连续纤维增韧陶瓷基复合材料(Ceramic Matrix Composites, CMCs)具有耐高温、低密度、高比强度、高比模量等优点, 可应用于航空发动机、空天飞行器热防护系统、飞机/高速列车刹车制动系统、核能电站、空间探测以及光伏和电子等领域[1,2,3,4,5]。目前常见的CMCs主要有碳纤维增韧碳化硅陶瓷基复合材料(C/SiC)和碳化硅纤维增韧碳化硅陶瓷基复合材料(SiC/SiC)两种。CMCs在性能调控方面具有明显的优势: 可对其纤维/界面/基体的组分和微结构进行多尺度优化设计, 实现材料强韧化与多功能性(抗辐照、抗烧蚀以及电磁屏蔽效能)的协同提升, 有效提高其在耦合环境下的服役性能。

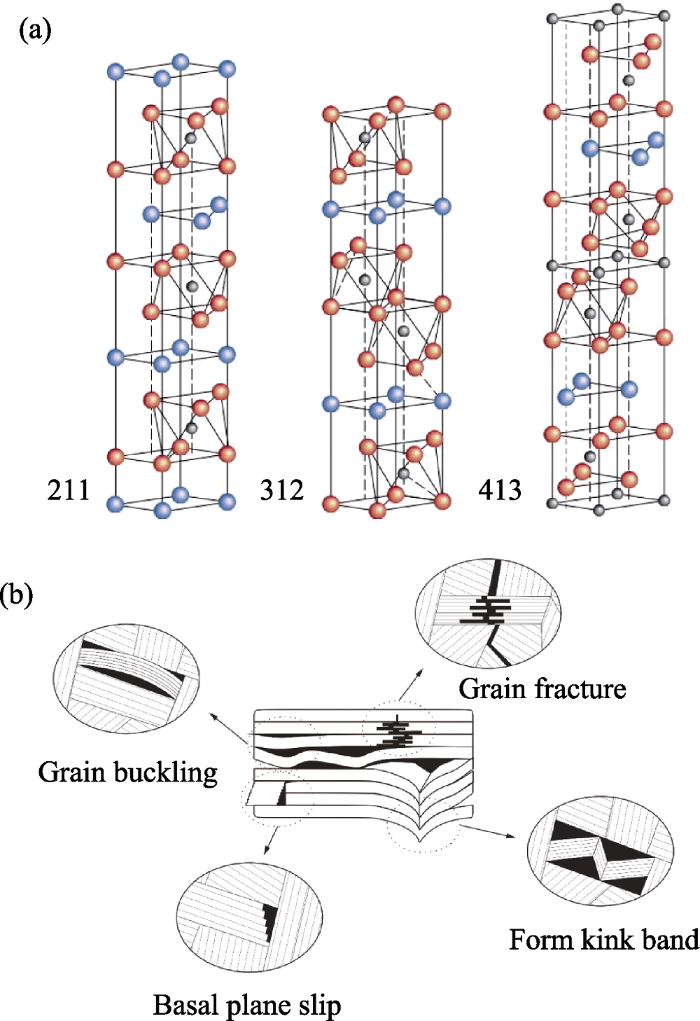

二十世纪60年代, 奥地利维也纳大学Nowotny等[6]提出了三元过渡族金属碳化物或氮化物“H-phase”的概念。1996年, 美国德雷塞尔大学Barsoum团队[7]通过热压法成功制备出了块状Ti3SiC2, 随后将这类材料统称为Mn+1AXn相, 可简称为MAX相, 其中M代表部分过渡族金属元素(如Ti、V、Cr、Zr、Hf等); A为Ⅲ A和Ⅳ A族及Cd、P、S、Zn等元素[8]; X为C或N元素; 通常情况下n取1~3, M2AX、M3AX2、M4AX3相可以分别简称为211、312、413相, 同时, 514、615和716相的存在也已逐步被证实[9,10]。如图1(a)所示, MAX相具有特殊的层状结构, M原子层和A原子层在c方向上交替堆垛, X原子填充于M原子的八面体空隙中, 相邻八面体之间共棱。MAX相中同时存在着强M-X共价键以及弱M-A金属键, 这种特殊的晶体结构使其既具有类似金属材料的高导电、高导热、高损伤容限以及易于机械加工等特性, 也具有陶瓷材料的高模量、耐高温、抗氧化等特性[11,12]。

