Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (6): 679-684.DOI: 10.15541/jim20180528

• RESEARCH LETTERS • Previous Articles

Peng LI,Xiao-Lei NIE( ),Ye TIAN,Wen-Bing FANG,Ping WEI,Wan-Ting ZHU,Zhi-Gang SUN,Qing-Jie ZHANG,Wen-Yu ZHAO(

),Ye TIAN,Wen-Bing FANG,Ping WEI,Wan-Ting ZHU,Zhi-Gang SUN,Qing-Jie ZHANG,Wen-Yu ZHAO( )

)

Received:2018-11-09

Published:2019-06-20

Online:2019-05-23

Supported by:CLC Number:

Peng LI, Xiao-Lei NIE, Ye TIAN, Wen-Bing FANG, Ping WEI, Wan-Ting ZHU, Zhi-Gang SUN, Qing-Jie ZHANG, Wen-Yu ZHAO. Fabrication and Planar Cooling Performance of Flexible Bi0.5Sb1.5Te3/epoxy Composite Thermoelectric Films[J]. Journal of Inorganic Materials, 2019, 34(6): 679-684.

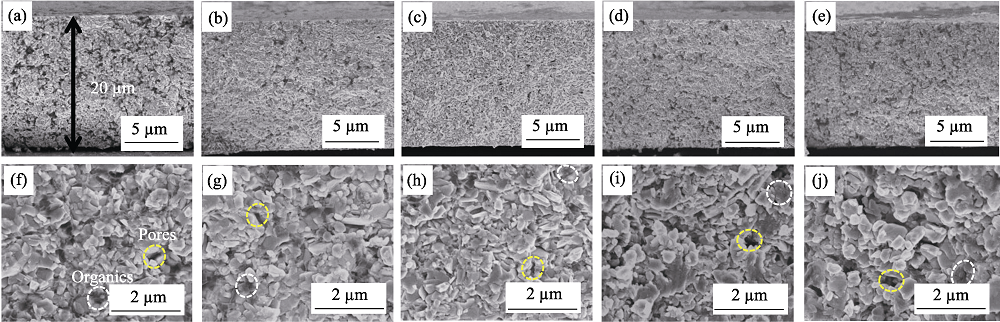

Fig. 2 Cross-sectional FESEM images of the composite thick films prepared with different contents of Bi0.5Sb1.5Te3 powder (a, f) x= 6.5; (b, g) x= 7; (c, h) x= 8; (d, i) x= 9; (e, j) x= 10

| x | ρ/(g·cm-3) | RH/(×10-1, cm3·C-1) | n/(×1019, cm-3) | μH/(cm2·V-1·s-1) | σ/(×104, S·m-1) |

|---|---|---|---|---|---|

| 6.5 | 3.93 | 3.72 | 1.67 | 45.15 | 1.21 |

| 7 | 4.08 | 3.69 | 1.69 | 52.17 | 1.41 |

| 8 | 4.32 | 3.57 | 1.74 | 58.85 | 1.65 |

| 9 | 4.19 | 3.56 | 1.73 | 54.69 | 1.51 |

| 10 | 4.05 | 3.55 | 1.72 | 50.59 | 1.40 |

| x | ρ/(g·cm-3) | RH/(×10-1, cm3·C-1) | n/(×1019, cm-3) | μH/(cm2·V-1·s-1) | σ/(×104, S·m-1) |

