1 聚合物前驱体转化陶瓷及其特点

陶瓷前驱体一般指经过高温热解后能够转变为无机陶瓷相的有机聚合物材料。其在大分子主链或侧基包含硅、硼、氮等元素, 在一定条件下可发生交联, 随后在1000 ℃左右热解得到陶瓷相。

相对于传统的固相或液相陶瓷制备方法, 聚合物前驱体转化陶瓷(Polymer Derived Ceramics, PDCs)具有以下特点[8-9]: (1)可以从微观结构和元素角度对陶瓷的性能进行设计, 通过调节官能团的数量和种类实现对陶瓷功能的调控; (2)可成型和加工性高, 可以用于制备各类纤维、涂层和复杂形状器件; (3)制备温度较低, 一般在1000 ℃以内通过热解即可转化为陶瓷产物, 实现陶瓷化; (4)热解后的陶瓷组分均匀, 耐高温、抗氧化性能较好, 可靠性高。目前比较常见的PDCs主要有二元、三元和多元陶瓷体系, 比如SiC、Si3N4、SiCN、SiOC、SiBCN、SiBCO等。需要强调的是, 前驱体材料的微观结构和元素组成对最终陶瓷产物的物理和化学性能具有至关重要的影响, 因此对其配方的设计和调控也是目前该领域研究的热点之一[8,10 -11]。

2 增材制造技术与陶瓷前驱体

增材制造技术(Additive Manufacturing, AM)通常被称为3D打印技术。该技术主要基于离散原理, 将三维实体模型进行切片分层数据处理, 再通过层层累加的材料堆积过程制造三维零件。近年来, 陶瓷材料增材制造技术得到国内外各研究单位的广泛关注与研究: 国外如意大利帕多瓦大学、奥地利Lithoz公司、德国弗劳恩霍夫研究所、美国GE、波音公司; 国内如西安交通大学、华中科技大学、西北工业大学、清华大学、北京理工大学、哈尔滨工业大学、大连理工大学、广东工业大学、南京航空航天大学、山东大学、中国科学院上海硅酸盐研究所、深圳大学等。

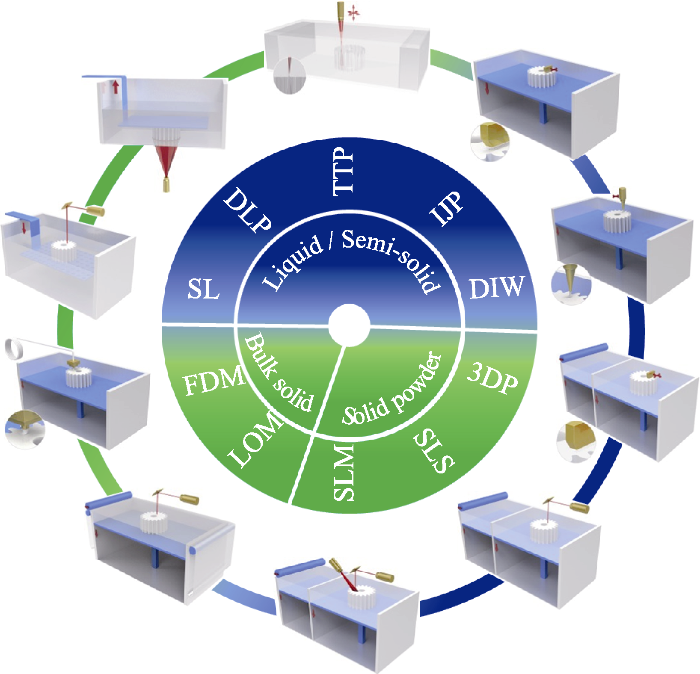

与传统制造方法相比, 增材制造技术在制造复杂结构零部件方面具有独特的优势。而将增材制造应用于陶瓷材料制备与成型也为陶瓷零件的制造开辟了全新的途径。不同材料适用于不同类型的增材制造技术, 如图1所示。

图1

目前, 陶瓷材料增材制造技术按照原材料的形态可分为三类[1-2,12-13]: (1)基于液态或者半固态材料的陶瓷增材制造技术, 主要包括光固化技术(如立体光刻Stereolithography, SL; 数字光处理Digital Light Processing, DLP; 双光子聚合Two- Photon Polymerization, TPP)、喷墨打印技术(Inkjet Printing, IJP)和挤出直写技术(Direct Ink Writing, DIW)等; (2)基于粉状固态材料的黏接剂喷射技术(Binder Jetting, BJ)、激光选区烧结技术(Selective Laser Sintering, SLS)、激光选区熔化技术(Selective Laser Melting, SLM); (3)基于固态材料的熔融沉积造型技术(Fused Deposition Modeling, FDM)和分层实体制造技术(Laminated Object Manufacturing, LOM)等。

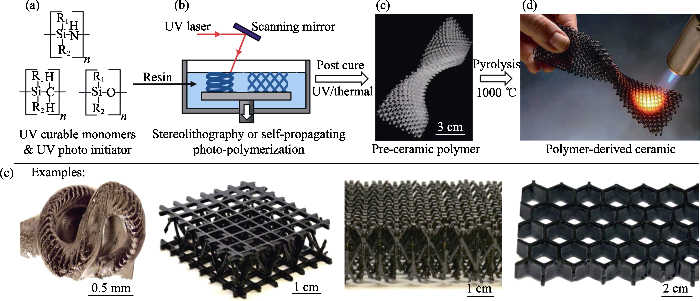

图2

3 陶瓷前驱体的增材制造

3.1 增材制造用陶瓷前驱体材料的发展

Yang等[25]合成了一种新型的紫外光固化SiOC陶瓷前驱体, 并向其中引入SiC晶须, 而后利用DLP 3D打印技术, 制备出各种具有复杂结构的陶瓷坯体, 在1000 ℃热解即可获得SiOC陶瓷以及SiOC-SiCw陶瓷复合材料。采用3D打印工艺成型的构件表面光滑, 结构清晰。对于打印获得的SiOC-SiCw陶瓷复合材料, 可以观察到SiC晶须均匀地分布在SiOC-SiCw陶瓷复合材料中, 并且在热解过程中保持原有形貌。SiOC与SiOC-SiCw陶瓷复合材料的抗压强度分别为(77.5±10.2)、(98.4± 12.3) MPa, 这也证实了引入碳化硅晶须对于SiOC陶瓷的收缩率控制以及复合材料机械性能的提升具有十分重要的作用。

