无机材料学报 ›› 2014, Vol. 29 ›› Issue (6): 605-613.DOI: 10.3724/SP.J.1077.2014.13493 CSTR: 32189.14.SP.J.1077.2014.13493

孟姝虔, 周德凤, 朱晓飞, 杨国程, 李朝辉

收稿日期:2013-09-29

修回日期:2013-11-11

出版日期:2014-06-20

网络出版日期:2014-05-27

作者简介:孟姝虔(1988-), 女, 硕士. E-mail: 760632976@qq.com

基金资助:MENG Shu-Qian, ZHOU De-Feng, ZHU Xiao-Fei, YANG Guo-Cheng, LI Zhao-Hui

Received:2013-09-29

Revised:2013-11-11

Published:2014-06-20

Online:2014-05-27

About author:MENG Shu-Qian. E-mail: 760632976@qq.com

摘要:

通过溶胶-凝胶和静电纺丝技术相结合的方法, 成功制备不同复合浓度聚乙烯吡咯烷酮(PVP)/钛酸四正丁酯(Ti(OC4H9)4)/钨酸铵(N5H37W6O24·H2O)前驱体。通过控温煅烧获得不同煅烧温度、不同复合浓度的TiO2/WO3微纳米纤维复合材料。采用X射线衍射(XRD)、傅里叶变换红外光谱(FT-IR)、场发射扫描电子显微镜(FE-SEM)和紫外-可见漫反射光谱(UV-Vis )技术对样品进行表征。以亚甲基蓝(MB)的光降解为模型反应, 研究TiO2/WO3微纳米纤维复合材料在紫外光照射下的光催化活性。结果表明, 煅烧温度500℃时, n(Ti):n(W) = 12:1形成WO3掺杂的TiO2微纳米纤维及n(Ti):n(W) = 4:1形成的TiO2/WO3复合微纳米纤维的光催化活性均高于纯TiO2。

中图分类号:

孟姝虔, 周德凤, 朱晓飞, 杨国程, 李朝辉. TiO2/WO3微纳米纤维复合材料的制备及光催化性能[J]. 无机材料学报, 2014, 29(6): 605-613.

MENG Shu-Qian, ZHOU De-Feng, ZHU Xiao-Fei, YANG Guo-Cheng, LI Zhao-Hui. Fabrication of TiO2/WO3 Micro-nanofibers Composites and Their Photocatalytic Activity[J]. Journal of Inorganic Materials, 2014, 29(6): 605-613.

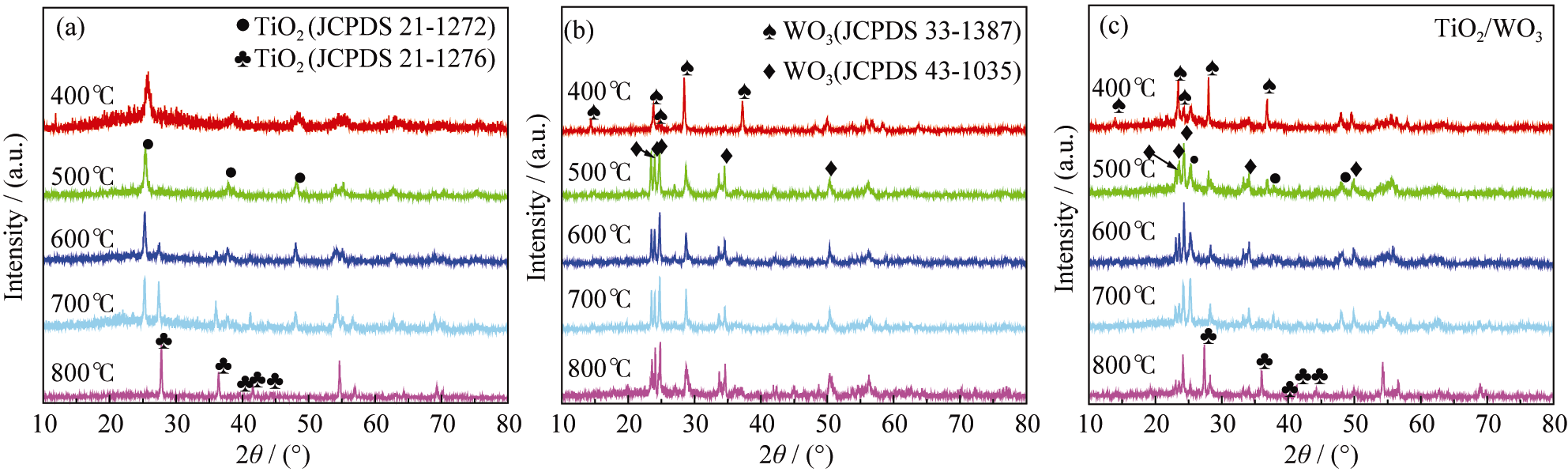

图1 纯TiO2 (a)、纯WO3 (b)和TiO2/WO3 (c)样品不同煅烧温度的XRD图谱

Fig. 1 XRD patterns of pure TiO2 (a), pure WO3 (b) and TiO2/ WO3 composite (c) samples calcined at different temperatures