|---|---|---|---|---|---|

| 6.5 | 3.93 | 3.72 | 1.67 | 45.15 | 1.21 |

| 7 | 4.08 | 3.69 | 1.69 | 52.17 | 1.41 |

| 8 | 4.32 | 3.57 | 1.74 | 58.85 | 1.65 |

| 9 | 4.19 | 3.56 | 1.73 | 54.69 | 1.51 |

| 10 | 4.05 | 3.55 | 1.72 | 50.59 | 1.40 |

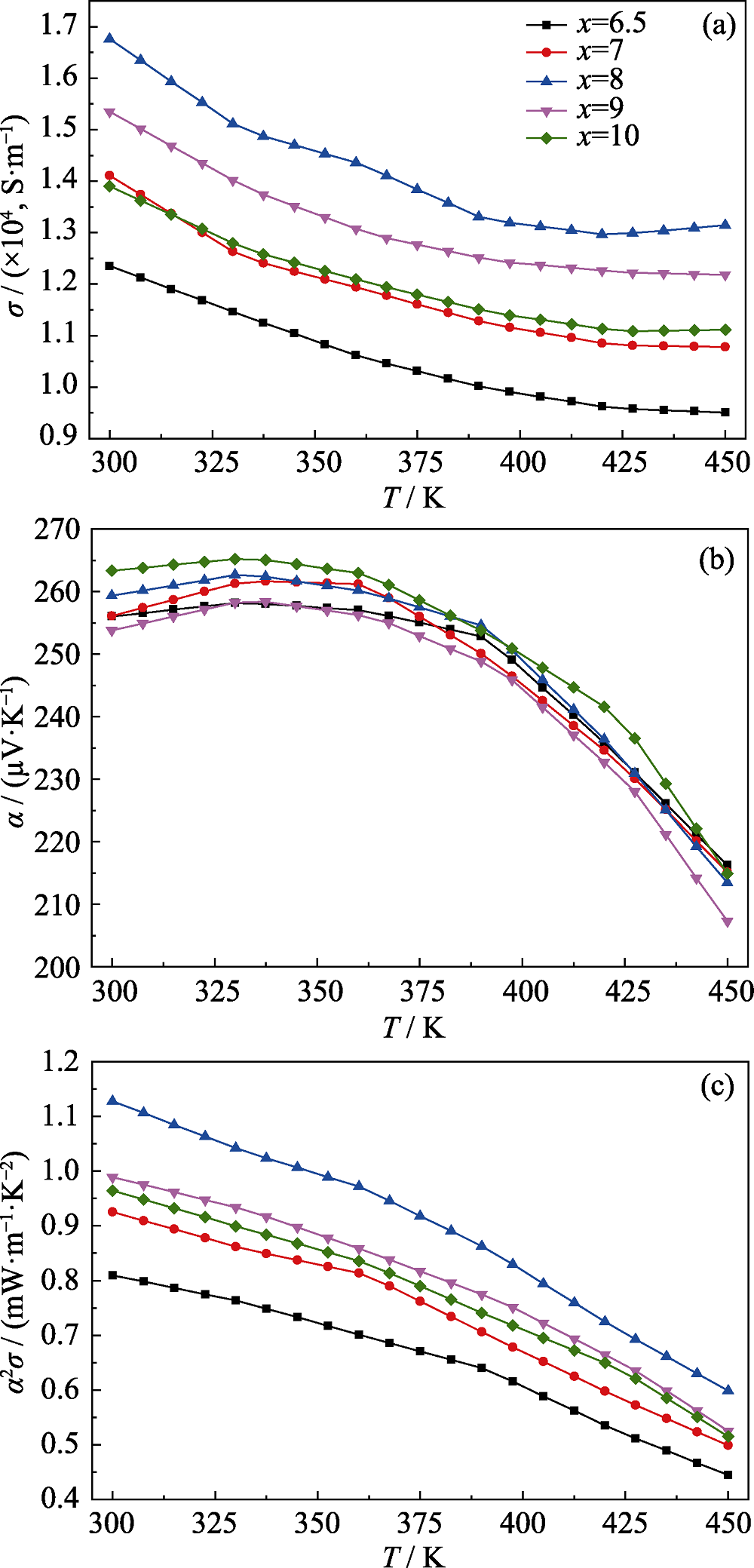

Fig. 3 Temperature dependence of (a) electrical conductivity σ, (b) Seebeck coefficient α and (c) power factor α2σ of the composite thick films prepared with different content of Bi0.5Sb1.5Te3 powder

| Materials | Fabrication process | Annealing methods | σ/(×104, S·m-1) | α2σ/(mW·m-1·K-2) | Ref. |

|---|---|---|---|---|---|

| Bi0.5Sb1.5Te3+epoxy | Screen printing | 573 K, 4 h, hot pressing | 1.67 | 1.12 | This work |

| Bi0.5Sb1.5Te3 ink | Inkjet printing | 673 K, 30 min | 0.20 | 0.07 | [10] |

| Bi0.5Sb1.5Te3+8%Te-epoxy | Dispenser printing | 523 K | 0.11 | 0.06 | [14] |

| Bi0.5Sb1.5Te3+C24H44O6 | Brush-printed | 673 K, 4 h | 0.29 | 0.15 | [17] |

| Bi2Te3+1%Se-epoxy | Dispenser printing | 623 K, 12 h | 1.03 | 0.26 | [20] |

| Bi0.5Sb1.5Te3+epoxy | Brush-printed | 623 K, 4 h, hot pressing | 1.15 | 0.84 | [22] |