He等[26]合成了一种新型的液态光敏硅基陶瓷前驱体(EPS-丙烯酸聚合物), 并3D打印制备了SiOC陶瓷点阵结构。在3D打印过程中, 引入非光敏羟基硅油(HPMS)以促进副产物气体的释放。相比之下, 引入HPMS的样品比未引入的样品具有更好的形貌以及更高的抗压强度。Wang等[27]也利用陶瓷前驱体聚合物改性的方法, 制备了一系列新型的陶瓷前驱体, 这也代表了一种灵活、快速的制备高性能陶瓷前驱体的技术路线, 可以在各种工程领域得到广泛应用, 特别是在恶劣环境和高温下应用的承载材料。通过增材制造技术, 陶瓷可以在一系列尺度与维度上实现高精度定制化制造, 这为航空航天、汽车、能源转换和化学工程等行业应用提供了新的价值。

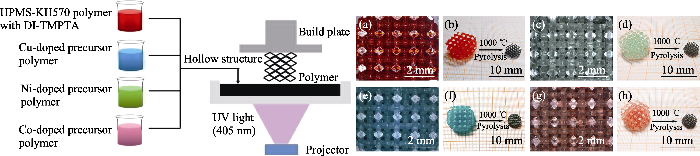

Guo等[26,28-29]制备了具有良好的水相容性和优异的紫外光敏性的γ-甲基丙烯氧丙基三甲氧基(KH570)改性HPMS陶瓷前驱体, 通过对不同配方的陶瓷前驱体的光固化性能研究, 确定HPMS、KH570和双三羟甲基丙烷丙烯酸酯(DI-TMPTA)的最佳质量比。以无机盐(硝酸铜、硝酸镍及硝酸钴)为金属源, 采用DLP法成功制备了三种不同金属掺杂的SiOC陶瓷点阵结构(Cu/SiOC、Ni/SiOC和Co/SiOC复合材料), 如图3所示。金属掺杂SiOC陶瓷点阵具有高分辨率的微观结构、独特的表面形貌以及均匀的金属元素分布。以无机金属盐为金属源掺杂的SiOC陶瓷与以金属聚合物为金属源掺杂的SiOC陶瓷形成的金属微晶的形貌和分布没有明显差异, 表明无机金属盐是一种新型有效的金属源, 可用于制备金属改性PDCs。

图3

图3

四种不同的陶瓷前驱体的DLP 3D打印工艺示意图(左)及实物照片和显微照片[28]

Fig. 3

Schematic diagram (left) of DLP printing process of four different preceramic polymers, and optical microscopic images and photographs of the printed structures [28]

(a, c, e, g) Optical microscopic images of the printed structures; (b, d, f, h) Photographs of the printed structures before and after pyrolysis

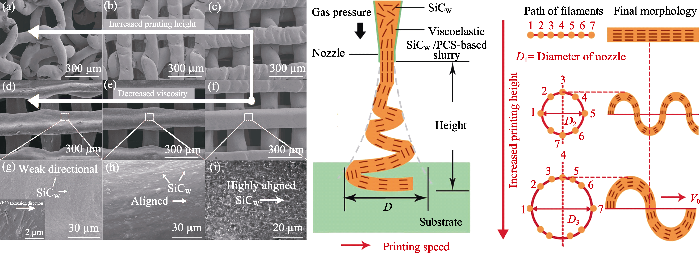

Pearce等[30]将低成本FDM技术与PDC工艺相结合, 成功制备出线宽为200~250 μm的三维陶瓷结构, 这也为具有几何稳定性、高温高强的陶瓷的定制化制造提供了新的技术路径。按此方法, 几乎所有的3D打印聚合物均能制备出不同密度与结构的陶瓷产物, 甚至可以制备出厚度<100 μm的陶瓷涂层。另外, 可以选择以熔丝制造为基础的聚合物, 用于加工制造广泛的PDC, 如热交换器、散热器、骨组织生长支架、化学/气体过滤器等。Xiong等[19-20]采用挤出直写技术研究了引入SiCw/SiCp、烧结温度对SiCxOy基陶瓷物相组成、组织结构以及性能的影响。结果表明, 通过向PCS中引入不同含量的SiCw/SiCp, 最终获得了稳定性良好的复杂三维结构(图4)。在喷嘴径向剪应力减小的作用下, 所得产物中出现了具有核壳结构的特征区域。所得点阵结构的机械性能显示SiCw/SiCp含量对三维SiCxOy基陶瓷矩阵的最终强度发挥着至关重要的作用。

图4

图4

SiCw/SiC矩阵在不同打印高度或不同固体负载悬浮液下的SEM照片(左)及其示意图(右)[19]

Fig. 4

SEM images of SiCw/SiC lattices under different printing height or using suspensions with different solid loading (left) and schematic illustration of the morphology of extruded filaments with different printing height (right)[19]

(a-c) Printed with 62.3% solid loading (in vol.); (d-f) Printed with 57.7%, 59.9% and 62.3% solid loadings (in vol.); (g-i) Enlarged views of the squares in (d-f)