图1

基于MAX相的优异性能, 国内外学者将其引入CMCs以满足多功能一体化的需求, 其中MAX相既可作为界面相, 也可作为基体相。本文将从CMCs多功能一体化的设计原理出发, 对MAX相在CMCs中的研究现状进行概述, 在阐明其重要作用的同时, 对其未来发展趋势进行展望。

1 MAX相界面

MAX相有着与PyC及h-BN相似的层状结构, 同时具有高的c/a值和低的层间剪切应力, 在外加应力作用下通常会出现滑移、屈曲、扭结等微区塑性变形(如图1(b)所示)。故MAX相可作为弱界面层, 能够有效偏转裂纹, 消耗大量断裂能。同时, 与PyC和h-BN相比, MAX相具有更高的层间结合强度, 能有效提高载荷传递效率。因此, MAX相可看作“强”的弱界面, 有助于实现CMCs强度和韧性的协同提高。

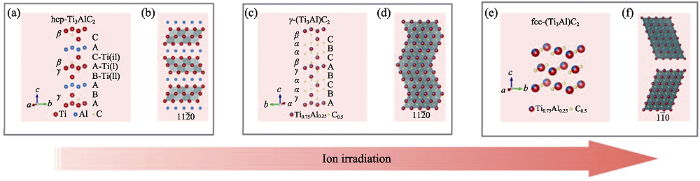

研究表明, MAX相具有优异的抗辐照性能。MAX相本身的辐照损伤容限很高, 辐照条件下MAX相实现完全非晶化所需的辐照损伤要在100 dpi以上[18], 且在由相同元素组成的MAX(Mn+1AXn)相中, n值越大抗辐照诱导相变能力越强[19]。在低剂量Au离子辐照条件下, MAX相的Ti原子和Al原子通过无序化混合共同占据阳离子位置, C原子均匀占据阴离子位置, 形成了同样是六方结构的γ-(Ti3Al)C2相。随着辐照剂量增加, 引入缺陷(堆垛层错等)增多, 材料发生相变, 最终形成fcc-(Ti3Al)C2相(如图2所示)。在fcc阶段, 晶体无序化过程缓慢, 材料能够有效抵抗辐照过程的非晶化损伤[20]。因此, MAX相是下一代核反应堆的候选材料之一, 可以应用于核反应堆第一壁以及燃料包壳或涂层[21,22]。与此同时, 采用MAX相替代PyC和h-BN作为界面相, 可望在满足强韧化要求的同时, 有效改善当前CMCs的抗辐照性能, 实现强韧化与抗辐照性能的协同提高。

图2

目前, 国内外已经开展了很多关于MAX相涂层制备的研究工作。法国里昂大学Jacques等[23,24]采用化学气相沉积方法实现了MAX相涂层的制备, 其制备过程中会伴随较多副产物的生成。德国埃尔兰根-纽伦堡大学Filbert-Demut等[25,26]通过电泳沉积(Electrophoresis Deposition, EPD)方法在SCS-6 SiC纤维上制备了厚度为0.5 μm到5 μm的Ti3SiC2界面相。韩国KAERI研究院Lee等[27,28]通过EPD方法在Tyranno-SA3 SiC纤维布上成功制备了Ti3SiC2界面相, 界面层主要分布在纤维束的表层纤维上。中国科学院宁波材料技术与工程研究所黄庆等[29]利用熔盐反应在碳纤维布表面生成了金属碳化物/MAX相的复合界面层, 制备过程中熔体与纤维发生扩散反应, 制约了纤维承载性能的发挥。由此可见, 与PyC和h-BN相比, MAX相界面层的制备工艺尚不成熟, 还需进一步优化才能实现工程化应用。

