气凝胶材料具有较低的密度和热导率, 是目前常用的隔热材料[4,5]。但其力学性能低、脆性大, 且在高温条件下其内部纳米孔结构易坍塌, 难以满足航空航天等领域中瞬间热冲击和长时间承受高温等极端环境应用要求[6]。陶瓷纤维具有耐高温、抗氧化、化学稳定性好和耐机械振动性能好等优点, 既可作为气凝胶材料的增强体和红外遮光剂, 也可单独作为高温隔热材料, 在航空航天、化工冶金和核能发电等领域具有广阔的应用前景[7,8]。相比于传统陶瓷隔热纤维(ϕ≥5 μm), 细化纤维直径制备微纳陶瓷隔热纤维(ϕ<5 μm)不仅有助于降低纤维热导率, 还能改善其力学性能, 近年来受到了广泛研究和关注[9,10,11]。此外, 对微纳陶瓷纤维的组成和结构进行优化, 可进一步改善其隔热性能, 是当前微纳陶瓷隔热纤维研究的重点[12,13,14]。本文结合国内外研究现状, 介绍了微纳陶瓷纤维及其隔热机理。在此基础上, 将微纳陶瓷隔热纤维根据其组成和结构特点分为了微纳陶瓷纤维气凝胶、中空/多孔微纳陶瓷纤维和复合微纳陶瓷纤维三类, 系统综述了这三类纤维的最新研究进展(图1), 并对其存在的问题进行分析总结, 展望了微纳陶瓷隔热纤维未来发展方向。

图1

图1

微纳陶瓷隔热纤维发展趋势示意图

Fig. 1

Schematic of development trend of the micro-nano ceramic fiber

1 微纳陶瓷纤维及其隔热机理

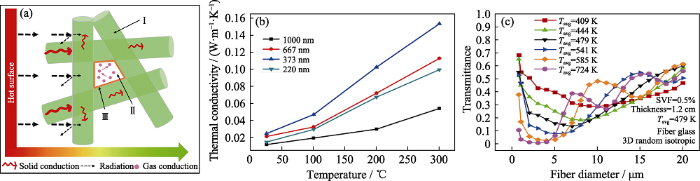

图2

图2

微纳陶瓷纤维热传导示意图(a), 不同温度下直径对碳纳米纤维热导率的影响(b)和不同温度条件下不同直径纤维红外透过率(c)[13,21]

Fig. 2

Schematic of micro-nano fiber heat conduction (a), effect of fiber diameter on thermal conductivity of carbon nanofiber at different testing temperatures (b), and transmittance values for fibers with different fiber diameters at different operating temperatures (c)[13,21]

式中, λg,0为气体分子自身热导率, θ、ψ和β是与库森数相关的参数, Pr为普朗特数, ε为常数, lg,0为气体分子平均自由程, fv为纤维体积分数, d为纤维直径。

由式(1)可以看出, 通过增加气体分子平均自由程、增加纤维体积分数或减小纤维直径可降低有效气体热导率。其中, 增加气体分子平均自由程可通过降低气体压力或使用平均自由程较大的气体替换空气来实现, 但操作工艺复杂, 且成本较高, 在实际应用中可行度不大。因而, 通过增加纤维体积分数和减小纤维直径是降低气体热导率最简单有效的方法。但纤维体积分数过高也会使纤维之间固体热传导增加。因此在纤维隔热材料设计中应综合考虑, 选取合适的纤维体积分数。

式中, Cs为单位体积声子的定容比热容, ${{\nu }_{\text{ph}}}$为声子平均速度, ls为声子平均自由程。对于固体材料而言, 单位体积声子的定容比热容即是材料的比热容与密度的乘积, 声子平均速度近似等于声速。

由式(2)可以看出, 材料的固体热导率与声子的平均自由程紧密相关。声子的平均自由程主要受以下几个因素影响: 晶界和相界面对声子的散射、声子与声子自身之间的散射, 以及材料中的缺陷和杂质等对声子的散射[19]。声子的散射作用越强, 声子的平均自由程越小。一般而言, 声子的平均自由程越小, 材料的固体热导率也越低。因此, 对于陶瓷纤维隔热材料, 可通过增加材料中缺陷浓度、杂质含量和晶界数量等手段来减小声子平均自由程, 进而降低固体热导率。

辐射传热是指温度高于绝对零度的物体通过红外辐射线向外进行热量传递。辐射传热主要取决于材料对红外辐射区电磁波的光学响应。纤维材料的辐射热导率可由公式3表示[16]:

式中, kB为斯蒂芬玻尔兹曼常数, n为材料折射率, T为温度, e为消光系数, ρ为材料密度。消光系数是指红外辐射通过材料后因散射和吸收作用而导致的辐射能量的衰减程度。提高纤维的消光系数, 即红外遮蔽性能, 可有效降低辐射热传导。

综上所述, 微纳陶瓷纤维的隔热性能与其组成和结构密切相关。当纤维体密度相同时, 纤维越 细, 纤维间的孔隙尺寸越小, 对气体分子运动的限制作用越大, 则气体热传导越低。同时, 纤维直径减小, 则纤维间的接触点增多, 热量在纤维中传递时经过的路径更为曲折, 遇到的界面屏障增多, 也使得固体热传导减小。因而, 减小纤维直径有助于提高纤维材料隔热性能。Gibson[20]和Wang[21]分别研究了玻璃纤维和碳纤维(图2(b))直径对其热导率的影响。结果均表明, 随纤维直径减小, 其热导率呈下降趋势。此外, Arambakam等[13]通过理论计算表明, 减小纤维直径还有助于降低纤维的红外透过率(图2(c))。尤其是在高温条件下, 微纳纤维具有较低的红外透过率, 辐射热导率较小。

