无机材料学报 ›› 2020, Vol. 35 ›› Issue (8): 939-946.DOI: 10.15541/jim20190469 CSTR: 32189.14.10.15541/jim20190469

所属专题: 结构陶瓷论文精选(2020); 功能材料论文精选(2020); 【虚拟专辑】分离膜,复相陶瓷(2020~2021)

收稿日期:2019-09-10

修回日期:2019-11-01

出版日期:2020-08-20

网络出版日期:2020-01-20

作者简介:张 博(1995–), 女, 硕士研究生. E-mail: 基金资助:

ZHANG Bo1( ),ZHANG Ning1,YANG Jianhua2,LAN Jiancheng2,WANG Jinqu1,2

),ZHANG Ning1,YANG Jianhua2,LAN Jiancheng2,WANG Jinqu1,2

Received:2019-09-10

Revised:2019-11-01

Published:2020-08-20

Online:2020-01-20

Supported by:摘要:

采用廉价的大孔α-Al2O3作为载体, 通过二次晶种诱导+两步变温水热合成工艺, 成功制备出薄而致密的高性能T型沸石膜。该方法能够充分发挥晶种的诱导成核作用, 通过改变两阶段水热晶化温度和时间来控制晶种外延生长和晶体生长方向, 最终获得了连续、无缺陷的a&b取向T型沸石膜。实验过程中详细考察了第一阶段的晶化温度、晶化时间以及第二阶段的晶化温度对沸石膜表面结构和性能的影响, 并将最优两步晶化条件下制备的膜用于90wt%的异丙醇/水渗透汽化分离, 在75 ℃下膜的通量为3.84 kg·m -2·h -1, 分离因子大于10000。

中图分类号:

张博,张宁,杨建华,兰建成,王金渠. 两步晶化制备高性能a&b取向T型沸石膜[J]. 无机材料学报, 2020, 35(8): 939-946.

ZHANG Bo,ZHANG Ning,YANG Jianhua,LAN Jiancheng,WANG Jinqu. High Performance a&b Oriented T Zeolite Membrane by a Two-stage Crystallization Synthesis[J]. Journal of Inorganic Materials, 2020, 35(8): 939-946.

