Journal of Inorganic Materials ›› 2026, Vol. 41 ›› Issue (3): 340-348.DOI: 10.15541/jim20250249

• RESEARCH ARTICLE • Previous Articles Next Articles

QI Fang1( ), LIU Hui1, WU Zhengmin1, LU Yi1, WU Wenwen2, WANG Zhen1(

), LIU Hui1, WU Zhengmin1, LU Yi1, WU Wenwen2, WANG Zhen1( )

)

Received:2025-06-12

Revised:2025-08-08

Published:2025-08-26

Online:2025-08-26

Contact:

WANG Zhen, professor. E-mail: wangz@wuzhenlab.comAbout author:QI Fang (1996-), female, Master candidate. E-mail: qif@wuzhenlab.com

Supported by:CLC Number:

QI Fang, LIU Hui, WU Zhengmin, LU Yi, WU Wenwen, WANG Zhen. Matrix/Interface/Fiber Integrated Oxidation Mechanism of Mini-SiCf/BN/SiC in Water-oxygen Environment at 1100 ℃[J]. Journal of Inorganic Materials, 2026, 41(3): 340-348.

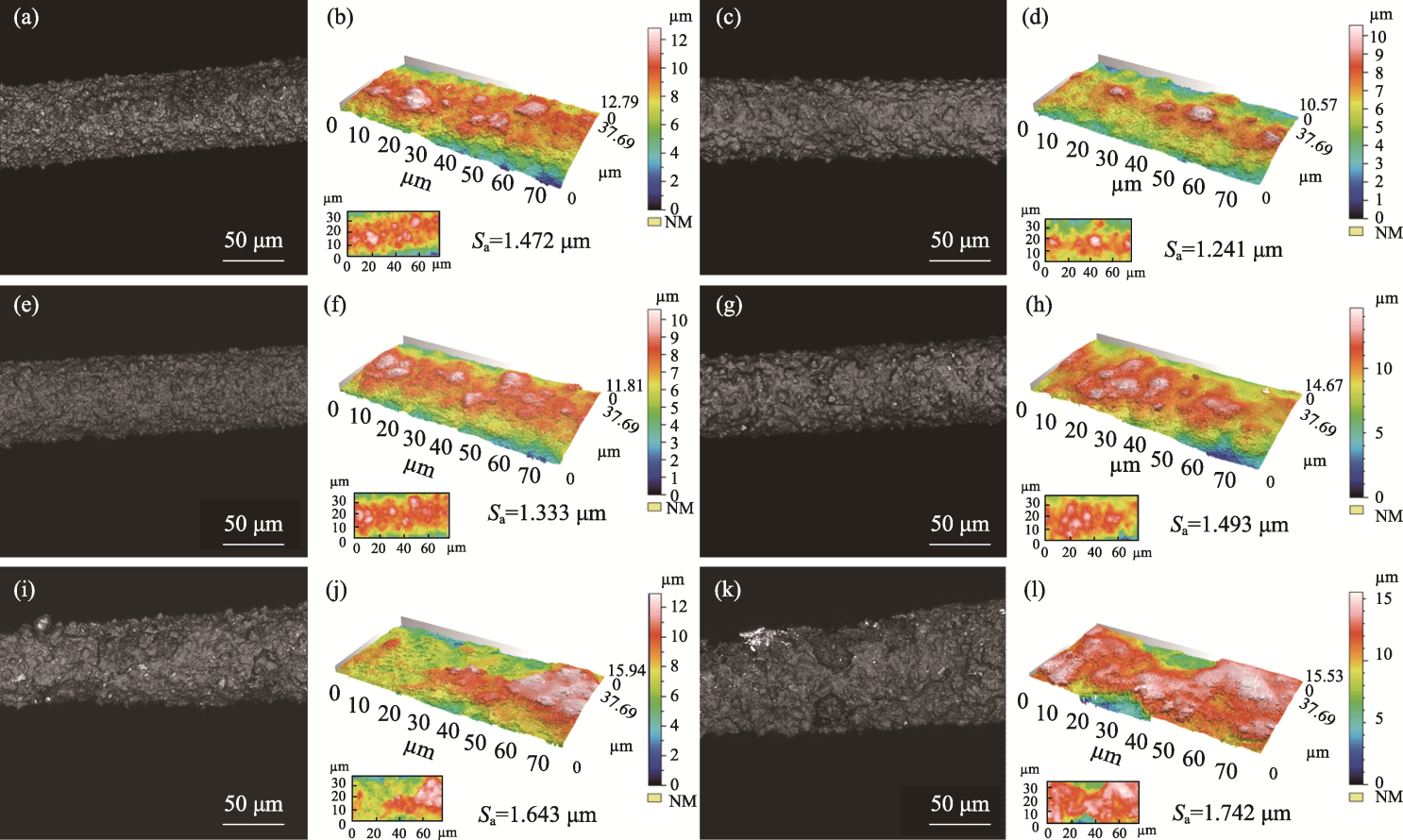

Fig. 5 Surface morphologies, 3D images and roughnesses of Mini-SiCf/BN/SiC after cyclic oxidation for different time (a, b) 0 h; (c, d) 20 h; (e, f) 40 h; (g, h) 60 h; (i, j) 80 h; (k, l) 100 h

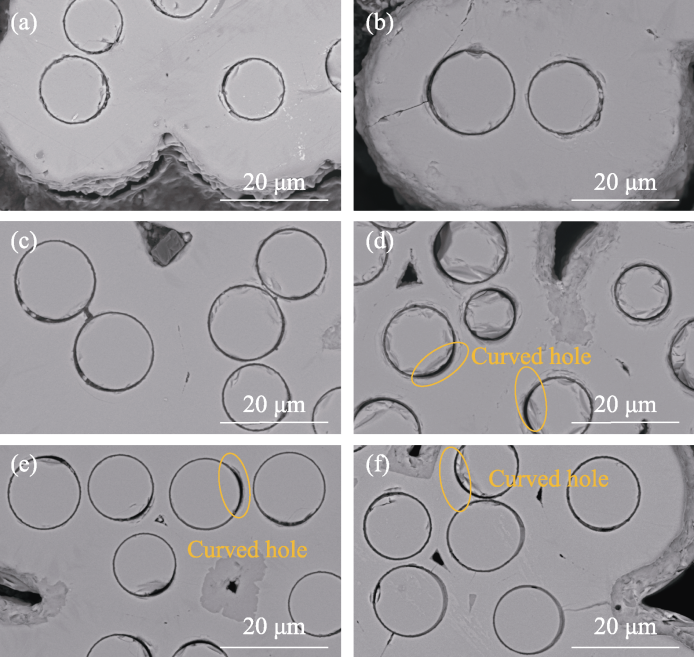

Fig. 7 SEM images of the middle part of Mini-SiCf/BN/SiC (10 mm from the end) after cyclic oxidation for different time (a) 0 h; (b) 20 h; (c) 40 h; (d) 60 h; (e) 80 h; (f) 100 h