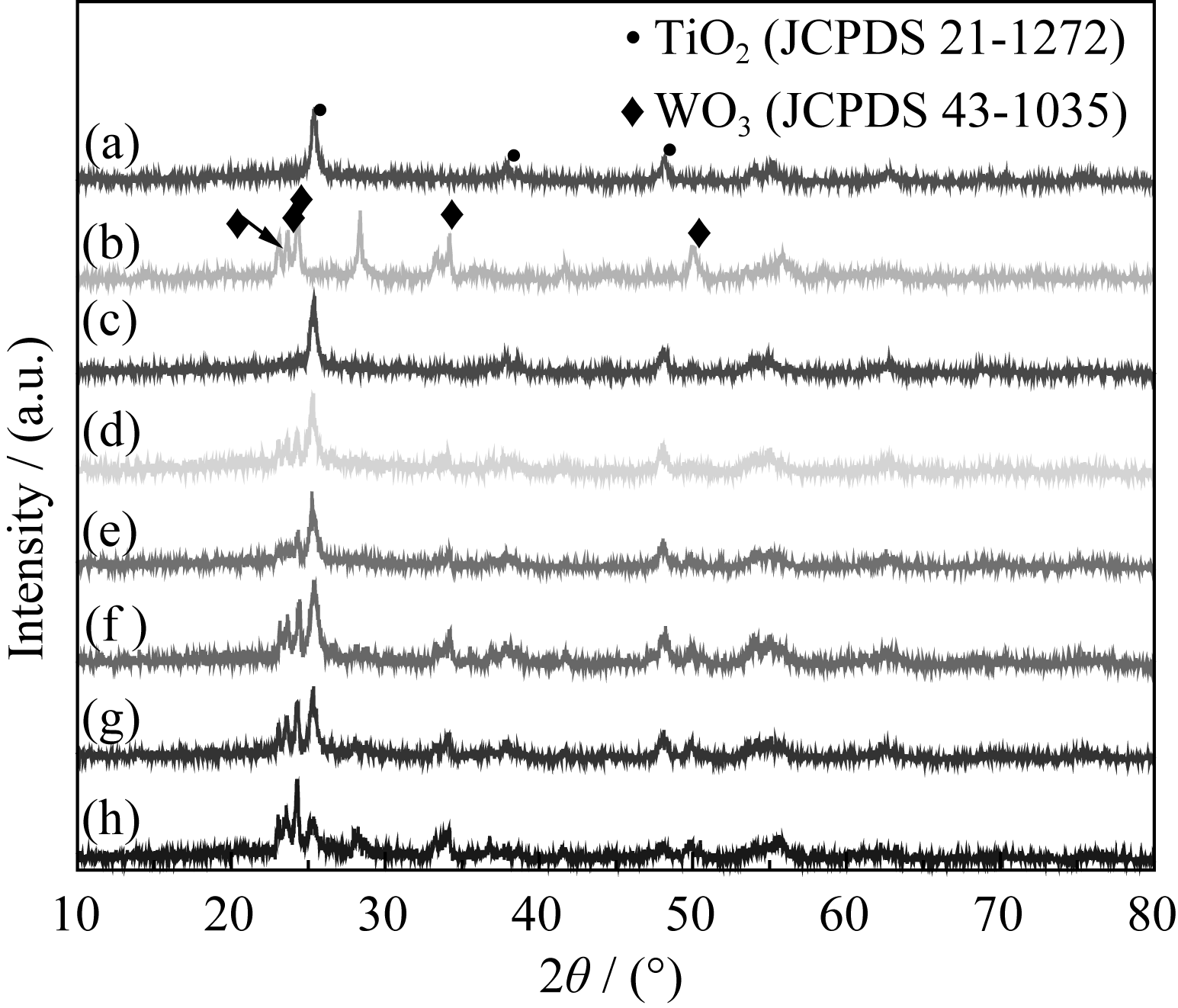

图2 煅烧温度500℃时TiO2、WO3和不同复合浓度的TiO2/WO3微纳米纤维的XRD图谱

Fig. 2 XRD patterns of TiO2 ,WO3 and TiO2/WO3 micro- na-no-f-ibers with different Ti/W molar ratios calcined at 500℃ (a) TiO2; (b) WO3; (c) TW-12; (d) TW-10; (e)TW-8; (f) TW-6; (g)TW-4; (h) TW-2

