氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] 。氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] 。但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] 。对此, 研究人员开展了许多针对性的研究。本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望。

1 氧化铝气凝胶的合成工艺

1.1 溶胶-凝胶工艺

氧化铝气凝胶的合成需先将铝前驱体通过溶胶-凝胶过程水解、缩聚形成醇凝胶, 再经过老化、溶剂置换和干燥, 最后得到气凝胶。根据前驱体种类不同, 醇凝胶一般通过有机铝醇盐法和无机铝盐法获得。

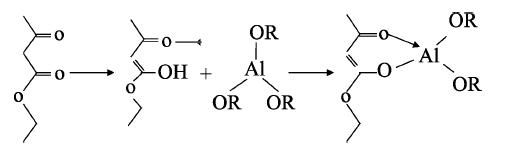

(1)有机铝醇盐中铝的反应活性较高, 需要采用螯合剂来控制其凝胶过程[16 ,17 ] 。常用的螯合剂有乙酰丙酮[18 ] 、乙酸[19 ] 、乙酰乙酸乙酯(Etac)[20 ] 等, 以乙酰乙酸乙酯(Etac)为例, 其螯合机理如图1 所示。Etac取代铝醇盐中的烷氧基后, 形成稳定的六元环状络合物, 给水分子的亲核取代造成困难, 从而延缓了铝醇盐的水解和缩聚速率[21 ,22 ] 。但是螯合剂的加入也降低了凝胶的聚合程度, 制备的氧化铝气凝胶强度较低, 容易碎裂成粉。

图1 乙酰乙酸乙酯的螯合机理[22 ]

Fig. 1 Ethyl acetoacetate chelating effect[22 ]

2013年, Zu等[23 ] 在以仲丁醇铝为前驱体制备醇凝胶的过程中, 加入了丙酮和苯胺来控制水解及缩聚反应的速率。丙酮和苯胺在酸性条件下会反应生成水, 反应见(1)式, 反应生成的副产物亚胺$\text{(}{{\text{C}}_{\text{6}}}{{\text{H}}_{\text{5}}}\text{N=C(C}{{\text{H}}_{\text{3}}}{{\text{)}}_{\text{2}}}\text{)}$也被证明并不和铝醇盐发生反应, 可以通过后期热处理除去。该研究使得有机铝醇盐的凝胶过程更容易控制, 避免了螯合剂的加入对凝胶强度的影响。

(1)

另外, 有机铝醇盐制备氧化铝气凝胶根据用水量不同, 制备的气凝胶结构与性能有较大差异。当水量过多, 制备的A12 O3 气凝胶多为非晶结构, 凝胶结构不稳定, 容易成粉[24 ] ; 当水量较少时, 制备的A12 O3 气凝胶为多晶勃姆石结构, 孔径比较均匀, 热稳定性好[25 ,26 ] 。

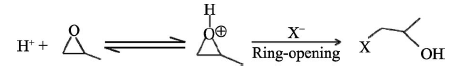

(2)无机铝盐价格低廉, 一般制备的氧化铝气凝胶颗粒及孔径较大, 热稳定性差[27 ,28 ] 。2001年, Gash等[29 ,30 ] 发现以环氧丙烷作凝胶诱导剂容易控制凝胶形成过程, 极大地推动了无机铝盐法合成A12 O3 气凝胶的研究。此后, 许多研究人员采用AlCl3 · 6H2 O和Al(NO3 )3 • 9H2 O作为前驱体, 环氧丙烷作为凝胶剂, 制备了块体A12 O3 气凝胶, 性能可以媲美有机铝醇盐制备的A12 O3 气凝胶[17 ,31 -33 ] 。环氧丙烷在无机铝盐的凝胶过程中涉及的反应如式(2~3)所示:铝离子先溶剂化形成水合铝离子, 进一步水解后提供了质子(式2)。环氧丙烷中氧原子的强亲核性使得其与游离质子不断进行开环反应, 促进水合铝离子的水解和聚合(式3), 同时反应体系中的阴离子X- (如Cl- 或NO3 - )也参与开环反应消耗氧离子。

$\begin{align} & \text{A}{{\text{l}}^{3+}}+n({{H}_{2}}O)\to {{[Al{{({{H}_{2}}O)}_{n}}]}^{3+}}\to \\ & \ \ \ \ {{[Al{{(OH)}_{x}}{{({{H}_{2}}O)}_{n-x}}]}^{(3-x)+}}+x{{\text{H}}^{+}} \\ \end{align}$ (2)

(3)

1.2 氧化铝醇凝胶的干燥工艺

氧化铝醇凝胶的干燥一般有超临界干燥、常压干燥及冷冻干燥等方式, 表1 为不同干燥工艺的工艺特点及其制备的气凝胶性能, 从中可以看出干燥工艺对气凝胶性能有重要影响, 因此研究人员在改进干燥工艺以及发展新的干燥工艺方面做出了不懈努力。2010年, Michael等[6 ] 将包含湿凝胶的不锈钢模具用石墨片和Capton薄膜密封, 用液压机对模具加压并加热, 使得模具内的溶剂达到超临界条件, 然后通过一定的泄压速率实现介质溶剂的快速超临界干燥(RSCE)(图2 )。该方法可一次干燥多个气凝胶产品, 提高了氧化铝气凝胶的制备效率,将以往在高压釜上进行的超临界干燥转移到液压机和模具上来, 降低了操作风险, 也节省了时间。

图2 快速超临界干燥的模具装配示意图[6 ]

Fig. 2 Schematic diagram of the mold assembly used for RSCE[6 ]

超临界干燥过程中溶剂先从液体转变成气体, 所产生的表面张力会影响凝胶网络中的孔结构。2016年, Yang等[38 ] 通过控制乙醇超临界干燥过程的温度与压力, 使得乙醇从液体直接到达超临界状态, 越过气相区域, 消除了液-气转变过程中表面张力对孔的影响, 从而获得高比表面积和热稳定性的氧化铝气凝胶(图3 )。该方法也可用于二氧化碳等其他介质溶剂的超临界干燥, 可以进一步缩短气凝胶的合成时间, 并提高其性能

图3 乙醇的相图[35 ]

Fig. 3 Phase diagram of ethanol[35 ]

2014年, Ren等[39 ] 发展了一种有机溶剂升华干燥(OSSD)方法。该方法采用低表面张力、高凝固点且容易升华的有机溶剂, 如乙腈、叔丁醇等, 代替醇凝胶结构中的溶剂和水, 然后在低真空下干燥。干燥期间醇凝胶表面的溶剂首先蒸发, 蒸发吸收热量导致周围溶剂从液体转变成固体, 然后再通过升华将溶剂除掉(图4 )。升华干燥避免了气-液界面的出现, 消除了表面张力对孔的影响。采用该方法能够制备出完整的块体氧化铝气凝胶, 有较高强度, 但体积收缩仍较大。

图4 OSSD制备气凝胶的干燥机理示意图[39 ]

Fig. 4 Mechanism illustration of the formation of aerogels by OSSD[39 ]

常压干燥工艺复杂, 干燥周期较长[35 ,36 ,37 ] 。Xu 等[31 ] 在溶胶-凝胶过程中通过添加干燥化学控制剂与结构支撑剂, 采用环氧丙烷为凝胶诱导剂, 经老化及溶剂交换, 实现了常压干燥, 制备的氧化铝气凝胶与超临界干燥工艺得到的氧化铝气凝胶性能相近, 制备周期长达8 d。考虑到氧化铝气凝胶的连续化及规模化生产, 常压干燥仍然是首选方式, 但仍需要进一步研究并简化。

2 氧化铝气凝胶的性能

2.1 Al2 O3 气凝胶的比表面积和热稳定性

Al2 O3 气凝胶虽然具有大的比表面积及热稳定性, 但离实际应用还有一定差距。Al2 O3 气凝胶在1000℃以上的γ相到α相的转变伴随着较大的比表面积损失和体积收缩, 限制了其应用[4 ] 。研究人员通过向A12 O3 气凝胶中掺杂La, Y, Ba, Si等多种元素, 使其比表面积和热稳定性均有不同程度的改善[40 ,41 ,42 ,43 ,44 ] 。Alphonse等[45 ] 对A12 O3 气凝胶掺杂La后, 发现1000℃时其比表面积为180 m2 /g; 1200℃时其比表面积为70 m2 /g, 热稳定性得到了显著改善, 这是由于形成的La-Al混合氧化物(LaAl11 O18 或LaAlO3 )抑制了氧化铝的烧结。Wu等[46 ] 研究显示Si掺杂的A12 O3 气凝胶的比表面积1000℃时为373 m2 /g, 1200℃时为120 m2 /g; 即使在1400℃时仍保持 40 m2 /g[41 ] , 因此Si的掺杂效果比La更为显著。分析认为, Si对A12 O3 气凝胶热稳定性的改善主要是由于高温下SiO2 和A12 O3 会形成莫来石结构, 抑制A12 O3 的α相变, 从而保持大的比表面积[38 ,41 -42 ,47 ] 。

2.2 Al2 O3 气凝胶的强度及隔热性能

纯Al2 O3 气凝胶强度较低, 难以形成块体材料, 影响其使用。通过结构设计、改性等方法来提高强度一直是Al2 O3 气凝胶研究的一个重要内容。2014年, Zu等[48 ] 以仲丁醇铝为前驱体制备的醇凝胶, 经化学液相沉积Al2 O3 -SiO2 和SiO2 溶胶后, 超临界干燥得到了核壳结构Al2 O3 气凝胶。他们发现核壳结构的Al2 O3 气凝胶压缩模量相比纯Al2 O3 气凝胶 (1.7 MPa)提高了几乎4倍, 达到6.7 MPa(图5 (a)); 1300℃热处理2 h后, 形貌变化不大, 线收缩仅4%, 显示了优异的热稳定性(图5 (b)), 常温下导热系数 0.042 W/(m•K), 高温隔热性能优于莫来石纤维隔热材料。研究认为, 核壳结构增强了气凝胶纳米粒子的强度, 抑制了高温热处理过程中晶粒的生长和相变, 这为提高Al2 O3 气凝胶材料的热稳定性和机械强度提供了新的思路和方法。

图5 Al2 O3 气凝胶的应力应变曲线(a)和高温热处理前后Al2 O3 气凝胶(b)[48 ]

Fig. 5 Stress-strain curves of Al2 O3 aerogels (a) and Al2 O3 aerogels before and after heat treatment at high temperature (b)[48 ]

Cao等[49 ] 用AlCl3 •6H2 O为前驱体, 引入纳米凹凸棒石(Attapulgite, ATP), 环氧丙烷为凝胶诱导剂, 常压干燥制备了ATP/Al2 O3 复合气凝胶。研究发现, ATP/Al2 O3 复合气凝胶压缩强度随ATP含量增加先增加后降低, ATP含量为26%时, 压缩强度最高达到75.44 MPa。研究认为, A12 O3 纳米粒子能粘附在ATP的棒状结构单元上, 然后随机组装形成ATP/Al2 O3 复合气凝胶的网络骨架, 大幅提高了A12 O3 气凝胶的强度。该研究对于A12 O3 气凝胶的合成和应用具有重要意义, 但是强度的大幅增高, 使得其结构更加致密, 比表面积和隔热性能降低, 因此, ATP/Al2 O3 复合气凝胶的强度和比表面积、导热系数以及热稳定性的制约关系还需进一步研究。