在众多的陶瓷纤维中, 氧化物陶瓷纤维(ZrO2、SiO2和Al2O3等)以其较好的抗氧化性能和较低的热导率成为目前常用的隔热纤维。Si等[27]制备了SiO2纳米纤维, 并通过在先驱体中加入NaCl实现了纤维之间连接, 有效提高了纤维膜的拉伸强度, 制备的SiO2纤维膜具有较低的热导率(0.0058 W∙m-1·K-1)。Mao等[28]制备了不同直径的ZrO2纳米纤维, 可将其用作高温隔热材料。但SiO2和ZrO2纤维经1200 ℃热处理后, 纤维中晶粒长大明显, 使得纤维膜强度和柔性显著下降, 在更高温度应用受限[27,28]。Al2O3纳米纤维以其较好的耐高温性能而备受关注[29,30]。Zhang等[29]制备了由α-Al2O3纳米片沿[0001]晶面堆叠而成纳米纤维, 由于在纳米片之间形成了MgAl2O4结晶抑制剂, 制备的α-Al2O3纳米纤维展现出较好的耐高温性能(1400 ℃), 在高温隔热领域具有较好的应用前景。

此外, 具有较高红外反射率的陶瓷纤维也可用作高温隔热材料, 有效降低高温条件下辐射热传导。研究人员利用Y2O3自身高红外反射率的特点, 制备了Y2O3纳米纤维, 该纳米纤维在近红外波段内平均红外反射率高达92%, 在高温条件下隔绝辐射传热具有显著优势[33]。

目前, 微纳陶瓷隔热纤维取得了较大发展, 制备了一系列具有较好隔热性能的微纳陶瓷纤维。但当前的微纳陶瓷隔热纤维强度相对较低, 且在高温条件下晶粒长大导致强度下降、脆性增大, 长期工作温度较低。因此, 如何提高微纳陶瓷隔热纤维的强度和耐高温性能是其未来发展中需关注的重点。

2 微纳陶瓷纤维气凝胶

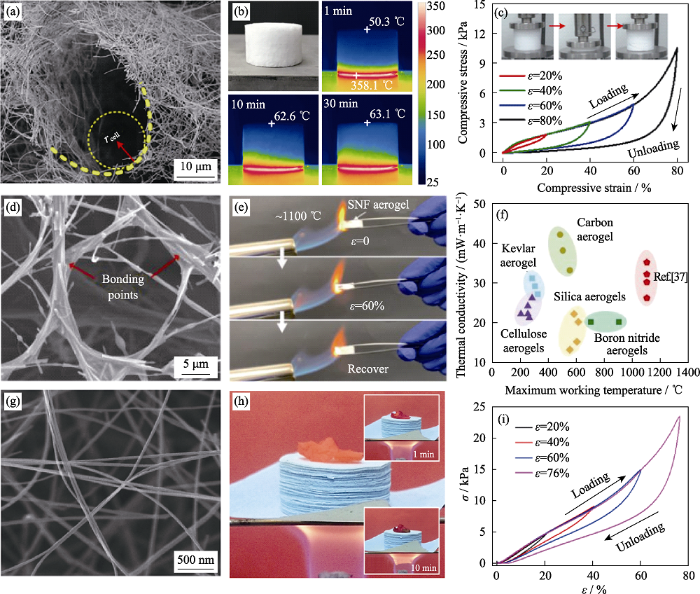

将微纳陶瓷纤维组装成轻质、高孔隙率的纤维气凝胶有助于充分发挥纤维自身柔性和低热导率的特性, 有望克服传统陶瓷隔热纤维脆性大、热导率高等不足, 制备出具有较好力学性能的高效隔热材料, 在高温隔热领域具有较大应用潜力。自东华大学丁彬课题组[34]成功制备出具有良好压缩弹性的SiO2/PAN复合纤维气凝胶以来, 纤维气凝胶引起了学者们的广泛研究。近来, 该课题组以SiO2纳米纤维为基体, 采用硼硅溶胶为粘结剂先驱体, 制备了纤维之间由硼硅酸盐陶瓷连接的SiO2纳米纤维气凝胶(图3(a))。得益于SiO2纳米纤维较低的热导率、较好的柔性和耐高温性能及纤维气凝胶的多孔结构, 该气凝胶表现出了较好的隔热性能(图3(b))和压缩弹性(图3(c))[7]。为进一步降低纤维气凝胶的热导率, 该课题组在纳米纤维气凝胶制备过程中加入了SiO2气凝胶纳米颗粒, 使SiO2气凝胶颗粒均匀分散在纤维之间的孔隙中, 有效降低了纤维气凝胶热导率, 但其压缩弹性不受影响[35,36]。上述纳米纤维气凝胶, 纤维之间均是刚性的陶瓷节点(如硅硼酸盐和SiO2)连接。这使得其在长期使用过程中弹性降低, 脆性增大。为解决这一问题, 该组研究者采用硅溶胶作为纤维之间的节点(图3(d)), 实现了纤维之间的弹性连接, 制备的SiO2纳米纤维气凝胶可以经受一百万次压缩测试而压缩弹性无明显下降, 且能在较宽的温度范围内(-196~1100 ℃)保持优异的压缩弹性(图3(e))。该纤维气凝胶最高使用温度可达1100 ℃, 明显优于其他气凝胶材料(图3(f))[37]。但由于SiO2纤维自身耐高温性能限制(<1200 ℃), SiO2纳米纤维气凝胶不能满足更高温度应用要求。

图3

(a)SEM照片; (b)隔热性能测试红外成像照片; (c)压缩应力应变图; SiO2纳米纤维气凝胶的(d)SEM照片, (e)高温条件下压缩性能测试图和(f)热导率对比图; (g)SiC纳米纤维气凝胶的SEM照片, (h)隔热性能测试光学照片和(i)压缩应力应变曲线

Fig. 3

SiO2 and SiC nanofiber aerogel[7-8,37]

(a,d) SEM images of SiO2 nanofiber aerogel; (b) Infrared thermal image; (c) Compression stress-strain; (e) Compression test under high temperature; (f) Thermal conductivity comparison; (g) SEM image of SiC nanofiber aerogel; (h) Optical photo of thermal insulation performance of SiC nanofiber aerogel; (i) Compression stress-strain of SiC nanofiber aerogel

