无机材料学报 ›› 2026, Vol. 41 ›› Issue (3): 349-358.DOI: 10.15541/jim20250184 CSTR: 32189.14.jim20250184

刘明扬1( ), 王纯2, 程鹏飞2, 马雪寒1, 高祥云3, 由博杰1, 赵录峰4, 成来飞1,4, 张毅1(

), 王纯2, 程鹏飞2, 马雪寒1, 高祥云3, 由博杰1, 赵录峰4, 成来飞1,4, 张毅1( )

)

收稿日期:2025-04-29

修回日期:2025-07-17

出版日期:2025-07-31

网络出版日期:2025-07-31

通讯作者:

张 毅, 副研究员. E-mail: zhangyit@nwpu.edu.cn作者简介:刘明扬(2002-), 男, 硕士研究生. E-mail: lmy123@mail.nwpu.edu.cn

LIU Mingyang1( ), WANG Chun2, CHENG Pengfei2, MA Xuehan1, GAO Xiangyun3, YOU Bojie1, ZHAO Lufeng4, CHENG Laifei1,4, ZHANG Yi1(

), WANG Chun2, CHENG Pengfei2, MA Xuehan1, GAO Xiangyun3, YOU Bojie1, ZHAO Lufeng4, CHENG Laifei1,4, ZHANG Yi1( )

)

Received:2025-04-29

Revised:2025-07-17

Published:2025-07-31

Online:2025-07-31

Contact:

ZHANG Yi, associate professor. E-mail: zhangyit@nwpu.edu.cnAbout author:LIU Mingyang (2002-), male, Master candidate. E-mail: lmy123@mail.nwpu.edu.cn

摘要:

随着航空发动机热端部件对高温性能与轻量化的要求日益严苛, SiC/SiC复合材料凭借其优异的耐高温性、低密度和耐腐蚀性, 成为极具应用潜力的替代材料。然而, 其服役过程中不可避免地承受复杂振动载荷, 振动引发的疲劳损伤已成为限制其工程应用的关键问题。本工作采用化学气相渗透法制备了2D SiC/SiC板材, 并加工成两侧具有圆弧状缺口的试样, 在一阶振型下开展了窄带随机振动疲劳试验, 系统揭示其损伤演化过程及拉伸性能退化规律。研究结果表明, 随着等效应力增大, 2D SiC/SiC板结构的归一化全时域曲线整体向下偏移, 低应力区的响应表现出显著的分散性。基于微结构图像分析, 2D SiC/SiC板结构的损伤演化可分为基体损伤、界面损伤和纤维损伤三个阶段, 损伤速率呈现快-慢-快的变化趋势。残余拉伸性能结果表明, 2D SiC/SiC板结构的拉伸性能呈指数型下降趋势, 当共振频率降幅为31.9%时, 其拉伸强度、比例极限应力、弹性模量和回弹模量分别下降至270.0 MPa、64.1 MPa、106.3 GPa和0.020 MJ/m3, 均不足制备态性能的70%。拉伸断口形貌分析表明, 基体裂纹和纤维磨损是导致拉伸性能退化的关键因素。本研究为评估2D SiC/SiC板结构在振动环境下的服役可靠性提供了重要依据和实验支撑。

中图分类号:

刘明扬, 王纯, 程鹏飞, 马雪寒, 高祥云, 由博杰, 赵录峰, 成来飞, 张毅. 化学气相渗透2D SiC/SiC窄带随机振动疲劳损伤与性能退化[J]. 无机材料学报, 2026, 41(3): 349-358.

LIU Mingyang, WANG Chun, CHENG Pengfei, MA Xuehan, GAO Xiangyun, YOU Bojie, ZHAO Lufeng, CHENG Laifei, ZHANG Yi. 2D SiC/SiC Manufactured by Chemical Vapor Infiltration: Narrow Band Random Vibration Fatigue Damage and Performance Degradation[J]. Journal of Inorganic Materials, 2026, 41(3): 349-358.