Wu等[50 ] 还采用AlCl3 • 6H2 O作为铝源, 间苯二酚(R)和甲醛(F)作为碳源, CO2 超临界干燥制备了RF/Al2 O3 气凝胶, 然后在氩气保护下800~1500℃进行了热处理, 将RF/Al2 O3 气凝胶转变成C/Al2 O3 气凝胶。结果发现, 先制备的RF/Al2 O3 中由于存在-CH2 或者-CH2 OCH2 柔性单元, 压缩模量较低, 而在碳化后转变为C/Al2 O3 后, 强度大幅提高, 压缩模量可以达到90 MPa(图6 (a)), 并指出C/Al2 O3 气凝

胶强度的大幅提高主要因为热处理提高了Al2 O3 气凝胶的网络骨架强度, 同时无定型C覆盖在Al2 O3 纳米粒子上, 阻碍了Al2 O3 纳米粒子的烧结, α-Al2 O3 的相变被延缓到1500℃以上。在室温到1500℃范围, C/Al2 O3 气凝胶的导热系数为0.033~0.049 (W/(m•K)), 密度约0.1~0.2 g/cm3 (图6 (b)), 显示出优异的强度、热稳定性以及隔热性能, 为惰性气氛条件下隔热材料的应用提供了参考。

图6 C/Al2 O3 气凝胶不同温度热处理后的应力-应变曲线(a)和密度、导热系数变化(b)[50 ]

Fig. 6 Compressive stress-strain curves (a) and bulk densities and thermal conductivities (b) of C/Al2 O3 aerogels heat treated at different temperatures[50 ]

2.3 纤维/Al2 O3 气凝胶复合材料

2015年, He等[51 ] 在仲丁醇铝为前驱体制备的溶胶中, 引入了纤维素(Cellulose), 经冷冻干燥制备了Al2 O3 -Cellulose气凝胶材料(ACA), 研究发现ACA热稳定性与Al2 O3 气凝胶比较接近, 在1200℃热处理后体积收缩约15%, ACA能保持完整块状。引入Cellulose改善了Al2 O3 气凝胶的强度, 在纤维素含量为2%时压缩强度为0.553 MPa(图7 ), 并在受压形变20%以下具有部分形状恢复性能, 展示出部分柔性(图7 插图), 克服了长久以来Al2 O3 气凝胶的易碎易掉渣的缺点, 为Al2 O3 气凝胶的应用提供了新方法, 但合成周期过长, 仍需进一步研究。

图7 不同纤维素含量ACA的应力应变曲线(ACA0.5, ACA1, ACA2分别为纤维素含量0.5%, 1%, 2%)[51 ]

Fig. 7 Stress-strain curves of ACAs with different contents of cellulose (ACA0.5, ACA1 and ACA2 corresponding to the cellulose content of 0.5wt%, 1wt% and 2wt%, respectively)[51 ]

Xu等[52 ] 考察了莫来石纤维/Al2 O3 -SiO2 气凝胶材料的高温隔热性能。由于高温下热辐射对热传导影响较大, 一般在气凝胶中添加红外遮蔽剂来减小热辐射的措施。Xu等在莫来石纤维表面涂覆了SiC涂层,再制备莫来石纤维/Al2 O3 -SiO2 气凝胶材料, 解决了SiC作为红外遮蔽剂在纤维/气凝胶复合材料中的分散问题。结果发现, 前驱物浓度为10%时, 具有SiC涂层的纤维/气凝胶复合材料的有效比消光系数达到56.3 m2 /kg(图8 ), 使得其在1000℃的导热系数为0.049 W/(m•K), 表明SiC涂层可以有效遮蔽高温热辐射, 制备的复合材料具有优异的隔热性能, 为氧化铝气凝胶在高温隔热领域的应用提供了可能。

图8 不同前驱物浓度得到的SiC涂层的莫来石纤维/Al2 O3 - SiO2 气凝胶的有效比消光系数[52 ]

Fig. 8 Effective specific extinction coefficient of Al2 O3 -SiO2 aerogel composites reinforced by SiC-coated mullite fibers prepared with different concentration of precursor[52 ]

3 氧化铝气凝胶的应用

氧化铝气凝胶优异的热稳定性和大的比表面积, 使其在催化剂及催化剂载体方面有广泛应用。Yoo等[53 ] 研究了Ni-Al2 O3 气凝胶催化剂在天然气蒸汽重整制氢过程中的催化性能, 发现Ni在Al2 O3 气凝胶中可以高度分散并具有较小的粒径, 使得催化性能得到显著提升。此外, Ni-Al2 O3 气凝胶在CH4 -CO2 重整过程中能抑制表面积碳导致的催化剂失活, 具有好的催化活性和稳定性[54 ,55 ] 。Ozawa等[8 ] 研究显示La/CuOx 2 O3 气凝胶用作汽车尾气催化剂, 在1000℃高温下, NO和碳氢化合物的去除效率得到大幅提升。Mi等[56 ] 在合成单壁碳纳米管中发现, Fe/Mo/A12 O3 气凝胶600℃煅烧后催化活性最高。

作为隔热材料, 氧化铝气凝胶可用于航空航天领域, 如美国NASA研究双组分的Al2 O3 -SiO2 气凝胶用于航天飞行器的热防护系统[2 ,13 ] ; Gao等[57 ] 研究显示莫来石纤维复合氧化铝气凝胶隔热材料在高温1000℃时导热系数比莫来石纤维下降了47.5%, 比氧化硅气凝胶下降了13.4%, 可将其用于航天飞行器的热防护系统、导弹舵机舱隔热和热电池隔热构件; Jiang等[58 ] 研究了芳砜纶纤维复合氧化铝气凝胶用作隔热耐火消防服, 用垂直燃烧法测试后发现复合材料损毁长度大大降低, 具有优异的阻燃性能和隔热性能; Xie等[59 ] 研究了聚氨酯泡沫中引入氧化铝气凝胶, 得到的复合材料的阻燃和隔热性能得到显著提高, 可用于建筑、电力工业等领域的阻燃隔热材料。

4 结束语

尽管近年来人们对氧化铝气凝胶的合成工艺以及性能改善的研究已取得了很大的进展, 但随着科技的发展, 氧化铝气凝胶离实际高温隔热及催化剂应用仍存在一定差距。作为催化剂或催化剂载体, 氧化铝气凝胶需要通过掺杂改性、与高催化活性的组分结合来进一步提高比表面积、热稳定性以及催化活性。在高温隔热领域, 纤维增强氧化铝气凝胶仍是未来高温隔热材料的发展方向, 其高强度和低导热系数、低密度之间的制约关系需要通过进一步研究来突破, 高温下的热辐射及热传导对实际隔热性能的影响还需深入研究, 从而发展出集高强度、低导热系数、低密度为一体的耐高温纤维/氧化铝气凝胶复合材料, 解决高温环境的隔热难题。此外, 研究氧化铝气凝胶现有的合成工艺, 特别是简化干燥工艺, 制备出较大尺寸的纤维/氧化铝气凝胶材料, 是实现氧化铝气凝胶产业化的关键。

参考文献

文献选项

[1]

AMEEN K B RAJASEKAR K RAJASEKHARAN T et al The effect of heat-treatment on the physico-chemical properties of silica aerogel prepared by sub-critical drying technique

. Journal of Sol-Gel Science and Technology 2008 , 45 (1 ): 9 -15 .

[本文引用: 1]

[2]

HURWITZ F I GUO H ROGERS R B et al Influence of Ti addition on boehmite-derived aluminum silicate aerogels: structure and properties

. Journal of Sol-Gel Science and Technology 2012 , 64 (2 ): 367 -374 .

[本文引用: 2]

[3]

JUHL S J DUNN N J H, CARROLL M K , et al Epoxide-assisted alumina aerogels by rapid supercritical extraction

. Journal of Non-Crystalline Solids 2015 , 426 : 141 -149 .

[本文引用: 1]

[4]

SMITH S J HUANG B BARTHOLOMEW C H et al La-dopant location in La-doped γ-Al2 O3 nanoparticles synthesized using a novel one-pot process

. The Journal of Physical Chemistry C 2015 , 119 (44 ): 25053 -25062 .

[本文引用: 2]

[5]

WEI Q CHEN Z X WANG Z H et al Effect of La, Ce, Y and B addition on thermal stability of unsupported alumina membranes

. Journal of alloys and compounds 2005 , 387 (1 ): 292 -296 .

[本文引用: 1]

[6]

JR. M S B, ANDERSON A M, CARROLL M K . Alumina aerogels prepared via rapid supercritical extraction

.[J]. Sol-Gel Sci. Technol ., 2010 , 53 (2010 ): 216 -226 .

[本文引用: 4]

[7]

AL-YASSIR N LE VAN MAO R . Thermal stability of alumina aerogel doped with yttrium oxide, used as a catalyst support for the thermocatalytic cracking (TCC) process: an investigation of its textural and structural properties

. Applied Catalysis A: General 2007 , 317 (2 ): 275 -283 .

[本文引用: 1]

[8]

OZAWA M . Thermal stabilization of catalytic compositions for automobile exhaust treatment through rare earth modification of alumina nanoparticle support

. Journal of Alloys and Compounds 2006 , 408 -412 : 1090 -1095 .

[本文引用: 2]

[9]

CHEN X LIU Y NIU G et al High temperature thermal stabilization of alumina modified by lanthanum species

. Applied Catalysis A: General 2001 , 205 (1 ): 159 -172 .

[本文引用: 1]

[10]

GUIDOTTI R A REED S T ASHLEY C S et al Evaluation of Aerogel Materials for High-Temperature Batteries

. SAE International 1999 .

[本文引用: 1]

[11]

AEGERTER M A LEVENTIS N KOEBEL M M Aerogels handbook

. Springer Science & Business Media 2011 .

[本文引用: 1]

[12]

JONES S M Aerogel: Space exploration applications

. Journal of Sol-Gel Science and Technology 2006 , 40 (2/3 ): 351 -357 .

[本文引用: 1]

[13]

HURWITZ F I . Thermal Protection Systems (TPSs)

. In book: Richard Blockley, Wei Shyy, Encyclopedia of Aerospace Engineering. John Wiley & Sons, Ltd . 2010 : 1 -13 .

[本文引用: 2]

[14]

YANG X WEI J SHI D et al Comparative investigation of creep behavior of ceramic fiber-reinforced alumina and silica aerogel

. Materials Science and Engineering: A 2014 , 609 : 125 -130 .

[本文引用: 1]

[15]

YANG J LI S LUO Y et al Compressive properties and fracture behavior of ceramic fiber-reinforced carbon aerogel under quasi-static and dynamic loading

. Carbon 2011 , 49 (5 ): 1542 -1549 .

[本文引用: 1]

[16]

ZU G SHEN J WEI X et al Preparation and characterization of monolithic alumina aerogels

. Journal of 2011 , 357 (15 ): 2903 -2906 .

[本文引用: 1]

[17]

BAUMANN T F GASH A E CHINN S C et al Synthesis of high-surface-area alumina aerogels without the use of alkoxide precursors

. Chemistry of Materials 2005 , 17 (2 ): 395 -401 .

[本文引用: 2]

[18]

JI L LIN J TAN K et al Synthesis of high-surface-area alumina using aluminum tri-sec-butoxide-2, 4-pentanedione-2-propanolnitric acid precursors

. Chemistry of Materials 2000 , 12 (4 ): 931 -939 .

[本文引用: 1]

[19]

POCO J SATCHER J HRUBESH L Synthesis of high porosity, monolithic alumina aerogels

. Journal of Non-Crystalline Solids 2001 , 285 (1 ): 57 -63 .