尽管, 目前已制备出了多种微纳陶瓷纤维气凝胶, 纤维材料的隔热性能有了一定提高。但纤维气凝胶内部孔洞尺寸较大, 气体热导率较高。减小其内部孔洞尺寸, 有望进一步提高其隔热性能, 在未来研究中值得关注。此外, 纤维自身的一些不足(如强度低和耐高温性能不佳等), 也是限制纤维气凝胶在高温隔热领域应用的关键问题。

3 中空/多孔微纳陶瓷纤维

3.1 中空微纳陶瓷纤维

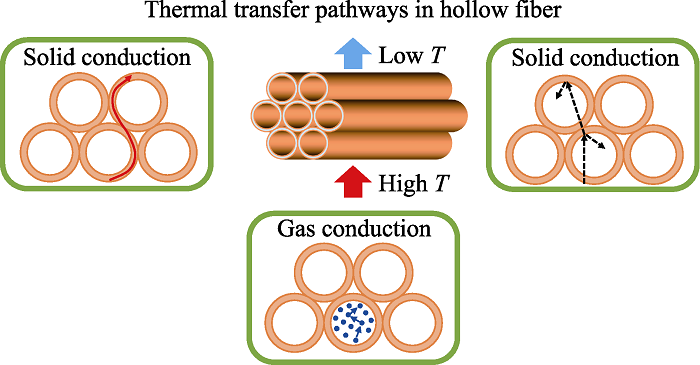

在中空纤维中, 固体传热仅能在管壁传输, 因而中空纤维固体热导率较低。此外, 纤维的空心结构还对其内部的气体分子具有限制作用。尤其当中空尺寸小于气体分子的平均自由程时, 气体分子的自由运动被强烈限制, 气体热导率较小[42]。Brendel等[43]通过理论计算表明, 在高温条件下, 中空纤维具有更大的红外辐射线散射截面。这可能是由于中空结构增加了气固相界面, 红外辐射线通过两相界面时发生了较多次数的反射、折射和吸收, 辐射传热减小。中空纤维热传输示意图如图4所示。因而, 相比于实芯纤维, 将纤维设计为中空结构有助于进一步降低其热导率, 提高纤维材料的隔热性能。目前, 制备中空微纳陶瓷隔热纤维的方法主要有模板法和静电纺丝法两种。

图4

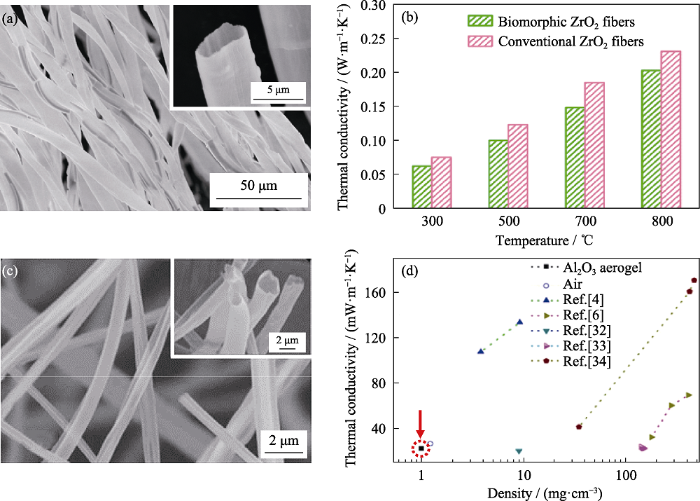

图5

(a)中空ZrO2纤维表面和截面SEM照片; (b)中空ZrO2纤维与传统实芯ZrO2纤维热导率对比; (c)中空Al2O3纤维表面和截面SEM照片; (d)中空Al2O3纤维气凝胶与其他材料热导率对比

Fig. 5

Hollow micro-nano ceramic fiber[44,48]

(a) Surface and cross section SEM images of hollow ZrO2 fiber; (b) Comparison of thermal conductivity between hollow ZrO2 fiber and traditional ZrO2 fiber; (c) Surface and cross section SEM images of hollow Al2O3 fiber; (d) Thermal conductivity comparison among hollow Al2O3 fiber aerogel and other materials

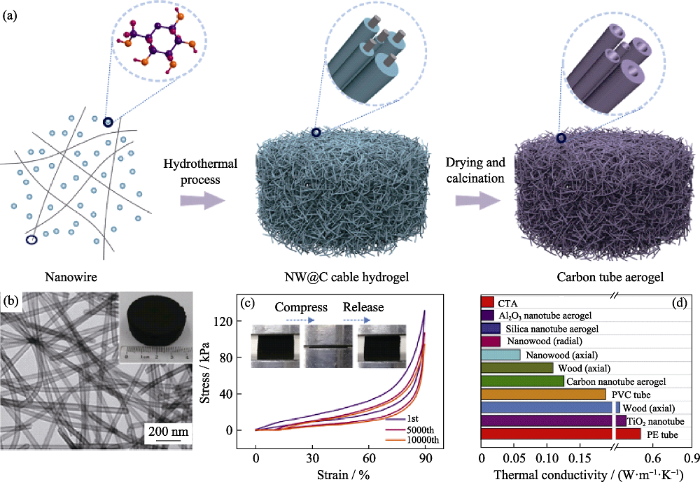

受北极熊中空结构的毛发具有较好的防寒保温性能的启发。Zhan等[49]采用直径较细(~35 nm), 且以具有较好分散性的碲纳米线为模板, 通过水热反应结合高温烧成工艺制备了中空碳纳米纤维(图6(a-b))。研究发现, 这种中空纳米纤维构成的气凝胶表现出了较好的压缩弹性(图6(c))和较低的热导率(图6(d))。但由于碳材料特性的限制, 其在空气中应用温度较低(<450 ℃)。Du等[50]制备了中空SiO2纳米纤维, 由中空SiO2纳米纤维构成的气凝胶在室温下具有较低的热导率(0.030~0.033 W·m-1·K-1)。但由于SiO2材料的红外透过性较强, 该纤维气凝胶在高温条件下辐射热导率较高。