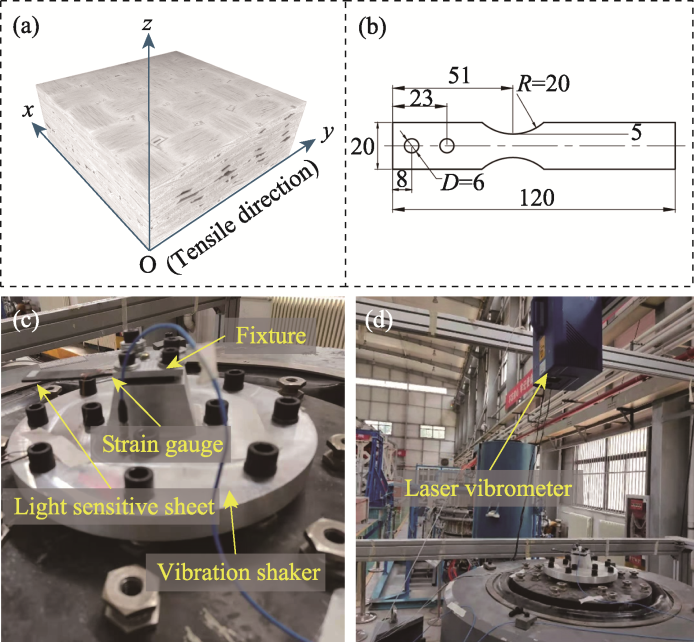

图1 2D SiC/SiC的预制体结构(a)、试样形状设计(b)及随机振动测试系统(c, d)

Fig. 1 Preform structure (a), specimen shape design (b) and vibration testing system (c, d) of 2D SiC/SiC Unit: mm

| Specimen | Resonance frequency/Hz | Vibration load/ (g2·Hz-1) | Strain RMS, με |

|---|---|---|---|

| No.V1 | 325.00 | 1.01 | 430 |

| No.V2 | 317.65 | 1.01 | 430 |

| No.V3 | 326.00 | 0.91 | 430 |

| No.V4 | 309.66 | 2.88 | 450 |

| No.V5 | 315.05 | 5.00 | 530 |

| No.V6 | 315.05 | 0.99 | 400 |

表1 2D SiC/SiC试样随机振动试验参数

Table 1 Parameters of 2D SiC/SiC specimens for random vibration test

| Specimen | Resonance frequency/Hz | Vibration load/ (g2·Hz-1) | Strain RMS, με |