[本文引用: 1]

[20]

PIERRE A BEGAG R PAJONK G Structure and texture of alumina aerogel monoliths made by complexation with ethyl acetoacetate

. Journal of Materials Science 1999 , 34 (20 ): 4937 -4944 .

[本文引用: 1]

[21]

PIERRE A C PAJONK G M Chemistry of aerogels and their applications

. Chemical Reviews 2002 , 102 (11 ): 4243 -4266 .

[本文引用: 1]

[22]

GAO Q F ZHANG C R FENG J et al Preparation of low density, monolithic alumina aerogels

. Chinese Journal of Inorganic Chemistry 2008 , 9 : 19 -25 .

[本文引用: 3]

[23]

ZU G SHEN J ZOU L et al Nanoengineering super heat-resistant, strong alumina aerogels

. Chemistry of Materials 2013 , 25 (23 ): 4757 -4764 .

[本文引用: 1]

[24]

JANOSOVITS U ZIEGLER G SCHARF U et al Structural characterization of intermediate species during synthesis of Al2 O3 - aerogels

. Journal of Non-crystalline Solids 1997 , 210 (1 ): 1 -13 .

[本文引用: 1]

[25]

HORIUCHI T CHEN L OSAKI T et al A novel alumina catalyst support with high thermal stability derived from silica-modified alumina aerogel

. Catalysis Letters 1999 , 58 (2/3 ): 89 -92 .

[本文引用: 1]

[26]

OSAKI T NAGASHIMA K WATARI K et al Silica-doped alumina cryogels with high thermal stability

. Journal of Non-crystalline Solids 2007 , 353 (24 ): 2436 -2442 .

[本文引用: 1]

[27]

HE FEI HE XIAO-DONG LI YAO Al2 O3 Xerogels synthesized by inorganic salt and organic alkoxide

. Journal of the Chinese Ceramic Society 2006 , 34 (9 ): 1093 -1097 .

[本文引用: 1]

[28]

HAO Z LIU H GUO B et al Sol-Gel synthesis of alumina using inorganic salt precursor

. Acta Physico-Chimica Sinica 2007 , 23 (3 ): 289 -294 .

[本文引用: 1]

[29]

GASH A E TILLOTSON T M SATCHER J H et al Use of epoxides in the Sol-Gel synthesis of porous iron (III) oxide monoliths from Fe (III) salts

. Chemistry of Materials 2001 , 13 (3 ): 999 -1007 .

[本文引用: 1]

[30]

GASH A E TILLOTSON T M SATCHER JR J H , et al New Sol-Gel synthetic route to transition and main-group metal oxide aerogels using inorganic salt precursors

. Journal of 2001 , 285 (1 ): 22 -28 .

[本文引用: 1]

[31]

XU ZI-JIE GAN LI-HUA PANG YING-CONG et al Preparation of Al2 O3 bulk aerogels by non-supercritical fluid drying technology

. Acta Phys.-Chim.Sin ., 2005 , 21 (2 ): 221 -224 .

[本文引用: 2]

[32]

WU X SHAO G SHEN X et al Novel Al2 O3 -SiO2 composite aerogels with high specific surface area at elevated temperatures with different alumina/silica molar ratios prepared by a non-alkoxide Sol-Gel method

. RSC Adv 2016 , 6 (7 ): 5611 -5620 .

[33]

JUHL S J DUNN N J H, CARROLL M K, et al

. Epoxide-assisted alumina aerogels by rapid supercritical extraction. Journal of 2015 , 426 : 141 -149 .

[本文引用: 1]

[34]

SHEWALE P M RAO A V RAO A P Effect of different trimethyl silylating agents on the hydrophobic and physical properties of silica aerogels

. Applied Surface Science 2008 , 254 (21 ): 6902 -6907 .

[本文引用: 2]

[35]

HILONGA A KIM J K SARAWADE P B et al Low-density TEOS-based silica aerogels prepared at ambient pressure using isopropanol as the preparative solvent

. Journal of Alloys and Compounds 2009 , 487 (1 ): 744 -750 .

[本文引用: 5]

[36]

WU L HUANG Y WANG Z et al Fabrication of hydrophobic alumina aerogel monoliths by surface modification and ambient pressure drying

. Applied Surface Science 2010 , 256 (20 ): 5973 -5977 .

[本文引用: 2]

[37]

TALEBI MAZRAEH-SHAHI Z MOUSAVI SHOUSHTARI A BAHRAMIAN A R et al Synthesis, pore structure and properties of polyurethane/silica hybrid aerogels dried at ambient pressure

. Journal of Industrial and Engineering Chemistry 2015 , 21 : 797 -804 .

[本文引用: 2]

[38]

YANG J WANG Q WANG T et al Facile one-step precursor- to-aerogel synthesis of silica-doped alumina aerogels with high specific surface area at elevated temperatures

. Journal of Porous Materials 2017 , 24 (4 ): 889 -897 .

[本文引用: 2]

[39]

REN L CUI S CAO F et al An easy way to prepare monolithic inorganic oxide aerogels

. Angew Chem. Int. Ed. Engl ., 2014 , 53 (38 ): 10147 -10149 .

[本文引用: 3]

[40]

ZHONG X ZHAO H LIU C et al Improvement in thermal shock resistance of gadolinium zirconate coating by addition of nanostructured yttria partially-stabilized zirconia

. Ceramics International 2015 , 41 (6 ): 7318 -7324 .

[本文引用: 1]

[41]

TATSURO H TOSHIHIKO O TOYOHIKO S et al Maintenance of large surface area of alumina aerogel heated at elevated temperature above 1300 by preparing silica-containing aerogel

. Journal of 2001 , 291 (3 ): 187 -198 .

[本文引用: 3]

[42]

MIZUSHIMA Y HORI M Preparation of heat-resistant alumina aerogels

. Journal of Materials Research 1993 , 8 (11 ): 2993 -2999 .

[本文引用: 2]

[43]

YANG J WANG Q WANG T et al Rapid preparation process, structure and thermal stability of lanthanum doped alumina aerogels with a high specific surface area

. RSC Adv 2016 , 6 (31 ): 26271 -26279 .

[本文引用: 1]

[44]

BANG Y SEO J G SONG I K Hydrogen production by steam reforming of liquefied natural gas (LNG) over mesoporous Ni- La-Al2 O3 aerogel catalysts: effect of La content

. International Journal of Hydrogen Energy 2011 , 36 (14 ): 8307 -8315 .

[本文引用: 1]

[45]

ALPHONSE P FAURE B Thermal stabilization of alumina modified by lanthanum

. Microporous and Mesoporous Materials 2014 , 196 : 191 -198 .

[本文引用: 1]

[46]

WU X SHAO G CUI S et al Synthesis of a novel Al2 O3 -SiO2 composite aerogel with high specific surface area at elevated temperatures using inexpensive inorganic salt of aluminum

. Ceramics International 2016 , 42 (1 ): 874 -882 .

[本文引用: 1]

[47]

WU X SHAO G SHEN X et al Novel Al2 O3 -SiO2 composite aerogels with high specific surface area at elevated temperatures with different alumina/silica molar ratios prepared by a non-alkoxide Sol-Gel method

. RSC Adv ., 2016 , 6 (7 ): 5611 -5620 .

[本文引用: 1]

[48]

ZU G SHEN J WANG W et al Robust, highly thermally stable, core-shell nanostructured metal oxide aerogels as high-temperature thermal superinsulators, adsorbents, and catalysts

. Chemistry of Materials 2014 , 26 (19 ): 5761 -5772 .

[本文引用: 3]

[49]

CAO F REN L LI X Synthesis of high strength monolithic alumina aerogels at ambient pressure

. RSC Adv ., 2015 , 5 (23 ): 18025 -18028 .

[本文引用: 1]

[50]

WU X ZHONG Y KONG Y et al Preparation and characterization of C/Al2 O3 composite aerogel with high compressive strength and low thermal conductivity

. Journal of Porous Materials 2015 , 22 (5 ): 1235 -1243 .

[本文引用: 3]

[51]

HE F SUI C HE X et al Facile synthesis of strong alumina- cellulose aerogels by a freeze-drying method

. Materials Letters 2015 , 152 : 9 -12 .

[本文引用: 3]

[52]

XU L JIANG Y FENG J et al Infrared-opacified Al2 O3 -SiO2 aerogel composites reinforced by SiC-coated mullite fibers for thermal insulations

. Ceramics International 2015 , 41 (1 ): 437 -442 .

[本文引用: 3]

[53]

YOO J BANG Y HAN S J et al Hydrogen production by steam reforming of liquefied natural gas (LNG) over magnesium-doped nickel-alumina aerogel catalyst

. Journal of Nanoscience and Nanotechnology 2016 , 16 (10 ): 10835 -10840 .

[本文引用: 1]

[54]

HAO Z ZHU Q JIANG Z et al Characterization of aerogel Ni/Al2 O3 catalysts and investigation on their stability for CH4 -CO2 reforming in a fluidized bed

. Fuel Processing Technology 2009 , 90 (1 ): 113 -121 .

[本文引用: 1]

[55]

CHEN JI-XIANG WANG RI-JIE LI YU-MIN et al Study of nickel-based aerogel catalyzing CO2 reforming of CH4 to synthesis gas

. Journal of Fuel Chemistry and Technology 2002 , 30 (1 ): 45 -48 .

[本文引用: 1]

[56]

MI YU-HONG ZHANG XIAO-BIN LUO JUN-HANG et al Influence of calcining temperature of aerogel catalyst on its catalytic activity for synthesizing SWNTs

. Journal of Inorganic Materials 2007 , 22 (4 ): 604 -608 .

[本文引用: 1]

[57]

GAO QING-FU ZHANG CHANG-RUI FENG JIAN et al Preparation and thermal performance of alumina aerogel insulation composites

. Journal of National University of Denfense Technology 2008 , 30 (4 ): 39 -42 .

[本文引用: 1]

[58]

JIANG YING-YING ZHANG LIN-PING XU HONG et al Preparation and characterization of thermal protective aluminum hydroxide aerogel/PSA fabric composites

. Journal of Sol-Gel Science and 2017 , 82 (2 ): 370 -379 .

[本文引用: 1]

[59]

XIE HONG-YAN YANG WEI YUEN ANTHONY CHUN YIN , et al Study on flame retarded flexible polyurethane foam/alumina aerogel composites with improved fire safety

. Chemical Engineering Journal 2017 , 311 : 310 -317 .

[本文引用: 1]

The effect of heat-treatment on the physico-chemical properties of silica aerogel prepared by sub-critical drying technique

1

2008

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

Influence of Ti addition on boehmite-derived aluminum silicate aerogels: structure and properties

2

2012

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

... 作为隔热材料, 氧化铝气凝胶可用于航空航天领域, 如美国NASA研究双组分的Al2 O3 -SiO2 气凝胶用于航天飞行器的热防护系统[2 ,13 ] ; Gao等[57 ] 研究显示莫来石纤维复合氧化铝气凝胶隔热材料在高温1000℃时导热系数比莫来石纤维下降了47.5%, 比氧化硅气凝胶下降了13.4%, 可将其用于航天飞行器的热防护系统、导弹舵机舱隔热和热电池隔热构件; Jiang等[58 ] 研究了芳砜纶纤维复合氧化铝气凝胶用作隔热耐火消防服, 用垂直燃烧法测试后发现复合材料损毁长度大大降低, 具有优异的阻燃性能和隔热性能; Xie等[59 ] 研究了聚氨酯泡沫中引入氧化铝气凝胶, 得到的复合材料的阻燃和隔热性能得到显著提高, 可用于建筑、电力工业等领域的阻燃隔热材料. ...

