19世纪初, 英国科学家Michael Faraday发现液态氨在蒸发时会导致周围空气温度降低, 由此打开了压缩制冷技术的先河。随着经济社会的发展, 基于机械压缩的制冷技术已在日常生活、工业生产和科学研究中发挥越来越重要的作用。经过近两个世纪的研究, 机械压缩制冷技术已得到充分优化, 然而其能源利用效率依旧低于50%[1]。此外, 氢氟烃气体作为一种常用的机械压缩冷媒介质, 具有很强的温室效应。氢氟烃气体的使用和泄露加剧了全球气候的异常变化, 已被世界上超过150个国家禁用。在这一背景下, 以电卡效应、磁卡效应和热电效应为代表的新一代制冷技术吸引了科学界和工业界的广泛关注。电卡制冷效应由于理论效率高(60%~ 70%)、无噪音、环境友好、易于操作等优点, 成为下一代制冷技术的有力竞争者[1-2]。

电卡效应是指电介质材料在外加电场施加或去除的过程中, 由熵变而导致的材料温度变化的现象[1,3⇓-5]。19世纪30年代, Kobeko和Kurchatov首先在罗息盐(即酒石酸钾钠, NaKC4H4O6·4H2O, 是一种典型的铁电材料)中观察到了电卡效应[2]。2006年, Mischenko等[6]利用溶胶-凝胶法制备了Pb(Zr0.95,Ti0.05)铁电薄膜, 并在其中发现了高达12 K的巨大温度变化, 由此掀开了电卡效应研究的热潮。2019年, Nair等[5]在Pb(Sc0.5Ta0.5)O3多层铁电陶瓷电容器中发现了宽温区大电卡效应(在294~470 K的温度区间内温度变化超过3 K), 并指明该多层陶瓷电容器具有优于磁卡制冷设备中永磁材料的制冷性能, 从而能够显著减小固态制冷设备的体积并降低生产和运行成本。

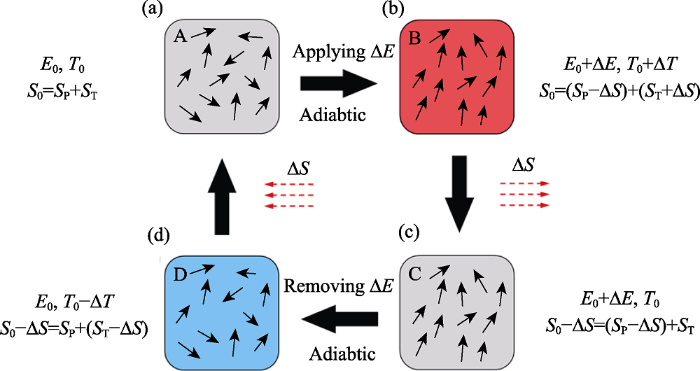

铁电材料中的电卡效应起源于自发极化在外加电场作用下的翻转, 其制冷循环如图1所示。在外加电场为E0(通常E0=0)、环境温度为T0的条件下, 铁电材料的自发极化随机分布(图1(a))。此时铁电材料的总熵为S0, 包括来自于晶格振动的热熵ST和来自于铁电极化随机排布的极化熵SP。若在绝热条件下增加作用于铁电材料上的外加电场(E0+ΔE), 铁电极化的排列变得更为有序, 如图1(b)所示。此时极化熵(SP-ΔS)减小, 而系统总熵S0不变(系统与外界无热交换), 铁电材料的热熵(ST+ΔS)增加, 铁电材料温度(T0+ΔT)上升。图1(b, c)说明了恒电场条件下铁电材料的等温过程。在此过程中, 铁电材料的温度恢复至环境温度(T0), 热熵恢复为ST, 系统熵(S0-ΔS)减小。当在绝热条件下去掉外加电场ΔE, 铁电极化会恢复至随机排列状态, 如图1(d)所示, 铁电极化熵也相应恢复至SP。而由于绝热条件下系统熵(S0-ΔS)保持不变, 材料热熵(ST-ΔS)减小, 材料温度降低为(T0-ΔT)。在图1(d)至图1(a)的过程中, 铁电材料从外界热源吸热, 并恢复至起始状态。

图1

图1

电卡效应冷却循环中的极化翻转、温度变化和熵变示意图

Fig. 1

Schematic of polarization switching, temperature change and entropy change during cooling cycle of electrocaloric effect

