Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (3): 288-295.DOI: 10.15541/jim20220485

• RESEARCH ARTICLE • Previous Articles Next Articles

MU Honghe1( ), WANG Pengfei1(

), WANG Pengfei1( ), SHI Yufeng1, ZHANG Zhonghan1(

), SHI Yufeng1, ZHANG Zhonghan1( ), WU Anhua1,2, SU Liangbi1,2

), WU Anhua1,2, SU Liangbi1,2

Received:2022-08-15

Revised:2022-09-08

Published:2023-03-20

Online:2022-11-20

Contact:

WANG Pengfei, lecturer. E-mail: wangpengfei@mail.sic.ac.cn;About author:About author: MU Honghe (1997-), female, Master candidate. E-mail: muhonghe@mails.ucas.ac.cn

Supported by:CLC Number:

MU Honghe, WANG Pengfei, SHI Yufeng, ZHANG Zhonghan, WU Anhua, SU Liangbi. Large-size CeF3 Crystal Growth by Heat Exchanger-Bridgman Method: Thermal Field Design and Optimization[J]. Journal of Inorganic Materials, 2023, 38(3): 288-295.

| Physical properties | Thermal conductivity/ (W·m-1·K-1) | Density/(kg·m-3) | Heat capacity/(J·kg-1·K-1) | Emissivity | Absorption coefficient |

|---|---|---|---|---|---|

| Vacuum | 2.4×10-4 | 2.9×10-3 | 150 | - | - |

| Molybdenum | 163.7-0.062T+9.72×10-6T2 | 10200 | 250.78 | 0.4 | - |

| Graphite | exp(-5.7×10-4T+4.5) | 1950 | 710 | 0.8 | - |

| Stainless Steel | 9.2+0.0175T-2×10-6T2 | 7930 | 500 | 0.66 | - |

| CeF3 melt | 0.5 | 3200 | 1470.8 | - | 900 |

| CeF3 crystal | 1.72 | 5800 | 1064.52+0.198T+9.29×10-5T2 | - | 10 |

Table 1 Thermophysical parameters of materials

| Physical properties | Thermal conductivity/ (W·m-1·K-1) | Density/(kg·m-3) | Heat capacity/(J·kg-1·K-1) | Emissivity | Absorption coefficient |