Epoxide-assisted alumina aerogels by rapid supercritical extraction

1

2015

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

La-dopant location in La-doped γ-Al2 O3 nanoparticles synthesized using a novel one-pot process

2

2015

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

... Al2 O3 气凝胶虽然具有大的比表面积及热稳定性, 但离实际应用还有一定差距.Al2 O3 气凝胶在1000℃以上的γ相到α相的转变伴随着较大的比表面积损失和体积收缩, 限制了其应用[4 ] .研究人员通过向A12 O3 气凝胶中掺杂La, Y, Ba, Si等多种元素, 使其比表面积和热稳定性均有不同程度的改善[40 ,41 ,42 ,43 ,44 ] .Alphonse等[45 ] 对A12 O3 气凝胶掺杂La后, 发现1000℃时其比表面积为180 m2 /g; 1200℃时其比表面积为70 m2 /g, 热稳定性得到了显著改善, 这是由于形成的La-Al混合氧化物(LaAl11 O18 或LaAlO3 )抑制了氧化铝的烧结.Wu等[46 ] 研究显示Si掺杂的A12 O3 气凝胶的比表面积1000℃时为373 m2 /g, 1200℃时为120 m2 /g; 即使在1400℃时仍保持 40 m2 /g[41 ] , 因此Si的掺杂效果比La更为显著.分析认为, Si对A12 O3 气凝胶热稳定性的改善主要是由于高温下SiO2 和A12 O3 会形成莫来石结构, 抑制A12 O3 的α相变, 从而保持大的比表面积[38 ,41 -42 ,47 ] . ...

Effect of La, Ce, Y and B addition on thermal stability of unsupported alumina membranes

1

2005

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

Alumina aerogels prepared via rapid supercritical extraction

4

2010

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

... 氧化铝醇凝胶的干燥一般有超临界干燥、常压干燥及冷冻干燥等方式, 表1 为不同干燥工艺的工艺特点及其制备的气凝胶性能, 从中可以看出干燥工艺对气凝胶性能有重要影响, 因此研究人员在改进干燥工艺以及发展新的干燥工艺方面做出了不懈努力.2010年, Michael等[6 ] 将包含湿凝胶的不锈钢模具用石墨片和Capton薄膜密封, 用液压机对模具加压并加热, 使得模具内的溶剂达到超临界条件, 然后通过一定的泄压速率实现介质溶剂的快速超临界干燥(RSCE)(图2 ).该方法可一次干燥多个气凝胶产品, 提高了氧化铝气凝胶的制备效率,将以往在高压釜上进行的超临界干燥转移到液压机和模具上来, 降低了操作风险, 也节省了时间. ...

... 快速超临界干燥的模具装配示意图[6 ] ...

... Schematic diagram of the mold assembly used for RSCE[6 ] ...

Thermal stability of alumina aerogel doped with yttrium oxide, used as a catalyst support for the thermocatalytic cracking (TCC) process: an investigation of its textural and structural properties

1

2007

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

Thermal stabilization of catalytic compositions for automobile exhaust treatment through rare earth modification of alumina nanoparticle support

2

2006

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

... 氧化铝气凝胶优异的热稳定性和大的比表面积, 使其在催化剂及催化剂载体方面有广泛应用.Yoo等[53 ] 研究了Ni-Al2 O3 气凝胶催化剂在天然气蒸汽重整制氢过程中的催化性能, 发现Ni在Al2 O3 气凝胶中可以高度分散并具有较小的粒径, 使得催化性能得到显著提升.此外, Ni-Al2 O3 气凝胶在CH4 -CO2 重整过程中能抑制表面积碳导致的催化剂失活, 具有好的催化活性和稳定性[54 ,55 ] .Ozawa等[8 ] 研究显示La/CuOx 2 O3 气凝胶用作汽车尾气催化剂, 在1000℃高温下, NO和碳氢化合物的去除效率得到大幅提升.Mi等[56 ] 在合成单壁碳纳米管中发现, Fe/Mo/A12 O3 气凝胶600℃煅烧后催化活性最高. ...

High temperature thermal stabilization of alumina modified by lanthanum species

1

2001

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

Evaluation of Aerogel Materials for High-Temperature Batteries

1

1999

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

Aerogels handbook

1

2011

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

Aerogel: Space exploration applications

1

2006

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

Thermal Protection Systems (TPSs)

2

2010

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

... 作为隔热材料, 氧化铝气凝胶可用于航空航天领域, 如美国NASA研究双组分的Al2 O3 -SiO2 气凝胶用于航天飞行器的热防护系统[2 ,13 ] ; Gao等[57 ] 研究显示莫来石纤维复合氧化铝气凝胶隔热材料在高温1000℃时导热系数比莫来石纤维下降了47.5%, 比氧化硅气凝胶下降了13.4%, 可将其用于航天飞行器的热防护系统、导弹舵机舱隔热和热电池隔热构件; Jiang等[58 ] 研究了芳砜纶纤维复合氧化铝气凝胶用作隔热耐火消防服, 用垂直燃烧法测试后发现复合材料损毁长度大大降低, 具有优异的阻燃性能和隔热性能; Xie等[59 ] 研究了聚氨酯泡沫中引入氧化铝气凝胶, 得到的复合材料的阻燃和隔热性能得到显著提高, 可用于建筑、电力工业等领域的阻燃隔热材料. ...

Comparative investigation of creep behavior of ceramic fiber-reinforced alumina and silica aerogel

1

2014

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

Compressive properties and fracture behavior of ceramic fiber-reinforced carbon aerogel under quasi-static and dynamic loading

1

2011

... 氧化铝气凝胶具有低密度、低导热系数、大比表面积和高孔隙率等特点, 还具有优异的热稳定 性[1 ,2 ,3 ] .氧化铝气凝胶的γ相具有大的比表面积和宽的晶相范围, 可以稳定到900~1000℃[4 ,5 ,6 ] , 被广泛用于石油化工热裂解[7 ] 、汽车尾气催化系统[8 ,9 ] 及热电发动机[10 ,11 ] 等高温环境的催化剂或催化剂载体, 以及航空航天领域的高温隔热材料[12 ,13 ] .但是, 氧化铝气凝胶强度较低, 难以制备成块体材料, 且制备工艺复杂, 限制了其应用[14 ,15 ] .对此, 研究人员开展了许多针对性的研究.本文综述了近年来氧化铝气凝胶的合成工艺, 及其在比表面积、热稳定性、隔热性能及强度等性能改善方面取得的代表性研究成果, 并对氧化铝气凝胶在高温催化及隔热领域的应用前景进行了展望. ...

Preparation and characterization of monolithic alumina aerogels

1

2011

... (1)有机铝醇盐中铝的反应活性较高, 需要采用螯合剂来控制其凝胶过程[16 ,17 ] .常用的螯合剂有乙酰丙酮[18 ] 、乙酸[19 ] 、乙酰乙酸乙酯(Etac)[20 ] 等, 以乙酰乙酸乙酯(Etac)为例, 其螯合机理如图1 所示.Etac取代铝醇盐中的烷氧基后, 形成稳定的六元环状络合物, 给水分子的亲核取代造成困难, 从而延缓了铝醇盐的水解和缩聚速率[21 ,22 ] .但是螯合剂的加入也降低了凝胶的聚合程度, 制备的氧化铝气凝胶强度较低, 容易碎裂成粉. ...

Synthesis of high-surface-area alumina aerogels without the use of alkoxide precursors

2

2005

... (1)有机铝醇盐中铝的反应活性较高, 需要采用螯合剂来控制其凝胶过程[16 ,17 ] .常用的螯合剂有乙酰丙酮[18 ] 、乙酸[19 ] 、乙酰乙酸乙酯(Etac)[20 ] 等, 以乙酰乙酸乙酯(Etac)为例, 其螯合机理如图1 所示.Etac取代铝醇盐中的烷氧基后, 形成稳定的六元环状络合物, 给水分子的亲核取代造成困难, 从而延缓了铝醇盐的水解和缩聚速率[21 ,22 ] .但是螯合剂的加入也降低了凝胶的聚合程度, 制备的氧化铝气凝胶强度较低, 容易碎裂成粉. ...

... (2)无机铝盐价格低廉, 一般制备的氧化铝气凝胶颗粒及孔径较大, 热稳定性差[27 ,28 ] .2001年, Gash等[29 ,30 ] 发现以环氧丙烷作凝胶诱导剂容易控制凝胶形成过程, 极大地推动了无机铝盐法合成A12 O3 气凝胶的研究.此后, 许多研究人员采用AlCl3 · 6H2 O和Al(NO3 )3 • 9H2 O作为前驱体, 环氧丙烷作为凝胶剂, 制备了块体A12 O3 气凝胶, 性能可以媲美有机铝醇盐制备的A12 O3 气凝胶[17 ,31 -33 ] .环氧丙烷在无机铝盐的凝胶过程中涉及的反应如式(2~3)所示:铝离子先溶剂化形成水合铝离子, 进一步水解后提供了质子(式2).环氧丙烷中氧原子的强亲核性使得其与游离质子不断进行开环反应, 促进水合铝离子的水解和聚合(式3), 同时反应体系中的阴离子X- (如Cl- 或NO3 - )也参与开环反应消耗氧离子. ...

Synthesis of high-surface-area alumina using aluminum tri-sec-butoxide-2, 4-pentanedione-2-propanolnitric acid precursors

1

2000

... (1)有机铝醇盐中铝的反应活性较高, 需要采用螯合剂来控制其凝胶过程[16 ,17 ] .常用的螯合剂有乙酰丙酮[18 ] 、乙酸[19 ] 、乙酰乙酸乙酯(Etac)[20 ] 等, 以乙酰乙酸乙酯(Etac)为例, 其螯合机理如图1 所示.Etac取代铝醇盐中的烷氧基后, 形成稳定的六元环状络合物, 给水分子的亲核取代造成困难, 从而延缓了铝醇盐的水解和缩聚速率[21 ,22 ] .但是螯合剂的加入也降低了凝胶的聚合程度, 制备的氧化铝气凝胶强度较低, 容易碎裂成粉. ...

Synthesis of high porosity, monolithic alumina aerogels

1

2001

... (1)有机铝醇盐中铝的反应活性较高, 需要采用螯合剂来控制其凝胶过程[16 ,17 ] .常用的螯合剂有乙酰丙酮[18 ] 、乙酸[19 ] 、乙酰乙酸乙酯(Etac)[20 ] 等, 以乙酰乙酸乙酯(Etac)为例, 其螯合机理如图1 所示.Etac取代铝醇盐中的烷氧基后, 形成稳定的六元环状络合物, 给水分子的亲核取代造成困难, 从而延缓了铝醇盐的水解和缩聚速率[21 ,22 ] .但是螯合剂的加入也降低了凝胶的聚合程度, 制备的氧化铝气凝胶强度较低, 容易碎裂成粉. ...

Structure and texture of alumina aerogel monoliths made by complexation with ethyl acetoacetate

1

1999

... (1)有机铝醇盐中铝的反应活性较高, 需要采用螯合剂来控制其凝胶过程[16 ,17 ] .常用的螯合剂有乙酰丙酮[18 ] 、乙酸[19 ] 、乙酰乙酸乙酯(Etac)[20 ] 等, 以乙酰乙酸乙酯(Etac)为例, 其螯合机理如图1 所示.Etac取代铝醇盐中的烷氧基后, 形成稳定的六元环状络合物, 给水分子的亲核取代造成困难, 从而延缓了铝醇盐的水解和缩聚速率[21 ,22 ] .但是螯合剂的加入也降低了凝胶的聚合程度, 制备的氧化铝气凝胶强度较低, 容易碎裂成粉. ...