图6

图6

中空碳纳米纤维气凝胶[49]

(a)制备流程示意图; (b)TEM照片; (c)中空碳纳米纤维气凝胶经10000次压缩应力应变曲线及压缩测试图; (d)中空碳纳米纤维气凝胶与其他中空材料热导率比较

Fig. 6

Hollow carbon micro-nano fiber aerogel[49]

(a) Schematic illustration of the fabrication processes; (b) TEM image; (c) Stress-strain curves for 10000 cycles; (d) Thermal conductivity comparison among different hollow-structured thermally insulating materials

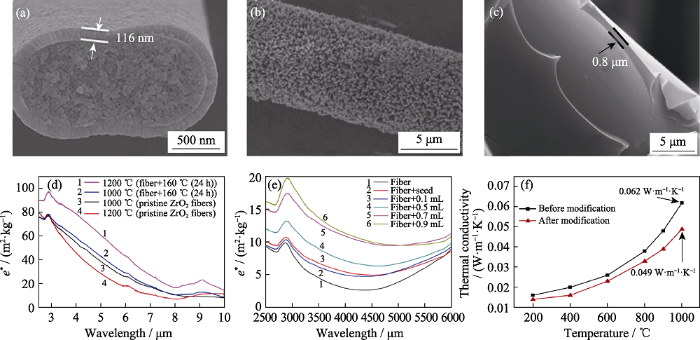

静电纺丝法制备中空纤维具有纤维直径小和形貌结构易调控等优点, 是制备微纳中空陶瓷纤维的重要方法。Liu等[51]采用同轴静电纺丝法制备了氮掺杂的中空SiC纤维(图7(a))。研究发现, 纤维是由SiOxCy、SiCxOyNz和自由碳多相组成, 其独特的组成及中空结构使其表现出了优异的隔热性能, 在600 ℃下热导率仅为0.039~0.042 W·m-1·K-1(图7(d))。最近, 本课题组采用微乳液静电纺丝法制备了中空SiC纤维(图7(b))。研究发现, 中空SiC纤维红外消光系数明显高于实芯SiC纤维, 在800 ℃下中空SiC纤维热导率为~0.1049 W·m-1·K-1, 比实芯纤维热导率下降了约71%(图7(e))[52]。

图7

(a)氮掺杂中空SiC纤维SEM照片; (b)中空SiC纤维SEM照片; (c)多孔SiO2-TiO2纤维SEM照片; (d)氮掺杂中空SiC纤维热导率和热扩散系数; (e)中空和实芯SiC纤维热导率; (f)多孔SiO2-ZrO2纤维SEM照片

Fig. 7

Hollow and porous micro-nano fiber[51-52,54]

(a) SEM image of N-doped hollow SiC fiber; (b) SEM image of hollow SiC fiber; (c)SEM image of porous SiO2-TiO2 fiber; (d) Thermal conductivities and thermal diffusivities of N-doped hollow SiC fiber; (e) Thermal conductivities of solid SiC fiber and hollow SiC fiber; (f) SEM image of SiO2-ZrO2 fiber

目前, 采用模板法和静电纺丝法已制备出了多种中空微纳陶瓷隔热纤维, 并取得了较好的隔热效果。但由于纤维的中空结构极大地增加了纤维的比表面积, 使得纤维表面存在缺陷的可能性增加。因而, 目前制备的中空陶瓷纤维强度较低。在未来优化中空纤维隔热性能的同时, 如何有效提高其强度也是需关注的重点。

3.2 多孔微纳陶瓷纤维

目前, 多孔微纳陶瓷隔热纤维正处于新兴阶段, 制备具有较好力学性能的多孔微纳陶瓷隔热纤维还存在着较大挑战, 是其未来发展中面临的难题。此外, 孔结构与隔热性能之间的构效关系等科学问题还有待进一步研究。且对于多孔纤维的隔热机制研究还不充分, 在未来研究中也需重点关注。

4 复合微纳陶瓷纤维

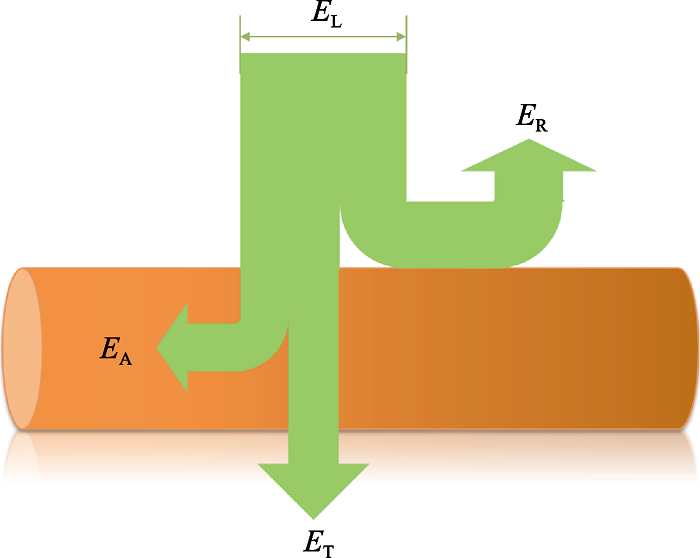

当红外辐射线(总能量EL)传递到纤维表面时会发生反射(反射能量ER)、吸收(吸收能量EA)和透过(透过能量ET), 如图8所示。由能量守恒定律可知, 只有增加对红外辐射线的反射和吸收才能降低透过的红外辐射能量。目前, 降低纤维的红外透过性主要有两种方法: 1)在纤维表面构筑高反射率涂层, 提高纤维对红外辐射线的反射能力; 2)在纤维中复合具有较高红外反射和吸收能力的遮光剂相。