(a) In virgin state, the ferroelectric polarization randomly distributs; (b) With the application of electric field, the ferroelectric polarization is aligned, and the temperature of the ferroelectric materials is increased; (c) After an isothermal process, the temperature of the ferroelectric materials decreases to the environment temperature; (d) After removal of the electric field, the ferroelectric polarization recovers randomly distribution, the temperature of the ferroelectric materials decreases

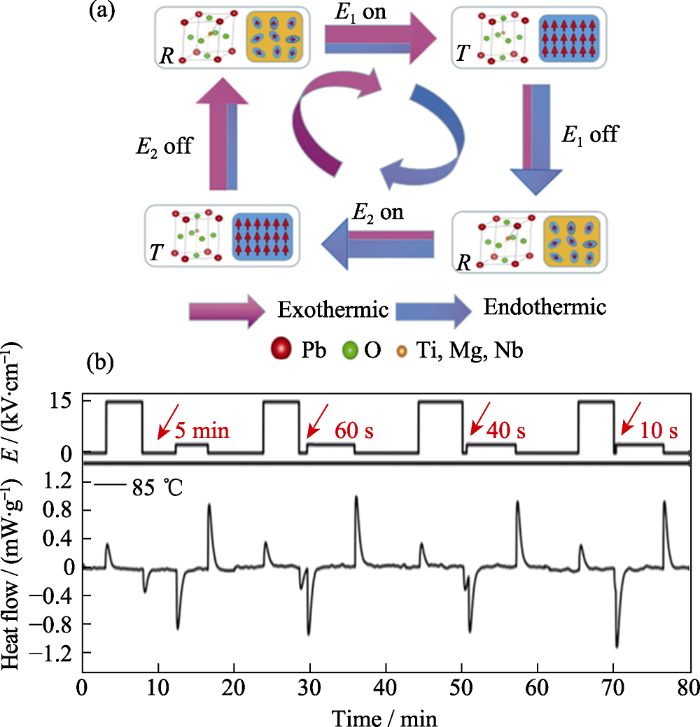

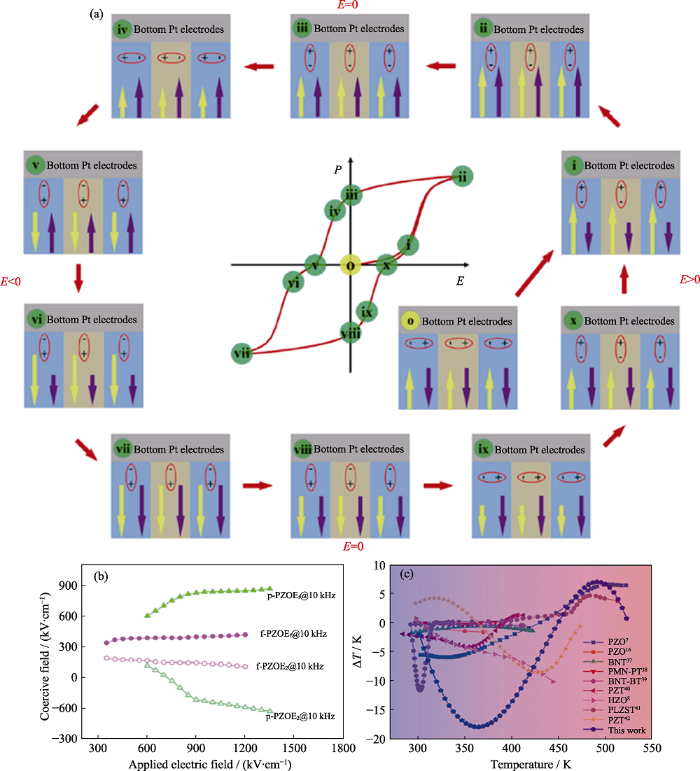

负电卡效应(Negative electrocaloric effect)是一种特殊的电卡效应, 也被称之为异常电卡效应(Abnormal electrocaloric effect)或逆电卡效应(Inverse electrocaloric effect)。与电卡效应相反, 在负电卡效应中, 施加会降低外加电场材料温度, 而去除外加电场则会升高材料温度(将在2.1中详细讨论)。负电卡效应广泛见于反铁电材料、含缺陷铁电材料、多层铁电薄膜、弛豫铁电材料和具有不同铁电相的铁电材料等材料体系中, 它与电卡效应既可以同时存在于同一种材料中, 也可以分别存在于不同材料中。研究人员发现, 将电卡效应和负电卡效应结合, 可有效提高电卡效应的制冷能力[7⇓-9]。北京科技大学白洋课题组[10]在<001>取向的Pb(Mg1/3Nb2/3)0.7Ti0.3O3(PMN-PT)单晶中巧妙设计了一个双制冷循环, 显著提升了电卡效应制冷能力。PMN-PT单晶在低温下表现为稳定的铁电三方相(R相), 在高温下表现为铁电四方相(T相)。