2 MAX相基体

2.1 强韧化设计

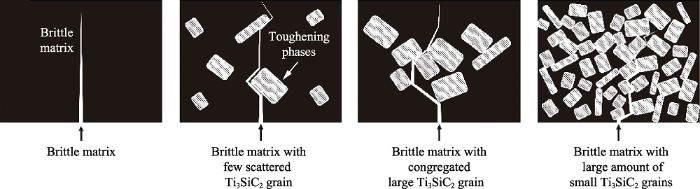

图3

2010年, 西北工业大学殷小玮等[31,32,33]通过浆料浸渍结合液硅渗透工艺在陶瓷基复合材料中原位生成了MAX相基体, 成功将MAX相引入CMCs中。在此基础上, 发展了低温熔体渗透工艺, 采用Al-Si合金浸渗的方法实现了Ti3Si(Al)C2基体的生成。相比于液硅渗透, Al-Si合金渗透可在1300 ℃下实现基体的致密化, 这种低的致密化温度成功拓展了此类工艺的应用范围, 实现了MAX相基体在SiC纤维或Al2O3纤维增韧CMCs中的制备[34,35]。其所制备的C/SiC-Ti3Si(Al)C2弯曲强度和断裂韧性可达到556 MPa和21.6 MPa·m1/2[36], 实现了致密CMCs强度和韧性的协同提高。2011年, 德国拜罗伊特大 学Lenz等[37,38]将TiC粉和Al粉加入到酚醛树脂溶液中, 采用液硅渗透与先驱体浸渍裂解(Precursor Infiltration and Pyrolysis, PIP)结合的方法制备了Ti3SiC2改性C/C-SiC复合材料, 但未见其力学性能的报道。

2.2 强韧化与抗烧蚀性能协同

高超音速飞行器在大气中飞行时, 鼻锥和机翼前缘的温度可达2000 ℃以上, 会经历严重的热冲击, 对于材料的结构承载性能和抗烧蚀性能都提出了严苛的要求。当温度超过1700 ℃时, SiC基体会发生主动氧化, 生成气相SiO, 故基体不能起到对纤维的保护作用, 制约了CMCs在高温烧蚀环境下的应用。

研究表明, 高速氧乙炔焰气流烧蚀后, Ti2AlC表面会形成双层氧化保护膜, 其线烧蚀率和质量烧蚀率比W、TiC/W、ZrC/W等一些常见的抗烧蚀材料都要低, 表现出了良好的抗烧蚀性能[46,47,48]。北京交通大学李世波等[49,50]在氧乙炔焰条件下研究了Cr2AlC的烧蚀行为, 并尝试通过引入ZrC来进一步提高其抗烧蚀性能。在此基础上, 西北工业大学范晓孟等[33]对于Ti3SiC2改性C/SiC的烧蚀性能进行了研究, 强韧性Ti3SiC2-SiC基体可抑制裂纹扩展, 能够有效缓解烧蚀过程中火焰对基体的剥蚀作用, 从而大幅提高CMCs的抗烧蚀性能。通过MAX相的引入实现了陶瓷基复合材料强韧化与抗烧蚀性能的协同。

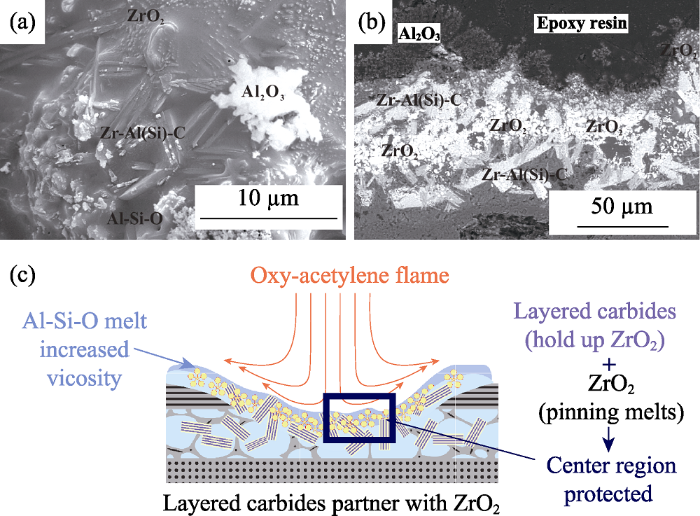

(TC)nAl3C2及(TC)n[Al(Si)]4C3(其中T为Zr或Hf, n=1, 2, 3,…)是一类新型层状过渡金属碳化物, 具有与MAX相相似的层状结构, 其晶体结构是ZrCx或HfCx和Al3C2或[Al(Si)]4C3在c方向上交替堆垛。这类材料在高温烧蚀条件下会生成高熔点的ZrO2或HfO2, 在抗烧蚀领域更具应用潜力[51]。西北工业大学殷小玮等[52]制备了Zr3Al3C5改性C/SiC复合材料, 氧乙炔焰烧蚀后层状碳化物Zr3Al3C5残留于烧蚀中心区表面, 作为骨架支撑结构同ZrO2颗粒结合起来, 对高熔点Al-Si-O熔体起到钉扎作用, 使材料表现出了良好的抗烧蚀性能(如图4所示)。