图8

图8

红外辐射线在纤维中传输示意图

Fig. 8

Schematic of infrared radiation transmission in the fiber

4.1 高反射涂层复合微纳陶瓷纤维

目前, 在纤维表面构筑高反射率的涂层种类主要有TiO2、In2O3、CeO2和SiC等[62,63,64,65,66,67,68], 如表1所示。Hass等[64]在Al2O3纤维表面分别制备了TiO2、TiO2/SiO2/TiO2和TiO2-Pt纳米颗粒复合薄膜。结果表明, 在纤维表面构筑TiO2/SiO2/TiO2多层反射膜, 具有较好的红外反射性能, 有效降低了红外透过性。与无涂层纤维相比, 其消光系数提高了近40%。此外, 在SiO2纤维表面制备掺锡氧化铟(ITO)反射膜和ITO/Ag/ITO多层反射膜也可有效降低纤维的红外透过率[59,65]。Gan等[66]采用水热反应法在ZrO2纤维表面制备了具有较高反射率的CeO2涂层(图9(a))。

表1 高反射率涂层纤维制备方法及涂层种类

Table 1

| Fiber | Method | Infrared reflectance layer | Coating thickness/μm | Ref. |

|---|---|---|---|---|

| Al2O3 | Dip-coating | TiO2, TiO2/SiO2/TiO2, TiO2-Pt | - | [64] |

| SiO2 | Dip-coating | ITO, ITO/Ag/ITO | ~0.2 | [60,65] |

| ZrO2 | Hydrothermal | CeO2 | 52-214 | [66] |

| Mullite | Hydrothermal | TiO2 | - | [67] |

| ZrO2 | Hydrothermal | TiO2 | 89-236 | [68] |

| Mullite | Dip-coating | SiC | ~0.8 | [69] |

图9

(a)CeO2/ZrO2纤维SEM照片; (b)TiO2/莫来石纤维SEM照片; (c)SiC/莫来石纤维表面SEM照片; (d)ZrO2纤维和CeO2/ZrO2纤维的比消光系数对比; (e)莫来石纤维和TiO2/莫来石纤维比消光系数对比; (f)莫来石纤维和SiC/莫来石纤维增强气凝胶复合材料热导率对比

Fig. 9

High-reflectivity coated fiber[66-67,69]

(a) SEM image of ZrO2 fiber with CeO2 coating; (b) SEM image of mullite fiber with TiO2 coating; (c) SEM image of mullite fiber with SiC coating; (d) Specific extinction coefficients comparison of ZrO2 fiber and CeO2/ZrO2 fiber; (e) Specific extinction coefficients comparison of mullite fiber and TiO2/mullite fiber; (f) Thermal conductivity comparison of mullite fiber and SiC/mullite fiber reinforced aerogel composite

目前, 通过在纤维表面构筑高反射涂层, 使得氧化物陶瓷纤维的红外遮蔽性能有了一定提高。但由于部分高反射率材料, 其自身固体热导率较高(如TiO2和SiC等)。将其作为红外反射涂层后, 会使纤维之间的固体热传导增加, 综合热导率降低不明显或反而增大。因此, 在选择反射涂层时也需考虑其固体热导率, 尽量选用固体热导率较低但反射率较高的材料作为反射涂层。此外, 由于涂层与纤维之间结合较弱, 在长期使用过程中涂层易脱落, 这也是未来涂层纤维发展需解决的问题。

4.2 复相微纳陶瓷纤维

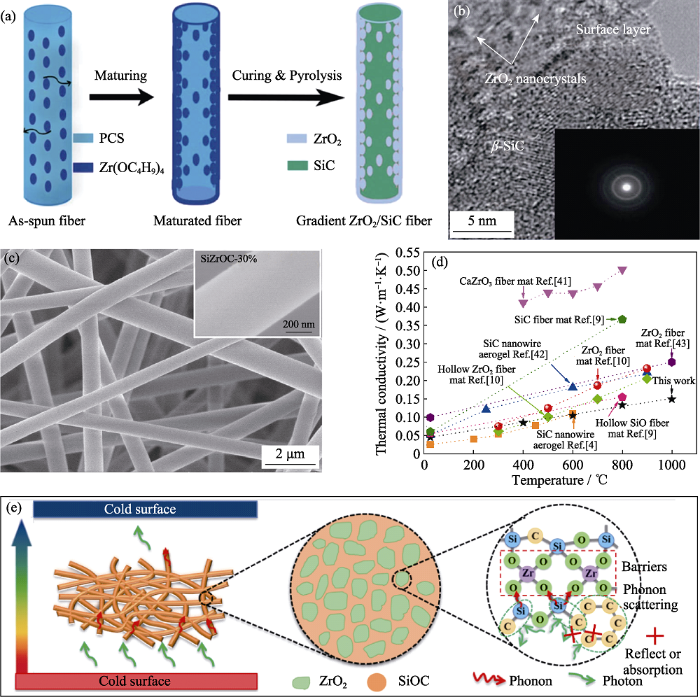

除了在纤维表面构筑高反射涂层外, 将具有低固体热导率和高红外遮蔽性能的材料复合, 设计复相微纳陶瓷纤维, 有望制备出兼具低固体热导率和高红外遮蔽性能的新型微纳陶瓷隔热纤维。目前, 制备的复相微纳陶瓷纤维主要有两种, 两相复合纤维和多元均相复合纤维。前期, 本课题组[70]通过控制熟化工艺, 制备了表面富ZrO2层的ZrO2/SiC两相复合纤维(图10(a,b))。纤维表面的ZrO2层具有较低的固体热导率, 有助于降低纤维之间固体热传导。同时, 芯部的SiC具有较好的红外遮蔽性能, 能有效降低辐射热传输。制备的ZrO2/SiC复相纤维是较理想的高温隔热材料[70]。近期, 本课题组设计制备了多元复相SiZrOC纳米纤维(图10(c))[14]。研究发现, 纤维是由SiC、SiO2、自由碳和ZrO2多相组成。纤维内部的复杂多相结构使其内部存在大量相界面, 增加了声子-界面散射, 纤维固体热导率较低。同时, 纤维内部的SiC和自由碳具有较高的红外反射和吸收能力, 有效降低了辐射热传导, 因而制备的SiZrOC纤维在高温条件下具有较低的热导率(图10(d)), 纤维隔热机理示意图如图10(e)所示。因此, 设计复相微纳陶瓷隔热纤维有望制备出高效隔热纤维, 这也是未来微纳陶瓷隔热纤维发展的重要方向之一。

