changes of millerite by mechanical activation. International Journal of Mineral Processing, 2002, 66(1/2/3/4): 233-240. |

| [17] | NEIRA I S, KOLEN'KO Y V, KOMMAREDDY K P, et al. Reinforcing of a calcium phosphate cement with hydroxyapatite crystals of various morphologies. ACS Applied Materials & Interfaces, 2010, 2(11): 3276-3284. |

| [18] | JIANG X X, QU S X, LIN S Z, et al. Influence of drynaria on physicochemical and in vitro biological properties of calcium phosphate cement. Journal of Inorganic Materials, 2011, 26(1): 29-37. |

| [19] | JGJ 52-2006. 普通混凝土用砂、石质量及检验方法标准. |

| [20] | ASTM C29/C29M-97. Standard Test Method for Bulk Density (Unit Weight) and Voids in Aggregate. |

| [21] | GIROD FULLANA S, TERNET H, FRECHE M, et al.Controlled release properties and final macroporosity of a pectin microspheres-calcium phosphate composite bone cement. Acta Biomaterialia, 2010, 6(6): 2294-2300. |

| [22] | MOHAMMADI M, HESARAKI S, HAFEZI-ARDAKANI M.Investigation of biocompatible nanosized materials for development of strong calcium phosphate bone cement: comparison of nano-titania, nano-silicon carbide and amorphous nano-silica. Ceramics International, 2014, 40(6): 8377-8387. |

| [23] | LIU C S, CHEN F Y, HUANG Y, et al.Effects of particles size of the starting materials on hydration and hardening progress of calcium phosphate cement. Journal of the Chinese Ceramic Society, 1999, 27(2): 139-147. |

| [24] | YANG J J, YE J D.Effects of particle size on the rheological properties and injectability of a calcium phosphate cement.Bulletin of the Chinese Ceramic Society, 2008, 27(2): 213-219. |

| [25] | LEWIS G.Viscoelastic properties of injectable bone cements for orthopaedic applications: state-of-the-art review.Journal of Biomedical Materials Research Part B: Applied Biomaterials, 2011, 98(1): 171-191. |

| [26] | HUANG Z L, LIU Y, WANG D W, et al.Properties of crystallizing and absorbing F- ion of HAP synthesized by Sol-Gel process. Journal of Inorganic Materials, 2001, 16(4): 661-666. |

| [27] | NASIRI-TABRIZI B, FAHAMI A.Mechanochemical synthesis and structural characterization of nano-sized amorphous tricalcium phosphate.Ceramics International, 2013, 39(8): 8657-8666. |

| [28] | KO C L, CHEN J C, HUNG C C, et al.Biphasic products of dicalcium phosphate-rich cement with injectability and nondispersibility.Materials Science and Engineering C, Materials for Biological Applications, 2014, 39: 40-46. |

| [29] | TAMIMI F, LE NIHOUANNEN D, EIMAR H, et al.The effect of autoclaving on the physical and biological properties of dicalcium phosphate dihydrate bioceramics: brushite vs monetite. Acta Biomaterialia, 2012, 8(8): 3161-3169. |

| [30] | BOHNER M.Calcium orthophosphates in medicine: from ceramics to calcium phosphate cements.Injury, 2000, 31: D37-D47. |

| [31] | BOANINI E, GAZZANO M, BIGI A.Ionic substitutions in calcium phosphates synthesized at low temperature.Acta biomaterialia, 2010, 6(6): 1882-1894. |

| [32] | WEI J, JIA J, WU F, et al.Hierarchically microporous/macroporous scaffold of magnesium-calcium phosphate for bone tissue regeneration.Biomaterials, 2010, 31(6): 1260-1269. |

| [1] | YANG Shuqi, YANG Cunguo, NIU Huizhu, SHI Weiyi, SHU Kewei. GeP3/Ketjen Black Composite: Preparation via Ball Milling and Performance as Anode Material for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(3): 329-336. |

| [2] | ZHANG Hang, HAN Kunyuan, DONG Lanlan, LI Xiang. Preparation and Characterization of β-tricalcium Phosphate/Nano Clay Composite Scaffolds via Digital Light Processing Printing [J]. Journal of Inorganic Materials, 2022, 37(10): 1116-1122. |