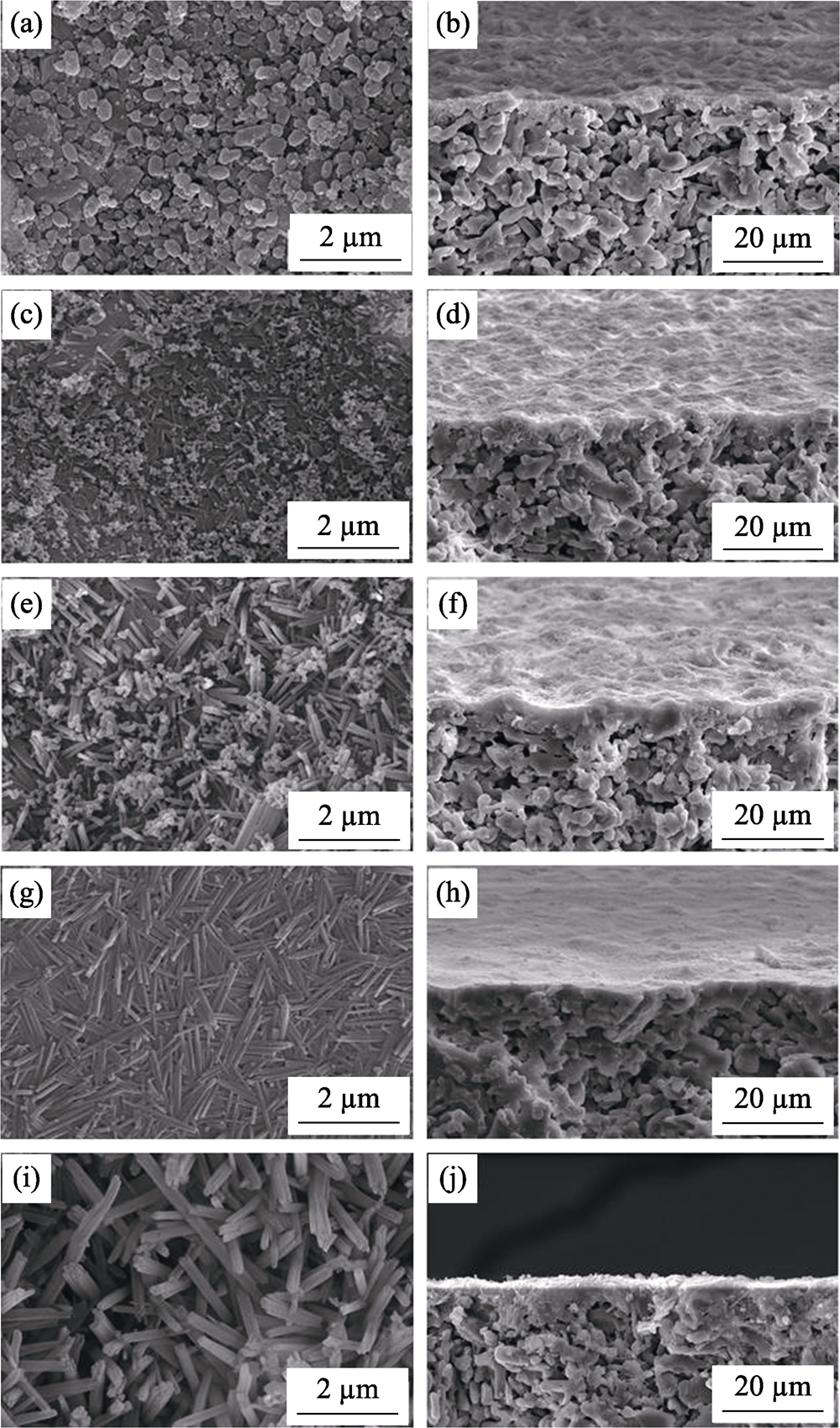

图1 α-Al2O3载体((a)-表面, (b)-截面)、大晶种(c)、小晶种(d)、大晶种修饰后的载体((e)-表面, (f)-截面)以及小晶种层((g)-表面, (h)-截面)的SEM照片

Fig. 1 SEM images of α-Al2O3 support photographed from surface (a) and cross section (b), large seeds (c), small seeds (d), modified by large seeds photographed from surface (e) and cross section (f), and the small seed layer photographed from surface (g) and cross section (h)