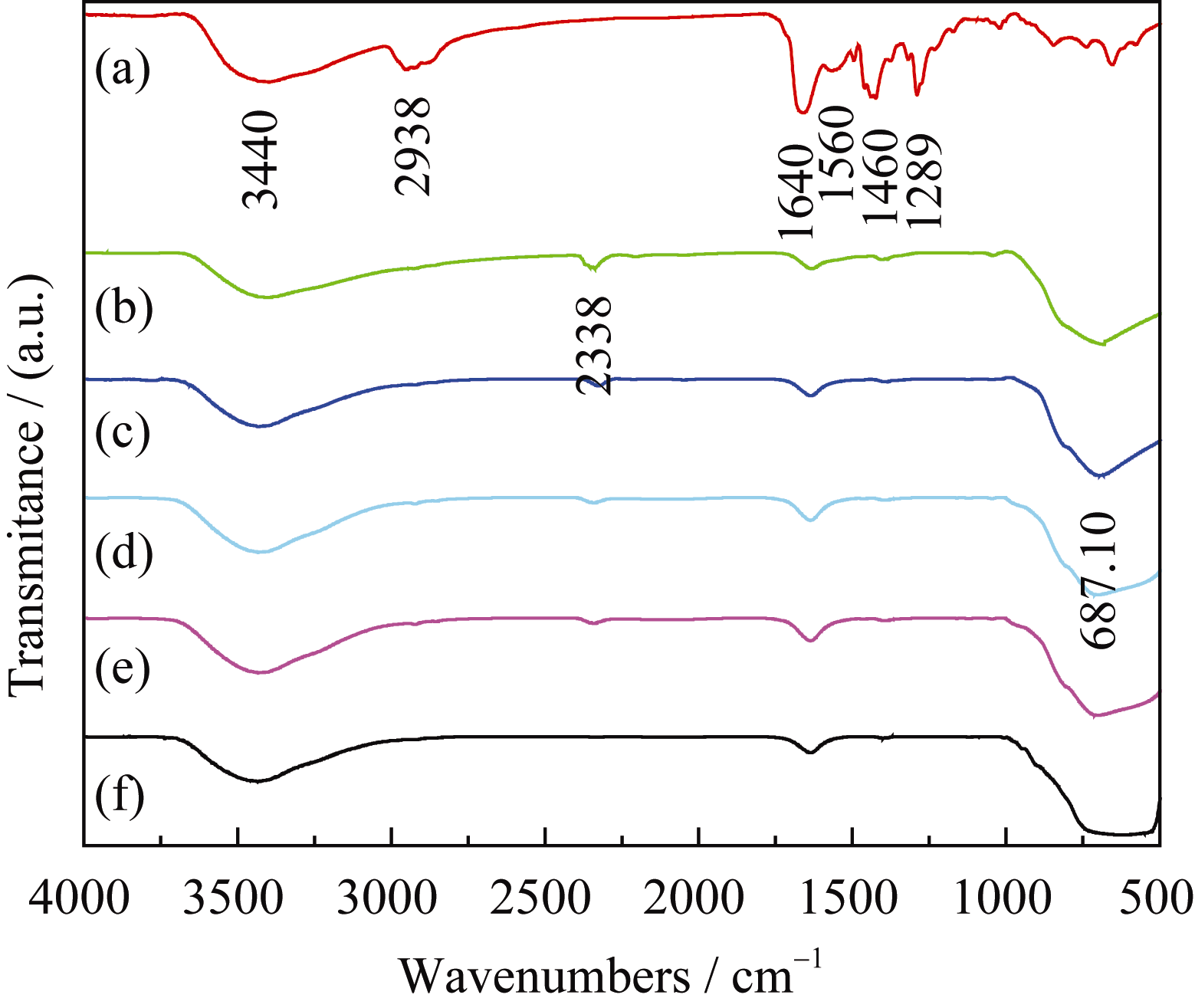

图3 PVP/Ti(OC4H9)4/N5H37W6O24·H2O(n(Ti):n(W) = 2:1)纤维热处理前后的红外光谱图

Fig. 3 FT-IR spectra of the precursors calcined at different temperatures (a) PVP/Ti(OC4H9)4/N5H37W6O24·H2O (n(Ti):n(W)=2:1) precursors, (b)-(f) Precursors calcined at 400, 500, 600, 700 and 800℃, respectively

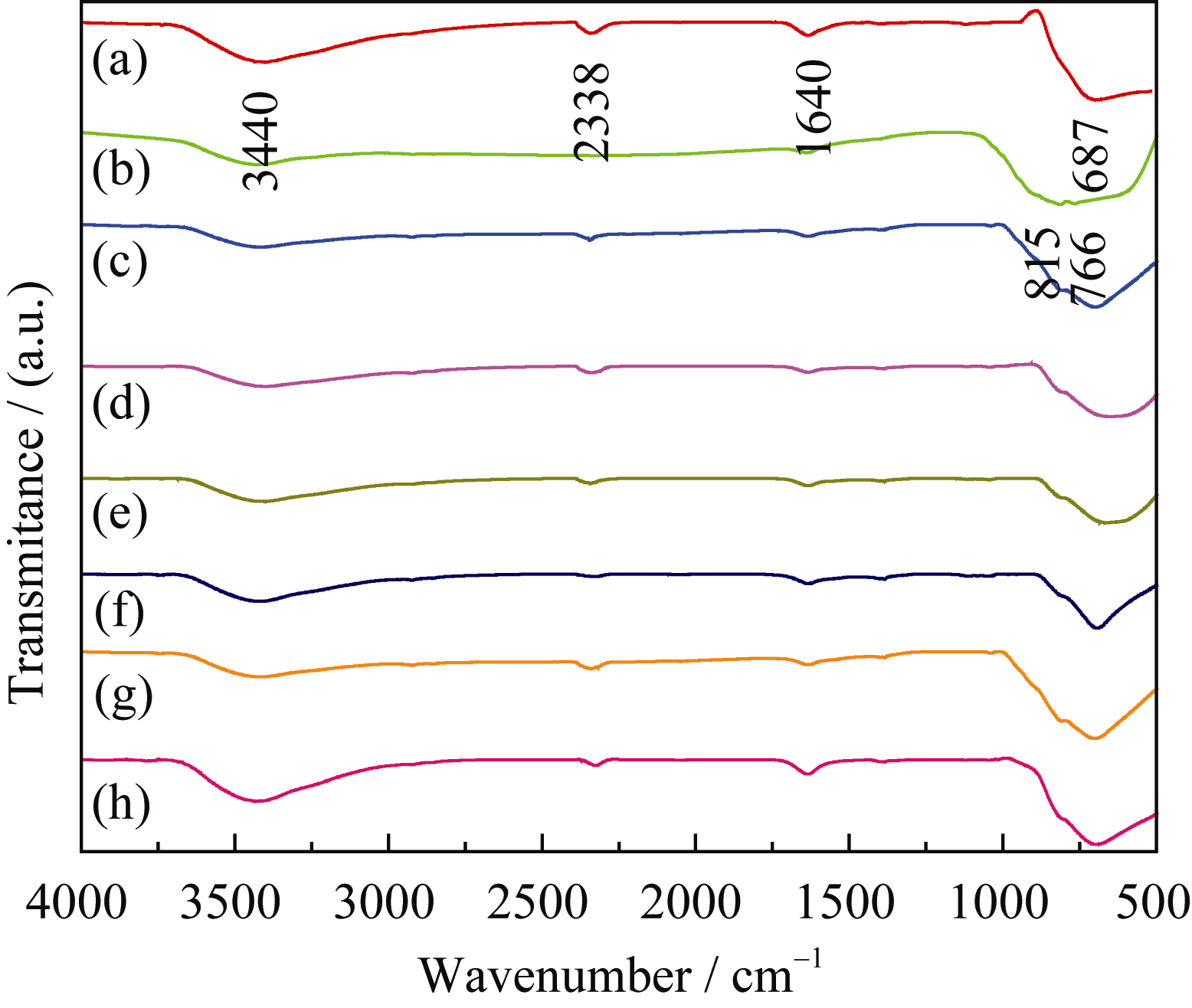

图4 煅烧温度500℃时TiO2、WO3和不同复合比例的TiO2/WO3微纳米纤维的红外图谱

Fig. 4 FT-IR patterns of TiO2, WO3 and TiO2/WO3 micro- nan-o-fiber composites with different Ti/W molar ratios calcined at 500℃ (a) TiO2; (b) WO3; (c) TW-12; (d) TW-10; (e) TW-8; (f) TW-6; (g) TW-4; (h) TW-2