| [3] | ZENG Fanxin, LIU Chuang, CAO Yuliang. Sodium Storage Behavior of Nanoporous Sb/MCNT Anode Material with High Cycle Stability by Dealloying Route [J]. Journal of Inorganic Materials, 2021, 36(11): 1137-1144. |

| [4] | LIU Jing, LIU Jun, LI Jiang, LIN Li, PAN Yu-Bai, CHENG Xiao-Nong, GUO Jing-Kun. Influence of Ball Milling Speed on Microstructure and Optical Transparency of Nd:YAG Ceramics [J]. Journal of Inorganic Materials, 2015, 30(6): 581-587. |

| [5] | ZHAO Jun-Sheng, QU Shu-Xin, HUANG Ping, LIU Zong-Guang, WANG Shi-Wen, WENG Jie. Calcium Phosphate Cement Reinforced by Nanocrystalline Cellulose [J]. Journal of Inorganic Materials, 2015, 30(3): 318-324. |

| [6] | DAI Hong-Lian, HU Fu-Jian, FANG Cai-Ping, LI Shi-Pu. Study on the Injectable Magnesium-calcium Phosphate Cements [J]. Journal of Inorganic Materials, 2014, 29(9): 991-996. |

| [7] | GONG Meng-An, Rao Qun-Li, WANG Hong-Lie. A Novel Technique to Prepare Porous 3D Fluoridated Hydroxyapatite Scaffold Using Pore-forming and Foaming Agents [J]. Journal of Inorganic Materials, 2014, 29(3): 289-293. |

| [8] | WU Xiao-Xian, LI Hong-Xia, LIU Guo-Qi, NIU Chong-Chong, WANG Gang, SUN Jia-Lin. Nanocarbon-coated α-Al2O3 Composite Powders Synthesized by High-energy Ball Milling [J]. Journal of Inorganic Materials, 2013, 28(3): 261-266. |

| [9] | QIU Tian, HUANG Jing-Jing, ZHANG Miao, WANG Xian-Fu, LI Chen, LU Xiao-Ying, WENG Jie. Effects of Adding Carbon Nanotubes/Hydroxyapatite Composites on the Properties and Structure of Calcium Phosphate Cement [J]. Journal of Inorganic Materials, 2013, 28(1): 91-96. |

| [10] | CAO Lie-Hui, YU Bao-Qing, WU Guo-Sheng, SU Jia-Can. Study on Adulterate Sodium Silica Apatite Cement Porous Scaffolds for Bone Defect Repair [J]. Journal of Inorganic Materials, 2011, 26(6): 591-596. |

| [11] | JIANGXiao-Xin, QU Shu-Xin, LIN Sun-Zhong, DUANKe, WENG Jie. Influenceof Drynaria on Physicochemical and <>in vitro Biological Properties ofCalcium Phosphate Cement [J]. Journal of Inorganic Materials, 2011, 26(1): 29-37. |

| [12] | WANG Zhi-Wei, SU Jia-Can, MA Yu-Hai, ZHANG Xin, CAO Lie-Hu, LI Ming. Preparation and Properties of Nano Calcium Deficient Apatite/Poly (ε-caprolactone) Composite Scaffold [J]. Journal of Inorganic Materials, 2010, 25(5): 500-506. |

| [13] | LI Mao-Hong1,2, QU Shu-Xin2, YAO Ning2,3, GUO Yue-Hua2, ZHANG Tao2, WENG Jie2. Properties of Calcium Phosphate Cement with various Concentrations of Xiangdan Injection [J]. Journal of Inorganic Materials, 2010, 25(5): 507-511. |

| [14] | SUN Jin-Feng,LI Xiao-Pu,LIANG Bao-Yan,ZHAO Yu-Cheng,WANG Ming-Zhi. Study on Reaction Mechanism of Reactive Ball Milling of Ti with Urea to Prepare TiN Powder [J]. Journal of Inorganic Materials, 2009, 24(4): 759-763. |

| [15] | LIANG Bao-Yan,WANG Ming-Zhi,SUN Jin-Feng,HAN Xin,LI Xiao-Pu. Combustion Synthesis of Ti3SiC2 in Air from 3Ti/Si/2C/0.2Al Powder Mixtures [J]. Journal of Inorganic Materials, 2009, 24(3): 623-626. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||