在温度和电场的共同作用下, PMN- PT单晶发生R-T相变, 且相变温度取决于外加电场的大小。利用该特性, Li等[11]将PMN-PT单晶中由极化有序-极化无序诱导的电卡效应和R-T相变诱导的负电卡效应相结合(图2(a)), 使电卡效应制冷能力提升了150%。此外, 图2(b)表明, 该双制冷循环的制冷能力可通过调节外加电场的大小和时间间隔得到进一步优化。注意到该双制冷循环的工作温度为85 ℃(图2(b)), 不利于室温下的制冷应用。白洋课题组[10]进一步开发了PbMg0.5W0.5O3电卡制冷材料, 该材料在36 ℃表现出温度变化为1.79 K的正电卡效应, 而在34 ℃表现出温度变化为2.02 K的负电卡效应。这些工作对基于双制冷循环的室温制冷器件设计具有重要意义。

图2

1 负电卡效应的测量方法

电卡效应引起的介质材料温度变化既可以由电场诱导的极化变化间接推算, 也可以通过监测材料的温度或热流变化进行直接测量。

1.1 基于麦克斯韦关系的间接测量法

其中

式中, E1是施加于电介质材料的起始电场(通常是0), E2是终止电场, P是极化, T是温度, ρ是电荷密度, CE是比热容。熵变ΔS和温变ΔT是评价材料电卡效应的最重要参数。

根据麦克斯韦关系, 通过测量电介质材料在不同温度下的极化强度并绘制极化-温度曲线(称为P-T曲线), 可以很容易地估算电卡效应。该方法加速了铁电材料中电卡效应的研究。在某些情况下, 温度升高会导致材料漏电流增大, 此时麦克斯韦方法会计算出假的负电卡效应[14]。使用麦克斯韦方法估算电卡效应, 特别是负电卡效应的估算时, 应特别重视测试高温条件下漏电流, 以避免假的负电卡效应。值得注意的是, 麦克斯韦方法在二级相变材料体系中能够给出较为准确的电卡效应估算, 而在一阶相变和弛豫铁电相变中, 麦克斯韦方法估算的温度变化低于实际情况。

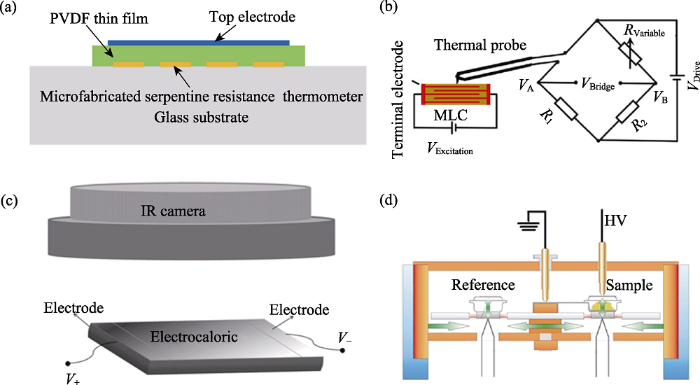

1.2 直接测量法

图3

直接法的精确度依赖于温度测量过程中的绝热条件[17], 否则直接法的结果会被低估。从这个角度来看, 对于沉积在衬底上的铁电薄膜而言, 想要直接、准确地测量电卡效应是相当困难的。薄膜和衬底之间的热扩散相当迅速且很难避免。对于厚度通常为数百纳米的铁电薄膜而言, 其热容相对于衬底来说可以忽略不计。因此薄膜中由电卡效应导致的温度变化将很快被衬底平衡, 难以准确检测。