Xiao等[31]在DLP 3D打印中, 用一定量的CNTs作为吸光剂, 同时使用丙烯酸酯单体对聚硅氮烷陶瓷前驱体进行修饰, 并利用优化后的打印参数制备了具有复杂结构的SiCN陶瓷。结果表明引入碳纳米管能够有效地调节光固化厚度, 提高打印精度。与之前报道的光固化陶瓷前驱体聚合物相比, 在1300 ℃热解后样品的线收缩率、孔隙率和陶瓷收率都有所提高, 且在1400 ℃高温热解所得的陶瓷构件具有更高的抗弯强度和模量。结合SiCN陶瓷独特的介电性能和3D打印技术, 制备具有特定功能周期性三维结构的致密陶瓷, 可获得适合航空航天应用的超轻高强吸波元件。He等[32-33]利用DLP 3D打印技术, 以陶瓷前驱体聚硅氮烷(PSZ)为原料制备了多种构型的氮化硅陶瓷部件, 并探究了打印与热解工艺对其性能的影响。结果表明, 最佳热解温度为1400 ℃, 其中二维结构的Si3N4陶瓷蜂窝的抗压强度和弹性模量分别为65.5和768.5 MPa, 三维结构Si3N4陶瓷矩阵的抗压强度和弹性模量分别为5.12和2.1 MPa。Giovanni等[34]以一种硅基陶瓷前驱体为原料, 利用直写式3D打印工艺制备了具有复杂三维结构的SiOC陶瓷构件, 并通过向硅基陶瓷前驱体引入氧化石墨烯薄片, 制备出石墨烯-SiOC复合陶瓷构件, 这也证明了该种前驱体材料与打印工艺能够满足具有悬浮支撑和精细结构组件的制备需求。所获得的SiOC支架具有良好的抗压强度((2.5±0.97) MPa), 与无氧化石墨烯支架相比, 引入少量氧化石墨烯薄片的打印支架在裂解过程中具有良好的结构保留能力, 能够有效地抑制收缩形变以及裂缝的产生。

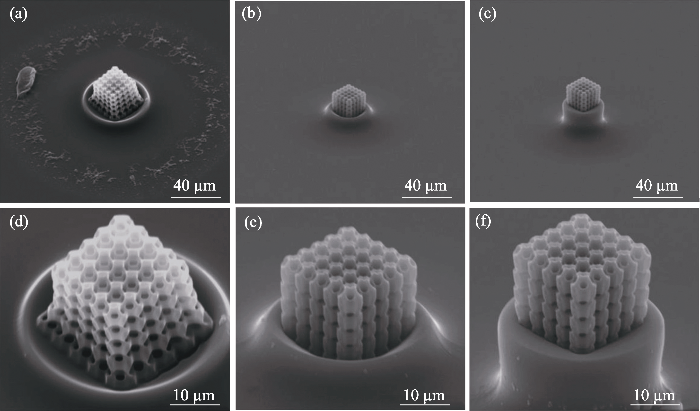

图5

图5

1000 ℃热解处理后的开尔文点阵结构的SEM照片

Fig. 5

SEM images of Kelvin cell structures pyrolyzed at 1000 ℃[38]

(a-c) Kelvin cell structures pyrolyzed at 1000 ℃ on support pillars with increasing height, to reduce shrinkage constraints from the glass substrate during pyrolysis; (d-f) Magnification of the samples shown in the upper row

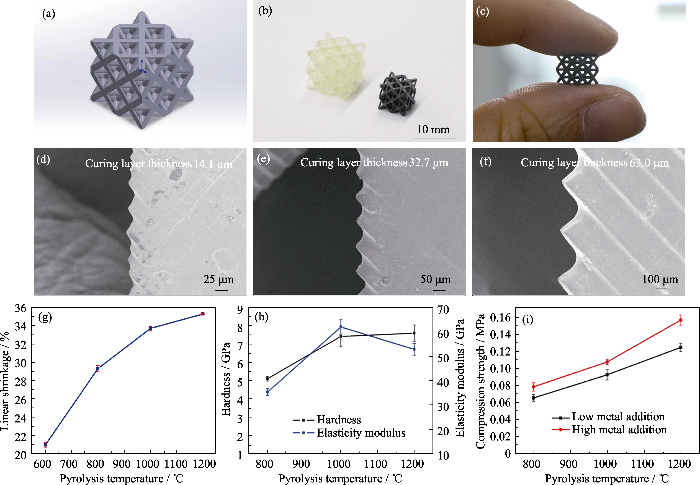

深圳大学陈张伟团队近年来开展了陶瓷前驱体光敏树脂的制备及其光固化3D打印工艺的研究。基于溶胶凝胶原理合成了Zr/Ti共掺的低黏度高固化强度的有机硅光敏树脂, 利用DLP 3D打印制备了点阵结构陶瓷前驱体, 在高温、氮气环境下裂解得到了致密的点阵结构SiOC陶瓷, 并对前驱体树脂的陶瓷化过程进行了热力学分析, 表征了物相组成以及微观组织结构的演变[41⇓⇓-44]。结果表明, 点阵结构陶瓷的压缩强度随着裂解温度的升高而得到明显提高, 而且较高浓度的金属掺杂进一步提高了其压缩强度。此外, 利用金属醇盐合成了锆基光敏树脂, 并通过优化树脂各成分的配比, 得到了适用于光固化3D打印的新型锆基光敏树脂, 并成功制备出具有高比强度的多孔点阵结构ZrOC陶瓷, 相关结果如图6所示[45]。比较经不同裂解温度处理后的宏观照片可以发现, 裂解后产品收缩均匀, 表面光滑, 内部无堵塞与塌陷, 其收缩率随裂解温度的上升而不断提高, 对应的产物机械性能也不断提高。