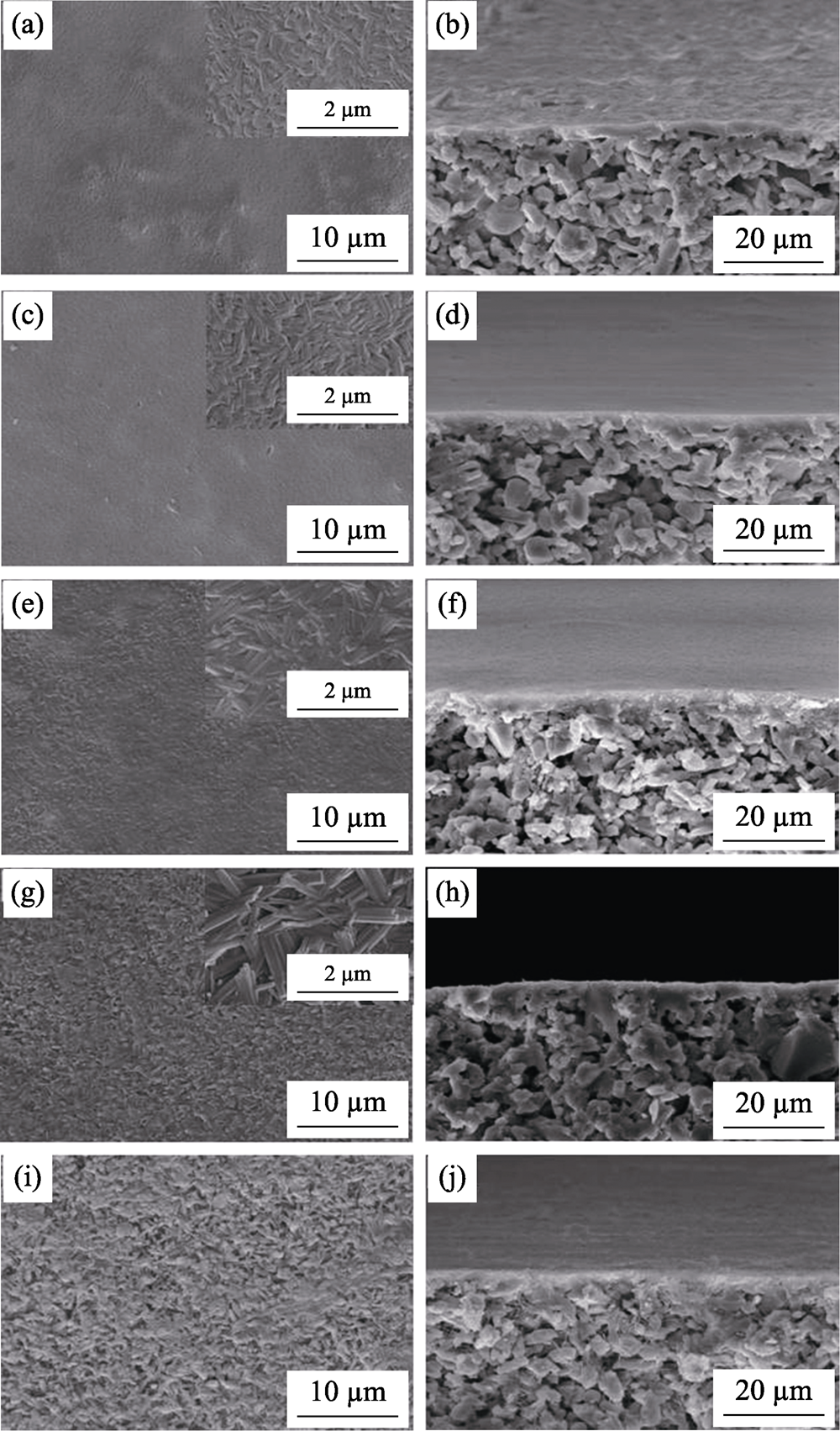

图3 不同的第一步晶化温度下第一步晶化后的T型沸石膜的SEM照片

Fig. 3 SEM images of T-type zeolite membranes after first-step crystallization prepared at different first-step crystallization temperatures (a, b) M1-1, 110 ℃; (c, d) M2-1, 120 ℃; (e, f) M3-1, 130 ℃; (g, h) M4-1, 135 ℃; (i, j) M5-1, 150 ℃

图4 不同的第一步晶化温度下两步晶化后的T型沸石膜的SEM照片

Fig. 4 SEM images of T-type zeolite membranes after two-step crystallizations prepared at different first-step crystallization temperature (a, b) M1, 110 ℃; (c, d) M2, 120 ℃; (e, f) M3, 130 ℃; (g, h) M4, 135 ℃; (i, j) M5, 150 ℃

| No. | First-step crystallization | Second-step crystallization | J/ (kg·m-2·h-1) | α | ||

|---|---|---|---|---|---|---|

| Temp./℃ | Time/h | Temp./℃ | Time/h | |||

| M1 | 110 | 4 | 110 | 6 | - | - |

| M2 | 120 | 4 | 110 | 6 | 4.19 | 968 |

| M3 | 130 | 4 | 110 | 6 | 3.87 | 5219 |

| M4 | 135 | 4 | 110 | 6 | 3.84 | >10000 |

| M5 | 150 | 4 | 110 | 6 | 3.53 | 2918 |

表1 不同的第一步晶化温度制备的T型沸石膜的渗透汽化性能

Table 1 Pervaporation performance of T zeolite membranes prepared under different first-step crystallization temperatures

| No. | First-step crystallization | Second-step crystallization | J/ (kg·m-2·h-1) | α | ||