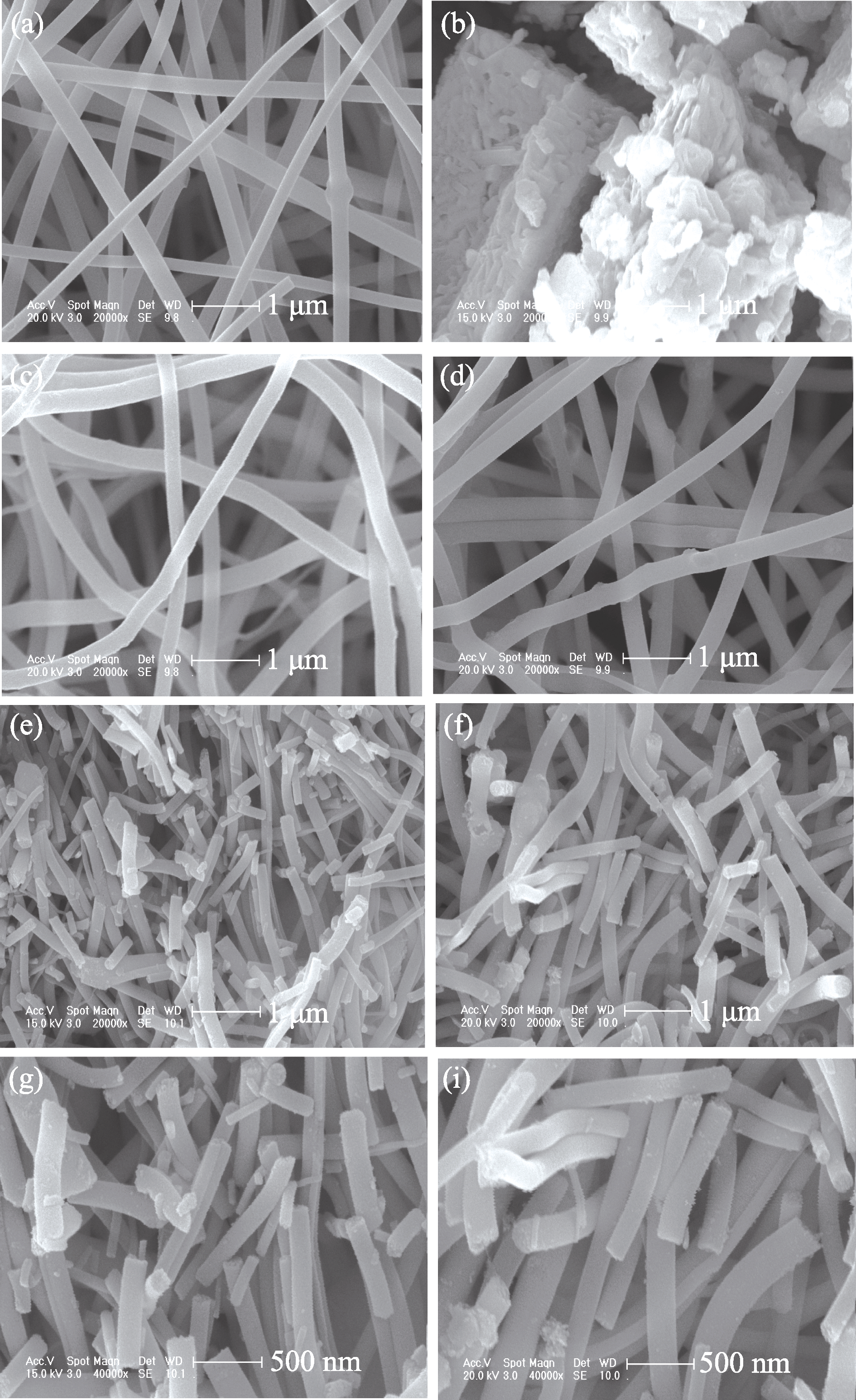

图5 500℃煅烧的TiO2、WO3和不同复合浓度的TiO2/WO3微纳米纤维的FE-SEM照片

Fig. 5 SEM images of TiO2, WO3 and TiO2/WO3 micro-nanofibers with different Ti/W molar ratios calcined at 500℃ (a) TiO2; (b) WO3; (c) TW-8; (d) TW-6; (e) TW-4; (f ) TW-2; (g) Magnified FE-SEM image of TW-4; (h) Magnified FE-SEM image of TW-2

| Sample | SBET/(m2?g-1) |

|---|---|

| TiO2 | 8.48 |

| TW-12 | 9.04 |

| TW-4 | 40.97 |

| TW-2 | 17.92 |

表1 500℃煅烧的TiO2、WO3和不同复合浓度的TiO2/WO3微纳米纤维的比表面积

Table 1 Specific surface area of TiO2, WO3 and TiO2/WO3 micro-nanofibers with different Ti/W molar ratios calcined at 500℃