Chemistry of aerogels and their applications

1

2002

... (1)有机铝醇盐中铝的反应活性较高, 需要采用螯合剂来控制其凝胶过程[16 ,17 ] .常用的螯合剂有乙酰丙酮[18 ] 、乙酸[19 ] 、乙酰乙酸乙酯(Etac)[20 ] 等, 以乙酰乙酸乙酯(Etac)为例, 其螯合机理如图1 所示.Etac取代铝醇盐中的烷氧基后, 形成稳定的六元环状络合物, 给水分子的亲核取代造成困难, 从而延缓了铝醇盐的水解和缩聚速率[21 ,22 ] .但是螯合剂的加入也降低了凝胶的聚合程度, 制备的氧化铝气凝胶强度较低, 容易碎裂成粉. ...

Preparation of low density, monolithic alumina aerogels

3

2008

... (1)有机铝醇盐中铝的反应活性较高, 需要采用螯合剂来控制其凝胶过程[16 ,17 ] .常用的螯合剂有乙酰丙酮[18 ] 、乙酸[19 ] 、乙酰乙酸乙酯(Etac)[20 ] 等, 以乙酰乙酸乙酯(Etac)为例, 其螯合机理如图1 所示.Etac取代铝醇盐中的烷氧基后, 形成稳定的六元环状络合物, 给水分子的亲核取代造成困难, 从而延缓了铝醇盐的水解和缩聚速率[21 ,22 ] .但是螯合剂的加入也降低了凝胶的聚合程度, 制备的氧化铝气凝胶强度较低, 容易碎裂成粉. ...

... 乙酰乙酸乙酯的螯合机理[22 ] ...

... Ethyl acetoacetate chelating effect[22 ] ...

Nanoengineering super heat-resistant, strong alumina aerogels

1

2013

... 2013年, Zu等[23 ] 在以仲丁醇铝为前驱体制备醇凝胶的过程中, 加入了丙酮和苯胺来控制水解及缩聚反应的速率.丙酮和苯胺在酸性条件下会反应生成水, 反应见(1)式, 反应生成的副产物亚胺$\text{(}{{\text{C}}_{\text{6}}}{{\text{H}}_{\text{5}}}\text{N=C(C}{{\text{H}}_{\text{3}}}{{\text{)}}_{\text{2}}}\text{)}$也被证明并不和铝醇盐发生反应, 可以通过后期热处理除去.该研究使得有机铝醇盐的凝胶过程更容易控制, 避免了螯合剂的加入对凝胶强度的影响. ...

Structural characterization of intermediate species during synthesis of Al2 O3 - aerogels

1

1997

... 另外, 有机铝醇盐制备氧化铝气凝胶根据用水量不同, 制备的气凝胶结构与性能有较大差异.当水量过多, 制备的A12 O3 气凝胶多为非晶结构, 凝胶结构不稳定, 容易成粉[24 ] ; 当水量较少时, 制备的A12 O3 气凝胶为多晶勃姆石结构, 孔径比较均匀, 热稳定性好[25 ,26 ] . ...

A novel alumina catalyst support with high thermal stability derived from silica-modified alumina aerogel

1

1999

... 另外, 有机铝醇盐制备氧化铝气凝胶根据用水量不同, 制备的气凝胶结构与性能有较大差异.当水量过多, 制备的A12 O3 气凝胶多为非晶结构, 凝胶结构不稳定, 容易成粉[24 ] ; 当水量较少时, 制备的A12 O3 气凝胶为多晶勃姆石结构, 孔径比较均匀, 热稳定性好[25 ,26 ] . ...

Silica-doped alumina cryogels with high thermal stability

1

2007

... 另外, 有机铝醇盐制备氧化铝气凝胶根据用水量不同, 制备的气凝胶结构与性能有较大差异.当水量过多, 制备的A12 O3 气凝胶多为非晶结构, 凝胶结构不稳定, 容易成粉[24 ] ; 当水量较少时, 制备的A12 O3 气凝胶为多晶勃姆石结构, 孔径比较均匀, 热稳定性好[25 ,26 ] . ...

Al2 O3 Xerogels synthesized by inorganic salt and organic alkoxide

1

2006

... (2)无机铝盐价格低廉, 一般制备的氧化铝气凝胶颗粒及孔径较大, 热稳定性差[27 ,28 ] .2001年, Gash等[29 ,30 ] 发现以环氧丙烷作凝胶诱导剂容易控制凝胶形成过程, 极大地推动了无机铝盐法合成A12 O3 气凝胶的研究.此后, 许多研究人员采用AlCl3 · 6H2 O和Al(NO3 )3 • 9H2 O作为前驱体, 环氧丙烷作为凝胶剂, 制备了块体A12 O3 气凝胶, 性能可以媲美有机铝醇盐制备的A12 O3 气凝胶[17 ,31 -33 ] .环氧丙烷在无机铝盐的凝胶过程中涉及的反应如式(2~3)所示:铝离子先溶剂化形成水合铝离子, 进一步水解后提供了质子(式2).环氧丙烷中氧原子的强亲核性使得其与游离质子不断进行开环反应, 促进水合铝离子的水解和聚合(式3), 同时反应体系中的阴离子X- (如Cl- 或NO3 - )也参与开环反应消耗氧离子. ...

Sol-Gel synthesis of alumina using inorganic salt precursor

1

2007

... (2)无机铝盐价格低廉, 一般制备的氧化铝气凝胶颗粒及孔径较大, 热稳定性差[27 ,28 ] .2001年, Gash等[29 ,30 ] 发现以环氧丙烷作凝胶诱导剂容易控制凝胶形成过程, 极大地推动了无机铝盐法合成A12 O3 气凝胶的研究.此后, 许多研究人员采用AlCl3 · 6H2 O和Al(NO3 )3 • 9H2 O作为前驱体, 环氧丙烷作为凝胶剂, 制备了块体A12 O3 气凝胶, 性能可以媲美有机铝醇盐制备的A12 O3 气凝胶[17 ,31 -33 ] .环氧丙烷在无机铝盐的凝胶过程中涉及的反应如式(2~3)所示:铝离子先溶剂化形成水合铝离子, 进一步水解后提供了质子(式2).环氧丙烷中氧原子的强亲核性使得其与游离质子不断进行开环反应, 促进水合铝离子的水解和聚合(式3), 同时反应体系中的阴离子X- (如Cl- 或NO3 - )也参与开环反应消耗氧离子. ...

Use of epoxides in the Sol-Gel synthesis of porous iron (III) oxide monoliths from Fe (III) salts

1

2001

... (2)无机铝盐价格低廉, 一般制备的氧化铝气凝胶颗粒及孔径较大, 热稳定性差[27 ,28 ] .2001年, Gash等[29 ,30 ] 发现以环氧丙烷作凝胶诱导剂容易控制凝胶形成过程, 极大地推动了无机铝盐法合成A12 O3 气凝胶的研究.此后, 许多研究人员采用AlCl3 · 6H2 O和Al(NO3 )3 • 9H2 O作为前驱体, 环氧丙烷作为凝胶剂, 制备了块体A12 O3 气凝胶, 性能可以媲美有机铝醇盐制备的A12 O3 气凝胶[17 ,31 -33 ] .环氧丙烷在无机铝盐的凝胶过程中涉及的反应如式(2~3)所示:铝离子先溶剂化形成水合铝离子, 进一步水解后提供了质子(式2).环氧丙烷中氧原子的强亲核性使得其与游离质子不断进行开环反应, 促进水合铝离子的水解和聚合(式3), 同时反应体系中的阴离子X- (如Cl- 或NO3 - )也参与开环反应消耗氧离子. ...

New Sol-Gel synthetic route to transition and main-group metal oxide aerogels using inorganic salt precursors

1

2001

... (2)无机铝盐价格低廉, 一般制备的氧化铝气凝胶颗粒及孔径较大, 热稳定性差[27 ,28 ] .2001年, Gash等[29 ,30 ] 发现以环氧丙烷作凝胶诱导剂容易控制凝胶形成过程, 极大地推动了无机铝盐法合成A12 O3 气凝胶的研究.此后, 许多研究人员采用AlCl3 · 6H2 O和Al(NO3 )3 • 9H2 O作为前驱体, 环氧丙烷作为凝胶剂, 制备了块体A12 O3 气凝胶, 性能可以媲美有机铝醇盐制备的A12 O3 气凝胶[17 ,31 -33 ] .环氧丙烷在无机铝盐的凝胶过程中涉及的反应如式(2~3)所示:铝离子先溶剂化形成水合铝离子, 进一步水解后提供了质子(式2).环氧丙烷中氧原子的强亲核性使得其与游离质子不断进行开环反应, 促进水合铝离子的水解和聚合(式3), 同时反应体系中的阴离子X- (如Cl- 或NO3 - )也参与开环反应消耗氧离子. ...

Preparation of Al2 O3 bulk aerogels by non-supercritical fluid drying technology

2

2005

... (2)无机铝盐价格低廉, 一般制备的氧化铝气凝胶颗粒及孔径较大, 热稳定性差[27 ,28 ] .2001年, Gash等[29 ,30 ] 发现以环氧丙烷作凝胶诱导剂容易控制凝胶形成过程, 极大地推动了无机铝盐法合成A12 O3 气凝胶的研究.此后, 许多研究人员采用AlCl3 · 6H2 O和Al(NO3 )3 • 9H2 O作为前驱体, 环氧丙烷作为凝胶剂, 制备了块体A12 O3 气凝胶, 性能可以媲美有机铝醇盐制备的A12 O3 气凝胶[17 ,31 -33 ] .环氧丙烷在无机铝盐的凝胶过程中涉及的反应如式(2~3)所示:铝离子先溶剂化形成水合铝离子, 进一步水解后提供了质子(式2).环氧丙烷中氧原子的强亲核性使得其与游离质子不断进行开环反应, 促进水合铝离子的水解和聚合(式3), 同时反应体系中的阴离子X- (如Cl- 或NO3 - )也参与开环反应消耗氧离子. ...

... 常压干燥工艺复杂, 干燥周期较长[35 ,36 ,37 ] .Xu 等[31 ] 在溶胶-凝胶过程中通过添加干燥化学控制剂与结构支撑剂, 采用环氧丙烷为凝胶诱导剂, 经老化及溶剂交换, 实现了常压干燥, 制备的氧化铝气凝胶与超临界干燥工艺得到的氧化铝气凝胶性能相近, 制备周期长达8 d.考虑到氧化铝气凝胶的连续化及规模化生产, 常压干燥仍然是首选方式, 但仍需要进一步研究并简化. ...