|---|---|---|---|---|---|---|

| Temp./℃ | Time/h | Temp./℃ | Time/h | |||

| M1 | 110 | 4 | 110 | 6 | - | - |

| M2 | 120 | 4 | 110 | 6 | 4.19 | 968 |

| M3 | 130 | 4 | 110 | 6 | 3.87 | 5219 |

| M4 | 135 | 4 | 110 | 6 | 3.84 | >10000 |

| M5 | 150 | 4 | 110 | 6 | 3.53 | 2918 |

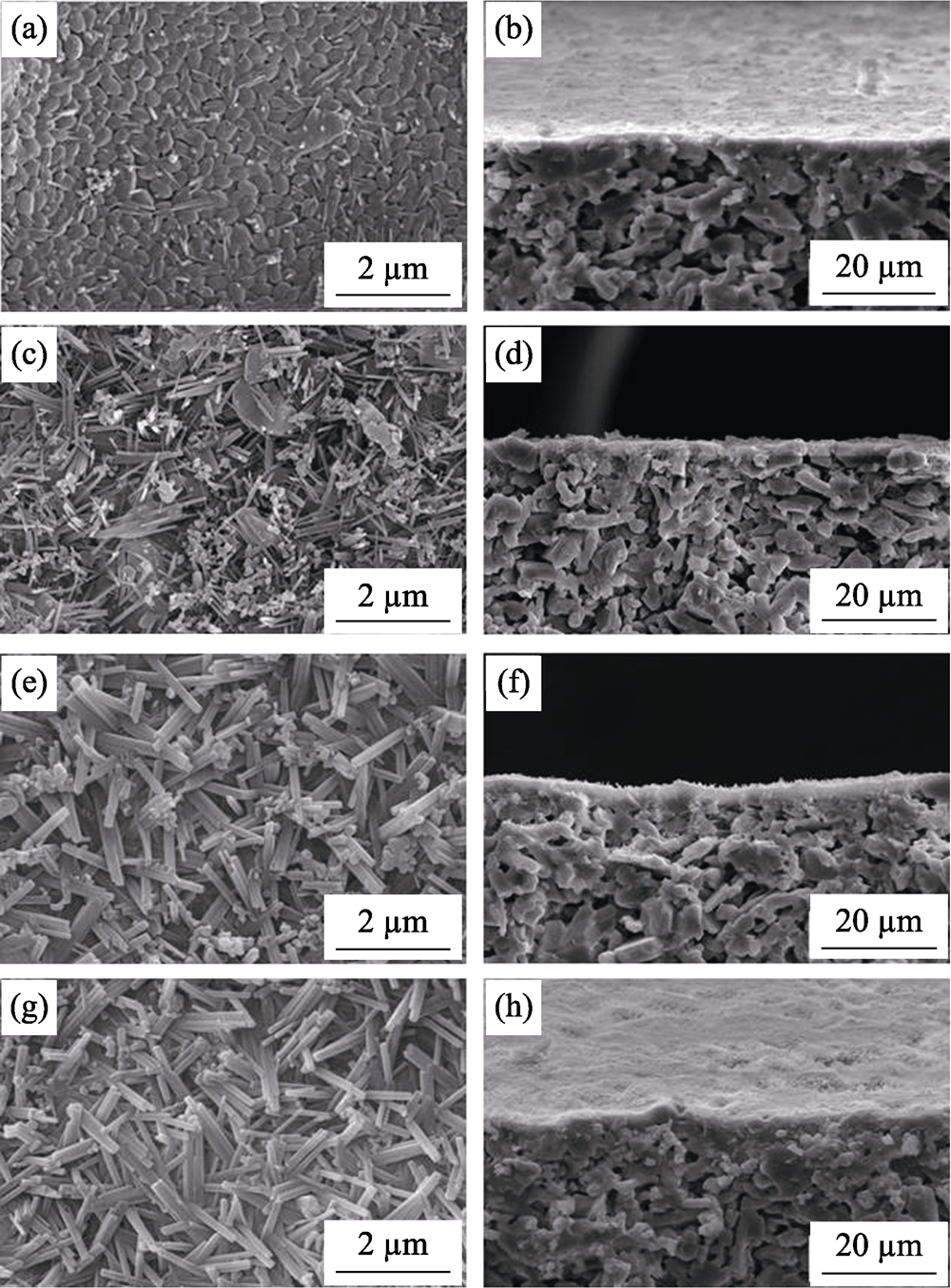

图6 不同的第一步晶化时间下第一步晶化后的T型沸石膜的SEM照片

Fig. 6 SEM images of T-type zeolite membranes after first-step crystallization prepared with varying first-step crystallization time (a, b) M6-1, 2 h; (c, d) M7-1, 3 h; (e, f) M8-1, 5 h; (g, h) M9-1, 6 h