图10

(a)ZrO2/SiC纤维制备示意图; (b) ZrO2/SiC纤维TEM照片; (c) SiZrOC纤维SEM照片; (d) SiZrOC纤维热导率对比; (e) SiZrOC纤维隔热机理示意图

Fig. 10

Composite micro-nano ceramic fiber[14,70]

(a) Schematic illustration of the preparation of ZrO2/SiC fiber; (b) TEM images of ZrO2/SiC fiber; (c) SEM images of SiZrOC fiber; (d) Thermal conductivity comparison of SiZrOC fiber with other ceramic fibers; (e) Schematic illustration of thermal insulation mechanisms of SiZrOC fibers

通过在纤维表面构筑高反射涂层或在纤维内部复合遮光剂相, 有效提高了微纳陶瓷纤维的高温隔热性能。相比于传统陶瓷纤维和气凝胶隔热材料, 复合微纳陶瓷纤维较佳的力学性能和优异的红外遮蔽性能, 使其在高温隔热领域具有显著优势。

5 总结及展望

微纳陶瓷隔热纤维以其较佳的耐高温和隔热性能, 在高温隔热领域具有广阔的应用前景。通过优化纤维的组成和结构可进一步改善其隔热性能, 是当前微纳陶瓷隔热纤维研究的重点。尽管目前微纳 陶瓷纤维的隔热性能有了一定提高, 但仍面临诸多挑战:

1)目前制备的微纳陶瓷隔热纤维强度相对较 低, 尤其是对于中空和多孔结构纤维。如何有效提高纤维的强度是未来微纳陶瓷隔热纤维发展需关注的重点。

2)对于广泛应用的氧化物陶瓷纤维, 其在高温条件下晶粒长大, 致使纤维易脆, 且强度下降显著。因此, 在优化纤维隔热性能的同时, 提高其耐高温性能也是未来必须解决的问题。

3)多孔微纳陶瓷隔热纤维处于新兴阶段, 结合理论计算和实验手段, 阐明其高温隔热机制, 对于指导纤维的结构设计和提高其隔热性能具有重要的理论指导意义。

4)目前, 制备微纳陶瓷隔热纤维生产效率较低, 难以满足实际工业应用需求。开发高效的微纳陶瓷隔热纤维规模化生产方法是推动其在隔热领域广泛应用的关键问题。

参考文献

Ceramic-based thermal protection materials for aerospace vehicle

Technologies for thermal protection systems applied on reusable launcher

Research progress on lightweight and high strength heat-insulating porous ceramics

Silica aerogel composites with embedded fibres: a review on their preparation, properties and applications

Progress on the preparation of SiO2 aerogel composites by ambient pressure drying technique

Double-negative-index ceramic aerogels for thermal superinsulation

Ceramic aerogels are attractive for thermal insulation but plagued by poor mechanical stability and degradation under thermal shock. In this study, we designed and synthesized hyperbolic architectured ceramic aerogels with nanolayered double-pane walls with a negative Poisson's ratio (-0.25) and a negative linear thermal expansion coefficient (-1.8 x 10(-6) per degrees C). Our aerogels display robust mechanical and thermal stability and feature ultralow densities down to ~0.1 milligram per cubic centimeter, superelasticity up to 95%, and near-zero strength loss after sharp thermal shocks (275 degrees C per second) or intense thermal stress at 1400 degrees C, as well as ultralow thermal conductivity in vacuum [~2.4 milliwatts per meter-kelvin (mW/m.K)] and in air (~20 mW/m.K). This robust material system is ideal for thermal superinsulation under extreme conditions, such as those encountered by spacecraft.

Ultralight and fire-resistant ceramic nanofibrous aerogels with temperature-invariant superelasticity

Ultralight, recoverable, and high-temperature-resistant SiC nanowire aerogel

Ultralight ceramic aerogels with the property combination of recoverable compressibility and excellent high-temperature stability are attractive for use in harsh environments. However, conventional ceramic aerogels are usually constructed by oxide ceramic nanoparticles, and their practical applications have always been limited by the brittle nature of ceramics and volume shrinkage at high temperature. Silicon carbide (SiC) nanowire offers the integrated properties of elasticity and flexibility of one-dimensional (1D) nanomaterials and superior high-temperature thermal and chemical stability of SiC ceramics, which makes it a promising building block for compressible ceramic nanowire aerogels (NWAs). Here, we report the fabrication and properties of a highly porous three-dimensional (3D) SiC NWA assembled by a large number of interweaving 3C-SiC nanowires of 20-50 nm diameter and tens to hundreds of micrometers in length. The SiC NWA possesses ultralow density ( approximately 5 mg cm(-3)), excellent mechanical properties of large recoverable compression strain (>70%) and fatigue resistance, refractory property, oxidation and high-temperature resistance, and thermal insulating property (0.026 W m(-1) K(-1) at room temperature in N2). When used as absorbents, the SiC NWAs exhibit an adsorption selectivity of low-viscosity organic solvents with high absorption capacity (130-237 g g(-1)). The successful fabrication of such an attractive material may provide promising perspectives to the design and fabrication of other compressible and multifunctional ceramic NWAs.