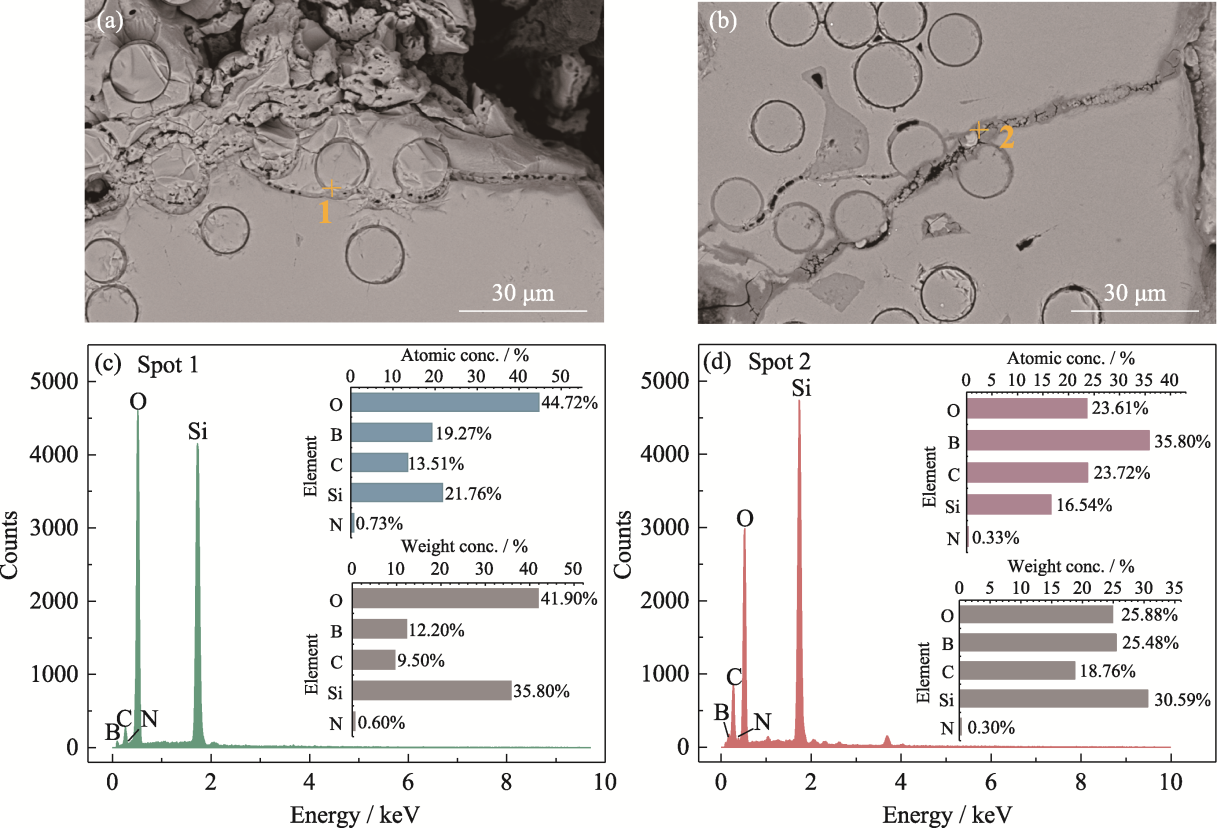

Fig. 8 SEM images and EDS patterns of Mini-SiCf/BN/SiC near the tip (1 mm away from the tip) after oxidation for 100 h (a, b) SEM images; (c) EDS-spot 1; (d) EDS-spot 2