图7 不同的第一步晶化时间下两步晶化后的T型沸石膜的SEM照片

Fig. 7 SEM images of T-type zeolite membranes after two-step crystallizations prepared with different first-step crystallization time (a, b) M6, 2 h; (c, d) M7, 3 h; (e, f) M8, 5 h; (g, h) M9, 6 h

| No. | First-step crystallization | Second-step crystallization | J/ (kg ·m-2·h-1) | α | ||

|---|---|---|---|---|---|---|

| Temp./℃ | Time/h | Temp./℃ | Time/h | |||

| M6 | 135 | 2 | 110 | 6 | - | - |

| M7 | 135 | 3 | 110 | 6 | 4.04 | 915 |

| M4 | 135 | 4 | 110 | 6 | 3.84 | >10000 |

| M8 | 135 | 5 | 110 | 6 | 4.2 | 2371 |

| M9 | 135 | 6 | 110 | 6 | 4.97 | 697 |

表2 不同的第一步晶化时间制备的T型沸石膜的渗透汽化性能

Table 2 Pervaporation performance of T zeolite membranes prepared with different first-step crystallization time

| No. | First-step crystallization | Second-step crystallization | J/ (kg ·m-2·h-1) | α | ||

|---|---|---|---|---|---|---|

| Temp./℃ | Time/h | Temp./℃ | Time/h | |||

| M6 | 135 | 2 | 110 | 6 | - | - |

| M7 | 135 | 3 | 110 | 6 | 4.04 | 915 |

| M4 | 135 | 4 | 110 | 6 | 3.84 | >10000 |

| M8 | 135 | 5 | 110 | 6 | 4.2 | 2371 |

| M9 | 135 | 6 | 110 | 6 | 4.97 | 697 |

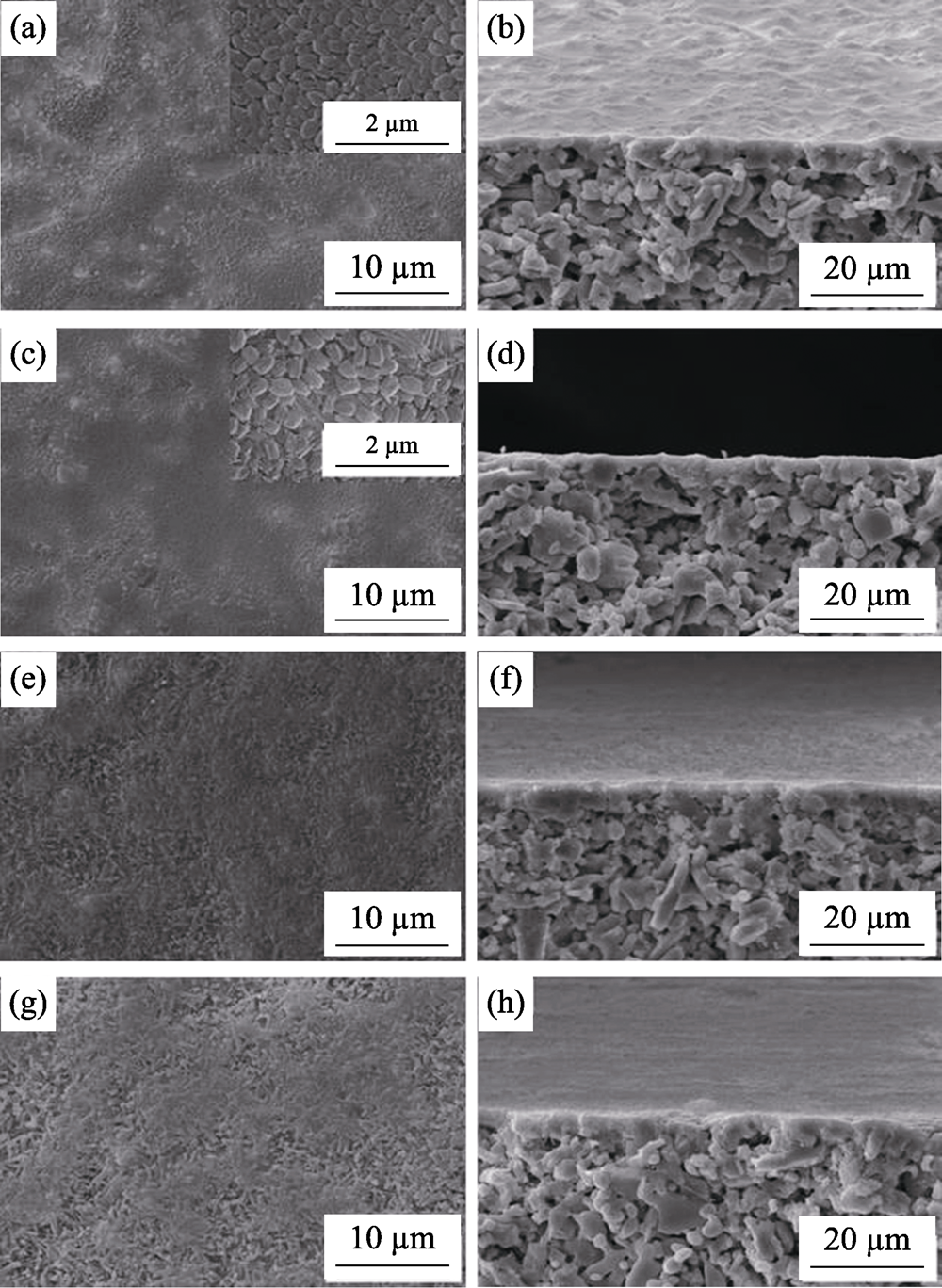

图8 不同第二步晶化温度下两步晶化后的T型沸石膜的SEM照片

Fig. 8 SEM images of T-type zeolite membranes after two-step crystallizations prepared at different second-step crystallization temperatures (a, b) M10, 90 ℃; (c, d) M11, 100 ℃; (e, f) M12, 120 ℃; (g, h) M13, 130 ℃

| No | First-step crystallization | Second-step crystallization | J/ (kg·m-2·h-1) | α | ||

|---|---|---|---|---|---|---|

| Temp./℃ | Time/h | Temp./℃ | Time/h | |||

| M10 | 135 | 4 | 90 | 6 | - | - |

| M11 | 135 | 4 | 100 | 6 | 3.94 | 2646 |

| M4 | 135 | 4 | 110 | 6 | 3.84 | >10000 |

| M12 | 135 | 4 | 120 | 6 | 3.97 | 5867 |

| M13 | 135 | 4 | 130 | 6 | 3.41 | 5594 |

表3 不同的第二步晶化温度制备的T型沸石膜的渗透汽化性能

Table 3 Pervaporation performance of T zeolite membranes prepared under different second-step crystallization temperatures