| Bi0.5Sb1.5Te3+8%Te-polymer | Dispenser printing | 523 K | 0.13 | 0.16 | [25] |

| Materials | Fabrication process | Annealing methods | σ/(×104, S·m-1) | α2σ/(mW·m-1·K-2) | Ref. |

|---|---|---|---|---|---|

| Bi0.5Sb1.5Te3+epoxy | Screen printing | 573 K, 4 h, hot pressing | 1.67 | 1.12 | This work |

| Bi0.5Sb1.5Te3 ink | Inkjet printing | 673 K, 30 min | 0.20 | 0.07 | [10] |

| Bi0.5Sb1.5Te3+8%Te-epoxy | Dispenser printing | 523 K | 0.11 | 0.06 | [14] |

| Bi0.5Sb1.5Te3+C24H44O6 | Brush-printed | 673 K, 4 h | 0.29 | 0.15 | [17] |

| Bi2Te3+1%Se-epoxy | Dispenser printing | 623 K, 12 h | 1.03 | 0.26 | [20] |

| Bi0.5Sb1.5Te3+epoxy | Brush-printed | 623 K, 4 h, hot pressing | 1.15 | 0.84 | [22] |

| Bi0.5Sb1.5Te3+8%Te-polymer | Dispenser printing | 523 K | 0.13 | 0.16 | [25] |

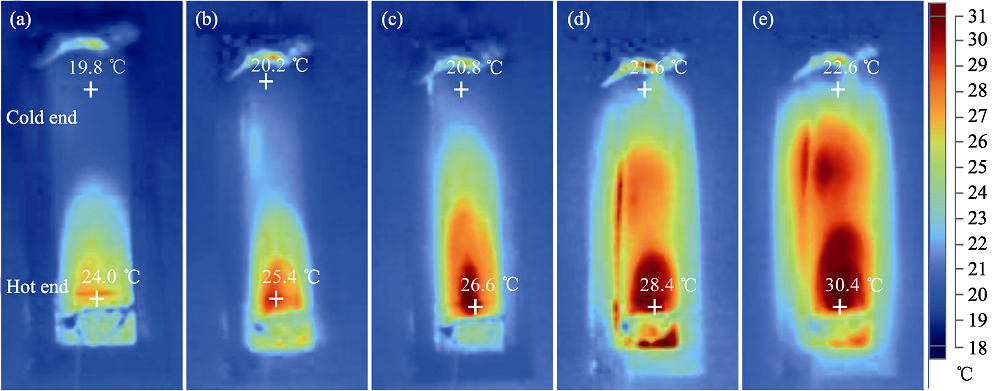

Fig. 5 Visual infrared images of the composite thick films measured with different currents (I) (a) I=0.01 A; (b) I=0.02 A; (c) I=0.03 A; (d) I=0.04 A; (e) I=0.05 A

| [1] |

SIMONS R E, EllSWORTH M J, CHU R C . An assessment of module cooling enhancement with thermoelectric coolers.[J]. Heat Transf., 2005,127(1):76-84.

DOI URL |

| [2] |

ZHANG H Y, MUI Y C, TARIN M . Analysis of thermoelectric cooler performance for high power electronic package. Appl. Therm. Eng., 2010,30(6/7):561-568.

DOI URL |

| [3] |

AVRAM B C, IYENGAR M, KRAUS A D . Design of optimum plate-fin natural convective heat sinks.[J]. Electronic Packag., 2003,125(2):208-216.

DOI URL |

| [4] |

BELL L E . Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science, 2008,321(5895):1457-1461.

DOI URL |

| [5] |

HARMAN T C, TAYLOR P J, WALSH M P , et al. Quantum dot superlattice thermoelectric materials and devices. Science, 2002,297(5590):2229-2232.

DOI URL |

| [6] |

CHOWDHURY I, PRASHER R, LOFGREE K , et al. On-chip cooling by superlattice-based thin-film thermoelectrics. Nat. nanotechnol., 2009,4(4):235-238.

DOI |

| [7] | HAO F, QIU P F, TANG Y S , et al. High efficiency Bi2Te3-based materials and devices for thermoelectric power generation between 100 and 300 ℃. Energy & Environ Sci., 2016,9(10):3120-3127. |

| [8] |

DISALVO F J . Thermoelectric cooling and power generation. Science, 1999,285(5428):703-706.