图6

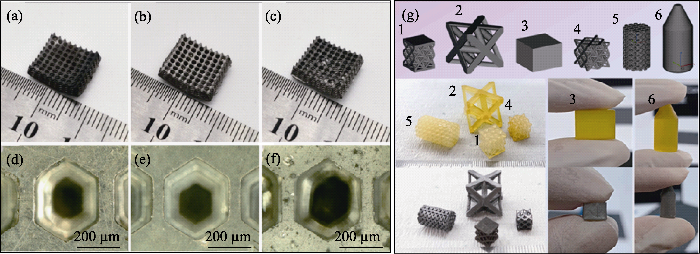

针对现有光固化陶瓷前驱体材料配方与工艺普遍较为复杂的问题, 陈张伟团队[3,44]基于三种含有不同官能团/取代基的商用廉价有机聚硅氧烷陶瓷前驱体作为硅源, 提出以简单的物理混溶工艺制备有机硅陶瓷前驱体光敏树脂的方法, 重点围绕陶瓷前驱体光敏树脂的流变性能、稳定性能、打印性能及热解成瓷质量等关键性能与机理进行研究, 形成了兼顾轻质高强和结构精度要求的点阵陶瓷打印工艺与烧结制度, 对轻质高强结构和性能实现了调控。陈张伟团队成功设计并制备了多种点阵结构, 热解成瓷后生成结构完整、表面精细、接近完全致密且具备极高碳氧比的前驱体转化SiOC陶瓷, 获得表观密度为0.33 g/cm3, 比强度高达5.74×104 N·m/kg的八角点阵结构SiOC陶瓷, 显著优于文献报道的具有相似密度的材料结构体系(图7)。该研究为复杂结构陶瓷前驱体零件轻质高强化提供了有力的理论和工艺支撑。

图7

由于陶瓷前驱体聚合物打印件在陶瓷化过程中会脱去有机官能团, 这些有机官能团热解形成的小分子气体会从结构中溢出, 并且这种溢出通常是连续和无序的, 易导致样品开裂、变形和坍塌等缺陷, 难以获得比较好的尺寸精度和表面形貌, 以及较大的样件尺寸。这也是目前前驱体转化陶瓷增材制造面临的一个重要挑战。针对此类问题, 陈张伟等[46-47]从聚合物热解的特点出发, 通过在光敏树脂配方中引入低熔点或其他有机添加剂, 利用添加剂在热解过程中持续产生的小分子气体形成的物理微通道, 为其他大分子热解形成的气体的溢出提供流畅的途径, 进而减少甚至避免了开裂、变形和坍塌的发生, 从而获得了具有较高精度、良好表面形貌、较小变形缺陷和较大致密厚度与尺寸的前驱体转化陶瓷热解件。目前, 利用该方法, 引入添加剂的样品已可获得高精度表面相貌, 蜂窝骨架厚度超过2 mm和实体厚度超过5 mm的陶瓷件(图8)。该种方法与其他控制开裂、变形的制备方法, 如热压、热等静压和等离子烧结相比, 具有工艺简单、操作方便、周期短和低成本的优势。

图8

图8

引入不同比例硅油添加剂的SiOC陶瓷热解样件的宏观(a~c)与微观(d~f)形貌照片[46], (g)添加适当比例酚醛树脂制备的样件的CAD模型、打印素坯与热解后样件宏观实物图[47]

Fig. 8

(a-c) Optical images of the SiOC ceramic samples with different proportion of silicone oil additive, (d-f) closer looks of the corresponding samples in (a-c) [46], and (g) CAD models, green and pyrolyzed samples with the addition of phenolic resin additive [47]

3.2 陶瓷前驱体材料增材制造技术的发展

近年来, 有关陶瓷前驱体增材制造技术也有了一定发展。先前, 陶瓷前驱体的增材技术手段主要是以光固化工艺以及直写式成型为主, 而最近有多种新的技术手段被用于陶瓷前驱体材料的增材制造。

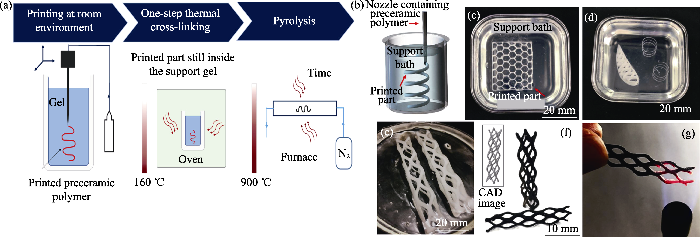

Mahmoudi等[53-54]提出了一种借助于触变性载体浴进行聚合物陶瓷前驱体增材制造的新工艺, 即在同一浴槽打印与交联固化后, 将所打印的部件从浴槽中取出并热解为最终的陶瓷部件(图9), 由于在打印过程中不会产生层间界面, 所以打印完成后的一步固化过程有利于提高机械性能。尽管该研究只是针对SiOC体系进行了研究, 但是这一打印技术可以很容易地扩展到其他陶瓷前驱体体系, 诸如SiC,SiCN,SiBCN等。打印完成之后, 再经过交联与热解, 具有特定构型的陶瓷前驱体坯体即可转化为最终的陶瓷构件。通过向其中添加短切陶瓷纤维和/或功能性纳米颗粒, 该成型工艺也可以很容易地扩展到陶瓷复合材料。同时, 得益于支撑凝胶的低成本, 该技术的应用规模还可以进一步扩大。