|---|---|---|---|

| No.V1 | 325.00 | 1.01 | 430 |

| No.V2 | 317.65 | 1.01 | 430 |

| No.V3 | 326.00 | 0.91 | 430 |

| No.V4 | 309.66 | 2.88 | 450 |

| No.V5 | 315.05 | 5.00 | 530 |

| No.V6 | 315.05 | 0.99 | 400 |

| Property | No.T1 | No.T2 | No.T3 | Average | Standard error |

|---|---|---|---|---|---|

| Tensile strength/MPa | 418.5 | 397.8 | 382.2 | 399.5 | 18.2 |

| Proportional limit stress/MPa | 131.8 | 132.6 | 133.0 | 132.5 | 0.6 |

| Elastic modulus/GPa | 282.3 | 267.5 | 276.0 | 275.3 | 7.4 |

| Rebound modulus/(MJ·m-3) | 0.035 | 0.032 | 0.031 | 0.033 | 0.002 |

表2 制备态2D SiC/SiC的拉伸性能

Table 2 Tensile properties of as-received 2D SiC/SiC

| Property | No.T1 | No.T2 | No.T3 | Average | Standard error |

|---|---|---|---|---|---|

| Tensile strength/MPa | 418.5 | 397.8 | 382.2 | 399.5 | 18.2 |

| Proportional limit stress/MPa | 131.8 | 132.6 | 133.0 | 132.5 | 0.6 |

| Elastic modulus/GPa | 282.3 | 267.5 | 276.0 | 275.3 | 7.4 |

| Rebound modulus/(MJ·m-3) | 0.035 | 0.032 | 0.031 | 0.033 | 0.002 |

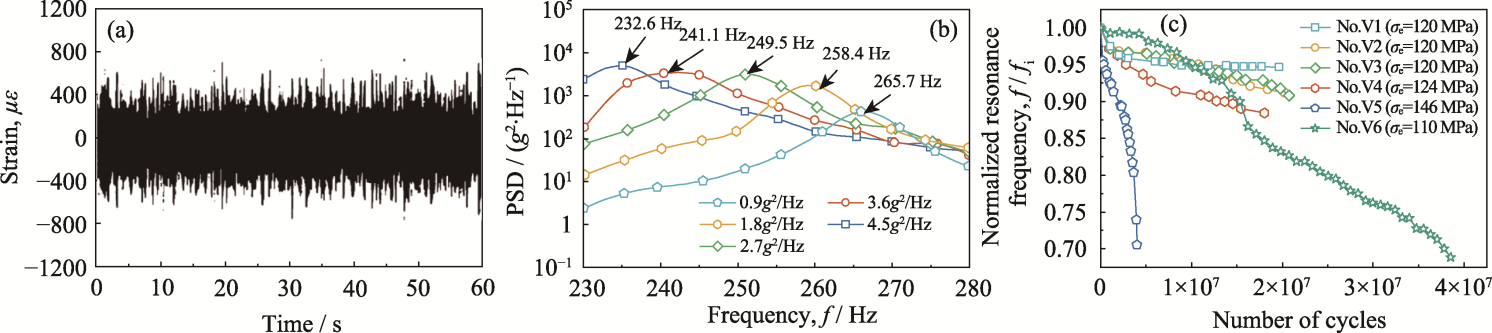

图4 2D SiC/SiC的应变时域曲线(a)、加速度功率谱密度(b)与随机振动试验归一化全时域曲线(c)

Fig. 4 Strain time-domain response curves (a), acceleration power spectral density response curves (b) and normalized full-time domain curves of random vibration test (c) of 2D SiC/SiC

| Specimen | Equivalent stress | Initial resonance frequency, fi/Hz | Terminal resonance frequency/Hz | Decrease in resonance frequency, Δf/% | Number of cycles |

|---|---|---|---|---|---|

| No.V1 | 120 | 285.63 | 270.31 | 5.3 | 1.96×107 |

| No.V2 | 120 | 282.81 | 257.81 | 8.8 | 2.02×107 |

| No.V3 | 120 | 289.38 | 262.81 | 9.2 | 2.07×107 |

| No.V4 | 124 | 273.56 | 242.07 | 14.1 | 1.80×107 |

| No.V5 | 146 | 268.80 | 196.29 | 26.9 | 4.00×106 |

| No.V6 | 110 | 299.06 | 203.75 | 31.9 | 3.85×107 |

表3 2D SiC/SiC随机振动试验结果

Table 3 Results of 2D SiC/SiC random vibration test

| Specimen | Equivalent stress | Initial resonance frequency, fi/Hz | Terminal resonance frequency/Hz | Decrease in resonance frequency, Δf/% | Number of cycles |