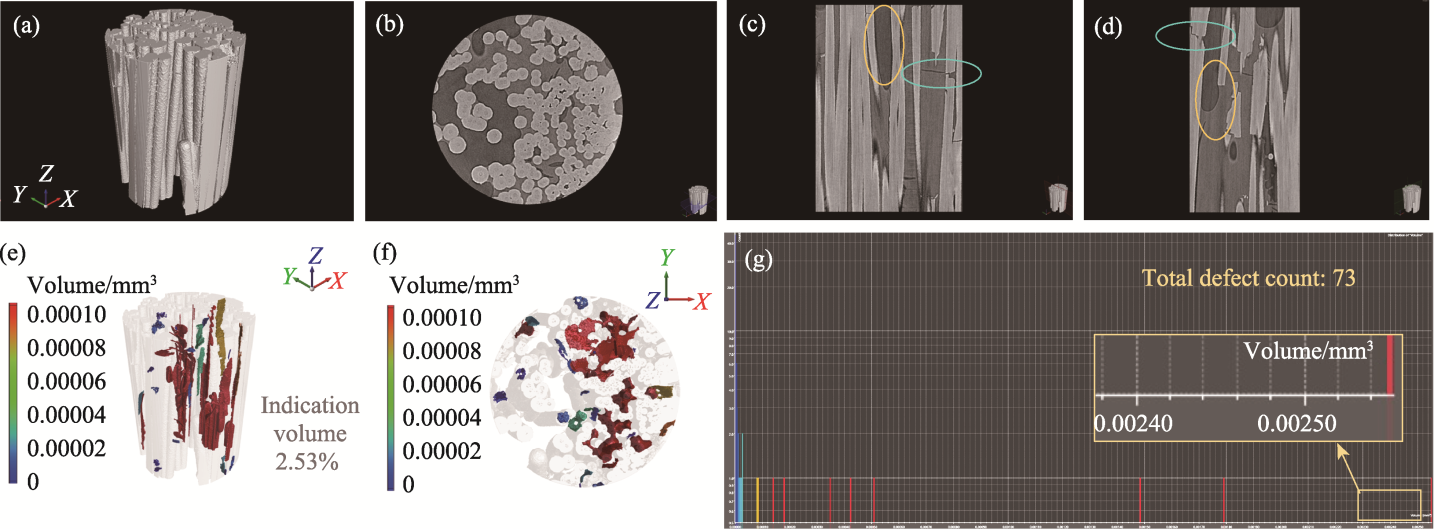

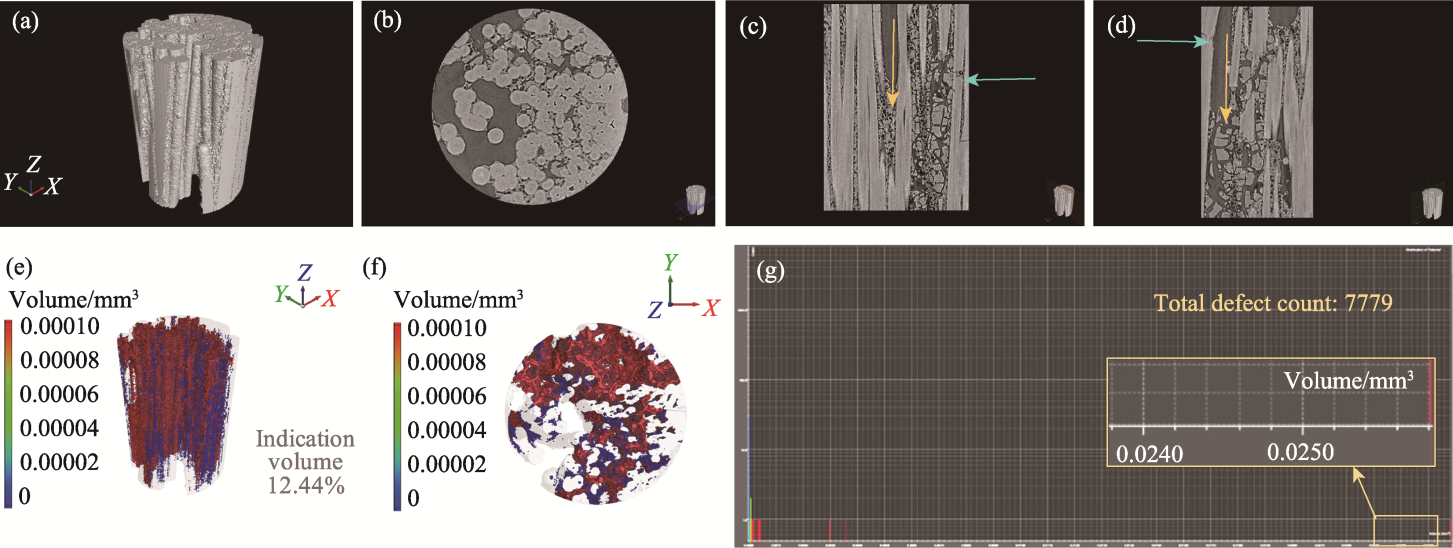

Fig. 9 XRM analyses of Mini-SiCf/BN/SiC before oxidation (a) Overall diagram; (b-d) Slice diagrams; (e, f) Defect distribution diagrams; (g) Defect statistical diagram

Fig. 10 XRM analyses of Mini-SiCf/BN/SiC after oxidation for 100 h (a) Overall diagram; (b-d) Slice diagrams; (e, f) Defect distribution diagrams; (g) Defect statistical diagram

| [1] | 沙建军, 代吉祥, 张兆甫. 纤维增韧高温陶瓷基复合材料(Cf, SiCf/SiC)应用研究进展. 航空制造技术, 2017(19): 16. |

| [2] | LU Z L, YUE J L, FU Z Y, et al. Microstructure and mechanical performance of SiCf/BN/SiC mini-composites oxidized at elevated temperature from ambient temperature to 1500 ℃ in air. Journal of the European Ceramic Society, 2020, 40(8): 2821. |

| [3] | CHEN M W, QIU H P, XIE W J, et al. Research progress of continuous fiber reinforced ceramic matrix composite in hot section components of aero engine. IOP Conference Series: Materials Science and Engineering, 2019, 678: 012043. |

| [4] | CHEN X H, WU W J, SUN Z G, et al. Modeling the effect of oxidation on the creep behavior of SiC/PyC/SiC mini-composites under wet oxygen atmosphere. Applied Composite Materials, 2021, 28: 297. |