2 反铁电材料中的负电卡效应

2.1 反铁电体中负电卡效应的成因

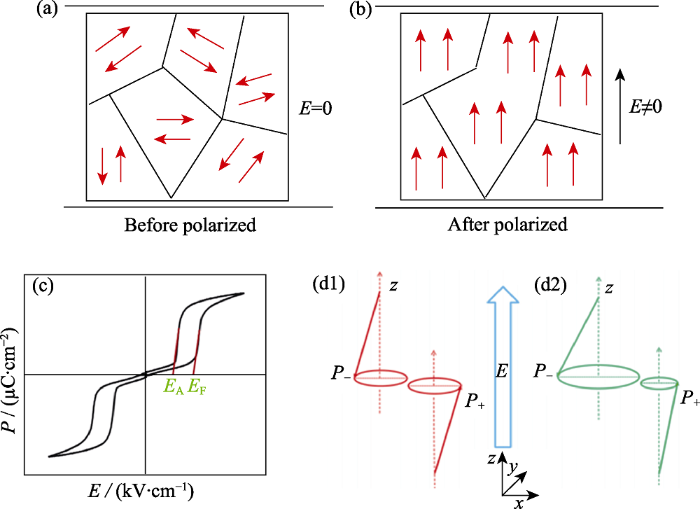

图4

图4

反铁电材料中的电畴、电滞回线和产生负电卡效应的可能机制示意图[27]

Fig. 4

Electric domain and representative hysteresis loop of antiferroelectrics, schematic of a possible mechanism of negative electrocaloric effect in antiferroelectrics[27]

Electric domain of antiferroelectrics (a) before and (b) after being polarized; (c) Representative hysteresis loop of antiferroelectrics; Schematic of a possible mechanism of negative ECE in antiferroelectrics (d1) without any electric field and (d2) under a modest electric field

2.2 PbZrO3基反铁电薄膜中的负电卡效应

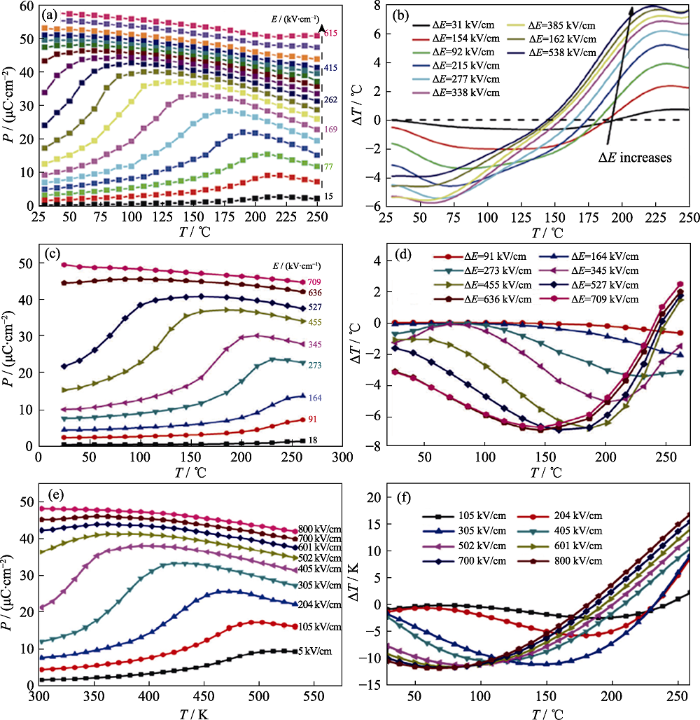

早期反铁电材料中的负电卡效应主要发现于块体材料(包括单晶和陶瓷)中, 由负电卡效应导致的温度变化|ΔT|通常小于2 K[30-31]。2015年, Geng等[21]在(Pb0.97La0.02)(Zr0.95Ti0.05)O3(PLZT)反铁电薄膜中首次报道了|ΔT|超过5 K的显著负电卡效应。他们采用溶胶-凝胶法在Pt(111)/ Ti/SiO2/Si衬底上制备了厚度为650 nm的PLZT薄膜, 并利用XRD验证了薄膜的正交反铁电钙钛矿结构和(100)方向的择优取向生长。图5(a)展示了该薄膜在不同电场下(0~615 kV/cm)的极化曲线(P-T曲线)随温度的变化关系。在较高电场下(E≥415 kV/cm), 薄膜的极化强度随温度升高而减小, 薄膜表现为电场诱导的铁电相特征。当电场低于415 kV/cm时, P-T曲线随温度升高先增大后减小。且随着外加电场增大, P-T曲线的峰位向低温方向移动。这是反铁电材料在电场-温度耦合作用下发生反铁电-铁电相变的结果。基于P-T曲线, 利用麦克斯韦关系计算的薄膜电卡效应结果如图5(b)所示。可以看出, PLZT薄膜在较低的温度范围内(即对应反铁电-铁电相变过程)主要表现为负电卡效应, 而在较高的温度下则主要表现为正电卡效应, 对应铁电-顺电相变。在59 ℃时, 薄膜中由负电卡效应导致的最大温度变化|ΔT|为5.76 K。