|---|---|---|---|---|---|

| No.V1 | 120 | 285.63 | 270.31 | 5.3 | 1.96×107 |

| No.V2 | 120 | 282.81 | 257.81 | 8.8 | 2.02×107 |

| No.V3 | 120 | 289.38 | 262.81 | 9.2 | 2.07×107 |

| No.V4 | 124 | 273.56 | 242.07 | 14.1 | 1.80×107 |

| No.V5 | 146 | 268.80 | 196.29 | 26.9 | 4.00×106 |

| No.V6 | 110 | 299.06 | 203.75 | 31.9 | 3.85×107 |

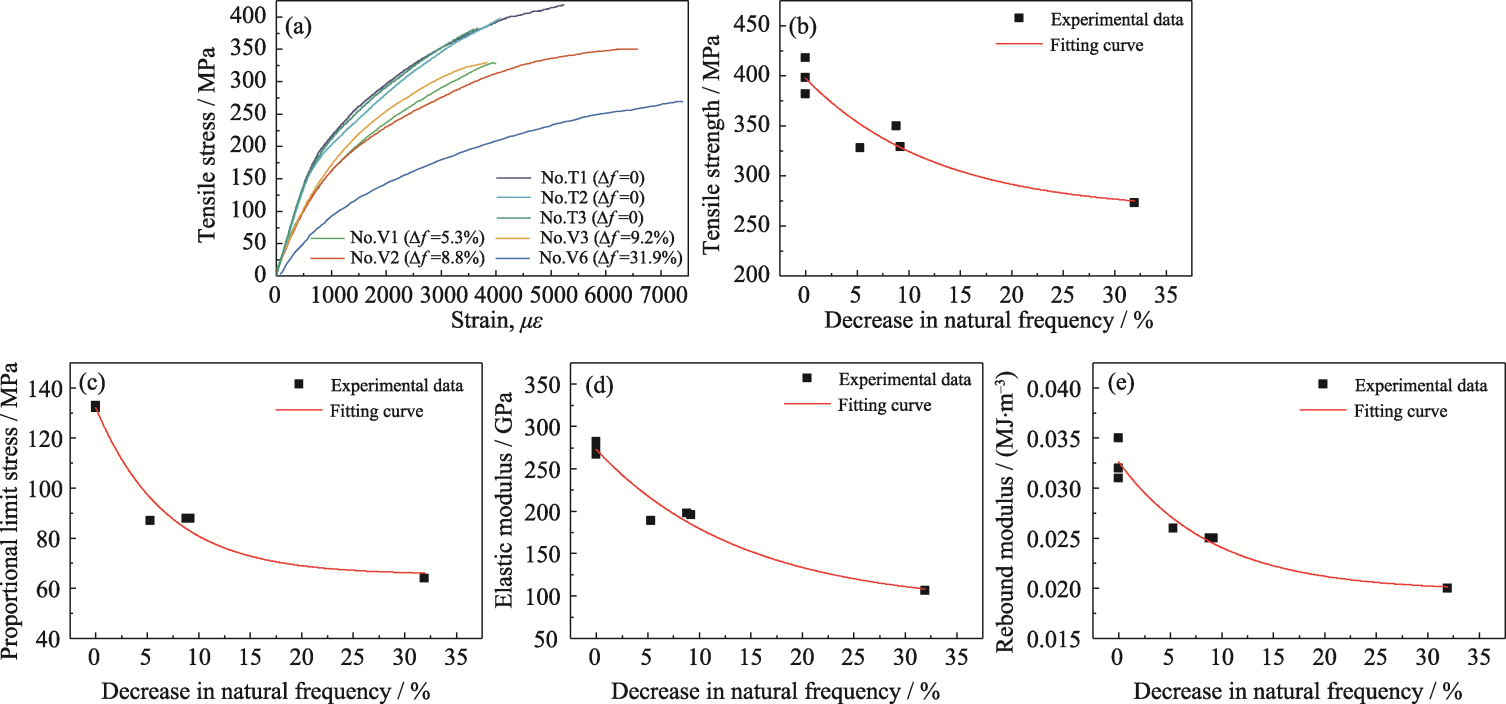

图9 2D SiC/SiC拉伸性能变化

Fig. 9 Degradation in tensile properties of 2D SiC/SiC (a) Stress-strain curves; (b) Tensile strength; (c) Proportional limit stress; (d) Elastic modulus; (e) Rebound modulus Colorful figures are available on website

| Tensile property | a | b | Goodness of fitting, R2 |

|---|---|---|---|

| Tensile strength | 132.71 | 12.54 | 0.89 |

| Proportional limit stress | 66.67 | 6.82 | 0.97 |

| Elastic modulus | 183.71 | 14.12 | 0.95 |

| Rebound modulus | 0.01285 | 9.168 | 0.93 |

表4 随机振动疲劳后的残余拉伸性能拟合参数a和b

Table 4 Fitting parameters a and b for residual tensile properties after random vibration fatigue

| Tensile property | a | b | Goodness of fitting, R2 |

|---|---|---|---|

| Tensile strength | 132.71 | 12.54 | 0.89 |

| Proportional limit stress | 66.67 | 6.82 | 0.97 |

| Elastic modulus | 183.71 | 14.12 | 0.95 |

| Rebound modulus | 0.01285 | 9.168 | 0.93 |

| Decrease in resonance frequency, Δf/% | Matrix crack spacings, lc/μm | Average value/μm | Standard error/μm | ||