| No | First-step crystallization | Second-step crystallization | J/ (kg·m-2·h-1) | α | ||

|---|---|---|---|---|---|---|

| Temp./℃ | Time/h | Temp./℃ | Time/h | |||

| M10 | 135 | 4 | 90 | 6 | - | - |

| M11 | 135 | 4 | 100 | 6 | 3.94 | 2646 |

| M4 | 135 | 4 | 110 | 6 | 3.84 | >10000 |

| M12 | 135 | 4 | 120 | 6 | 3.97 | 5867 |

| M13 | 135 | 4 | 130 | 6 | 3.41 | 5594 |

| Support | Temp./ ℃ | Time/ h | J/ (kg·m-2·h-1) | α | Ref. |

|---|---|---|---|---|---|

| α-Al2O3 disc | 120 | 24 | 2.24 | 10000 | [29] |

| α-Al2O3 tube | 100 | 30 | 2.52 | 10000 | [21] |

| α-Al2O3 tube | 120 | 16 | 2.96 | 6400 | [23] |

| α-Al2O3 tube | 100+140a | 8+1a | 2.15 | 10000 | [19] |

| α-Al2O3 tube | 150+120b | 4+8b | 2.04 | 2874 | [30] |

| α-Al2O3 tube | 135+110c | 4+6c | 3.84 | >10000 | This work |

表4 T型沸石膜用于75 ℃、90wt%异丙醇/水体系分离的渗透蒸发性能

Table 4 Pervaporation performance of zeolite T membranes for 90wt% isopropanol/water mixture at 75 ℃

| Support | Temp./ ℃ | Time/ h | J/ (kg·m-2·h-1) | α | Ref. |

|---|---|---|---|---|---|

| α-Al2O3 disc | 120 | 24 | 2.24 | 10000 | [29] |

| α-Al2O3 tube | 100 | 30 | 2.52 | 10000 | [21] |

| α-Al2O3 tube | 120 | 16 | 2.96 | 6400 | [23] |

| α-Al2O3 tube | 100+140a | 8+1a | 2.15 | 10000 | [19] |

| α-Al2O3 tube | 150+120b | 4+8b | 2.04 | 2874 | [30] |

| α-Al2O3 tube | 135+110c | 4+6c | 3.84 | >10000 | This work |

| [1] | JUSOH N, YEONG Y F, LAU K K, et al. Fabrication of silanated zeolite T/6FDA-durene composite membranes for CO2/CH4 separation. Journal of Cleaner Production, 2017,166:1043-1058. |

| [2] | FARD A K, MCKAY G, BUEKENHOUDT A, et al. Inorganic membranes: preparation and application for water treatment and desalination. Materials, 2018,11(1):74. |

| [3] | BEDARD R, LIU C Q. Recent advances in zeolitic membranes. Annual Review of Materials Research, 2018,48:83-110. |

| [4] |

RANGNEKAR N, MITTAL N, ELYASSI B, et al. Zeolite membranes- a review and comparison with MOFs. Chemical Society Reviews, 2015,44(20):7128-7154.