DOI URL |

| [9] |

YANG J, STABLER F R . Automotive applications of thermoelectric materials.[J]. Electron. Mater., 2009,38(7):1245-1251.

DOI URL |

| [10] |

LU Z, LAYANI M, ZHAO X , et al. Fabrication of flexible thermoelectric thin film devices by inkjet printing. Small, 2014,10(17):3551-3554.

DOI URL |

| [11] | XU B, AGNE M T, FENG T L , et al. Nanocomposites from solution- synthesized PbTe-BiSbTe nanoheterostructure with unity figure of merit at low-medium temperatures (500-600 K). Adv.Mater., 2017, 29(10): 1605140-1-9. |

| [12] | ZHU T J, HU L P, ZHAO X B , et al. New insight into intrinsic point defects in V2VI3 thermoelectric materials. Adv. Sci., 2016, 3(7): 1600004-1-16. |

| [13] | MADAN D, CHEN A, WRIGHT P K , et al. Dispenser printed composite thermoelectric thick films for thermoelectric generator application. J. Appl. Phys., 2011, 109(3): 034904-1-6. |

| [14] | MADAN D, WANG Z Q, CHEN A, et al. Dispenser printed circular thermoelectric devices using Bi and Bi0.5Sb1.5Te3. Appl. Phys.Lett ., 2014, 104(1): 013902-1-4. |

| [15] | KIM S J, WE J H, CHO B J . A wearable thermoelectric generator fabricated on a glass fabric. Energy & Environ Sci., 2014,7(6):1959-1965. |

| [16] | VARGHESE T, HOLLAR C, RICHARDSON J , et al. High-performance and flexible thermoelectric films by screen printing solution-processed nanoplate crystals. Sci. Rep., 2016, 6(1): 33135-1-6. |

| [17] | WU H, LIU X, WEI P , et al. Fabrication and characterization of brush-printed p-type Bi0.5Sb1.5Te3 thick films for thermoelectric cooling devices.[J]. Electron. Mater., 2016,46(5):2950-2957. |

| [18] |

SHI J X, CHEN H L, JIA S H , et al. Rapid and low-cost fabrication of thermoelectric composite using low-pressure cold pressing and thermocuring methods. Mater. Lett., 2018,212:299-302.

DOI URL |

| [19] |

CAO Z, KOUKHARENKO E, TUDOR M J , et al. Flexible screen printed thermoelectric generator with enhanced processes and materials. Sens. Actuators, A, 2016,238:196-206.

DOI URL |

| [20] |

MADAN D, WANG Z Q, CHEN A , et al. Enhanced performance of dispenser printed MA n-type Bi2Te3 composite thermoelectric generator. ACS Appl. Mater. Inter., 2012,4(11):6117-6124.

DOI URL |

| [21] |

MADAN D, WANG Z Q, CHEN A , et al. High-performance dispenser printed MA p-type Bi0.5Sb1.5Te3 flexible thermoelectric generators for powering wireless sensor networks. ACS Appl. Mater. Inter., 2013,5(22):11872-11876.

DOI URL |

| [22] |

HOU W K, NIE X L, ZHAO W Y , et al. Fabrication and excellent performance of Bi0.5Sb1.5Te3/epoxy flexible thermoelectric cooling devices. Nano Energy, 2018,50:766-776.

DOI URL |

| [23] | GUO X, JIA X, QIN J , et al. Fast preparation and high thermoelectric performance of the stable Bi0.5Sb1.5Te3 bulk materials for different synthesis pressures. Chem. Phys. Lett., 2014,610:204-208. |

| [24] |

SUH D, LEE S, MUN H , et al. Enhanced thermoelectric performance of Bi0.5Sb1.5Te3-expanded grapheme composites by simultaneous modulation of electronic and thermal carrier transport. Nano Energy, 2015,13:67-76.

DOI URL |

| [25] |

MADAN D, WANG Z Q, WRIGHT P K , et al. Printed flexible thermoelectric generators for use on low levels of waste heat. Appl.Energy, 2015,156:587-592.

DOI URL |

| [26] |

CHEN J C, YAN Z J, WU L Q . Nonequilibrium thermodynamic analysis of a thermoelectric device. Energy, 1997,22(10):979-985.

DOI URL |

| [27] |

CHEN L G, WU C, SUN F R . Heat transfer effect on the specific cooling load of refrigerators. Appl. Therm. Eng., 1996,16(12):989-997.