图4

2.3 强韧化与电磁屏蔽效能协同

电磁屏蔽材料广泛应用于航空航天飞行器、智能汽车通讯自动化设备、精密医用电子器械以及新型柔性电子设备等许多不同领域。随着各类电子仪器设备性能要求的逐步提高, 发展轻质、力学性能和电磁屏蔽效能协同提高的多功能一体化材料成为了研究的重点。

基于晶体中金属键的存在, MAX相具有类似金属的高导电性和高介电损耗, 是一类性能优异的电磁屏蔽材料。以Ti3SiC2为例, 室温下其电导率为4.5×106 S/m, 大约是金属Ti的两倍[12]。因而, 将高电导率MAX相引入到CMCs的基体中, 可有效提高其电磁屏蔽效能。对于PIP工艺制备的SiC/SiC而言, Ti3SiC2引入后电磁屏蔽效能由17 dB提高至20 dB (X 波段)[45]。对于液硅渗透工艺制备的C/SiC-Ti3SiC2而言, Ti3SiC2引入后电磁屏蔽效能由31 dB提高至41 dB(X波段), 此时只有不到0.01%的入射电磁波透过材料[53]。当采用绝缘Al2O3纤维作为增强体时, 所制备的 Al2O3f/SiC-Ti3Si(Al)C2 同样能满足电磁屏蔽效能大于40 dB的要求[35]。

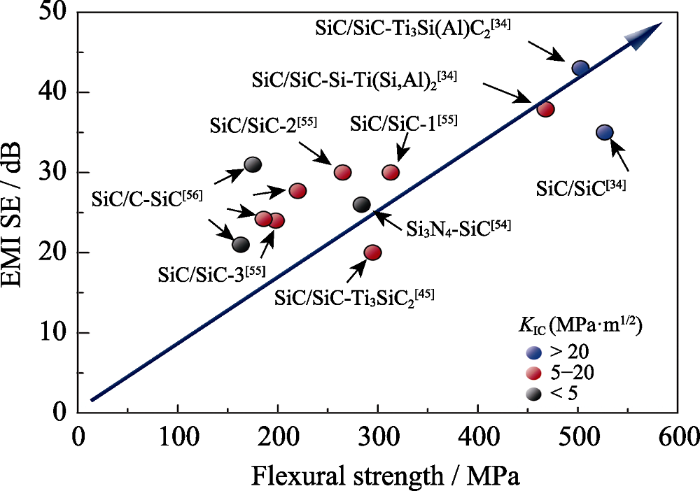

图5总结了不同方法制备SiC/SiC复合材料的抗弯强度、断裂韧性和电磁屏蔽效能。与其他SiC/SiC相比, Ti3Si(Al)C2改性SiC/SiC同时具有优异的力学性能和电磁屏蔽效能(σf>500 MPa, KIC> 20 MPa·m1/2, EMI SE>40 dB), 这就表明通过高导电MAX相增韧基体的引入实现了CMCs强韧化和电磁屏蔽效能的协同提高。

图5

3 总结与展望

陶瓷基复合材料的应用已由单一结构承载朝着多功能一体化方向发展, 通过对CMCs界面/基体进行改性, 将MAX相引入到CMCs中, 有助于在赋予材料良好力学性能的同时, 实现强韧化与抗辐照/抗烧蚀/电磁屏蔽效能的协同, 拓展其在核能防护、空天飞行器热防护以及电磁波屏蔽等方面的应用。随着对MAX相研究的不断深入, 一些新的MAX相陆续被发现, 将这些MAX相同CMCs结合起来有望进一步拓展CMCs的应用范围。另外, 由MAX相衍生出的二维MXenes在陶瓷基复合材料中的应用同样值得关注。

参考文献

Fibre-reinforced multifunctional SiC matrix composite materials

Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview

C/C-SiC composites for space applications and advanced friction systems

The purpose of the current study was to collect information about some techniques and armamentarium currently used by the Saudi Board of Endodontics residents in relation to the technical steps of root canal therapy.