DOI URL PMID |

| [5] |

JYOTHI M S, REDDY K R, SOONTARAPA K, et al. Membranes for dehydration of alcohols via pervaporation. Journal of Environmental Management, 2019,242:415-429.

DOI URL PMID |

| [6] | CAO Y, LI Y X, WANG M, et al. High-flux NaA zeolite pervaporation membranes dynamically synthesized on the alumina hollow fiber inner-surface in a continuous flow system. Journal of Membrane Science, 2019,570:445-454. |

| [7] | ALOMAIR A A, AL-JUBOURI S M, HOLMES S M. A novel approach to fabricate zeolite membranes for pervaporation processes. Journal of Materials Chemistry A, 2015,3(18):9799-9806. |

| [8] | LILLERUD K P, RAEDER J H. On the synthesis of erionite-offretite intergrowth zeolites. Zeolites, 1986,6(6):474-483. |

| [9] | WANG X Q, XU R R. Studies on the transformation between erionite and offretite in T-type zeolite. Studies in Surface Science and Catalysis, 1985,24:111-118. |

| [10] |

AGRAWAL K V, TOPUZ B, PHAM T C T, et al. Oriented MFI membranes by gel-less secondary growth of sub-100 nm MFI- nanosheet seed layers. Advanced Materials, 2015,27(21):3243-3249.

DOI URL PMID |

| [11] | ZHOU M, KORELSKIY D, YE P C, et al. A uniformly oriented MFI membrane for improved CO2 separation. Angewandte Chemie- International Edition, 2014,53(13):3492-3495. |

| [12] |

LI Y J, LIU H O, WANG H T, et al. GO-guided direct growth of highly oriented metal-organic framework nanosheet membranes for H2/CO2 separation. Chemical Science, 2018,9(17):4132-4141.

DOI URL PMID |

| [13] |

SUN Y W, LIU Y, CARO J, et al. In-plane epitaxial growth of highly c-oriented NH2-MIL-125(Ti) membranes with superior H2/CO2 selectivity. Angewandte Chemie-International Edition, 2018,57(49):16088-16093.

URL PMID |

| [14] |

HUANG P S, LAM C H, SU C Y, et al. Scalable wet deposition of zeolite AEI with a high degree of preferred crystal orientation. Angewandte Chemie-International Edition, 2018,57(40):13271-13276.

DOI URL PMID |

| [15] |

CAI R, SUN M W, CHEN Z W, et al. Ionothermal synthesis of oriented zeolite AEL films and their application as corrosion-resistant coatings. Angewandte Chemie-International Edition, 2008,47(3):525-528.

DOI URL PMID |

| [16] |

LI Z J, JOHNSON M C, SUN M W, et al. Mechanical and dielectric properties of pure-silica-zeolite low-k materials. Angewandte Chemie-International Edition, 2006,45(38):6329-6332.

DOI URL PMID |

| [17] |

NIAN P, YU T, SU M H, et al. Fabrication of b-oriented MFI film via Langmuir-Blodgett technique. Journal of Inorganic Materials, 2016,31(4):377-382.

DOI URL |

| [18] |

KIM E, HONG S, JANG E, et al. An oriented, siliceous deca-dodecasil 3R(DDR) zeolite film for effective carbon capture: insight into its hydrophobic effect. Journal of Materials Chemistry A, 2017,5(22):11246-11254.