图5

图5

PbZrO3基反铁电薄膜中的负电卡效应

Fig. 5

Negative electrocaloric effect in PbZrO3-based antiferroelectric thin films

(a) P-T curves and (b) temperature change of (Pb0.97, La0.02)(Zr0.95,Ti0.05)O3 thin film[21]; (c) P-T curves and (d) temperature change of 4% (molar ratio) Eu doped PbZrO3 thin film[32]; (e) P-T curves and (f) temperature change of 1% Yb (molar ratio) doped PbZrO3 thin film[33]

图6

图6

PbZrO3薄膜中利用界面缺陷增强负电卡效应[29]

Fig. 6

Interface-defect-enhanced negative electrocaloric effect in PbZrO3 thin films[29]

(a) Mechanism of the defect-dipole-suppressed antiferroelectric-ferroelectric phase transition during electric cycling; (b) Antiferroelctric-ferroelectric phase transition field of the PbZrO3 thin films with interface defect (p-PZO) and without interface defect (f-PZO); (c) Comparison of negative ECE in different materials

Colorful figures are available on website

2.3 反铁电块体材料中的负电卡效应

反铁电块体材料工作体积比薄膜高出几个数量级, 在短时间内可视为绝热系统, 这为直接测量反铁电材料中的负电卡效应提供了基础。直接测量法需要较高分辨率的温度计或是热流检测设备, 对反铁电块体材料负电电卡效应的研究也以基于麦克斯韦关系的间接法居多。

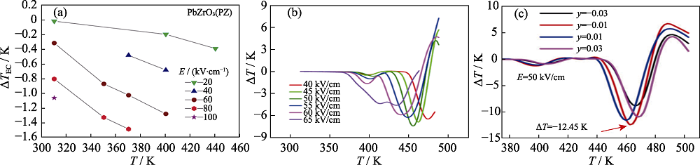

Pirc等[34]首次使用特制的高分辨率热量计测试了PbZrO3陶瓷中的负电卡效应, 发现在低于反铁电相变温度的较宽温度范围内, 负电卡效应导致的温度变化|ΔT|可高达1.6 K, 如图7(a)所示。元素掺杂可以进一步提高PbZrO3陶瓷的负电卡效应。Zhao等[35]通过La和Ti的共掺制备了(Pb0.97,La0.02)(Zr0.95,Ti0.05)O3陶瓷, 并用间接法测量了其负电卡效应, 发现 50 kV/cm的电场引起的最大温度变化|ΔT|为7.47 K, 如图7(b)所示。Niu等[36]发现, 非化学计量比对(Pb0.97,La0.02)(Zr0.95,Ti0.05)O3陶瓷的负电卡效应也有积极的影响, 并合成了(Pb0.97,La0.02)(Zr0.95,Ti0.05)1+yO3陶瓷(y=-0.03, -0.01, 0.01, 0.03), 并用间接法测试了负电卡效应, 发现当y=-0.01时, 所得负电卡效应温度变化最大, 为12.45 K, 如图7(c)所示。

图7

图7

不同电场下PbZrO3、(Pb0.97,La0.02)(Zr0.95,Ti0.05)O3和B位非化学计量比(Pb0.97,La0.02)(Zr0.95,Ti0.05)1+yO3 (y=-0.03, -0.01, 0.01, 0.03)陶瓷的负电卡效应

Fig. 7

Negative electrocaloric effects of PbZrO3, (Pb0.97,La0.02)(Zr0.95,Ti0.05)O3 and B-site nonstoichiometric (Pb0.97,La0.02)(Zr0.95,Ti0.05)1+yO3 (y=-0.03, -0.01, 0.01, 0.03) ceramics under different electric fields

(a) PbZrO3[34]; (b) (Pb0.97,La0.02)(Zr0.95,Ti0.05)O3[35]; (c) B-site nonstoichiometric (Pb0.97,La0.02)(Zr0.95,Ti0.05)1+yO3 (y=-0.03, -0.01, 0.01, 0.03)[36]