Research progress on the application of C/SiC composites in scramjet

Strukturchemie einiger verbindungen der übergangsmetalle mit den elementen C, Si, Ge, Sn

Synthesis and characterization of a remarkable ceramic: Ti3SiC2

Synthesis of novel MAX phase Ti3ZnC2 via A-site-element-substitution approach

Directed evolution is a powerful approach to study the molecular basis of protein evolution and to engineer proteins for a wide range of applications in synthetic organic chemistry and biotechnology. There are many methods based on random or focused mutagenesis to engineer successfully any protein trait. Focused approaches such as site-directed and saturation mutagenesis have become methods of choice for improving protein activity, selectivity, stability and many other traits because the screening step can be practically handled (bottleneck in directed evolution). Although novel mutagenesis methods based on CRISPR or solid-phase gene synthesis can eliminate bias when creating protein libraries, traditional PCR approaches, although imperfect, remain widely used due to their ease and low cost. One of the most common approaches in focused mutagenesis relies on NNK mutagenesis, however, the primer-based 22c-trick and small-intelligent methods have emerged as key tools for constructing less biased and unbiased libraries when all 20 canonical amino acids are needed for various reasons. In this minireview, we assess studies employing such methods for library creation and their areas of application. We also discuss the advantages and disadvantages of both methods and provide a perspective for creating smarter libraries.

Low-temperature instability of Ti2SnC: a combined transmission electron microscopy, differential scanning calorimetry, and x-ray diffraction investigations

Progress in research and development on MAX phases: a family of layered ternary compounds

Elastic and mechanical properties of the MAX phases

The crustacean cuticle forms skeletal elements consisting of chitin-protein fibrils reinforced by amorphous and crystalline calcium carbonate and phosphate minerals. The edges of skeletal elements are of particular interest. They are subject to repeated strain and stress because they form transitions to the arthrodial membranes connecting them. These allow for relative movements of skeletal elements. In this study, we investigate structure, chemical composition, mineral organization and local mechanical properties of the anterior and posterior edges of the tergite cuticle in the conglobating beach isopod Tylos europaeus and compare these with the protective dorsal region of the tergites. The distribution of mineral phases at the edges resembles that of dorsal regions of the tergites. At the transition with the unmineralized arthrodial membrane the calcite containing distal exocuticle is replaced by epicuticular material and the subjacent cuticular layers containing amorphous calcium carbonate become enriched with amorphous calcium phosphate. At the edges, the local elastic modulus and hardness values are significantly lower compared to dorsal regions of the tergite cuticle, for both, the calcite and the amorphous mineral containing layers. The calcite within the tergite cuticle is assembled in different texture patterns: (i) almost random co-orientation, (ii) almost single crystalline calcite, and (iii) a graded organization. Calcite organization and co-orientation strength is highly variable, not only on very few tens of micrometres, but also between regions with different skeletal functionality. Our results show that besides structure and composition, patterns of calcite organization contribute to the hierarchical architecture and functionality of biological composites.

The MAX phases: unique new carbide and nitride materials

Effects of interface properties on tensile strength of ceramic matrix composites

Regeneration of injuries at tendon-to-bone interface (TBI) remains a challenging issue due to the complex tissue composition involving both soft tendon tissues and relatively hard bone tissues. Tissue engineering using polymeric/ceramic composites has been of great interest to generate scaffolds for tissue's healing at TBI. Herein, we presented a novel method to blend polymers and bioceramics for tendon tissue engineering application. A homogeneous composite comprising of nanohydroxyapatite (nHA) particles in poly(ε-caprolactone) (PCL) matrix was obtained using a combination of solvent and mechanical blending process. X-ray diffraction analysis showed that the as-fabricated PCL/nHA composite film retained phase-pure apatite and semi-crystalline properties of PCL. Infrared spectroscopy spectra confirmed that the PCL/nHA composite film exhibited the characteristics functional groups of PCL and nHA, without alteration to the chemical properties of the composite. The incorporation of nHA resulted in PCL/nHA composite film with improved mechanical properties such as Young's Modulus and ultimate tensile stress, which were comparable to that of the native human rotator tendon. Seeding with human tenocytes, cells attached on the PCL/nHA composite film, and after 14days of culturing, these cells could acquire elongated morphology without induced cytotoxicity. PCL/nHA composite film could also result in increased cell metabolism with prolonged culturing, which was comparable to that of the PCL group and higher than that of the nHA group. All these results demonstrated that the developed technique of combining solvent and mechanical blending could be applied to fabricate composite films with potential for tendon tissue engineering applications.