Novel Al2 O3 -SiO2 composite aerogels with high specific surface area at elevated temperatures with different alumina/silica molar ratios prepared by a non-alkoxide Sol-Gel method

2016

DUNN N J H, CARROLL M K, et al

1

2015

... (2)无机铝盐价格低廉, 一般制备的氧化铝气凝胶颗粒及孔径较大, 热稳定性差[27 ,28 ] .2001年, Gash等[29 ,30 ] 发现以环氧丙烷作凝胶诱导剂容易控制凝胶形成过程, 极大地推动了无机铝盐法合成A12 O3 气凝胶的研究.此后, 许多研究人员采用AlCl3 · 6H2 O和Al(NO3 )3 • 9H2 O作为前驱体, 环氧丙烷作为凝胶剂, 制备了块体A12 O3 气凝胶, 性能可以媲美有机铝醇盐制备的A12 O3 气凝胶[17 ,31 -33 ] .环氧丙烷在无机铝盐的凝胶过程中涉及的反应如式(2~3)所示:铝离子先溶剂化形成水合铝离子, 进一步水解后提供了质子(式2).环氧丙烷中氧原子的强亲核性使得其与游离质子不断进行开环反应, 促进水合铝离子的水解和聚合(式3), 同时反应体系中的阴离子X- (如Cl- 或NO3 - )也参与开环反应消耗氧离子. ...

Effect of different trimethyl silylating agents on the hydrophobic and physical properties of silica aerogels

2

2008

... Characteristics of several drying methods

Drying Characteristics Drying process Alumina aerogel Supercritical drying Short drying period, Low density, high porosity and specific surface area, low volume shrinkage[34 ,35 ] Ambient pressure Long drying period, inexpensive synthesis cost, complicated drying process High volume shrinkage, large pore size, high density and low specific surface area [34 ,35 ,36 ,37 ] Freeze Long drying period, inexpensive synthesis cost High volume shrinkage, large pore size, high density and low specific surface area

图2 快速超临界干燥的模具装配示意图[6 ] ...

... [

34 ,

35 ,

36 ,

37 ]

Freeze Long drying period, inexpensive synthesis cost High volume shrinkage, large pore size, high density and low specific surface area 图2 快速超临界干燥的模具装配示意图[6 ] ...

Low-density TEOS-based silica aerogels prepared at ambient pressure using isopropanol as the preparative solvent

5

2009

... Characteristics of several drying methods

Drying Characteristics Drying process Alumina aerogel Supercritical drying Short drying period, Low density, high porosity and specific surface area, low volume shrinkage[34 ,35 ] Ambient pressure Long drying period, inexpensive synthesis cost, complicated drying process High volume shrinkage, large pore size, high density and low specific surface area [34 ,35 ,36 ,37 ] Freeze Long drying period, inexpensive synthesis cost High volume shrinkage, large pore size, high density and low specific surface area

图2 快速超临界干燥的模具装配示意图[6 ] ...

... ,

35 ,

36 ,

37 ]

Freeze Long drying period, inexpensive synthesis cost High volume shrinkage, large pore size, high density and low specific surface area 图2 快速超临界干燥的模具装配示意图[6 ] ...

... 乙醇的相图[35 ] ...

... Phase diagram of ethanol[35 ] ...

... 常压干燥工艺复杂, 干燥周期较长[35 ,36 ,37 ] .Xu 等[31 ] 在溶胶-凝胶过程中通过添加干燥化学控制剂与结构支撑剂, 采用环氧丙烷为凝胶诱导剂, 经老化及溶剂交换, 实现了常压干燥, 制备的氧化铝气凝胶与超临界干燥工艺得到的氧化铝气凝胶性能相近, 制备周期长达8 d.考虑到氧化铝气凝胶的连续化及规模化生产, 常压干燥仍然是首选方式, 但仍需要进一步研究并简化. ...

Fabrication of hydrophobic alumina aerogel monoliths by surface modification and ambient pressure drying

2

2010

... Characteristics of several drying methods

Drying Characteristics Drying process Alumina aerogel Supercritical drying Short drying period, Low density, high porosity and specific surface area, low volume shrinkage[34 ,35 ] Ambient pressure Long drying period, inexpensive synthesis cost, complicated drying process High volume shrinkage, large pore size, high density and low specific surface area [34 ,35 ,36 ,37 ] Freeze Long drying period, inexpensive synthesis cost High volume shrinkage, large pore size, high density and low specific surface area

图2 快速超临界干燥的模具装配示意图[6 ] ...

... 常压干燥工艺复杂, 干燥周期较长[35 ,36 ,37 ] .Xu 等[31 ] 在溶胶-凝胶过程中通过添加干燥化学控制剂与结构支撑剂, 采用环氧丙烷为凝胶诱导剂, 经老化及溶剂交换, 实现了常压干燥, 制备的氧化铝气凝胶与超临界干燥工艺得到的氧化铝气凝胶性能相近, 制备周期长达8 d.考虑到氧化铝气凝胶的连续化及规模化生产, 常压干燥仍然是首选方式, 但仍需要进一步研究并简化. ...

Synthesis, pore structure and properties of polyurethane/silica hybrid aerogels dried at ambient pressure

2

2015

... Characteristics of several drying methods

Drying Characteristics Drying process Alumina aerogel Supercritical drying Short drying period, Low density, high porosity and specific surface area, low volume shrinkage[34 ,35 ] Ambient pressure Long drying period, inexpensive synthesis cost, complicated drying process High volume shrinkage, large pore size, high density and low specific surface area [34 ,35 ,36 ,37 ] Freeze Long drying period, inexpensive synthesis cost High volume shrinkage, large pore size, high density and low specific surface area

图2 快速超临界干燥的模具装配示意图[6 ] ...

... 常压干燥工艺复杂, 干燥周期较长[35 ,36 ,37 ] .Xu 等[31 ] 在溶胶-凝胶过程中通过添加干燥化学控制剂与结构支撑剂, 采用环氧丙烷为凝胶诱导剂, 经老化及溶剂交换, 实现了常压干燥, 制备的氧化铝气凝胶与超临界干燥工艺得到的氧化铝气凝胶性能相近, 制备周期长达8 d.考虑到氧化铝气凝胶的连续化及规模化生产, 常压干燥仍然是首选方式, 但仍需要进一步研究并简化. ...

Facile one-step precursor- to-aerogel synthesis of silica-doped alumina aerogels with high specific surface area at elevated temperatures

2

2017

... 超临界干燥过程中溶剂先从液体转变成气体, 所产生的表面张力会影响凝胶网络中的孔结构.2016年, Yang等[38 ] 通过控制乙醇超临界干燥过程的温度与压力, 使得乙醇从液体直接到达超临界状态, 越过气相区域, 消除了液-气转变过程中表面张力对孔的影响, 从而获得高比表面积和热稳定性的氧化铝气凝胶(图3 ).该方法也可用于二氧化碳等其他介质溶剂的超临界干燥, 可以进一步缩短气凝胶的合成时间, 并提高其性能 ...

... Al2 O3 气凝胶虽然具有大的比表面积及热稳定性, 但离实际应用还有一定差距.Al2 O3 气凝胶在1000℃以上的γ相到α相的转变伴随着较大的比表面积损失和体积收缩, 限制了其应用[4 ] .研究人员通过向A12 O3 气凝胶中掺杂La, Y, Ba, Si等多种元素, 使其比表面积和热稳定性均有不同程度的改善[40 ,41 ,42 ,43 ,44 ] .Alphonse等[45 ] 对A12 O3 气凝胶掺杂La后, 发现1000℃时其比表面积为180 m2 /g; 1200℃时其比表面积为70 m2 /g, 热稳定性得到了显著改善, 这是由于形成的La-Al混合氧化物(LaAl11 O18 或LaAlO3 )抑制了氧化铝的烧结.Wu等[46 ] 研究显示Si掺杂的A12 O3 气凝胶的比表面积1000℃时为373 m2 /g, 1200℃时为120 m2 /g; 即使在1400℃时仍保持 40 m2 /g[41 ] , 因此Si的掺杂效果比La更为显著.分析认为, Si对A12 O3 气凝胶热稳定性的改善主要是由于高温下SiO2 和A12 O3 会形成莫来石结构, 抑制A12 O3 的α相变, 从而保持大的比表面积[38 ,41 -42 ,47 ] . ...

An easy way to prepare monolithic inorganic oxide aerogels

3

2014

... 2014年, Ren等[39 ] 发展了一种有机溶剂升华干燥(OSSD)方法.该方法采用低表面张力、高凝固点且容易升华的有机溶剂, 如乙腈、叔丁醇等, 代替醇凝胶结构中的溶剂和水, 然后在低真空下干燥.干燥期间醇凝胶表面的溶剂首先蒸发, 蒸发吸收热量导致周围溶剂从液体转变成固体, 然后再通过升华将溶剂除掉(图4 ).升华干燥避免了气-液界面的出现, 消除了表面张力对孔的影响.采用该方法能够制备出完整的块体氧化铝气凝胶, 有较高强度, 但体积收缩仍较大. ...

... OSSD制备气凝胶的干燥机理示意图[39 ] ...

... Mechanism illustration of the formation of aerogels by OSSD[39 ] ...

Improvement in thermal shock resistance of gadolinium zirconate coating by addition of nanostructured yttria partially-stabilized zirconia

1

2015

... Al2 O3 气凝胶虽然具有大的比表面积及热稳定性, 但离实际应用还有一定差距.Al2 O3 气凝胶在1000℃以上的γ相到α相的转变伴随着较大的比表面积损失和体积收缩, 限制了其应用[4 ] .研究人员通过向A12 O3 气凝胶中掺杂La, Y, Ba, Si等多种元素, 使其比表面积和热稳定性均有不同程度的改善[40 ,41 ,42 ,43 ,44 ] .Alphonse等[45 ] 对A12 O3 气凝胶掺杂La后, 发现1000℃时其比表面积为180 m2 /g; 1200℃时其比表面积为70 m2 /g, 热稳定性得到了显著改善, 这是由于形成的La-Al混合氧化物(LaAl11 O18 或LaAlO3 )抑制了氧化铝的烧结.Wu等[46 ] 研究显示Si掺杂的A12 O3 气凝胶的比表面积1000℃时为373 m2 /g, 1200℃时为120 m2 /g; 即使在1400℃时仍保持 40 m2 /g[41 ] , 因此Si的掺杂效果比La更为显著.分析认为, Si对A12 O3 气凝胶热稳定性的改善主要是由于高温下SiO2 和A12 O3 会形成莫来石结构, 抑制A12 O3 的α相变, 从而保持大的比表面积[38 ,41 -42 ,47 ] . ...

Maintenance of large surface area of alumina aerogel heated at elevated temperature above 1300 by preparing silica-containing aerogel

3

2001

... Al2 O3 气凝胶虽然具有大的比表面积及热稳定性, 但离实际应用还有一定差距.Al2 O3 气凝胶在1000℃以上的γ相到α相的转变伴随着较大的比表面积损失和体积收缩, 限制了其应用[4 ] .研究人员通过向A12 O3 气凝胶中掺杂La, Y, Ba, Si等多种元素, 使其比表面积和热稳定性均有不同程度的改善[40 ,41 ,42 ,43 ,44 ] .Alphonse等[45 ] 对A12 O3 气凝胶掺杂La后, 发现1000℃时其比表面积为180 m2 /g; 1200℃时其比表面积为70 m2 /g, 热稳定性得到了显著改善, 这是由于形成的La-Al混合氧化物(LaAl11 O18 或LaAlO3 )抑制了氧化铝的烧结.Wu等[46 ] 研究显示Si掺杂的A12 O3 气凝胶的比表面积1000℃时为373 m2 /g, 1200℃时为120 m2 /g; 即使在1400℃时仍保持 40 m2 /g[41 ] , 因此Si的掺杂效果比La更为显著.分析认为, Si对A12 O3 气凝胶热稳定性的改善主要是由于高温下SiO2 和A12 O3 会形成莫来石结构, 抑制A12 O3 的α相变, 从而保持大的比表面积[38 ,41 -42 ,47 ] . ...