图9

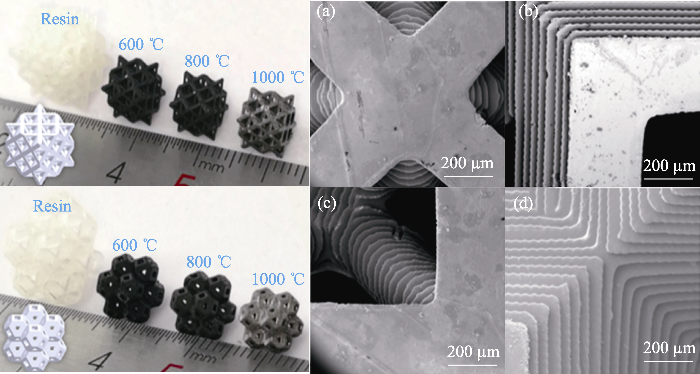

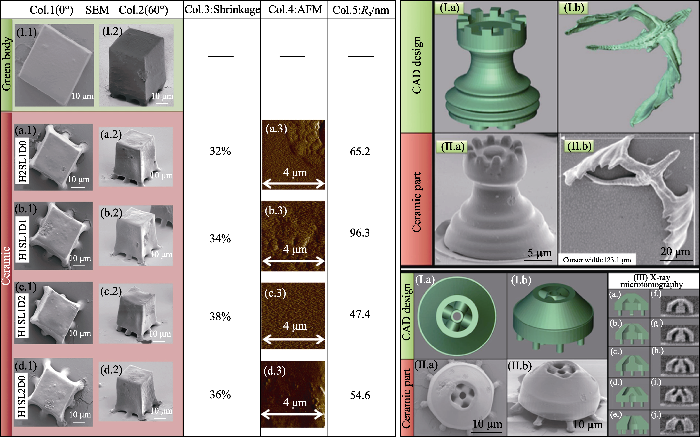

Kim等[57]基于双光子聚合激光直写提供了一种有效的解决方案, 是目前最有效的一种微纳尺度3D打印技术。不同于传统的微立体光刻的支架或光子晶体(是一种单光子微立体光刻工艺), 双光子聚合激光直写打印是基于双光子聚合原理(或者多光子吸收)。Georgia等[58]研发了一种聚硅氧烷陶瓷前驱体, 并利用双光子聚合3D打印工艺进行了成型。成型得到的陶瓷前驱体坯体在1000 ℃惰性气氛下进行热裂解, 得到200 μm×200 μm×200 μm的SiO2陶瓷微结构(图10)。在陶瓷前驱体转化的过程中, 各个维度呈现出各向同性收缩的趋势, 线性收缩率在32%~38%之间。相对较低的收缩率可归因于该类陶瓷前驱体自身的分子结构, 易引起快速的交联, 从而导致较高的陶瓷产率, 这意味着采用该类前驱体材料有望实现陶瓷构件的可控制备。通过优化光能量密度、打印路径与切片厚度等双光子聚合打印的工艺参数, 裂解后所得到陶瓷构件的孔隙率很低。基于测试长方体结构的打印结果, 选择特定的打印配置进行复杂三维结构的制作, 最终成功打印并热解制备了微喷嘴尖端。到目前为止, 大多数的支架或光子晶体微结构都是由PDCs的双光子聚合打印出来的, 其线性收缩率几乎都大于50%。这也证明了陶瓷微结构可以在陶瓷微喷嘴等多个部件得到应用。

图10

图10

不同参数打印的陶瓷立方体的SEM和AFM照片以及CAD设计[58]

Fig. 10

CAD design of the nozzle compared with the final pyrolysed part and SEM images[58]

Left: SEM images and AFM images (Col.1, 2 and 4) of ceramic cubes printed with different parameters, with the measured corresponding mean values of the linear shrinkage (Col.3) and the average roughness (Col.5). Upper-right: CAD designs of two different structures and final pyrolysed parts. Lower-right: CAD design of the nozzle compared with the final ceramic part with their SEM images at 0°(I.a and II.a) and 60°(I.b and II.b), and their corresponding X-ray microtomographies from different angles (a-j)

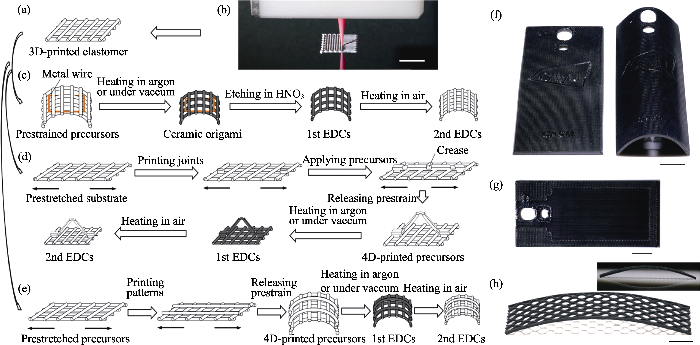

近年来, 4D打印逐渐成为智能制造领域中的一个新热点。所谓4D打印是指采用3D打印所得的三维物体, 在特定的环境和激励下(如电、光、磁、水、热及声音等), 其物理特性及功能(结构、形态、尺寸等)可以随时间的变化而发生自我转变。然而, 3D打印陶瓷前驱体通常难以变形, 从而在一定程度上阻碍了陶瓷4D打印的发展。为了克服这一限制, 香港大学吕坚院士团队[59]开发了可实现弹性形变的聚二甲基硅氧烷基纳米复合材料, 它可以通过3D打印成型具有变形能力的坯体, 而后通过裂解最终转化为SiOC陶瓷材料, 使得具有复杂结构的陶瓷构件的动态变形成为可能, 如图11所示。前驱体的几何灵活性使其可在自主变形结构、航空推进组件、空间探索、电子设备和高温微电子机械系统等领域得到广泛应用。

图11

图11

4D打印过程示意图及其成型构件[59]

Fig. 11

Origami and 4D printing of PDCs via DIW-morphing-heat treatment method[59]

(a) 3D printed elastomeric lattices; (b) Optical image of DIW; (c) Origami of ceramic structures; (d, e) Two 4D printing methods together with heat treatment; (f) Flat and curved cellphone back plate; (g) Top view of flat plate; (h) Curved ceramic honeycomb; Inset indicates the curvature of the honeycomb. Scale bars:1 cm