Swelling of nuclear graphite and high quality carbon fiber composite under very high irradiation temperature

Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: properties and irradiation effects

The critical issues of SiC materials for future nuclear systems

Modification and toughening of 3D needled C/SiC composite by deformable MAX phase-based matrix

Radiation tolerance of Mn+1AXn phases, Ti3AlC2 and Ti3SiC2

Abstract

During investigations of novel material types with uses in future nuclear technologies (ITER/DEMO and GenIV fission reactors), ternary carbides with compositions Ti3AlC2 and Ti3SiC2 have been irradiated with high Xe fluences, 6.25 × 1015 ions cm−2 (∼25–30 dpa), using the IVEM-TANDEM facility at Argonne National Laboratory. Both compositions show high tolerance to damage, and give indications that they are likely to remain crystalline to much higher fluences. There is a visible difference in tolerance between Ti3AlC2 and Ti3SiC2 that can be related to the changes in bonding within each material. These initial findings provide evidence for a novel class of materials (+200 compounds) with high radiation resistance, while, significantly, both of these materials are composed of low-Z elements and hence exhibit no long-term activation.

Role of the X and n factors in ion-irradiation induced phase transformations of Mn+1AXn phases

Disorder in Mn+1AXn phases at the atomic scale

Atomic disordering in materials alters their physical and chemical properties and can subsequently affect their performance. In complex ceramic materials, it is a challenge to understand the nature of structural disordering, due to the difficulty of direct, atomic-scale experimental observations. Here we report the direct imaging of ion irradiation-induced antisite defects in Mn+1AXn phases using double CS-corrected scanning transmission electron microscopy and provide compelling evidence of order-to-disorder phase transformations, overturning the conventional view that irradiation causes phase decomposition to binary fcc-structured Mn+1Xn. With the formation of uniformly distributed cation antisite defects and the rearrangement of X anions, disordered solid solution γ-(Mn+1A)Xn phases are formed at low ion fluences, followed by gradual transitions to solid solution fcc-structured (Mn+1A)Xn phases. This study provides a comprehensive understanding of the order-to-disorder transformations in Mn+1AXn phases and proposes a method for the synthesis of new solid solution (Mn+1A)Xn phases by tailoring the disorder.

Irradiation-induced structural transitions in Ti2AlC

Layered machinable and electrically conductive Ti2AlC and Ti3AlC2 ceramics: a review

Phase equilibria and reactive chemical vapor deposition (RCVD) of Ti3SiC2

The present article addresses the issue of properly modelling the thermodynamic aspect of chemical reactions proceeding at the solid/gas interface in a multi-component system. Attention is more especially paid to the formation of Ti3SiC2 by reactive chemical vapor deposition (RCVD) on a silicon carbide substrate heated at 1100 °C. A deposition diagram has been calculated by Gibbs free energy minimization in the C-Cl-H-Si-Ti quinary system. It is shown that this deposition diagram can account for experimental results obtained by RCVD only for the short period of time during which the reaction layer is thin and discontinuous. For thick, dense and continuous reaction layers, the deposition diagram is no longer appropriate and reaction-diffusion models developed for solid-state diffusion couples have to be used in place of it.

Reactive chemical vapor deposition of Ti3SiC2 with and without pressure pulses: effect on the ternary carbide texture

Polymer derived ceramics reinforced with Ti3SiC2 coated SiC fibers: a feasibility study

Influence of Ti3SiC2 fiber coating on interface and matrix cracking in an SiC fiber-reinforced polymer-derived ceramic

Formation of Ti3SiC2 interphase of SiC fiber by electrophoretic deposition method

Formation of Ti3SiC2 interphase coating on SiCf/SiC composite by electrophoretic deposition

Preparation of TiC/Ti2AlC coating on carbon fiber and investigation of the oxidation resistance properties

Fatigue- crack growth and fracture properties of coarse and fine-grained Ti3SiC2

Fabrication and characterization of a carbon fibre reinforced carbon-silicon carbide- titanium silicon carbide hybrid matrix composite