... [41 ], 因此Si的掺杂效果比La更为显著.分析认为, Si对A12 O3 气凝胶热稳定性的改善主要是由于高温下SiO2 和A12 O3 会形成莫来石结构, 抑制A12 O3 的α相变, 从而保持大的比表面积[38 ,41 -42 ,47 ] . ...

... ,41 -42 ,47 ]. ...

Preparation of heat-resistant alumina aerogels

2

1993

... Al2 O3 气凝胶虽然具有大的比表面积及热稳定性, 但离实际应用还有一定差距.Al2 O3 气凝胶在1000℃以上的γ相到α相的转变伴随着较大的比表面积损失和体积收缩, 限制了其应用[4 ] .研究人员通过向A12 O3 气凝胶中掺杂La, Y, Ba, Si等多种元素, 使其比表面积和热稳定性均有不同程度的改善[40 ,41 ,42 ,43 ,44 ] .Alphonse等[45 ] 对A12 O3 气凝胶掺杂La后, 发现1000℃时其比表面积为180 m2 /g; 1200℃时其比表面积为70 m2 /g, 热稳定性得到了显著改善, 这是由于形成的La-Al混合氧化物(LaAl11 O18 或LaAlO3 )抑制了氧化铝的烧结.Wu等[46 ] 研究显示Si掺杂的A12 O3 气凝胶的比表面积1000℃时为373 m2 /g, 1200℃时为120 m2 /g; 即使在1400℃时仍保持 40 m2 /g[41 ] , 因此Si的掺杂效果比La更为显著.分析认为, Si对A12 O3 气凝胶热稳定性的改善主要是由于高温下SiO2 和A12 O3 会形成莫来石结构, 抑制A12 O3 的α相变, 从而保持大的比表面积[38 ,41 -42 ,47 ] . ...

... -42 ,47 ]. ...

Rapid preparation process, structure and thermal stability of lanthanum doped alumina aerogels with a high specific surface area

1

2016

... Al2 O3 气凝胶虽然具有大的比表面积及热稳定性, 但离实际应用还有一定差距.Al2 O3 气凝胶在1000℃以上的γ相到α相的转变伴随着较大的比表面积损失和体积收缩, 限制了其应用[4 ] .研究人员通过向A12 O3 气凝胶中掺杂La, Y, Ba, Si等多种元素, 使其比表面积和热稳定性均有不同程度的改善[40 ,41 ,42 ,43 ,44 ] .Alphonse等[45 ] 对A12 O3 气凝胶掺杂La后, 发现1000℃时其比表面积为180 m2 /g; 1200℃时其比表面积为70 m2 /g, 热稳定性得到了显著改善, 这是由于形成的La-Al混合氧化物(LaAl11 O18 或LaAlO3 )抑制了氧化铝的烧结.Wu等[46 ] 研究显示Si掺杂的A12 O3 气凝胶的比表面积1000℃时为373 m2 /g, 1200℃时为120 m2 /g; 即使在1400℃时仍保持 40 m2 /g[41 ] , 因此Si的掺杂效果比La更为显著.分析认为, Si对A12 O3 气凝胶热稳定性的改善主要是由于高温下SiO2 和A12 O3 会形成莫来石结构, 抑制A12 O3 的α相变, 从而保持大的比表面积[38 ,41 -42 ,47 ] . ...

Hydrogen production by steam reforming of liquefied natural gas (LNG) over mesoporous Ni- La-Al2 O3 aerogel catalysts: effect of La content

1

2011

... Al2 O3 气凝胶虽然具有大的比表面积及热稳定性, 但离实际应用还有一定差距.Al2 O3 气凝胶在1000℃以上的γ相到α相的转变伴随着较大的比表面积损失和体积收缩, 限制了其应用[4 ] .研究人员通过向A12 O3 气凝胶中掺杂La, Y, Ba, Si等多种元素, 使其比表面积和热稳定性均有不同程度的改善[40 ,41 ,42 ,43 ,44 ] .Alphonse等[45 ] 对A12 O3 气凝胶掺杂La后, 发现1000℃时其比表面积为180 m2 /g; 1200℃时其比表面积为70 m2 /g, 热稳定性得到了显著改善, 这是由于形成的La-Al混合氧化物(LaAl11 O18 或LaAlO3 )抑制了氧化铝的烧结.Wu等[46 ] 研究显示Si掺杂的A12 O3 气凝胶的比表面积1000℃时为373 m2 /g, 1200℃时为120 m2 /g; 即使在1400℃时仍保持 40 m2 /g[41 ] , 因此Si的掺杂效果比La更为显著.分析认为, Si对A12 O3 气凝胶热稳定性的改善主要是由于高温下SiO2 和A12 O3 会形成莫来石结构, 抑制A12 O3 的α相变, 从而保持大的比表面积[38 ,41 -42 ,47 ] . ...

Thermal stabilization of alumina modified by lanthanum

1

2014

... Al2 O3 气凝胶虽然具有大的比表面积及热稳定性, 但离实际应用还有一定差距.Al2 O3 气凝胶在1000℃以上的γ相到α相的转变伴随着较大的比表面积损失和体积收缩, 限制了其应用[4 ] .研究人员通过向A12 O3 气凝胶中掺杂La, Y, Ba, Si等多种元素, 使其比表面积和热稳定性均有不同程度的改善[40 ,41 ,42 ,43 ,44 ] .Alphonse等[45 ] 对A12 O3 气凝胶掺杂La后, 发现1000℃时其比表面积为180 m2 /g; 1200℃时其比表面积为70 m2 /g, 热稳定性得到了显著改善, 这是由于形成的La-Al混合氧化物(LaAl11 O18 或LaAlO3 )抑制了氧化铝的烧结.Wu等[46 ] 研究显示Si掺杂的A12 O3 气凝胶的比表面积1000℃时为373 m2 /g, 1200℃时为120 m2 /g; 即使在1400℃时仍保持 40 m2 /g[41 ] , 因此Si的掺杂效果比La更为显著.分析认为, Si对A12 O3 气凝胶热稳定性的改善主要是由于高温下SiO2 和A12 O3 会形成莫来石结构, 抑制A12 O3 的α相变, 从而保持大的比表面积[38 ,41 -42 ,47 ] . ...

Synthesis of a novel Al2 O3 -SiO2 composite aerogel with high specific surface area at elevated temperatures using inexpensive inorganic salt of aluminum

1

2016

... Al2 O3 气凝胶虽然具有大的比表面积及热稳定性, 但离实际应用还有一定差距.Al2 O3 气凝胶在1000℃以上的γ相到α相的转变伴随着较大的比表面积损失和体积收缩, 限制了其应用[4 ] .研究人员通过向A12 O3 气凝胶中掺杂La, Y, Ba, Si等多种元素, 使其比表面积和热稳定性均有不同程度的改善[40 ,41 ,42 ,43 ,44 ] .Alphonse等[45 ] 对A12 O3 气凝胶掺杂La后, 发现1000℃时其比表面积为180 m2 /g; 1200℃时其比表面积为70 m2 /g, 热稳定性得到了显著改善, 这是由于形成的La-Al混合氧化物(LaAl11 O18 或LaAlO3 )抑制了氧化铝的烧结.Wu等[46 ] 研究显示Si掺杂的A12 O3 气凝胶的比表面积1000℃时为373 m2 /g, 1200℃时为120 m2 /g; 即使在1400℃时仍保持 40 m2 /g[41 ] , 因此Si的掺杂效果比La更为显著.分析认为, Si对A12 O3 气凝胶热稳定性的改善主要是由于高温下SiO2 和A12 O3 会形成莫来石结构, 抑制A12 O3 的α相变, 从而保持大的比表面积[38 ,41 -42 ,47 ] . ...

Novel Al2 O3 -SiO2 composite aerogels with high specific surface area at elevated temperatures with different alumina/silica molar ratios prepared by a non-alkoxide Sol-Gel method

1

2016

... Al2 O3 气凝胶虽然具有大的比表面积及热稳定性, 但离实际应用还有一定差距.Al2 O3 气凝胶在1000℃以上的γ相到α相的转变伴随着较大的比表面积损失和体积收缩, 限制了其应用[4 ] .研究人员通过向A12 O3 气凝胶中掺杂La, Y, Ba, Si等多种元素, 使其比表面积和热稳定性均有不同程度的改善[40 ,41 ,42 ,43 ,44 ] .Alphonse等[45 ] 对A12 O3 气凝胶掺杂La后, 发现1000℃时其比表面积为180 m2 /g; 1200℃时其比表面积为70 m2 /g, 热稳定性得到了显著改善, 这是由于形成的La-Al混合氧化物(LaAl11 O18 或LaAlO3 )抑制了氧化铝的烧结.Wu等[46 ] 研究显示Si掺杂的A12 O3 气凝胶的比表面积1000℃时为373 m2 /g, 1200℃时为120 m2 /g; 即使在1400℃时仍保持 40 m2 /g[41 ] , 因此Si的掺杂效果比La更为显著.分析认为, Si对A12 O3 气凝胶热稳定性的改善主要是由于高温下SiO2 和A12 O3 会形成莫来石结构, 抑制A12 O3 的α相变, 从而保持大的比表面积[38 ,41 -42 ,47 ] . ...

Robust, highly thermally stable, core-shell nanostructured metal oxide aerogels as high-temperature thermal superinsulators, adsorbents, and catalysts

3

2014

... 纯Al2 O3 气凝胶强度较低, 难以形成块体材料, 影响其使用.通过结构设计、改性等方法来提高强度一直是Al2 O3 气凝胶研究的一个重要内容.2014年, Zu等[48 ] 以仲丁醇铝为前驱体制备的醇凝胶, 经化学液相沉积Al2 O3 -SiO2 和SiO2 溶胶后, 超临界干燥得到了核壳结构Al2 O3 气凝胶.他们发现核壳结构的Al2 O3 气凝胶压缩模量相比纯Al2 O3 气凝胶 (1.7 MPa)提高了几乎4倍, 达到6.7 MPa(图5 (a)); 1300℃热处理2 h后, 形貌变化不大, 线收缩仅4%, 显示了优异的热稳定性(图5 (b)), 常温下导热系数 0.042 W/(m•K), 高温隔热性能优于莫来石纤维隔热材料.研究认为, 核壳结构增强了气凝胶纳米粒子的强度, 抑制了高温热处理过程中晶粒的生长和相变, 这为提高Al2 O3 气凝胶材料的热稳定性和机械强度提供了新的思路和方法. ...

... Al2 O3 气凝胶的应力应变曲线(a)和高温热处理前后Al2 O3 气凝胶(b)[48 ] ...

... Stress-strain curves of Al2 O3 aerogels (a) and Al2 O3 aerogels before and after heat treatment at high temperature (b)[48 ] ...

Synthesis of high strength monolithic alumina aerogels at ambient pressure

1

2015

... Cao等[49 ] 用AlCl3 •6H2 O为前驱体, 引入纳米凹凸棒石(Attapulgite, ATP), 环氧丙烷为凝胶诱导剂, 常压干燥制备了ATP/Al2 O3 复合气凝胶.研究发现, ATP/Al2 O3 复合气凝胶压缩强度随ATP含量增加先增加后降低, ATP含量为26%时, 压缩强度最高达到75.44 MPa.研究认为, A12 O3 纳米粒子能粘附在ATP的棒状结构单元上, 然后随机组装形成ATP/Al2 O3 复合气凝胶的网络骨架, 大幅提高了A12 O3 气凝胶的强度.该研究对于A12 O3 气凝胶的合成和应用具有重要意义, 但是强度的大幅增高, 使得其结构更加致密, 比表面积和隔热性能降低, 因此, ATP/Al2 O3 复合气凝胶的强度和比表面积、导热系数以及热稳定性的制约关系还需进一步研究. ...