Colorful figures are available on website

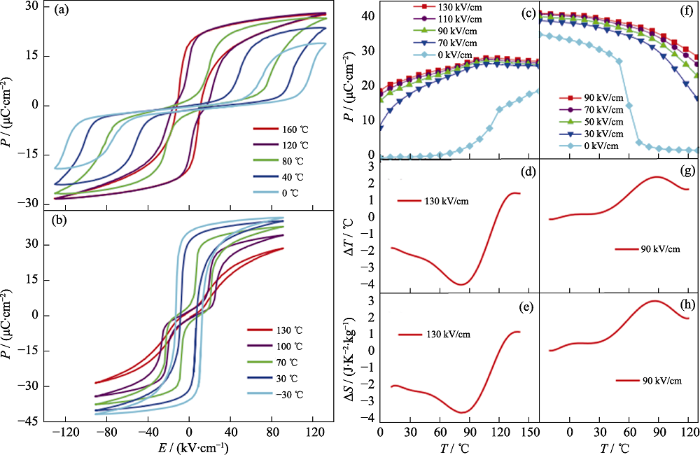

Xu等[37]研究了相变顺序对Pb(Nb, Zr, Sn, Ti)O3陶瓷电卡效应的影响, 制备了Pb0.99Nb0.02- [(Zr0.85Sn0.13Ti0.02)0.98O3(PNZST13/2/2)陶瓷和Pb0.99Nb0.02[(Zr0.57Sn0.43)0.92Ti0.08]0.98O3(PNZST43/8/2)陶瓷, 这两种陶瓷在加热过程中分别具有反铁电-铁电-顺电相变顺序(图8(a))和铁电-反铁电-顺电相变顺序(图8(b))。两种陶瓷中基于间接法测试的负电卡效应结果如图8(c~h)所示, 可以看出, 具有反铁电-铁电-顺电相变顺序的PNZST13/2/2陶瓷主要表现为负电卡效应, 如图8(c~e)所示; 而具有铁电-反铁电-顺电相变顺序的PNZST43/8/2陶瓷主要表现为正电卡效应, 如图8(f~h)所示。此外, PNZST13/2/2陶瓷的最大负电卡效应温度变化(|ΔT|为4 K)在82 ℃附近出现, 与130 kV电场作用下材料的反铁电-铁电相变温度相符。以上结果再次证明, 反铁电材料所展现的负电卡效应, 是材料发生反铁电-铁电相变的结果。

图8

图8

两种PNZST陶瓷在不同温度下测试的电滞回线以及两种陶瓷的P-T曲线、温度变化ΔT和熵变ΔS[37]

Fig. 8

Hysteresis loops of PNZST13/2/2 and PNZST43/8/2 under different temperatures, P-T curves, temperature change ΔT and entropy change ΔS of PNZST13/2/2 and PNZST43/8/2[37]

(a) Hysteresis loops of PNZST13/2/2; (b) Hysteresis loops of PNZST43/8/2; (c-e) P-T curves, temperature change ΔT and entropy change ΔS of PNZST13/2/2; (f-h) P-T curves, temperature change ΔT and entropy change ΔS of PNZST43/8/2