Thermal conductivity of polyacrylonitrile nanofibre web in various nanofibre diameters and surface densities

Polymer template synthesis of flexible BaTiO3 Crystal nanofibers

Polymer template synthesis of soft, light, and robust oxide ceramic films

Oxide ceramic materials underpin a wide variety of technologies. However, the inherent fragility of these materials limits their use in emerging fields like wearable electronics and soft energy storage devices. Here, we develop a sol-gel electrospinning technique followed by calcination to create a range of oxide ceramic nanofiber films that exhibit significant softness without fragility after various deformations. This approach causes the ceramic crystals to fuse together at a low temperature during their growth within the polymer nanofiber templates. All the synthesized ceramic films, from SiO2 to BaTiO3, Li0.33La0.56TiO3, and Li7La3Zr2O12, have silk-like softness of <31 mN, low density of <0.36 g/cm(3) and robust fire resistance to 1,000 degrees C. Fabricated separators based on these films display large electrolyte uptakes of >900% and high thermal insulation performance, enhancing the rate capability and safety of lithium batteries. The reported method allows scalable synthesis of soft oxide ceramic films with properties appealing for applications.

A simple simulation method for designing fibrous insulation materials

Dual-scale 3-D approach for modeling radiative heat transfer in fibrous insulations

Flexible and thermal-stable SiZrOC nanofiber membranes with low thermal conductivity at high-temperature

Heat transfer modeling for rigid high-temperature fibrous insulation

Hollow structured materials for thermal insulation

Modeling heat transfer with micro-scale natural convection in fibrous insulation

Combined heat transfer in high-porosity high-temperature fibrous insulation: theory and experimental validation

Advanced materials for high- temperature thermal transport

Application of nanofiber technology to nonwoven thermal insulation

Effect of fiber diameter on thermal conductivity of the electrospun carbon nanofiber mats

Transformation of oxide ceramic textiles from insulation to conduction at room temperature

Science Advances,

Mechanical evaluations of mullite fibrous ceramics processed by filtration and in situ pyrolysis of organic precursor

Preparation and characterization of the three-dimensional network mullite porous fibrous materials by pressure and freeze-casting method

Electrospinning and electrospun nanofibers: methods, materials, and applications

Electrospinning is a versatile and viable technique for generating ultrathin fibers. Remarkable progress has been made with regard to the development of electrospinning methods and engineering of electrospun nanofibers to suit or enable various applications. We aim to provide a comprehensive overview of electrospinning, including the principle, methods, materials, and applications. We begin with a brief introduction to the early history of electrospinning, followed by discussion of its principle and typical apparatus. We then discuss its renaissance over the past two decades as a powerful technology for the production of nanofibers with diversified compositions, structures, and properties. Afterward, we discuss the applications of electrospun nanofibers, including their use as

Enhanced mechanical properties of amorphous SiOC nanofibrous membrane through in situ embedding nanoparticles

Silica nanofibrous membranes with ultra-softness and enhanced tensile strength for thermal insulation

Flexible and highly temperature resistant polynanocrystalline zirconia nanofibrous membranes designed for air filtration

Fabrication of flexible α-alumina fibers composed of nanosheets

Fabrication and mechanical properties of flexible gamma-Al2O3 nanofibrous membranes

Formation of barium zirconate fibers for high-temperature thermal insulation applications

Electrospun fabrication, excellent high-temperature thermal insulation and alkali resistance performance of calcium zirconate fiber

Flexible, controllable, and high-strength near-infrared reflective Y2O3 nanofiber membrane by electrospinning a polyacetylacetone-yttrium precursor

Ultralight nanofibre-assembled cellular aerogels with superelasticity and multifunctionality

Temperature-invariant superelastic, fatigue resistant, and binary-network structured silica nanofibrous aerogels for thermal superinsulation

Hierarchical cellular structured ceramic nanofibrous aerogels with temperature-invariant superelasticity for thermal insulation

Silica aerogels are attractive for thermal insulation due to their low thermal conductivity and good heat resistance performance. However, the fabrication of silica aerogels with temperature-invariant superelasticity and ultralow thermal conductivity has remained extremely challenging. Herein, we designed and synthesized a hierarchical cellular structured silica nanofibrous aerogel by using electrospun SiO2 nanofibers (SNFs) and SiO2 nanoparticle aerogels (SNAs) as the matrix and SiO2 sol as the high-temperature nanoglue. This pathway leads to the intrinsically random deposited SNFs assembling into a fibrous cellular structure, and the SNAs are evenly distributed on the fibrous cell wall. The unique hierarchical cellular structure of the ceramic nanofibrous aerogels endows it with integrated performances of the ultralow density of approximately 0.2 mg cm(-3), negative Poisson's ratio, ultralow thermal conductivity (23.27 mW m(-1) K(-1)), temperature-invariant superelasticity from -196 to 1100 degrees C, and editable shapes on a large scale. These favorable multifeatures present the aerogels ideal for thermal insulation in industrial, aerospace, and even extreme environmental conditions.

In situ synthesis of biomimetic silica nanofibrous aerogels with temperature-invariant superelasticity over one million compressions

Resilient and compressible three-dimensional nanomaterials comprising polymers, carbon, and metals have been prepared in diverse forms. However, the creation of thermostable elastic ceramic aerogels remains an enormous challenge. We demonstrate an in situ synthesis strategy to develop biomimetic silica nanofibrous (SNF) aerogels with superelasticity by integrating flexible electrospun silica nanofibers and rubber-like Si-O-Si bonding networks. The stable bonding structure among nanofibers is in situ constructed along with a fibrous freeze-shaping process. The resultant SNF aerogels exhibit integrated properties of ultralow density (>0.25 mg cm(-3) ), temperature-invariant superelasticity up to 1100 degrees C, and robust fatigue resistance over one million compressions. The ceramic nature also endows the aerogels with fire resistance and ultralow thermal conductivity. The successful synthesis of the SNF aerogels opens new pathways for the design of superelastic ceramic aerogels in a structurally adaptive and scalable form.