| Sample | SBET/(m2?g-1) |

|---|---|

| TiO2 | 8.48 |

| TW-12 | 9.04 |

| TW-4 | 40.97 |

| TW-2 | 17.92 |

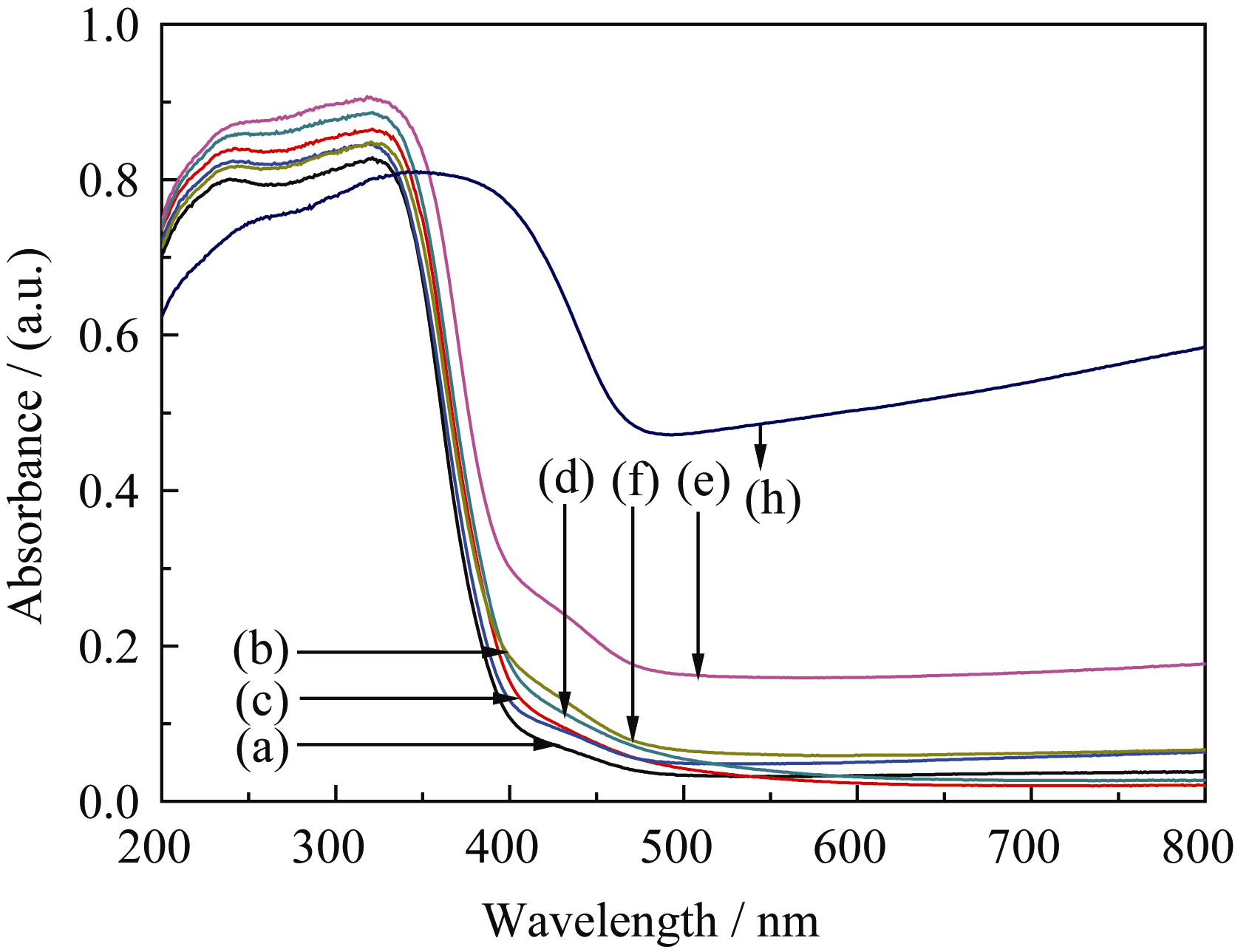

图6 500℃煅烧的TiO2、WO3和不同复合浓度的微纳米纤维的UV-Vis漫反射光图谱

Fig. 6 UV-Vis diffuse reflectance spectra of TiO2, WO3 and TiO2/WO3 micro-nanofibers with different Ti/W molar ratios calcined at 500℃ (a) TiO2; (b) TW-12; (c) TW-8; (d)TW-6; (e) TW-4; (f ) TW-2; (h) WO3