Colorful figures are available on website

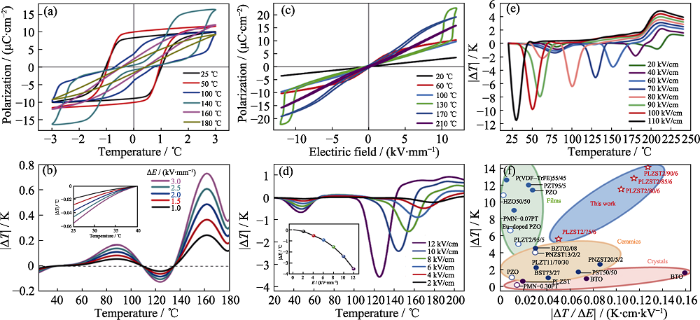

Zhuo等[9,38⇓ -40]主要研究了(Pb,La)(Zr,Sn,Ti)O3块体材料的负电卡效应, 用熔剂法制备了(Pb0.97La0.02) (Zr0.66Sn0.23Ti0.11)O3(PLZST66/23/11)单晶[9]。PLZST66/23/11单晶在室温下表现为反铁电相, 但在1.8 kV/mm的临界电场下可以被极化为铁电相。电场诱导的铁电相处于亚稳态, 当温度升高到退极化温度(70~100 ℃)以上时, 亚稳态铁电相又会恢复到反铁电相。该单晶材料在不同温度下的电滞回线如图9(a)所示, 用间接法测试的负电卡效应如图9(b)所示。结果表明, 在居里温度以下时, 材料主要表现为正电卡效应, 此时负电卡效应相对较小, 室温下的负电卡效应温度变化|ΔT|为0.054 K, 125 ℃下的负电卡效应温度变化|ΔT|为0.12 K。通过改变Sn/Ti的比值, 研究人员进一步合成了(Pb0.97La0.02) (Zr0.66Sn0.27Ti0.07)O3(PLZST66/27/7)单晶[40]。PLZST66/27/7单晶在加热过程中表现出从正交反铁电相到四方反铁电相再到立方顺电相的相变顺序, 这与PLZST66/23/11单晶有很大的不同。PLZST66/ 27/7单晶在不同温度下的电滞回线如图9(c)所示, 用间接方法测试的负电卡效应结果如图9(d)所示, 该单晶在125 ℃表现出温度变化为3.6 K的显著负电卡效应。在(Pb0.97La0.02)(ZrxSn0.94-xTi0.06)O3(x=0.90, 0.85, 0.80, 0.75)陶瓷中, 研究人员进一步优化了(Pb,La)(Zr,Sn,Ti)O3块体材料的负电卡效应[39]。当x=0.8时, (Pb0.97La0.02)(Zr0.80Sn0.14Ti0.06)O3陶瓷在 30 ℃附近表现出显著的负电卡效应, 温变|ΔT|为11.5 K(图9(e)), 满足了中、大规模固态制冷应用的多数关键制冷指标要求。此外, 与其它负电卡效应材料相比, (Pb0.97La0.02)(ZrxSn0.94-xTi0.06)O3陶瓷同时兼具了较高的温度变化和较好的电卡效应效率(|ΔT|/ΔE, 也就是电卡效应的能量效率), 如图9(f)所示, 表明该材料具有非常好的制冷应用前景。

图9

图9

(Pb0.97La0.02)(Zr0.66Sn0.23Ti0.11)O3单晶、(Pb0.97La0.02)(Zr0.66Sn0.27Ti0.07)O3单晶、(Pb0.97La0.02)(Zr0.80Sn0.14Ti0.06)O3陶瓷和(Pb0.97La0.02)(ZrxSn0.94-xTi0.06)O3陶瓷的电卡效应

Fig. 9

Electrocaloric effect of (Pb0.97La0.02)(Zr0.66Sn0.23Ti0.11)O3 single crystal, (Pb0.97La0.02)(Zr0.66Sn0.27Ti0.07)O3 single crystal, (Pb0.97La0.02)(Zr0.80Sn0.14Ti0.06)O3 ceramics, and (Pb0.97La0.02)(ZrxSn0.94-xTi0.06)O3 ceramics

(a, b) Hysteresis loops and temperature change ΔT of the (Pb0.97La0.02)(Zr0.66Sn0.23Ti0.11)O3 single crystal[9]; (c, d) Hysteresis loops and temperature change ΔT of the (Pb0.97La0.02)(Zr0.66Sn0.27Ti0.07)O3 single crystal[40]; (e) Temperature change ΔT of the (Pb0.97La0.02)(Zr0.80Sn0.14Ti0.06)O3 ceramics[39]; (f) Comparison of the temperature change in (Pb0.97La0.02)(ZrxSn0.94-xTi0.06)O3 ceramics with other dielectric materials[39]

Colorful figures are available on website

2.4 其它铁电材料的负电卡效应

3 总结与展望

本文介绍了负电卡效应的定义、测量方法和起源机制, 综述了反铁电薄膜和块体材料中负电卡效应的研究进展。关于反铁电材料中负电卡效应的研究还可以从如下几个方面展开:

1)研究反铁电厚膜的负电卡效应。

有关负电卡效应的研究大多集中在薄膜和块体材料上, 关于厚膜的报道很少。相对于薄膜和块体材料来说, 厚膜能够实现工作体积和击穿电场的兼具, 具有更好的制冷性能。从这个角度来看, 厚膜在集成电路的固态制冷中具有更好的应用前景。

2)优化(Pb,La)(Zr,Sn,Ti)O3材料的负电卡效应。

(Pb,La)(Zr,Sn,Ti)O3陶瓷所呈现的最大负电卡效应温度变化|ΔT|超过10 K, 几乎是已报道的块体材料的最高值, 远高于最近报道的Pb(Sc0.05,Ta0.05)O3陶瓷的温度变化[5]。(Pb,La)(Zr,Sn,Ti)O3陶瓷的工作温度范围相对较窄。通过调控陶瓷成分进一步优化(Pb,La)(Zr,Sn,Ti)O3陶瓷的负电卡效应, 拓宽其工作温度范围, 将使得该材料更具应用价值。

3) 开发基于负电卡效应的固态制冷样机。

目前, 研究人员已经设计了几种基于正电卡效应的制冷样机, 基于负电卡效应的制冷样机并不多见。在正负电卡效应结合的基础上设计更多的制冷循环, 也能显著提高电卡效应的制冷能力和制冷效率。