DOI URL |

| [1] | ZHAO Zhihan, GUO Peng, WEI Jing, CUI Li, LIU Shanze, ZHANG Wenlong, CHEN Rende, WANG Aiying. Ti Doped Diamond Like Carbon Films: Piezoresistive Properties and Carrier Transport Behavior [J]. Journal of Inorganic Materials, 2024, 39(8): 879-886. |

| [2] | WEI Tingting, GAO Xiguang, SONG Yingdong. Response of 2D SiC/SiC Composites Resistivity to Service Environments [J]. Journal of Inorganic Materials, 2022, 37(4): 420-426. |

| [3] | GUO Yinben, CHEN Zixi, WANG Hongzhi, ZHANG Qinghong. Progress of Inorganic Filler Based Composite Films for Triboelectric Nanogenerators [J]. Journal of Inorganic Materials, 2021, 36(9): 919-928. |

| [4] | FAN Yu-Chi, WANG Lian-Jun, JIANG Wan. Graphene Based Oxide Ceramic Composites with High Mechanical and Functional Performance: from Preparation to Property [J]. Journal of Inorganic Materials, 2018, 33(2): 138-146. |

| [5] | LIU Jiao, WANG Wen-Qing, WU Hong-Ye, TIAN Ye, CAO Feng-Ze, ZHAO Jian-Jun. Electromagnetic Property of Co-doped La0.8Sr0.2MnO3 Perovskite Manganese Oxides [J]. Journal of Inorganic Materials, 2018, 33(11): 1237-1247. |

| [6] | LU Yuan-Yuan, LI He-Jun, YANG Guan-Jun. Influence of Hydrogen Dilution on Two-phase Structure and Electrical Properties of Hydrogenated Silicon Thin Films [J]. Journal of Inorganic Materials, 2015, 30(5): 474-478. |

| [7] | LV Kun, ZHU Bai-Lin, LI Ke, HU Wen-Chao, XIE Ming, WU Jun. Effect of Hydrogen and Cu Interlayer on the Optical and Electrical Properties of GZO Thin Film [J]. Journal of Inorganic Materials, 2014, 29(5): 493-497. |

| [8] | FAN Yue-Nong, FENG Ze-Kun, CHEN Zhong-Yan, GONG Rong-Zhou. Design and Performance of Ni-Cu-Zn Ferrite Film for Inductor [J]. Journal of Inorganic Materials, 2012, 27(4): 375-378. |

| [9] | YAN Chang, LIU Fang-Yang, LAI Yan-Qing, LI Yi, LI Jie, LIU Ye-Xiang. Structure and Electrical Property of CuInS2 Thin Films Deposited by DC Reactive Magnetron Sputtering [J]. Journal of Inorganic Materials, 2011, 26(12): 1287-1292. |

| [10] | KONG Jiang-Rong, ZHOU Tao, LIU Peng, ZHANG Yong, XU Jing-Ming. Preparation and Characterization of La0.6Sr0.4Co0.2Fe0.8O3-δ-based Composite Anode for Solid Oxide Electrolysis Cell [J]. Journal of Inorganic Materials, 2011, 26(10): 1049-1052. |

| [11] | PENG Chang-Wen, ZHANG Hui-Min, CHANG Ai-Min, HUANG Xia, YAO Jin-Cheng. Microstructure and Electrical Properties of Mn2.25-xNi0.75CoxO4 Thermistor Ceramics [J]. Journal of Inorganic Materials, 2011, 26(10): 1037-1042. |

| [12] |

CHEN Nai-Bo,WU Hui-Zhen,XU Tian-Ning,YU Ping.

Effects of Post-annealing Treatment on the Structural and Optical Properties of Cubic MgxZn1-xO Thin Films Grown on Sapphire [J]. Journal of Inorganic Materials, 2006, 21(4): 993-998. |

| [13] | FU Jun. Effects of Film Thickness on the Gas Sensitivity of SnO2 Thick Film Sensors [J]. Journal of Inorganic Materials, 1999, 14(6): 951-955. |

| [14] | ZHANG Tian-Jin,ZHOU Dong-Xiang,GONG Shu-Ping. Effects of Valence States of Additions on the Grain Growth and Electrical Properties of Low Breakdown Voltage ZnO Varistors [J]. Journal of Inorganic Materials, 1999, 14(6): 921-926. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||