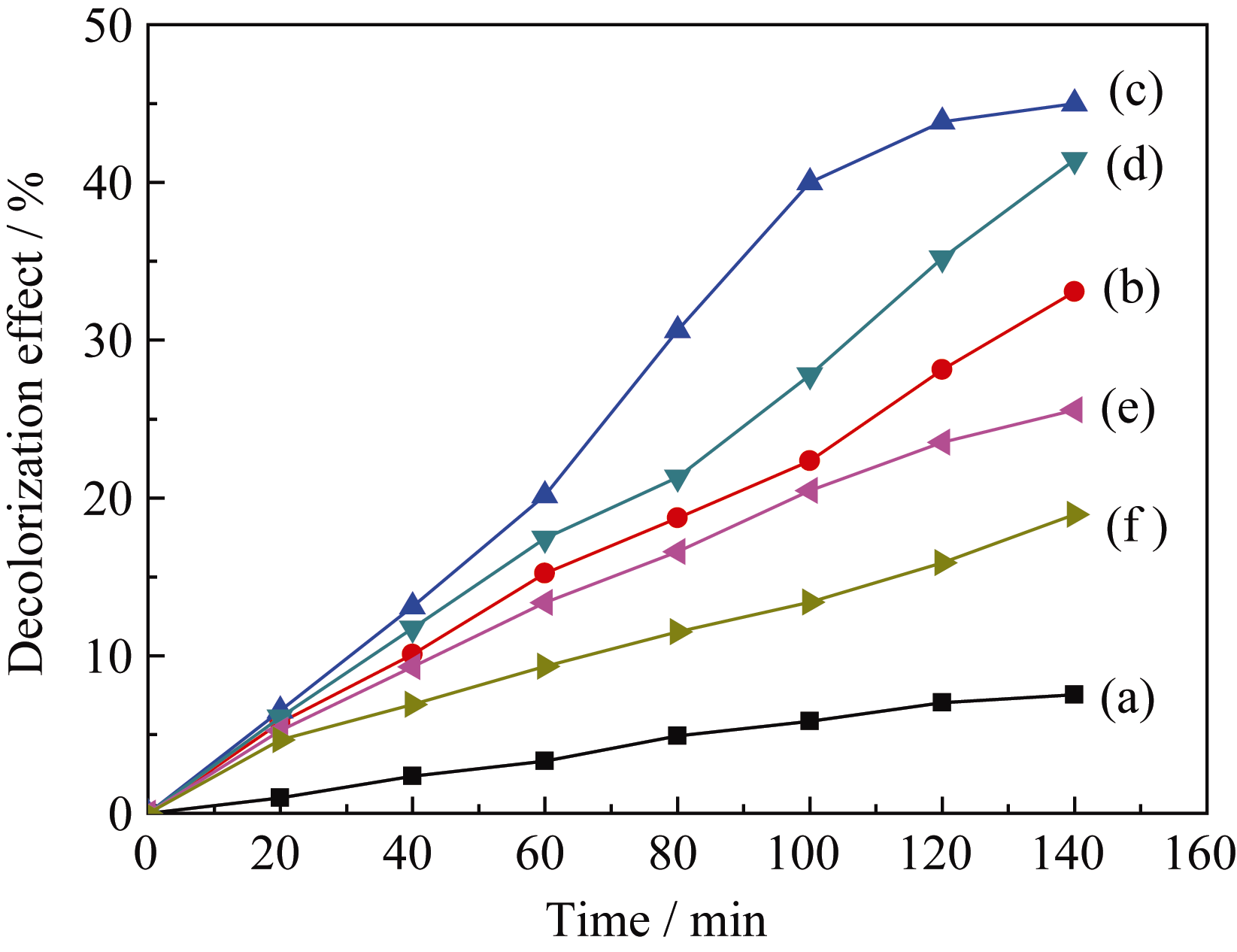

图7 TiO2/WO3复合微纳米纤维(n(Ti): n(W) = 2:1)在不同煅烧温度下对MB的光降解曲线

Fig. 7 Photocatalytic degradation of MB over TiO2/WO3 (n(Ti): n(W) = 2:1) micro-nanofibers composites calcined at different temperatures under UV light irradiation (a) MB; (b) Calcined at 400℃; (c) Calcined at 500℃; (d) Calcined at 600℃; (e) Calcined at 700℃; (f) Calcined at 800℃

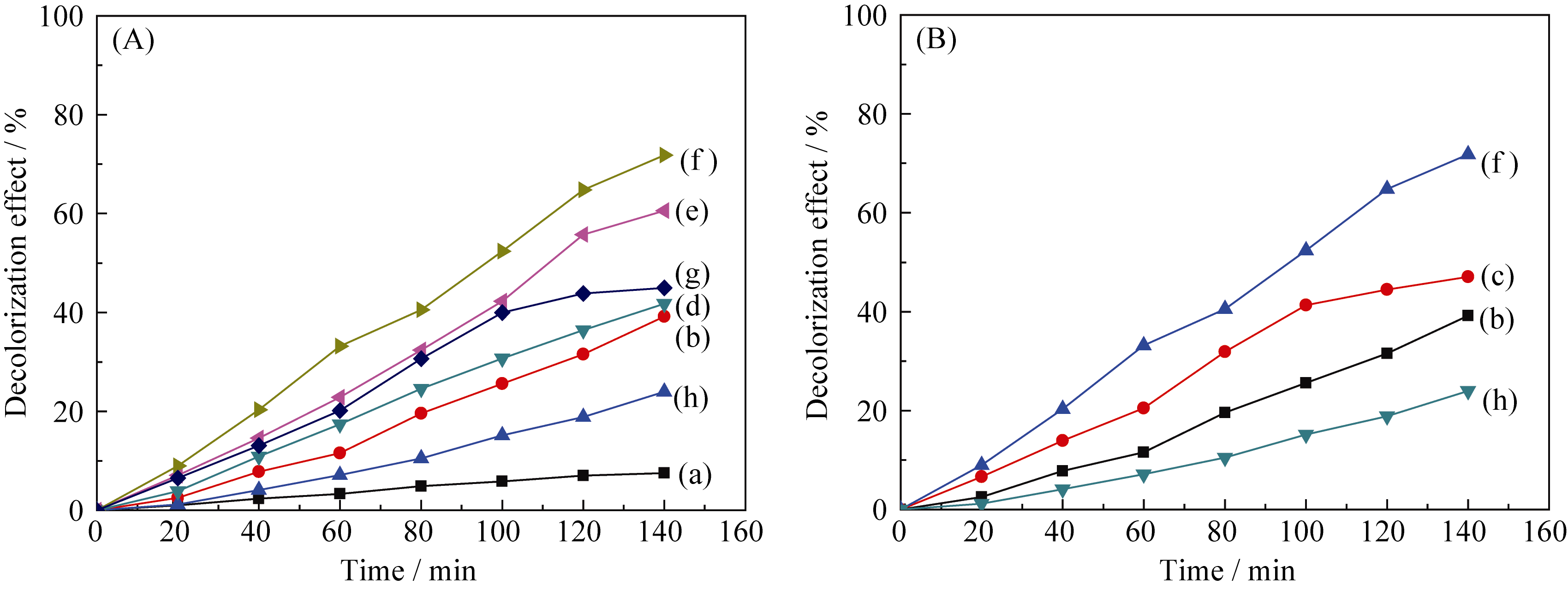

图8 TiO2、WO3和不同复合浓度的TiO2/WO3微纳米纤维对MB的光降解曲线

Fig. 8 Photocatalytic degradation of MB over TiO2, WO3 and TiO2/WO3 micro-nanofibers with different Ti/W molar ratios under UV light irradiation (a) MB; (b) TiO2; (c) TW-12; (d) TW-8; (e)TW-6; (f ) TW-4; (g) TW-2; (h) WO3

| [1] | CHEN X B, MAO S S. Titanium dioxide nanomaterials: synthesis, properties, modifications and application. Chem. Rev., 2007, 107(7): 2891-2959. |