A novel in-situ synthesis route of Ti3SiC2-SiC composite by liquid silicon infiltration

Processing, microstructure and ablation behavior of C/SiC-Ti3SiC2 composites fabricated by liquid silicon infiltration

Microstructure and properties of dense Tyranno-ZMI SiC/SiC containing Ti3Si(Al)C2 with plastic deformation toughening mechanism

Fabrication and electromagnetic interference shielding effectiveness of Ti3Si(Al)C2 modified Al2O3/SiC composites

Mechanical behavior and electromagnetic interference shielding properties of C/SiC-Ti3Si(Al)C2

Fabrication of fiber composites with a MAX phase matrix by reactive melt infiltration

Carbon fiber reinforced ceramics based on reactive melt infiltration processes

The reactivity of Ti2AlC and Ti3SiC2 with SiC fibers and powders up to temperatures of 1550 ℃

Interfacial reactions between polymer derived SiC fiber and Ti3Si(Al)C2

SiC(SCS-6) fiber-reinforced Ti3AlC2 matrix composites: interfacial characterization and mechanical behavior

Improvement of mechanical properties of SiC(SCS-6) fibre-reinforced Ti3AlC2 matrix composites with Ti barrier layer

Mechanical response and microstructure of 2D carbon fiber reinforced ceramic matrix composites with SiC and Ti3SiC2 fillers

Fabrication Fabrication and properties of Cf/Ti3SiC2-SiC composites using Ti3SiC2 as inert filler

High-temperature dielectric and electromagnetic interference shielding properties of SiCf/SiC composites using Ti3SiC2 as inert filler

Ultra-high temperature ablation behavior of Ti2AlC ceramics under an oxyacetylene flame

Microstructure and ablation properties of zirconium carbide doped carbon/carbon composites

Abstract

Carbon/carbon composites doped with zirconium carbide were prepared by a three-step process. Carbon fiber felts were first immersed in a zirconium oxychloride solution, followed by rapid densification using thermal gradient chemical vapor infiltration. The densified carbon/carbon composites were then graphitized at 2500 °C. The phase composition and morphology of the composites were investigated by X-ray diffraction and scanning electron microscopy. The ablation properties were tested in an oxyacetylene torch. The results show that the linear and mass ablation rates of the composites after doping with 4.14 wt.% zirconium carbide decreased by 83.0% and 77.0%, respectively. The ablated surface of the carbon matrix for pure carbon/carbon composites was very smooth and glossy, while that for doped carbon/carbon composites was honeycombed and dim. The bonding between carbon fibers and matrix decreased because of the formation of more zirconium dioxide, resulting in carbon fibers peeling off the matrix and the ablation resistance of carbon fibers could not be brought into play when the zirconium carbide contents achieved 4.14 wt.%. Although mechanical denudation does not seem to play a dominant role, the ablation was mainly controlled by heterogeneous mass transfer.

Elevated temperature ablation resistance and thermophysical properties of tungsten matrix composites reinforced with ZrC particles

Oxyacetylene torch testing and microstructural characterization of a Cr2AlC ceramic

Synthesis and ultra-high temperature ablation behavior of a ZrC/Cr2AlC composite

Synthesis and structure- property relationships of a new family of layered carbides in Zr-Al(Si)-C and Hf-Al(Si)-C systems

Ablation behavior of Zr-Al(Si)-C layered carbides modified 3D needled C/SiC composites

Mechanical and electromagnetic interference shielding behavior of C/SiC composite containing Ti3SiC2.

Effect of chemical vapor infiltration of SiC on the mechanical and electromagnetic properties of Si3N4-SiC ceramic

The mechanical and electromagnetic (EM) properties of Si3N4 ceramic were improved by infiltrating SiC into porous Si3N4 ceramic by chemical vapor infiltration (CVI). After CVI of SiC, the Si3N4–SiC ceramic possesses improved mechanical properties, high permittivity and dielectric loss, and excellent EM shielding effectiveness and EM absorbing properties compared to Si3N4 ceramic. The lowest EM reflection loss appears when the thickness of the Si3N4–SiC ceramic equals a quarter-wavelength, and the reflection loss remains unchanged for larger thicknesses.

Mechanical and electromagnetic shielding properties of SiCf/SiC composites fabricated by combined CVI and PIP process.