Microstructural evolution of mullite nanofibrous aerogels with different ice crystal growth inhibitors

Superelastic hard carbon nanofiber aerogels

Temperature-invariant superelastic and fatigue resistant carbon nanofiber aerogels

Ultralight, compressible and multifunctional carbon aerogels based on natural tubular cellulose

Understanding thermal insulation in porous, particulate materials

Heat transfer properties of hollow-fiber insulation materials at high temperatures

Amorphous silicon and silicates-stabilized ZrO2 hollow fiber with low thermal conductivity and high phase stability derived from a cogon template

Preparation and heat-insulating property of the bio-inspired ZrO2 fibers based on the silk template

Natural silk fibers were used as the template to prepare biomorphic ZrO2 fibers. Silk fibers were first immersed into a Zr(NO3)(4) solution and then sintered in air at high temperatures to produce the final ZrO2 fibers. Their microstructures, phases, synthesis process, infrared absorption spectra and thermal conductivity were analyzed. The results show that these synthesized fibers retained the morphologies of silk faithfully. These ZrO2 fibers also obtained the ability of absorbing infrared from the silk, so that they possessed better heat-insulating property than the traditional ZrO2 fibers. (c) 2012 Elsevier Ltd and Techna Group S.r.l.

Synthesis and heat-insulating properties of yttria-stabilized ZrO2 hollow fibers derived from a ceiba template

Preparation and heat-insulating properties of biomorphic ZrO2 hollow fibers derived from a cotton template

Ultralight and resilient Al2O3 nanotube aerogels with low thermal conductivity

Biomimetic carbon tube aerogel enables super-elasticity and thermal insulation

Multifunctional silica nanotube aerogels inspired by polar bear hair for light management and thermal insulation

Highly flexible, erosion resistant and nitrogen doped hollow SiC fibrous mats for high temperature thermal insulators

Fabrication of hollow SiC ultrafine fibers by single-nozzle electrospinning for high-temperature thermal insulation application

Low thermal conductivity carbon fibrous composite nanomaterial enabled by multi-scale porous structure

Self-assembly of ultralight and compressible inorganic sponges with hierarchical porosity by electrospinning

Nanofibrous Kevlar aerogel threads for thermal insulation in harsh environments

Aerogel with low density, high porosity, and large surface area is a promising structure for the next generation of high-performance thermal insulation fibers and textiles. However, aerogel fibers suffer from weak mechanical properties or complex fabricating processes. Herein, a facile wet-spinning approach for fabricating nanofibrous Kevlar (KNF) aerogel threads ( i.e., aerogel fibers) with high thermal insulation under extreme environments is demonstrated. The aerogel fibers made from nanofibrous Kevlar render a high specific surface area (240 m(2)/g) and wide-temperature thermal stability. The flexible and strong KNF aerogel fibers are woven into textiles to illustrate the excellent thermal insulation property under extreme temperature (-196 or +300 degrees C) and at room temperature. COMSOL simulation is applied to calculate the thermal conductivity of a single aerogel fiber and find an effective way to improve the thermal insulation property of the aerogel fiber. Furthermore, a series of functionalized fibers or textiles based on KNF aerogel fibers, such as phase-change fibers, conductive fibers, and hydrophobic textiles, have been prepared. Such KNF aerogel fibers represent a promising direction for the next generation of high-performance fibrous thermal-insulation materials.

Nanocellulose aerogel-based porous coaxial fibers for thermal insulation

Continuous, strong, porous silk firoin-based aerogel fibers toward textile thermal insulation

Prediction and optimization of radiative thermal properties of ultrafine fibrous insulations

Morphology and characterization of ITO-Ag-ITO films on fibers by layer-by-layer method

Radiative characteristics of opacifier-loaded silica aerogel composites

Conduction and radiation heat transfer in high-porosity fiber thermal insulation

Examination of the radiative properties of coated silica fibers

Reduction of radiative heat transfer in thermal insulations by use of dielectric coated fibers

Reflective Coating on Fibrous Insulation for Reduced Heat Transfer

ITO coated quartz fibers for heat radiative applications

Preparation of a CeO2-nanoparticle thermal radiation shield coating on ZrO2 fibers via a hydrothermal method

Preparations of TiO2 nanocrystal coating layers with various morphologies on mullite fibers for infrared opacifier application

TiO2 nanorods coatings (TONC) were prepared on the surface of Mullite fibers by seed-hydrothermal method, which were designed as infrared pacifier. The influences of different tetrabutyl-titanate amount on the TONC morphologies, crystalline and optical properties were investigated. Effective specific extinction (e*) was used to characterize their masking ability. The TONC morphologies could be adjusted from nanoparticles to nanorods, which had direct influence on their optical properties. In the 3 mu m-6 mu m range of infrared light, e* of TONC could be improved up to 2-4 folds compared with that of Mullite fibers. Present study indicated TONC is a promising infrared opacifier. Crown Copyright (C) 2011 Published by Elsevier B.V.

Hydrothermally grown uniform TiO2 coatings on ZrO2 fibers and their infrared reflective and thermal conductive properties

Infrared-opacified Al2O3-SiO2 aerogel composites reinforced by SiC-coated mullite fibers for thermal insulations

Large-scale, flexible and high-temperature resistant ZrO2/SiC ultrafine fibers with a radial gradient composition

Novel ultrafine ZrO2/SiC fibers with a radial gradient composition were prepared by a simple electrospinning technique combined with subsequent thermal treatment. The as-prepared ZrO2/SiC fibers were analyzed by a combination of characterizations. It was found that the content of Zr was gradually reduced from the surface to the inside of the ZrO2/SiC fiber. The gradient composition was formed in situ during maturation rather than a subsequent pyrolysis process. The ZrO2/SiC fibers with a gradient composition and different crystalline structures were obtained by pyrolysis in Ar at different temperatures. The gradient ZrO2 composition endows the fabricated fibers with better high-temperature stability (>1800 degrees C) and much superior erosion resistance over normal SIC fibers and ZrO2/SiC composite fibers without gradient composition. Combining the low thermal conductance of ZrO2 with the excellent infrared heat radiation interference ability of SIC, the radial gradient fibers may have potential applications in thermal insulation systems and some other rigorous environments.