|---|---|---|---|---|---|

| 0 | 134 | 196 | 169 | 166.3 | 25.38 |

| 5.3 | 98 | 100 | 66 | 88.0 | 15.58 |

| 8.8 | 127 | 48 | 58 | 78.7 | 35.12 |

| 9.2 | 258 | 94 | 187 | 179.7 | 67.15 |

| 31.9 | 215 | 182 | 178 | 191.7 | 16.58 |

表5 2D SiC/SiC基体裂纹间距

Table 5 Matrix crack spacings of 2D SiC/SiC

| Decrease in resonance frequency, Δf/% | Matrix crack spacings, lc/μm | Average value/μm | Standard error/μm | ||

|---|---|---|---|---|---|

| 0 | 134 | 196 | 169 | 166.3 | 25.38 |

| 5.3 | 98 | 100 | 66 | 88.0 | 15.58 |

| 8.8 | 127 | 48 | 58 | 78.7 | 35.12 |

| 9.2 | 258 | 94 | 187 | 179.7 | 67.15 |

| 31.9 | 215 | 182 | 178 | 191.7 | 16.58 |

| [1] | LIU X, SHEN X L, GONG L D, et al. Multi-scale thermodynamic analysis method for 2D SiC/SiC composite turbine guide vanes. Chinese Journal of Aeronautics, 2018, 31(1): 117. |

| [2] | GAO X Y, YOU B J, MA X H, et al. Understanding fiber preform effects on tensile strengths of SiC/SiC composites prepared by chemical vapor infiltration based on a unified fiber bundle bending view. Materials Characterization, 2024, 217: 114341. |

| [3] | 马雪寒, 王守财, 陈旭, 等. 陶瓷基复合材料紧固件制造技术及其连接性能研究进展. 复合材料学报, 2023, 40(6): 3075. |

| [4] | YOU B J, WANG X, LI B, et al. Microstructural evolution and phase transformation of Cansas 3303 SiC fibers during thermal shock at 1200 ℃. Ceramics International, 2024, 50(21): 42035. |

| [5] | MA X H, ZHAO L F, ZHANG Y, et al. Uncertainty analysis and B-basis value of tensile strength of 2D SiC/SiC composite. Journal of Materials Research and Technology, 2023, 24: 7058. |

| [6] | LI X, PAN K, ZHANG F, et al. An overview of tensile and shear failure mechanisms of silicon carbide-based ceramic matrix composites. Journal of Materials Research and Technology, 2024, 33: 2924. |

| [7] | GAO X, LEI B, ZHANG Y, et al. Identification of microstructures and damages in silicon carbide ceramic matrix composites by deep learning. Materials Characterization, 2023, 196: 112608. |

| [8] | KANG F, MEI H, GAO X, et al. Three-dimensional in-situ observation and cohesive zone modeling of tension-induced delamination of two-dimensional C/SiC composites via deep learning-based damage identification. Carbon, 2025, 233: 119842. |

| [9] | ZHANG Y, ZHANG L T, LIU Y S, et al. Oxidation effects on in-plane and interlaminar shear strengths of two-dimensional carbon fiber reinforced silicon carbide composites. Carbon, 2016, 98: 144. |

| [10] | LI B, CHEN X, TIAN L L, et al. In-situ formation of the BSG bubbles toward SiC/SiC composites protection mechanisms under thermal shock treatment. Journal of Materials Research and Technology, 2023, 26: 7097. |

| [11] | YOU B J, LI B, LI X Q, et al. Thermal shock damage and in-plane shear performance degradation of 2D SiCf/SiC at medium temperature. Journal of Inorganic Materials, 2024, 39(12): 1367. |

| [12] | LU Y H, XIANG P L, DONG P, et al. Analysis of the effects of vibration modes on fatigue damage in high-speed train bogie frames. Engineering Failure Analysis, 2018, 89: 222. |

| [13] | GE J R, SUN Y, XU J, et al. Fatigue life prediction of metal structures subjected to combined thermal-acoustic loadings using a new critical plane model. International Journal of Fatigue, 2017, 96: 89. |

| [14] | HABTOUR E, SRIDHARAN R, DASGUPTA A, et al. Phase influence of combined rotational and transverse vibrations on the structural response. Mechanical Systems and Signal Processing, 2018, 100: 371. |

| [15] | ANGELI A, CORNELIS B, TRONCOSSI M. Synthesis of sine-on-random vibration profiles for accelerated life tests based on fatigue damage spectrum equivalence. Mechanical Systems and Signal Processing, 2018, 103: 340. |