| [2] | HUANG C J, PAN F M, CHANG I C. Enhannced photocatalytic decomposition of methylene blue by the heterostructure of PdO nanoflakes and TiO2 nanoparticles. Appl. Surf. Sci., 2012, 263: 345-351. |

| [3] | HAN F, KAMBALA V S R, SRINIRASAN M, et al. Tailored titaniun dioxide photocatalysts for the degradation of organic dyes in wastewater treatment : a review. Appl. Catal., A: General , 2009, 359(1/2): 25-40. |

| [4] | ZHANG Z Y, SHAO C L, ZHANG L N, et al. Electrospun nanofibers of V-doped TiO2 with high photocatalytic activity . J.Colloid Interface Sci., 2010, 351(1): 57-62. |

| [5] | YANG Y, WANG H Y, LI X, et al. Electrospun mesoporous W6+-doped TiO2 thin films for efficient visible-light photocatalysis. Mater. Lett., 2009, 63(2): 331-333. |

| [6] | YUAN YUAN, ZHANG JUN-YING, FAN GUO-XING, et al. Electrospun TiO2-WO3 nanofibers for photocatalytic removal of mercury. Proceeding of the CSEE, 2012, 32(32): 1480-1485. |

| [7] | KUMARESAN L, MAHALAKSHMI M, PALANICHAMY M, et al. Synthesis, characterization and photocatalytic activity of Sr2+ doped TiO2 nanoplates. Ind. Eng. Chem. Res., 2010, 49(4): 1480-1485. |

| [8] | TENG D H, YU Y H, LIU H Y, et al. Facile fabrication of heterostructured TiO2-xNx/CNFs as an efficient visible-light responsive photocatalytic. Catal. Commun., 2009, 10(5): 442-446. |

| [9] | CAO Y Q, HE T, CHEN Y M, et al. Fabrication of rutile TiO2- Sn/anatase TiO2-N heterostructure and its application in visible- light photocatalysis. J. Phys. Chem. C, 2010, 114(8): 3627-3633. |

| [10] | HE T S, ZHOU Z F, XU W B, et al. Preparation and photocatalysis of TiO2-fluoroplymer electrospun fiber nanocomposites. Polymer, 2009, 50(13): 3031-3036. |

| [11] | LI Y F, XU D H, OH J I, et al. Mechanistic study of codoped titania with nonmetal and metal ions : a case of C + Mo codoped TiO2. ACS Catal., 2012, 2(3): 391-398. |

| [12] | SAJJAD A K L, SHAMAILA S, ZHANG J L. Study of new states in visible light active W,N co-doped TiO2 photo catalyst. Mater. Res. Bull., 2012, 47(11): 3083-3089. |

| [13] | ZHANG M Y, SHAO C L, GUO Z C, et al. Hierarchical nanostructures of copper(II) phthalocyanine on electrospun TiO2 nanofibers: controllable solvothermal-fabrication and enhanced visible photo¬catalytic properties. Appl. Mater. interfaces, 2011, 3(2): 369-377. |

| [14] | SHANG M, WANG W Z, ZHANG L, et al. 3D Bi2WO6/TiO2 hierar¬chical heterostructure: controllable synthesis and enhanced visible photocatalytic degradation performances. J. Phys. Chem. C, 2009, 113(33): 14727-14731. |

| [15] | WANG Y, ZHANG J W, LIU L X, et al. Visible light photocatalysis of V2O5/TiO2 nanoheterostructures prepared via electrospinning. Mater. Lett., 2012, 75: 95-98. |

| [16] | LIU R L, YE H Y, XIONG X P, et al. Fabrication of TiO2/ZnO composite nanofibers by electrospinning and their photocatalytic property. Mater. Chem. Phys., 2010, 121(3): 432-439. |

| [17] | SU C Y, SHAO C L, LIU Y C. Electrospun nanofibers of TiO2/CdS heteroarchitectures with enhanced photocatalytic activity by visible light. J.Colloid Interface Sci., 2011, 359(1): 220-227. |

| [18] | ZHOU M J, YAN J H, CUI P. synthesis and enhanced photocatalytic performance of WO3 nano rods@graphene nanocomposites. Mater. Lett., 2012, 89: 258-261. |

| [19] | SZILÁGYI I M, FÓRIZS B, ROSSELER O, et al.WO3 photocatalysts: influence of structure and composition. J. Catal., 2012, 294: 119-127. |

| [20] | SUNGPANICH J, THONGTEM T, THONGTEM S. Fabrication of WO3 nanofibers by high voltage electrospinning. Mater. Lett., 2011, 65(19/20): 3000-3004. |

| [21] | GUI M S, ZHANG W D, CHANG Y Q, et al. One-step hydro-thermal preparation strategy for nanostructured WO3/Bi2WO6 heteroju¬nction with high visible light photocatalytic activity. Chem. Eng. J., 2012, 197: 283-288. |

| [22] | WANG C H, SHAO C L, ZHANG X T, et al. SnO2 Nanostruc-tures-TiO2 nanofibers heterostructures: controlled fabrication and high photocatalytic properties. Inorg. Chem., 2009, 48(15): 7261-7268. |

| [23] | YUAN Y, ZHAO Y C, LI H L, et al. Electrospun metal oxide-TiO2 nanofibers for elemental mercury removal from flue gas. J. Hazard. Mater. , 2012, 227-228: 427-435. |

| [24] | YAN X X, ZONG X, LU G Q, et al. Ordered mesoporous tungsten oxide and titanium oxide composites and their photocatalytic degra¬dation behavior. Materials International, 2012, 22(6): 654-660. |

| [25] | SAJJAD A K L, SHAMAILA S, ZHANG J L. Tungstate/titanate composite nanorod as an efficient visible light photo catalyst. J. Hazard. Mater.,2012, 235-236: 307-315. |

| [26] | YANG J K, ZHANG X T, LIU H, et al. Heterostructured TiO2/WO3 porous microspheres: preparation, characterization and photoc¬atalytic properties. Catal. Today. , 2013, 201: 195-202. |