|---|---|---|---|---|---|

| Vacuum | 2.4×10-4 | 2.9×10-3 | 150 | - | - |

| Molybdenum | 163.7-0.062T+9.72×10-6T2 | 10200 | 250.78 | 0.4 | - |

| Graphite | exp(-5.7×10-4T+4.5) | 1950 | 710 | 0.8 | - |

| Stainless Steel | 9.2+0.0175T-2×10-6T2 | 7930 | 500 | 0.66 | - |

| CeF3 melt | 0.5 | 3200 | 1470.8 | - | 900 |

| CeF3 crystal | 1.72 | 5800 | 1064.52+0.198T+9.29×10-5T2 | - | 10 |

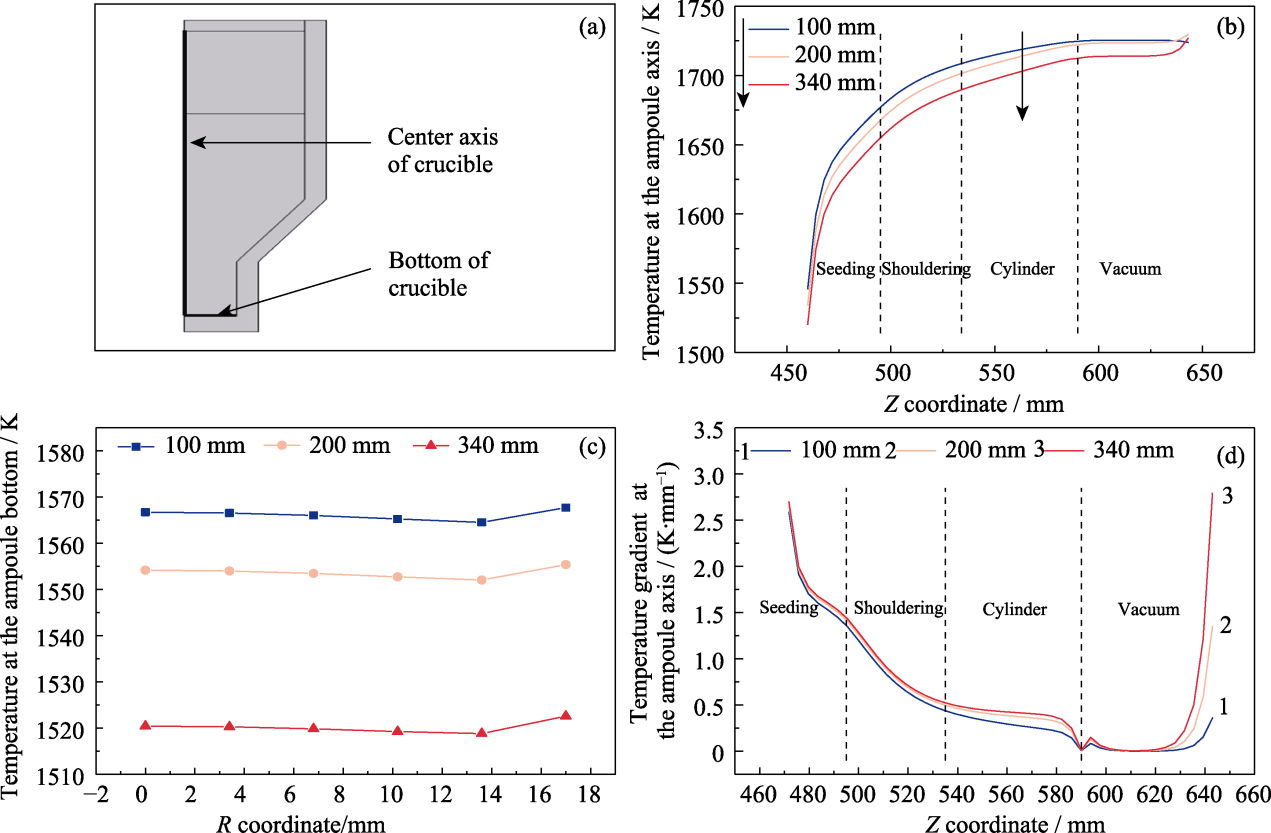

Fig. 3 Internal temperature distribution of the crucible corresponding to the heating elements of different lengths (a) Specific location schematic; (b) Longitudinal temperature at the central axis; (c) Radial temperature at the bottom of the crucible; (d) Longitudinal temperature gradient at the central axis; Colorful figures are available on website