Preparation and characterization of C/Al2 O3 composite aerogel with high compressive strength and low thermal conductivity

3

2015

... Wu等[50 ] 还采用AlCl3 • 6H2 O作为铝源, 间苯二酚(R)和甲醛(F)作为碳源, CO2 超临界干燥制备了RF/Al2 O3 气凝胶, 然后在氩气保护下800~1500℃进行了热处理, 将RF/Al2 O3 气凝胶转变成C/Al2 O3 气凝胶.结果发现, 先制备的RF/Al2 O3 中由于存在-CH2 或者-CH2 OCH2 柔性单元, 压缩模量较低, 而在碳化后转变为C/Al2 O3 后, 强度大幅提高, 压缩模量可以达到90 MPa(图6 (a)), 并指出C/Al2 O3 气凝 ...

... C/Al2 O3 气凝胶不同温度热处理后的应力-应变曲线(a)和密度、导热系数变化(b)[50 ] ...

... Compressive stress-strain curves (a) and bulk densities and thermal conductivities (b) of C/Al2 O3 aerogels heat treated at different temperatures[50 ] ...

Facile synthesis of strong alumina- cellulose aerogels by a freeze-drying method

3

2015

... 2015年, He等[51 ] 在仲丁醇铝为前驱体制备的溶胶中, 引入了纤维素(Cellulose), 经冷冻干燥制备了Al2 O3 -Cellulose气凝胶材料(ACA), 研究发现ACA热稳定性与Al2 O3 气凝胶比较接近, 在1200℃热处理后体积收缩约15%, ACA能保持完整块状.引入Cellulose改善了Al2 O3 气凝胶的强度, 在纤维素含量为2%时压缩强度为0.553 MPa(图7 ), 并在受压形变20%以下具有部分形状恢复性能, 展示出部分柔性(图7 插图), 克服了长久以来Al2 O3 气凝胶的易碎易掉渣的缺点, 为Al2 O3 气凝胶的应用提供了新方法, 但合成周期过长, 仍需进一步研究. ...

... 不同纤维素含量ACA的应力应变曲线(ACA0.5, ACA1, ACA2分别为纤维素含量0.5%, 1%, 2%)[51 ] ...

... Stress-strain curves of ACAs with different contents of cellulose (ACA0.5, ACA1 and ACA2 corresponding to the cellulose content of 0.5wt%, 1wt% and 2wt%, respectively)[51 ] ...

Infrared-opacified Al2 O3 -SiO2 aerogel composites reinforced by SiC-coated mullite fibers for thermal insulations

3

2015

... Xu等[52 ] 考察了莫来石纤维/Al2 O3 -SiO2 气凝胶材料的高温隔热性能.由于高温下热辐射对热传导影响较大, 一般在气凝胶中添加红外遮蔽剂来减小热辐射的措施.Xu等在莫来石纤维表面涂覆了SiC涂层,再制备莫来石纤维/Al2 O3 -SiO2 气凝胶材料, 解决了SiC作为红外遮蔽剂在纤维/气凝胶复合材料中的分散问题.结果发现, 前驱物浓度为10%时, 具有SiC涂层的纤维/气凝胶复合材料的有效比消光系数达到56.3 m2 /kg(图8 ), 使得其在1000℃的导热系数为0.049 W/(m•K), 表明SiC涂层可以有效遮蔽高温热辐射, 制备的复合材料具有优异的隔热性能, 为氧化铝气凝胶在高温隔热领域的应用提供了可能. ...

... 不同前驱物浓度得到的SiC涂层的莫来石纤维/Al2 O3 - SiO2 气凝胶的有效比消光系数[52 ] ...

... Effective specific extinction coefficient of Al2 O3 -SiO2 aerogel composites reinforced by SiC-coated mullite fibers prepared with different concentration of precursor[52 ] ...

Hydrogen production by steam reforming of liquefied natural gas (LNG) over magnesium-doped nickel-alumina aerogel catalyst

1

2016

... 氧化铝气凝胶优异的热稳定性和大的比表面积, 使其在催化剂及催化剂载体方面有广泛应用.Yoo等[53 ] 研究了Ni-Al2 O3 气凝胶催化剂在天然气蒸汽重整制氢过程中的催化性能, 发现Ni在Al2 O3 气凝胶中可以高度分散并具有较小的粒径, 使得催化性能得到显著提升.此外, Ni-Al2 O3 气凝胶在CH4 -CO2 重整过程中能抑制表面积碳导致的催化剂失活, 具有好的催化活性和稳定性[54 ,55 ] .Ozawa等[8 ] 研究显示La/CuOx 2 O3 气凝胶用作汽车尾气催化剂, 在1000℃高温下, NO和碳氢化合物的去除效率得到大幅提升.Mi等[56 ] 在合成单壁碳纳米管中发现, Fe/Mo/A12 O3 气凝胶600℃煅烧后催化活性最高. ...

Characterization of aerogel Ni/Al2 O3 catalysts and investigation on their stability for CH4 -CO2 reforming in a fluidized bed

1

2009

... 氧化铝气凝胶优异的热稳定性和大的比表面积, 使其在催化剂及催化剂载体方面有广泛应用.Yoo等[53 ] 研究了Ni-Al2 O3 气凝胶催化剂在天然气蒸汽重整制氢过程中的催化性能, 发现Ni在Al2 O3 气凝胶中可以高度分散并具有较小的粒径, 使得催化性能得到显著提升.此外, Ni-Al2 O3 气凝胶在CH4 -CO2 重整过程中能抑制表面积碳导致的催化剂失活, 具有好的催化活性和稳定性[54 ,55 ] .Ozawa等[8 ] 研究显示La/CuOx 2 O3 气凝胶用作汽车尾气催化剂, 在1000℃高温下, NO和碳氢化合物的去除效率得到大幅提升.Mi等[56 ] 在合成单壁碳纳米管中发现, Fe/Mo/A12 O3 气凝胶600℃煅烧后催化活性最高. ...

Study of nickel-based aerogel catalyzing CO2 reforming of CH4 to synthesis gas

1

2002

... 氧化铝气凝胶优异的热稳定性和大的比表面积, 使其在催化剂及催化剂载体方面有广泛应用.Yoo等[53 ] 研究了Ni-Al2 O3 气凝胶催化剂在天然气蒸汽重整制氢过程中的催化性能, 发现Ni在Al2 O3 气凝胶中可以高度分散并具有较小的粒径, 使得催化性能得到显著提升.此外, Ni-Al2 O3 气凝胶在CH4 -CO2 重整过程中能抑制表面积碳导致的催化剂失活, 具有好的催化活性和稳定性[54 ,55 ] .Ozawa等[8 ] 研究显示La/CuOx 2 O3 气凝胶用作汽车尾气催化剂, 在1000℃高温下, NO和碳氢化合物的去除效率得到大幅提升.Mi等[56 ] 在合成单壁碳纳米管中发现, Fe/Mo/A12 O3 气凝胶600℃煅烧后催化活性最高. ...

Influence of calcining temperature of aerogel catalyst on its catalytic activity for synthesizing SWNTs

1

2007

... 氧化铝气凝胶优异的热稳定性和大的比表面积, 使其在催化剂及催化剂载体方面有广泛应用.Yoo等[53 ] 研究了Ni-Al2 O3 气凝胶催化剂在天然气蒸汽重整制氢过程中的催化性能, 发现Ni在Al2 O3 气凝胶中可以高度分散并具有较小的粒径, 使得催化性能得到显著提升.此外, Ni-Al2 O3 气凝胶在CH4 -CO2 重整过程中能抑制表面积碳导致的催化剂失活, 具有好的催化活性和稳定性[54 ,55 ] .Ozawa等[8 ] 研究显示La/CuOx 2 O3 气凝胶用作汽车尾气催化剂, 在1000℃高温下, NO和碳氢化合物的去除效率得到大幅提升.Mi等[56 ] 在合成单壁碳纳米管中发现, Fe/Mo/A12 O3 气凝胶600℃煅烧后催化活性最高. ...

Preparation and thermal performance of alumina aerogel insulation composites

1

2008

... 作为隔热材料, 氧化铝气凝胶可用于航空航天领域, 如美国NASA研究双组分的Al2 O3 -SiO2 气凝胶用于航天飞行器的热防护系统[2 ,13 ] ; Gao等[57 ] 研究显示莫来石纤维复合氧化铝气凝胶隔热材料在高温1000℃时导热系数比莫来石纤维下降了47.5%, 比氧化硅气凝胶下降了13.4%, 可将其用于航天飞行器的热防护系统、导弹舵机舱隔热和热电池隔热构件; Jiang等[58 ] 研究了芳砜纶纤维复合氧化铝气凝胶用作隔热耐火消防服, 用垂直燃烧法测试后发现复合材料损毁长度大大降低, 具有优异的阻燃性能和隔热性能; Xie等[59 ] 研究了聚氨酯泡沫中引入氧化铝气凝胶, 得到的复合材料的阻燃和隔热性能得到显著提高, 可用于建筑、电力工业等领域的阻燃隔热材料. ...

Preparation and characterization of thermal protective aluminum hydroxide aerogel/PSA fabric composites

1

2017

... 作为隔热材料, 氧化铝气凝胶可用于航空航天领域, 如美国NASA研究双组分的Al2 O3 -SiO2 气凝胶用于航天飞行器的热防护系统[2 ,13 ] ; Gao等[57 ] 研究显示莫来石纤维复合氧化铝气凝胶隔热材料在高温1000℃时导热系数比莫来石纤维下降了47.5%, 比氧化硅气凝胶下降了13.4%, 可将其用于航天飞行器的热防护系统、导弹舵机舱隔热和热电池隔热构件; Jiang等[58 ] 研究了芳砜纶纤维复合氧化铝气凝胶用作隔热耐火消防服, 用垂直燃烧法测试后发现复合材料损毁长度大大降低, 具有优异的阻燃性能和隔热性能; Xie等[59 ] 研究了聚氨酯泡沫中引入氧化铝气凝胶, 得到的复合材料的阻燃和隔热性能得到显著提高, 可用于建筑、电力工业等领域的阻燃隔热材料. ...

Study on flame retarded flexible polyurethane foam/alumina aerogel composites with improved fire safety

1

2017

... 作为隔热材料, 氧化铝气凝胶可用于航空航天领域, 如美国NASA研究双组分的Al2 O3 -SiO2 气凝胶用于航天飞行器的热防护系统[2 ,13 ] ; Gao等[57 ] 研究显示莫来石纤维复合氧化铝气凝胶隔热材料在高温1000℃时导热系数比莫来石纤维下降了47.5%, 比氧化硅气凝胶下降了13.4%, 可将其用于航天飞行器的热防护系统、导弹舵机舱隔热和热电池隔热构件; Jiang等[58 ] 研究了芳砜纶纤维复合氧化铝气凝胶用作隔热耐火消防服, 用垂直燃烧法测试后发现复合材料损毁长度大大降低, 具有优异的阻燃性能和隔热性能; Xie等[59 ] 研究了聚氨酯泡沫中引入氧化铝气凝胶, 得到的复合材料的阻燃和隔热性能得到显著提高, 可用于建筑、电力工业等领域的阻燃隔热材料. ...