表1总结了部分代表性的前驱体转化陶瓷材料、打印工艺以及相关打印效果和性能等, 从表中可以看出, 目前前驱体转化陶瓷的增材制造以光固化(如DLP)技术和SiOC材料为主。产瓷率一般低于50%, 只有少部分能够达到80%以上, 且具有较高致密度。但是整体表观密度均在2.5 g/cm3以内, 具有一定的轻质结构特性。此外, 大部分样件在热解后基本上都会产生较大的线性和体积收缩。

表1 部分前驱体转化陶瓷材料所使用的3D打印工艺和热解样件的性能总结

Table 1

| Material | AM Tech. | Ceramic yield/% (in mass) | Monolith/ skeleton porosity/% | Density/ (g·cm-3) | Linear shrinkage/ % | Compressive strength/MPa | Tensile strength/ GPa | Hardness/ GPa | Elastic modulus/ GPa | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| SiCN | DLP | 80 | 0 | 2.28 | 20 | - | - | 10 | 78 | [60] |

| SiCN | DLP | 25.3 | 6.9 | 2.167 | 62.9 | >50 | - | >33 | [31] | |

| SiOC | DLP | 44.1 | 1.5 | 2.1 | 35.4 | 0.124-0.156 | - | ~7.61 | - | [41] |

| SiOC | DLP | 40.1 | 0 | 2.1 | 51.5 | 10 | 1.9 | - | 3.1 | [61] |

| SiOC | DIW | 94 | 0 | - | 8 | 56.4 | - | - | 28.9 | [62] |

| SiOC | DIW | - | 0 | - | 55(vol) | ∼3.1 | - | - | - | [34] |

| SiOCN | DIW | 77 | 50 | 1.05 | - | 0.3-0.9 | - | - | - | [63] |

| SiOC | SLS | 82 | 0 | 2.64 | 3 | 220 | - | - | - | [64] |

| SiOC | DIW | 31.3-58.84 | 86.5 | 1.97 | 46.7(vol) | 2.92 | - | - | - | [65] |

| SiOC | DLP | 29.63 | 3.64 | 1.60 | 42.01 | 19.08 | - | 5.82 | 46.4 | [44] |

| SiOC | BJ3DP | 16.5 | 19 | 1.84 | 22.2 | 20 | - | - | - | [66] |

| SiOC | DLP | ~30 | 47 | 1.95 | 30 | 12.9 | - | - | - | [67] |

4 聚合物前驱体增材制造技术的发展趋势

1) 需要进一步丰富材料体系

目前, 有关于陶瓷前驱体增材制造的研究, 仍集中在SiOC、SiCN、SiC等陶瓷前驱体体系。相较于陶瓷前驱体的总体种类与数量而言, 目前被关注的这些体系可以说只是九牛一毛。未来还需要进一步拓展与丰富能够适用于增材制造的陶瓷前驱体的体系, 诸如在高温陶瓷、透明陶瓷、超硬陶瓷等多个应用方向, 以满足更多高性能陶瓷体系成型的需求。此外, 还应该进一步探索将陶瓷前驱体增材制造与陶瓷基复合材料的制备相结合的可能性, 从而实现较大尺度或多维度的增强相, 如连续纤维、二维/三维织物等复合材料的增材制造。

2) 需要进一步创新增材制造技术

由于陶瓷前驱体自身理化性能的限制, 能够适用于增材制造的技术方案还是以光固化或直写式成型手段为主。相较于传统陶瓷的制备技术而言, 这些技术虽然在某些方面具有一定的优势, 但是仍然存在一定的短板, 诸如成型速度低、成型幅面小、成型精度不足等问题。因此, 未来需要对增材制造技术进一步进行革新与发展, 以适应更多应用背景的需求。

3) 需要进一步提升控形控性水平

陶瓷前驱体增材制造技术的优势在于成型过程自由可控, 但是这里所指的成型过程主要是前驱体坯体的成型过程。而由前驱体向陶瓷产物转变的过程将决定最终产品的结构与性能。如何做到“形”与“性”的定向调控, 实现目标产物的定制化制备, 将决定最终陶瓷前驱体增材制造技术所能达到的高度。未来需要结合前驱体材料的成分设计、陶瓷化转变过程的控制、陶瓷产物的后处理工艺等多个工艺过程最终实现控形控性, 为结构功能一体化前驱体转化陶瓷部件的定向制备与生产提供指导。

参考文献

3D printing of ceramics: a review

Along with extensive research on the three-dimensional (3D) printing of polymers and metals, 3D printing of ceramics is now the latest trend to come under the spotlight. The ability to fabricate ceramic components of arbitrarily complex shapes has been extremely challenging without 3D printing. This review focuses on the latest advances in the 3D printing of ceramics and presents the historical origins and evolution of each related technique. The main technical aspects, including feedstock properties, process control, post-treatments and energy source material interactions, are also discussed. The technical challenges and advice about how to address these are presented. Comparisons are made between the techniques to facilitate the selection of the best ones in practical use. In addition, representative applications of the 3D printing of various types of ceramics are surveyed. Future directions are pointed out on the advancement on materials and forming mechanism for the fabrication of high-performance ceramic components.

Additive manufacturing of advanced ceramic materials

Solid freeform fabrication-powder processing

Additive manufacturing of polymer-derived ceramics: materials, technologies, properties and potential applications

Polymer derived engineering ceramics

Polymer-derived Si-based ceramics: recent developments and perspectives

Polymer derived ceramics (PDCs) are promising candidates for usages as the functionalization of inorganic Si-based materials. Compared with traditional ceramics preparation methods, it is easier to prepare and functionalize ceramics with complex shapes by using the PDCs technique, thereby broadening the application fields of inorganic Si-based ceramics. In this article, we summarized the research progress and the trends of PDCs in recent years, especially most recent three years. Fabrication techniques (traditional preparation, 3D printing, template method, freezing casting techniques, etc.), microstructural tailoring mainly via additive doping, and properties (mechanical, thermal, electrical, as well as dielectric and electromagnetic wave absorption properties) of Si-based PDCs were explicated. Meanwhile, challenges and perspectives for PDCs techniques were proposed as well, with the purpose to enlighten multiple functionalized applications of polymer-derived Si-based ceramics.

Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics

Organosilicon polymer-derived ceramics: an overview

Polymer-derived ceramics (PDCs) strategy shows a great deal of advantages for the fabrication of advanced ceramics. Organosilicon polymers facilitate the shaping process and different silicon-based ceramics with controllable components can be fabricated by modifying organosilicon polymers or adding fillers. It is worth noting that silicate ceramics can also be fabricated from organosilicon polymers by the introduction of active fillers, which could react with the produced silica during pyrolysis. The organosilicon polymer-derived ceramics show many unique properties, which have attracted many attentions in various fields. This review summarizes the typical organosilicon polymers and the processing of organosilicon polymers to fabricate silicon-based ceramics, especially highlights the three-dimensional (3D) printing technique for shaping the organosilicon polymer-derived ceramics, which makes the possibility to fabricate silicon-based ceramics with complex structure. More importantly, the recent studies on fabricating typical non-oxide and silicate ceramics derived from organosilicon polymers and their biomedical applications are highlighted.

Research progress on powder-based laser additive manufacturing technology of ceramics

Ceramics, with its excellent thermal, physical and chemical properties, have great potential applications in various fields, such as aerospace, energy, environmental protection and bio-medicine. With the development of relevant technology in these fields, the structural design of core components is increasingly complex, and the internal microstructures gradually become customized and gradient. However, the hard and brittle features of ceramics make it difficult to realize the forming of special-shaped parts by traditional manufacturing methods, which in turn limits further application. As a rapidly developing additive manufacturing technology, laser additive manufacturing technology presents a momentous advantage in the manufacturing process of extremely precision ceramic components: free molding without mold and support, quick response feature and short developing cycle, etc. At the same time, the technology can realize the flexible deployment of ceramic parts, which is expected to solve the problems mentioned above. Three kinds of powder-based laser additive manufacturing techniques of ceramic were reviewed in this paper: selective laser sintering and selective laser melting based on powder bed fusion technology; laser engineered net shaping based on direct energy deposition technology. The forming principle and characteristics were mainly discussed; the research progress of ceramic green body densification process in selective laser sintering technology and the forming principle, propagation mechanism and control methods of ceramic green body cracks in selective laser melting, and laser engineered net shaping technology were reviewed; the technical characteristics of selective laser sintering, selective laser melting and laser engineered net shaping technologies in shaping of ceramic parts were compared and analyzed; and the future development trends of laser additive manufacturing technology of ceramic parts were prospected.

陶瓷挤出和喷射增材制造技术研究进展

增材制造技术被认为是解决复杂结构陶瓷零部件制造的有效新途径之一。其由点-线-面-体累加成型的制造过程还为具有特殊宏微观结构的陶瓷零部件赋予了一体化的结构功能特性。综述了熔融沉积造型、挤出直写、喷墨打印以及粘接剂喷射等四种基于挤出或喷射成型原理的陶瓷增材制造技术的历史起源、工作原理、原材料制备以及打印工艺研究等内容,并结合研究实例探讨打印件性能与应用研究。通过不同技术的特点对比,提出目前陶瓷挤出喷射增材制造技术面临的主要挑战并进行了展望。

3D printing additive manufacturing of polymer-derived ceramics

The extremely high melting point of many ceramics adds challenges to additive manufacturing as compared with metals and polymers. Because ceramics cannot be cast or machined easily, three-dimensional (3D) printing enables a big leap in geometrical flexibility. We report preceramic monomers that are cured with ultraviolet light in a stereolithography 3D printer or through a patterned mask, forming 3D polymer structures that can have complex shape and cellular architecture. These polymer structures can be pyrolyzed to a ceramic with uniform shrinkage and virtually no porosity. Silicon oxycarbide microlattice and honeycomb cellular materials fabricated with this approach exhibit higher strength than ceramic foams of similar density. Additive manufacturing of such materials is of interest for propulsion components, thermal protection systems, porous burners, microelectromechanical systems, and electronic device packaging. Copyright © 2016, American Association for the Advancement of Science.

陶瓷光固化技术及应用

陶瓷材料因具有高硬度、高强度、耐高温、抗腐蚀等优异性能,被广泛应用于航空航天、生物医疗等领域,但是应用于上述领域的复杂结构陶瓷的制造仍然是一个重要的挑战。增材制造技术通过逐层堆积材料的方式来获得实体,在制造复杂结构陶瓷方面具有传统成形方式所无法比拟的优势。在众多陶瓷增材制造技术中,陶瓷光固化技术因其理想的成形质量而受到广泛关注和重视。在介绍立体光固化、数字光处理这两种主流陶瓷光固化技术的原理和特点的基础上,系统地介绍和分析了立体光固化技术和数字光处理技术的研究现状、应用以及存在的问题。最后,对陶瓷光固化技术及其应用进行了总结和展望。

3D printing of PDC- SiOC@SiC twins with high permittivity and electromagnetic interference shielding effectiveness

3D printing of polymer-derived SiOC with hierarchical and tunable porosity

3D printing of complex-type SiOC ceramics derived from liquid photosensitive resin

3D SiC containing uniformly dispersed, aligned SiC whiskers: printability, microstructure and mechanical properties

SiCw/SiCpreinforced 3D-SiC ceramics using direct ink writing of polycarbosilane-based solution: microstructure, composition and mechanical properties

3D-printed monolithic SiCN ceramic microreactors from a photocurable preceramic resin for the high temperature ammonia cracking process

Polymer- derived SiCN cellular structures from replica of 3D printed lattices

Additive manufacturing of SiCN ceramic matrix for SiC fiber composites by flash pyrolysis of nanoscale polymer films