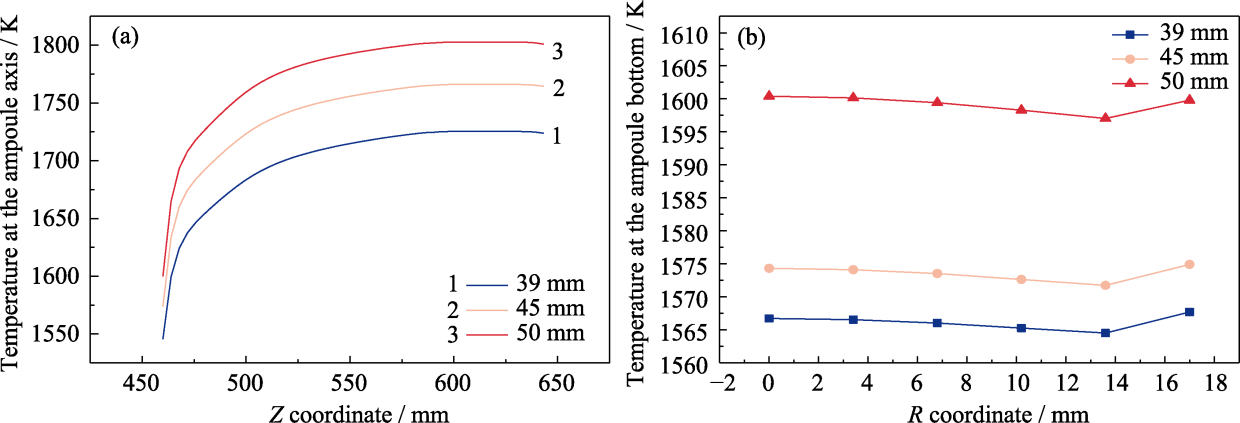

Fig. 4 Temperature distributions inside the crucible corresponding to the partitions of different widths (a) Longitudinal temperature at the central axis; (b) Radial temperature at the bottom of the crucible; Colorful figures are available on website