| [16] | AYKAN M, ÇELIK M. Vibration fatigue analysis and multi-axial effect in testing of aerospace structures. Mechanical Systems and Signal Processing, 2009, 23(3): 897. |

| [17] | MILOŠEVIĆ I, RENHART P, WINTER G, et al. A new high frequency testing method for steels under tension/compression loading in the VHCF regime. International Journal of Fatigue, 2017, 104: 150. |

| [18] | MRŠNIK M, SLAVIČ J, BOLTEŽAR M. Multiaxial vibration fatigue—a theoretical and experimental comparison. Mechanical Systems and Signal Processing, 2016, 76/77: 409. |

| [19] | LI L. Modeling temperature-dependent vibration damping in C/SiC fiber-reinforced ceramic-matrix composites. Materials, 2020, 13(7): 1633. |

| [20] | ELLYSON B, CHEKIR N, BROCHU M, et al. Characterization of bending vibration fatigue of WBD fabricated Ti-6Al-4V. International Journal of Fatigue, 2017, 101: 36. |

| [21] | COSTA P, VIEIRA M, REIS L, et al. New specimen and horn design for combined tension and torsion ultrasonic fatigue testing in the very high cycle fatigue regime. International Journal of Fatigue, 2017, 103: 248. |

| [22] | LIU L, LV B Y, HE T R. The stochastic dynamic snap-through response of thermally buckled composite panels. Composite Structures, 2015, 131: 344. |

| [23] | VASSILOPOULOS A P. Introduction to the fatigue life prediction of composite materials and structures:past, present and future prospects//VASSILOPOULOS A P. Fatigue Life Prediction of Composites and Composite Structures. Switzerland: Woodhead Publishing Limited, 2010: 1-44. |

| [24] | WU S D, SHANG D G, ZUO L X, et al. Vibration fatigue life prediction method for needled C/SiC composite based on frequency response curve with low signal strength. International Journal of Fatigue, 2023, 168: 107407. |

| [25] | WOLFSTEINER P. Fatigue assessment of non-stationary random vibrations by using decomposition in Gaussian portions. International Journal of Mechanical Sciences, 2017, 127: 10. |

| [26] | XIA J, YANG L, LIU Q X, et al. Comparison of fatigue life prediction methods for solder joints under random vibration loading. Microelectronics Reliability, 2019, 95: 58. |

| [27] | BRACCESI C, CIANETTI F, LORI G, et al. Evaluation of mechanical component fatigue behavior under random loads. International Journal of Fatigue, 2014, 61: 141. |

| [28] | WU S D, SHANG D G, ZUO L X, et al. Notch fatigue behavior of needled C/SiC composite under random vibration loading. Ceramics International, 2022, 48(6): 8349. |

| [29] | WU Z W, LIANG J, FU M Q, et al. Study of random fatigue behavior of C/SiC composite thin-wall plates. International Journal of Fatigue, 2018, 116: 553. |

| [30] | WANG Y N, GONG Y, ZHANG Q, et al. Fatigue behavior of 2.5D woven composites based on the first-order bending vibration tests. Composite Structures, 2022, 284: 115218. |

| [31] | EVANS A G. The mechanical performance of fiber-reinforced ceramic matrix composites. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 1989, 107: 227. |

| [32] | BRACCESI C, CIANETTI F, TOMASSINI L. Random fatigue. A new frequency domain criterion for the damage evaluation of mechanical components. International Journal of Fatigue, 2015, 70: 417. |

| [1] | 王新刚, 杨青青, 林根连, 高巍, 秦福林, 李荣臻, 康庄, 王小飞, 蒋丹宇, 闫继娜. 国产550级连续氧化铝陶瓷纤维的高温拉伸性能研究[J]. 无机材料学报, 2022, 37(6): 629-635. |

| [2] | 常岩军,矫桂琼,陶永强,王 波. 2.5D-C/SiC复合材料的拉伸损伤研究[J]. 无机材料学报, 2008, 23(3): 509-514. |

| [3] | 薛玉君,程先华,谢超英. 稀土元素对玻璃纤维增强PTFE复合材料拉伸性能的影响[J]. 无机材料学报, 2002, 17(3): 531-538. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||