除此之外, 负电卡效应在低温区间的工作潜力还有待更深入的挖掘[42], 负电卡效应材料的电疲劳性能也有待研究。

参考文献

Electrocaloric materials

Caloric effects in ferroic materials: new concepts for cooling

Electrocaloric cooling materials and devices for zero-global-warming-potential, high-efficiency refrigeration

Large electrocaloric effects in oxide multilayer capacitors over a wide temperature range

Giant electrocaloric effect in thin-film PbZr0.95Ti0.05O3

Pseudo-first-order phase transition for ultrahigh positive/negative electrocaloric effects in perovskite ferroelectrics

Giant negative electrocaloric effects of Hf0.5Zr0.5O2 thin films

Coexistence of multiple positive and negative electrocaloric responses in (Pb,La)(Zr,Sn,Ti)O3 single crystal

Flexible control of positive and negative electrocaloric effects under multiple fields for a giant improvement of cooling capacity

Room-temperature symmetric giant positive and negative electrocaloric effect in PbMg0.5W0.5O3 antiferroelectric ceramic

Large electrocaloric effect in ferroelectric materials

Electrocaloric effect of lead-free bulk ceramics: current status and challenges

Defect-controlled electrocaloric effect in PbZrO3 thin films

Direct characterization of the electrocaloric effects in thin films supported on substrates

High fidelity direct measurement of local electrocaloric effect by scanning thermal microscopy

Direct and indirect measurements on electrocaloric effect: recent developments and perspectives

Strong electrocaloric effect in lead-free 0.65Ba(Zr0.2Ti0.8)O3-0.35(Ba0.7Ca0.3) TiO3 ceramics obtained by direct measurements

Large room-temperature electrocaloric effect in lead-free BaHfxTi1-xO3 ceramics under low electric field

Direct and indirect measurement of electrocaloric effect in lead-free (100-x)Ba(Hf0.2Ti0.8)O3-x(Ba0.7Ca0.3)TiO3 ceramics near multi-phase boundary

Giant negative electrocaloric effect in antiferroelectric La-doped Pb(ZrTi)O3 thin films near room temperature

Positive and negative electrocaloric effect in BaTiO3 in the presence of defect dipoles

Impact of polarization dynamics and charged defects on the electrocaloric response of ferroelectric Pb(Zr,Ti)O3 ceramics

Complex phase transitions and associated electrocaloric effects in different oriented PMN-30PT single crystals under multi-fields of electric field and temperature

Giant pyroelectric energy harvesting and a negative electrocaloric effect in multilayered nanostructures

Positive/negative electrocaloric effect induced by defect dipoles in PZT ferroelectric bilayer thin films

A comprehensive review on the progress of lead zirconate-based antiferroelectric materials

Origins of the inverse electrocaloric effect

Remarkably enhanced negative electrocaloric effect in PbZrO3 thin film by interface engineering

Direct and indirect electrocaloric measurements on <001> PbMg1/3Nb2/3O3-30PbTiO3 single crystals

Abnormal electrocaloric effect of Na0.5Bi0.5TiO3-BaTiO3 lead-free ferroelectric ceramics above room temperature

A giant negative electrocaloric effect in Eu-doped PbZrO3 thin films

Tailoring the negative electrocaloric effect of PbZrO3 antiferroelectric thin films by Yb doping

Negative electrocaloric effect in antiferroelectric PbZrO3

Giant negative electrocaloric effect in anti-ferroelectric (Pb0.97La0.02)(Zr0.95Ti0.05)O3 ceramics

Giant negative electrocaloric effect in B-site non-stoichiometric (Pb0.97La0.02)(Zr0.95Ti0.05)1+yO3 anti-ferroelectric ceramics

Impact of phase transition sequence on the electrocaloric effect in Pb(Nb,Zr,Sn,Ti)O3 ceramics

Temperature induced phase transformations and negative electrocaloric effect in (Pb,La)(Zr,Sn,Ti)O3 antiferroelectric single crystal

Giant negative electrocaloric effect in (Pb,La)(Zr,Sn,Ti)O3 antiferroelectrics near room temperature

Field-induced phase transitions and enhanced double negative electrocaloric effects in (Pb,La)(Zr,Sn,Ti)O3 antiferroelectric single crystal

Giant negative electrocaloric effect over a broad temperature range in lead-free based Bi0.5(K0.15Na0.85)0.05TiO3 relaxor ferroelectric films