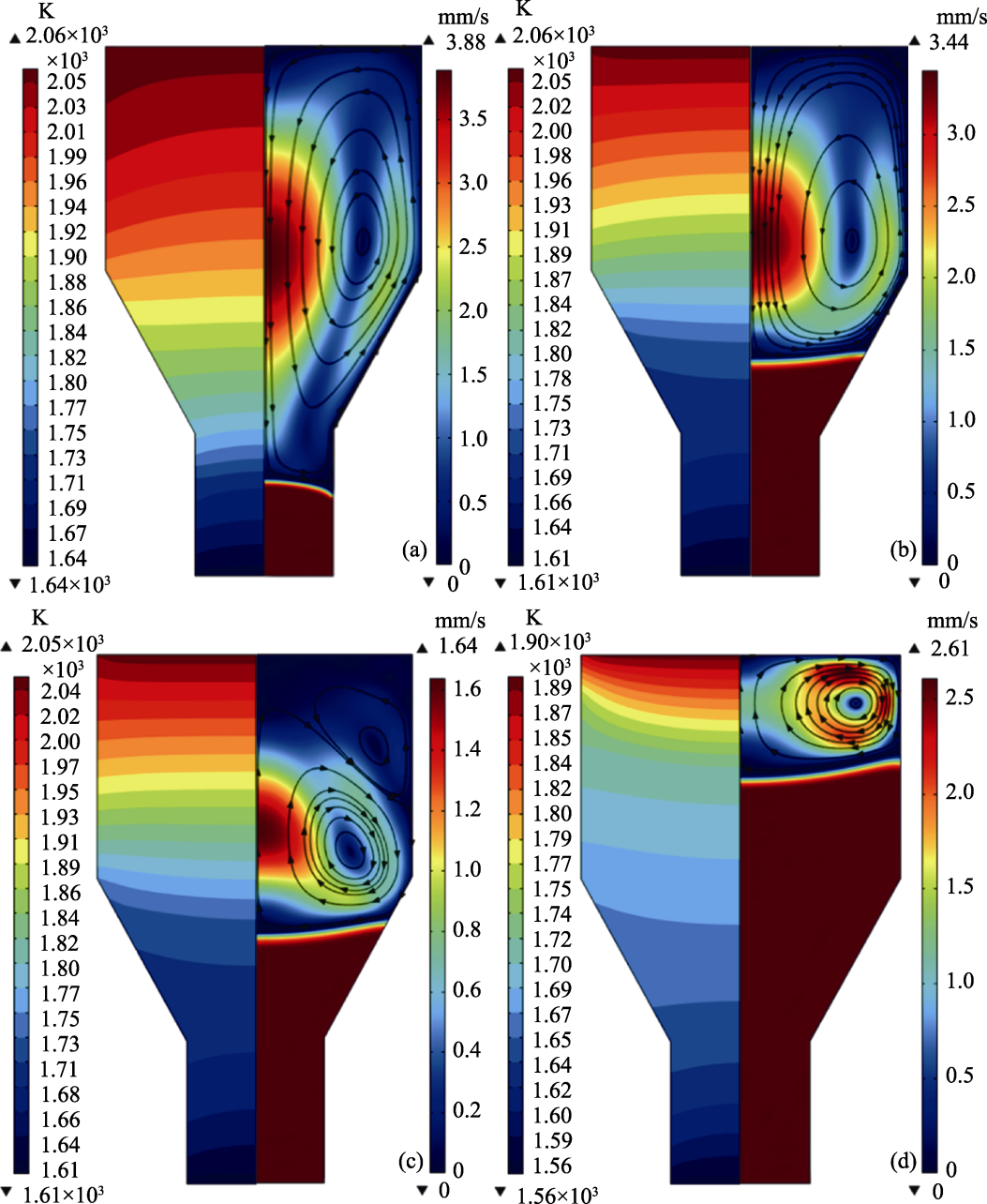

Fig. 5 Thermal field distribution (left) and flow field distribution, interface shape (right) at different growth stages (a) Seeding stage; (b) Beginning of shouldering stage; (c) End of shouldering stage; (d) Cylinder stage

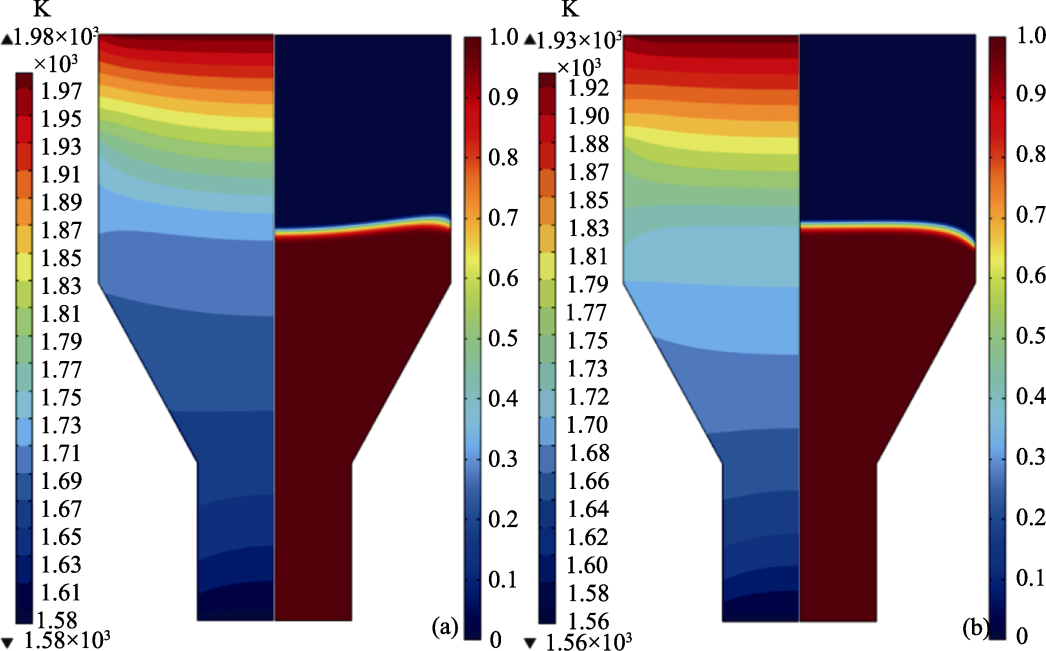

Fig. 8 Thermal field distribution (left) and interface shape (right) in the cylinder stage (a) Original partition without reflective screen; (b) Reflective screen without partition

| [1] |

STAROBOR A, MIRONOV E, PALASHOV O. High-power Faraday isolator on a uniaxial CeF3 crystal. Optics Letters, 2019, 44(6): 1297.

DOI URL |

| [2] |

LI H F, WANG J Y, CHEN J F, et al. Bridgman growth and magneto-optical properties of CeF3 crystal as Faraday Rotator. Optical Materials, 2020, 100: 109675.

DOI URL |

| [3] |

MOLINA P, VASYLIEV V, VILLORA E G, et al. CeF3 and PrF3 as UV-Visible Faraday rotators. Optics Express, 2011, 19(12): 11786.

DOI URL |

| [4] |

VOJNA D, SLEZAK O, YASUHARA R, et al. Faraday rotation of Dy2O3, CeF3 and Y3Fe5O12 at the mid-infrared wavelengths. Materials, 2020, 13(23): 5324.