DOI URL |

| [19] | ZHOU H, LI Y S, ZHU G Q, et al. Microwave-assisted hydrothermal synthesis of a&b-oriented zeolite T membranes and their pervaporation properties. Separation and Purification Technology, 2009,65(2):164-172. |

| [20] | ZHOU H, LI Y S, ZHU G Q, et al. Microwave synthesis of a&b- oriented zeolite T membranes and their application in pervaporation-assisted esterification. Chinese Journal of Catalysis, 2008,29(7):592-594. |

| [21] | CHEN X X, WANG J Q, YIN D H, et al. High-performance zeolite T membrane for dehydration of organics by a new varying temperature hot-dip coating method. Aiche Journal, 2013,59(3):936-947. |

| [22] | HUANG P, ZHOU L, LI H Z, et al. Preparation and characterization of high performance MFI zeolite membrane in ultradilute solution. Journal of Inorganic Materials, 2018,33(3):345-351. |

| [23] | LYU Y J, LI H Z, YANG J H, et al. Preparation and characterization of high performance zeolite T membranes from clear solutions. Journal of Inorganic Materials, 2016,31(7):705-710. |

| [24] | ZHANG X L, QIU L F, DING M Z, et al. Preparation of zeolite T membranes by a two-step temperature process for CO2 separation. Industrial & Engineering Chemistry Research, 2013,52(46):16364-16374. |

| [25] | MEHDIPOURGHAZI M, MOHEB A, KAZEMIAN H. Incorporation of boron into nano-size MFI zeolite structure using a novel microwave-assisted two-stage varying temperatures hydrothermal synthesis. Microporous and Mesoporous Materials, 2010,136(1/2/3):18-24. |

| [26] | ZHANG F, HU N, ZHOU R F, et al. Preparation of Zeolite T Membrane and Its Application in Esterification. Chinese Science and Technology Reporting Conference,Beijing, 2010: 537-540. |

| [27] | ZHOU R F, HU L L, ZHANG Y J, et al. Synthesis of oriented zeolite T membranes from clear solutions and their pervaporation properties. Microporous and Mesoporous Materials, 2013,174:81-89. |

| [28] | LI G, KIKUCHI E, MASTUKATA M. ZSM-5 zeolite membranes prepared from a clear template-free solution. Microporous and Mesoporous Materials, 2003,60(1/2/3):225-235. |

| [29] | SHAFIEI K, PAKDEHI S G, MOGHADDAM M K, et al. Improvement of zeolite T membrane via clear solution gel in dehydration of methanol, ethanol and 2-propanol. Separation Science and Technology, 2014,49(6):797-802. |

| [30] | XU Z X, WU H D, ZHOU Z H, et al. Preparation of high performance zeolite T membranes by a two-stage crystallization method. Petrochemical Technology, 2017,46(11):1403-1408. |

| [1] | 董淑蕊, 赵笛, 赵静, 金万勤. 离子化氨基酸对氧化石墨烯膜渗透汽化过程中水选择性渗透的影响[J]. 无机材料学报, 2022, 37(4): 387-394. |

| [2] | 朱春晖, 徐荣, 任秀秀, 左士祥, 龚耿浩, 钟璟. ZIF-8-NH2/有机硅杂化膜的制备及渗透汽化脱盐性能研究[J]. 无机材料学报, 2020, 35(11): 1239-1246. |

| [3] | 王晓磊, 张玉亭, 高冰, 张春, 顾学红. 四通道中空纤维NaA分子筛内膜的制备与表征[J]. 无机材料学报, 2018, 33(3): 339-344. |

| [4] | 吕尤佳, 李华征, 杨建华, 王金渠, 殷德宏, 鲁金明. 清液体系高性能T型分子筛膜的制备及表征[J]. 无机材料学报, 2016, 31(7): 705-710. |

| [5] | 周 亮, 杨建华, 王金渠, 鲁金明, 张 艳, 殷德宏. 蒸汽相转化涂晶法SAPO-34分子筛膜的制备及表征[J]. 无机材料学报, 2015, 30(3): 294-298. |

| [6] | 李良清, 张闻煦, 杨建华, 鲁金明, 殷德宏, 王金渠. 含氟体系下亲水性ZSM-5沸石分子筛膜的制备及其性能[J]. 无机材料学报, 2015, 30(11): 1167-1171. |

| [7] | 刘维桥,尚通明,李 工,吴非克,佟惠娟2,孙予罕. 两步晶化法制备介孔材料及其催化性能研究[J]. 无机材料学报, 2010, 25(3): 272-278. |

| [8] | 周志华,鲁金明,巫树锋,周敬林,王金渠. 两步晶化法制备MCM-48/ZSM-5复合分子筛[J]. 无机材料学报, 2009, 24(2): 325-329. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||