Additive manufacturing (AM) and nanotechnology: promises and challenges

Silicon carbide whiskers reinforced SiOC ceramics through digital light processing 3D printing technology

Polymer-derived SiOC ceramic lattice with thick struts prepared by digital light processing

Additive manufacturing of ceramics from preceramic polymers: a versatile stereolithographic approach assisted by thiolene click chemistry

Metal-doped polymer-derived SiOC composites with inorganic metal salt as the metal source by digital light processing 3D printing

Digital light processing fabrication of mullite component derived from preceramic precursor using photosensitive hydroxysiloxane as the matrix and alumina nanoparticles as the filler

Polymer-derived SiOC replica of material extrusion-based 3-D printed plastics

Carbon nanotubes as light absorbers in digital light processing three-dimensional printing of SiCN ceramics from preceramic polysilazane

Polymer-derived silicon nitride ceramics by digital light processing based additive manufacturing

Direct ink writing of micrometric SiOC ceramic structures using a preceramic polymer

Digital light processing of ceramic components from polysiloxanes

Additive manufacturing of silicon carbide by selective laser sintering of PA12 powders and polymer infiltration and pyrolysis

Additive manufacturing of ceramics: issues, potentialities, and opportunities

3D nanofabrication of SiOC ceramic structures

Stereolithography of SiOC ceramic microcomponents

Multiscale ceramic components from preceramic polymers by hybridization of vat polymerization-based technologies

Multiple metals doped polymer- derived SiOC ceramics for 3D printing

3D printing of ceramics: a review

Along with extensive research on the three-dimensional (3D) printing of polymers and metals, 3D printing of ceramics is now the latest trend to come under the spotlight. The ability to fabricate ceramic components of arbitrarily complex shapes has been extremely challenging without 3D printing. This review focuses on the latest advances in the 3D printing of ceramics and presents the historical origins and evolution of each related technique. The main technical aspects, including feedstock properties, process control, post-treatments and energy source material interactions, are also discussed. The technical challenges and advice about how to address these are presented. Comparisons are made between the techniques to facilitate the selection of the best ones in practical use. In addition, representative applications of the 3D printing of various types of ceramics are surveyed. Future directions are pointed out on the advancement on materials and forming mechanism for the fabrication of high-performance ceramic components.

Photopolymerization-based additive manufacturing of ceramics: a systematic review

Additive manufacturing of lightweight and high-strength polymer-derived SiOC ceramics

Preparation and stereo lithography 3D printing of ultralight and ultrastrong ZrOC porous ceramics

3D printing of complex-shaped polymer-derived ceramics with enhanced structural retention

3D printing of crack-free dense polymer-derived ceramic monoliths and lattice skeletons with improved thickness and mechanical performance

Continuous liquid interface production of 3D objects

\n Although three-dimensional (3D) printing is now possible using relatively small and low-cost machines, it is still a fairly slow process. This is because 3D printers require a series of steps to cure, replenish, and reposition themselves for each additive cycle. Tumbleston\n et al.\n devised a process to effectively grow solid structures out of a liquid bath. The key to the process is the creation of an oxygen-containing “dead zone” between the solid part and the liquid precursor where solidification cannot occur. The precursor liquid is then renewed by the upward movement of the growing solid part. This approach made structures tens of centimeters in size that could contain features with a resolution below 100 µm.\n

Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning

Carbide-derived carbon beads with tunable nanopores from continuously produced polysilsesquioxanes for supercapacitor electrodes

Layerless fabrication with continuous liquid interface production

Despite the increasing popularity of 3D printing, also known as additive manufacturing (AM), the technique has not developed beyond the realm of rapid prototyping. This confinement of the field can be attributed to the inherent flaws of layer-by-layer printing and, in particular, anisotropic mechanical properties that depend on print direction, visible by the staircasing surface finish effect. Continuous liquid interface production (CLIP) is an alternative approach to AM that capitalizes on the fundamental principle of oxygen-inhibited photopolymerization to generate a continual liquid interface of uncured resin between the growing part and the exposure window. This interface eliminates the necessity of an iterative layer-by-layer process, allowing for continuous production. Herein we report the advantages of continuous production, specifically the fabrication of layerless parts. These advantages enable the fabrication of large overhangs without the use of supports, reduction of the staircasing effect without compromising fabrication time, and isotropic mechanical properties. Combined, these advantages result in multiple indicators of layerless and monolithic fabrication using CLIP technology.

Single- step fabrication of computationally designed microneedles by continuous liquid interface production

Three-dimensional printing of ceramics through "carving" a gel and "filling in" the precursor polymer

3D printing polymer-derived ceramics using a thixotropic support bath

A review on 3D micro-additive manufacturing technologies

Effect of photoinitiator on photopolymerization of inorganic-organic hybrid polymers (ORMOCER (R))

Additive micro-manufacturing of crack-free PDCs by two-photon polymerization of a single, low-shrinkage preceramic resin

Origami and 4D printing of elastomer-derived ceramic structures

3D-printed monolithic SiCN ceramic microreactors from a photocurable preceramic resin for the high temperature ammonia cracking process

Analysis of multi-scale mechanical properties of ceramic trusses prepared from preceramic polymers (Revision prepared for additive manufacturing)

Boron nitride- reinforced polysilazane-derived ceramic composites via direct-ink writing

Polymer-derived ceramic/graphene oxide architected composite with high electrical conductivity and enhanced thermal resistance

Fabrication of polymer derived ceramic parts by selective laser curing

3D printing of polymer-derived SiOC with hierarchical and tunable porosity

SiOC ceramics with ordered porosity by 3D-printing of a preceramic polymer

Enhanced electromagnetic microwave absorption of SiOC ceramics targeting the integration of structure and function

Additive manufacturing (3D printing): a review of materials, methods, applications and challenges