| [5] | 王衍飞, 刘荣军, 张金, 等. SiCf/SiC陶瓷基复合材料制备技术研究进展. 材料工程, 2025, 53(4): 52. |

| [6] | 吴守军. 3D SiC/SiC复合材料热化学环境行为. 西安: 西北工业大学博士学位论文, 2006. |

| [7] | WANG L Y, LUO R Y, CUI G Y, et al. Oxidation resistance of SiCf/SiC composites with a PyC/SiC multilayer interface at 500 ℃ to 1100 ℃. Corrosion Science, 2020, 167: 108522. |

| [8] | CHRISTENSEN L V, DIAZ G O, SKILLETT R, et al. Influence of BN microstructure on oxidation of SiC/BN/SiC composites. Journal of the American Ceramic Society, 2024, 108(3): e20230. |

| [9] | ZHANG J, LIU R J, JIAN Y J, et al. Degradation mechanism of SiCf/SiC composites after long-time water vapor and oxygen corrosion at 1300 ℃. Corrosion Science, 2022, 197: 110099. |

| [10] | CHEN B, REN K, WANG Y G. Evolution of mechanical properties of mini-SiCf/SiC composites at high temperatures over a long period of time. Journal of Inorganic Materials, 2025, 40(9): 971. |

| [11] | EMMANUEL E B, THOMAS S K, PAVEL M, et al. SiC/SiC mini-composites with yttrium disilicate fiber coatings: oxidation in steam. Journal of the European Ceramic Society, 2021, 41(5): 3132. |

| [12] | NASIRI A N, PATRA N, NI N, et al. Oxidation behaviour of SiC/SiC ceramic matrix composites in air. Journal of the European Ceramic Society, 2016, 36(14): 3293. |

| [13] | WANG P, WANG Q L, ZHANG X Y, et al. Oxidation behavior of SiCf/SiC composites modified by layered-Y2Si2O7 in wet oxygen environment. Journal of Inorganic Materials, 2019, 34(8): 904. |

| [14] | PARTHASARATHY A T, PRZYBYL P C, HAY S R, et al. Modeling environmental degradation of SiC-based fibers. Journal of the American Ceramic Society, 2016, 99(5): 1725. |

| [15] | 张悦. 陶瓷基复合材料基体氧化行为研究. 南京: 南京航空航天大学硕士学位论文, 2021. |

| [16] | 汪海滨, 张卫红, 杨军刚, 等. 考虑孔隙和微裂纹缺陷的C/C-SiC编织复合材料等效模量计算. 复合材料学报, 2008, 25(3): 182. |

| [17] | JIANG L Y, PANG S Y, YANG C, et al. Preparation and oxidation behaviors of C/SiC-BN composites. Journal of Inorganic Materials, 2024, 39(7): 779. |

| [18] | PARK J D, JUNG I Y, KIM G H, et al. Oxidation behavior of silicon carbide at 1200 ℃ in both air and water-vapor-rich environments. Corrosion Science, 2014, 88: 416. |

| [19] | WILLEMIN S, CARMINATI P, JACQUES S, et al. Identification of complex oxidation/corrosion behaviours of boron nitride under high temperature. Oxidation of Metals, 2017, 88(3): 247. |

| [20] | 陈婧, 吕熙睿, 张佳平, 等. CVI+PIP复合工艺制备SiCf/SiC复合材料的微观结构和水氧腐蚀行为研究. 陶瓷学报, 2022, 43(6): 1030. |

| [21] | 向宇, 余金山, 王洪磊, 等. 碳化硅纤维高温抗氧化性研究进展. 硅酸盐通报, 2022, 41(9): 3234. |

| [22] | NIU Z B, LI Z, XIAO P, et al. Influence of h-BN as additive on microstructure and oxidation mechanism of C/C-SiC composite. Journal of the European Ceramic Society, 2019, 39(15): 4634. |

| [23] | 秦刚, 邹顺, 蒋龙, 等. 碳化硅纤维增韧碳化硅陶瓷基复合材料研究进展综述. 陶瓷学报, 2023, 44(3): 389. |

| [1] | TANG Hui-Yi,ZHU De-Gui,LIU Bo,SUN Hong-Liang. High Temperature Oxidation Mechanism of Ti3SiC2-64vol%SiC Ceramics [J]. Journal of Inorganic Materials, 2009, 24(4): 821-826. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||