DOI URL |

| [5] |

ZHAO G, ZHAO C C, YANG Y L, et al. Magneto-optical performances of novel neodymium-doped CeF3 crystal. Materials Letters, 2021, 300: 130134.

DOI URL |

| [6] |

KARIMOV D N, LISOVENKO D S, IVANOVA A G, et al. Bridgman growth and physical properties anisotropy of CeF3 single crystals. Crystals, 2021, 11(7): 793.

DOI URL |

| [7] |

YOSHIKAWA A, SATONAGA T, KAMADA K, et al. Crystal growth of Ce: PrF3 by micro-pulling-down method. Journal of Crystal Growth, 2004, 270(3/4): 427.

DOI URL |

| [8] | INAGAKI T, YOSHIMURA Y, KANDA Y, et al. Development of CeF3 crystal for high-energy electromagnetic calorimetry. Nuclear Instruments & Methods in Physics Research Section A-Accelerators Spectrometers Detectors and Associated Equipment, 2000, 443(1): 126. |

| [9] |

KUPPURAO S, DERBY J J. Designing thermal environments to promote convex interface shapes during the vertical Bridgman growth of cadmium zinc telluride. Journal of Crystal Growth, 1997, 172(3/4): 350.

DOI URL |

| [10] |

HAHN S H, YOON J K. Numerical analysis for the application of radiative reflectors to vertical Bridgman growth configurations. Journal of Crystal Growth, 1997, 177: 296.

DOI URL |

| [11] |

EPURE S, DUFFAR T, BRAESCU L. Comparison between analytical and numeric determination of the interface curvature during dewetted Bridgman crystal growth. Journal of Crystal Growth, 2008, 310(7/8/9): 1559.

DOI URL |

| [12] |

ZAPPETTINI A, ZhA M, MARCHINI L, et al. Control of the interface shape in vertical Bridgman grown CdZnTe crystals for X- ray detector applications. CrystEngComm, 2012, 14(18): 5992.

DOI URL |

| [13] |

YANG X, LV G, MA W, et al. The effect of radiative heat transfer characteristics on vacuum directional solidification process of multicrystalline silicon in the vertical Bridgman system. Applied Thermal Engineering, 2016, 93: 731.

DOI URL |

| [14] |

ZHAO W, LIU L. Control of heat transfer in continuous-feeding Czochralski-silicon crystal growth with a water-cooled jacket. Journal of Crystal Growth, 2017, 458: 31.

DOI URL |

| [15] |

ZHANG C, GAO B, TREMSIN A S, et al. Analysis of chemical stress and the propensity for cracking during the vertical Bridgman growth of BaBrCl:Eu. Journal of Crystal Growth, 2020, 546: 125794.

DOI URL |

| [16] | FEDYUSHKIN A I, BURAGO N G, PUNTUS A A. Convective heat and mass transfer modeling under crystal growth by vertical Bridgman method. Journal of Physics: Conference Series, 2020, 1479(1): 012029. |

| [17] |

KUPPURAO S, BRANDON S, DERBY J J. Modeling the vertical Bridgman growth of cadmium zinc telluride I. Quasi-steady analysis of heat transfer and convection. Journal of Crystal Growth, 1995, 155(1/2): 93.

DOI URL |

| [18] |

HONG B, ZHANG S, ZHENG L, et al. Studies on thermal and interface optimization for CdZnTe crystals by unseeded traveling heater method. Journal of Crystal Growth, 2020, 546: 125776.

DOI URL |

| [19] |

VOLLER V R, PRAKASH C. A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. International Journal of Heat and Mass Transfer, 1987, 30(8): 1709.

DOI URL |

| [20] |

SPEDDING F H, BEAUDRY B J, HENDERSON D C, et al. High-temperature enthalpies and related thermodynamic functions of trifluorides of Sc, Ce, Sm, Eu, Gd, Tb, Dy, Er, Tm, and Yb. Journal of Chemical Physics, 1974, 60(4): 1578.