| [27] | LI YUE-JUN, CAO TIE-PING, SHAO CHANG-LU, et al. Preparation and energy stored photocatalytic properties of WO3/TiO2 composite fibers. Chemical Journal of Chinese Universities, 2012 , 33(7): 1552-1558. |

| [28] | WANG F, CHEN X J, HU X L, et al. WO3/TiO2 microstructures for enhanced photocatalytic oxidation. Sep. Purif. Technol. ,2012, 91: 67-72. |

| [29] | PARK J A, MOON J, LEE S J, et al. Structural, electrical and gas sensing properties of eletrospun TiO2 nanofibers. Thin Solid Films. 2010, 518(22): 6642-6645. |

| [30] | NAVGIRE M, YELWANDE A, TAYDE D, et al. Photodegradation of molasses by a MoO3-TiO2 nanocrystalline composite material. Chin. J. Catal., 2012, 33(2): 261-266. |

| [31] | NGUYEN T A, PARK S, KIM J B, et al. Polycrystalline tungsten oxide nanofibers for gas-sensing applications. Sens. Actuators, B. , 2011, 160(1): 549-554. |

| [32] | SZILAGYI I M, SANTALA E, HEIKKILA M, et al. Thermal study on electrospun polyvinylpyrrolidone/ammonium metatung¬state nanofibers: optimising the annealing conditions for obtaining WO3 nanofibers. J. Therm. Anal. Calorim. , 2011, 105(1): 73-81. |

| [33] | ZHANG Z Y, SHAO C L, LI X H, et al. Electrospun nanofibers of ZnO-SnO2 heterojunction with high photocatalytic activity. J. Phys. Chem. C, 2010, 114(17): 7920-7925. |

| [34] | LIN C F, WU C H, ONN Z N. Degradation of 4-chlorophenol in TiO2, WO3, SnO2, TiO2/WO3 and TiO2/SnO2 syetems. J.Hazard. Mater ,2008, 154(1/2/3): 1033-1039. |

| [35] | WEI S Q, MA Y Y, CHEN Y Y, et al. Fabrication of WO3/Cu2O composite films and their photocatalytic activity. J. Hazard. Mater., 2011, 194: 243-249. |

| [1] | 盛丽丽, 常江. 光/磁热Fe2SiO4/Fe3O4双相生物陶瓷及其复合电纺丝膜制备及抗菌性能研究[J]. 无机材料学报, 2022, 37(9): 983-990. |

| [2] | 刘城, 赵倩, 牟志伟, 雷洁红, 段涛. 新型铋基SiOCNF复合膜对放射性气态碘的吸附性能[J]. 无机材料学报, 2022, 37(10): 1043-1050. |

| [3] | 张晓山, 王兵, 吴楠, 韩成, 刘海燕, 王应德. 高红外遮蔽SiZrOC纳米纤维膜的制备及其性能研究[J]. 无机材料学报, 2022, 37(1): 93-100. |

| [4] | 王袁杰, 裴学良, 李好义, 徐鑫, 何流, 黄政仁, 黄庆. 自由基引发活性聚碳硅烷交联及其在制备SiC纤维中的应用[J]. 无机材料学报, 2021, 36(9): 967-973. |

| [5] | 马玲玲, 常江. Nd掺杂硅酸钙及其复合电纺丝膜的制备及性能研究[J]. 无机材料学报, 2021, 36(9): 974-980. |

| [6] | 李婷婷, 张志明, 韩正波. 基于静电纺丝技术的聚合物基MOFs纳米纤维膜的研究进展[J]. 无机材料学报, 2021, 36(6): 592-600. |

| [7] | 包峰, 常江. 硅酸钙纳米线复合电纺丝支架的制备及离子释放研究[J]. 无机材料学报, 2021, 36(11): 1199-1207. |

| [8] | 朱正旺,冯锐,柳扬,张扬,谢文翰,董丽杰. 类鱼骨结构CoFe2O4纳米纤维的制备与性能[J]. 无机材料学报, 2020, 35(9): 1011-1016. |

| [9] | 孙晓璐,宋肖飞,刘艳华,吴越,蔡以兵,赵宏梅. 电纺FeMnO3纳米纤维毛毡的制备及电化学性能研究[J]. 无机材料学报, 2019, 34(7): 709-714. |

| [10] | 蒋海燕, 夏云生, 李育珍. 多孔棒状FeVO4的制备及可见光催化性能研究[J]. 无机材料学报, 2018, 33(9): 949-955. |

| [11] | 赵海雷, 孙振川, 陈馈, 王宏志, 杨延栋, 周建军, 李凤远, 张兵, 宋法亮. Ca0.68Si9Al3(ON)16 : Eu2+带状荧光纳米纤维的制备、性能及盾构盘型滚刀的磨损检测[J]. 无机材料学报, 2018, 33(8): 866-872. |

| [12] | 崔博, 贾巍, 陈振华, 李耀刚, 张青红, 王宏志. CaSi2O2N2:Ce/Tb、Eu叠层纤维膜的制备及其荧光性能研究[J]. 无机材料学报, 2018, 33(4): 403-408. |

| [13] | 杜海英, 姚朋军, 王兢, 孙炎辉, 于乃森, 张涛, 董良. 异质复合结构纳米纤维SnO2/ZnO的制备及其气敏特性研究[J]. 无机材料学报, 2018, 33(4): 453-461. |

| [14] | 蔡建信, 李志鹏, 李巍, 赵鹏飞, 杨震宇, 吁霁. Fe2O3纳米纤维锂离子电池负极材料的制备及其电化学性能研究[J]. 无机材料学报, 2018, 33(3): 301-306. |

| [15] | 吴楠, WANLynnYuqin, 王应德, FRANKKO. 静电纺聚碳硅烷制备SiOC超细纤维[J]. 无机材料学报, 2018, 33(3): 357-362. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||