DOI URL |

| [21] |

HU K, ZHENG L, ZHANG H. Control of interface shape during high melting sesquioxide crystal growth by HEM technique. Journal of Crystal Growth, 2018, 483: 175.

DOI URL |

| [22] | HAO P, ZHU J, LIAO J, et al. Quality control and process optimization of ingot crystalline silicon based on neural network and genetic algorithm. Journal of Synthetic Crystals, 2022, 51(3): 385. |

| [1] | SHI Yanlei, SUN Niefeng, XU Chengyan, WANG Shujie, LIN Peng, MA Chunlei, XU Senfeng, WANG Wei, CHEN Chunmei, FU Lijie, SHAO Huimin, LI Xiaolan, WANG Yang, QIN Jingkai. Thermal Field of 6-inch Indium Phosphide Single Crystal Growth by Semi-sealed Czochralski Method [J]. Journal of Inorganic Materials, 2023, 38(3): 335-342. |

| [2] | SUN Han, LI Wenjun, JIA Zixuan, ZHANG Yan, YIN Liying, JIE Wanqi, XU Yadong. Effect of ACRT Technology on the Large Size ZnTe Crystals Grown by Solution Method and Corresponding Terahertz Properties [J]. Journal of Inorganic Materials, 2023, 38(3): 310-315. |

| [3] | CHEN Wen-Bo, CHEN Lun-Jiang, LIU Chuan-Dong, CHENG Chang-Ming, TONG Hong-Hui, ZHU Hai-Long. Preparation of Spherical Alumina Powder by RF Thermal Plasma: Numerical Simulation and Experimentation [J]. Journal of Inorganic Materials, 2018, 33(5): 550-556. |

| [4] | WANG Xiao-Yuan, YAN Ya-Bin, SHIMADA Takahiro, KITAMURA Takayuki. Research Progress in Atomistic Simulation on Ferroelectricity and Electromechanical Coupling Behavior of Nanoscale Ferroelectrics [J]. Journal of Inorganic Materials, 2015, 30(6): 561-570. |

| [5] | LIU Guang-Xia, WANG Sheng-Lai, DING Jian-Xu, SUN Yun, LIU Wen-Jie, ZHU Sheng-Jun. Numerical Simulation of the Influence of Different Rotation Speeds on the Capping of KDP Crystal [J]. Journal of Inorganic Materials, 2013, 28(06): 665-670. |

| [6] |

WEI Xi,CHENG Lai-Fei,ZHANG Li-Tong,XU Yong-Dong.

Numerical Simulation of Isothermal Chemical Vapor Infiltration Process for Fabrication of C/SiC Composites [J]. Journal of Inorganic Materials, 2006, 21(5): 1179-1184. |

| [7] | CHANG Xu,TANG Chun-An,ZHANG Hou-Quan,ZHANG Yong-Bin,ZHANG Ya-Fang. Numerical Approach to Toughening Design of Laminated Ceramic Composites [J]. Journal of Inorganic Materials, 2005, 20(2): 459-464. |

| [8] | YU Hui-Ping,SUI Yun-Kang,ZHANG Feng-Yi,CHANG Xin-An,AN Guo-Ping. Numerical Simulation of a Czochralski Silicon Crystal Growth with a Large Diameter 300mm Under a Cusp Magnetic Field [J]. Journal of Inorganic Materials, 2005, 20(2): 453-458. |

| [9] | LIU Zhao-Hua,JIN Wei-Qing,PAN Zhi-Lei,LIANG Xin-An,CHEN Gang-Yi. Experiment and Numerical Simulation of Velocity and Temperature Fields in KNbO3 Solution [J]. Journal of Inorganic Materials, 2002, 17(6): 1112-1116. |

| [10] | ZHANG Hai-Bin,SHEN Ding-Zhong,REN Guo-Hao,GONG Bo. Research Progress on the Numerical Simulation of Transport Process in Vertical Bridgman Crystal Growth [J]. Journal of Inorganic Materials, 2002, 17(5): 910-914. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||