Journal of Inorganic Materials >

SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties

Received date: 2024-11-01

Revised date: 2024-12-19

Online published: 2024-12-27

Supported by

Aviation Science Foundation(2022Z055025001)

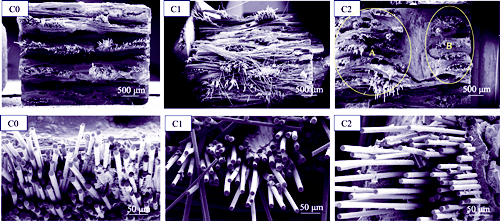

SiC/SiC composites have emerged as essential thermal structure materials for development of hypersonic vehicles and high thrust-to-weight ratio aero-engines. Design and utilization of boron-containing ceramic precursors as impregnation agents for precursor infiltration and pyrolysis (PIP) to introduce self-healing components into matrix represent a key strategy for enhancing the antioxidant properties of SiC/SiC composites. Here, borane pyridine or borane triethylamine were utilized as boron sources and subsequently mixed with a solid polycarbosilane (PCS) xylene solution to prepare different boron-modified PCS solutions. These solutions were used as PIP impregnation agents to fabricate various boron-modified SiC/PyC (pyrolytic carbon)/SiC composites. The physicochemical properties of boron-modified PCS-derived ceramics, along with the physical and mechanical properties of SiC/PyC/SiC composites before and after matrix boron modification, were investigated. Results demonstrated that addition of appropriate amounts of borane pyridine and borane triethylamine as boron sources in solid PCS solutions effectively introduced boron as a heterogeneous element into the derived SiC ceramics. Compared to PCS, the boron-modified PCS solutions (BP-1 and BP-2) exhibited increased ceramic yields. The derived ceramics exhibited a semi-crystalline β-SiC structure, with boron element contents of 1.7% and 2.2% (in mass), respectively. In contrast to unmodified composite, the boron-modified SiC/SiC composites exhibited negligible changes in density, apparent porosity, and fracture toughness. However, the flexural modulus increased from 116 GPa to 132 GPa. Furthermore, the flexural strength of the modified composite using borane pyridine alone as boron source was 658 MPa, comparable to the unmodified composite's strength of 643 MPa, but with a reduced dispersion coefficient. All above data demonstrate that borane pyridine can be used as boron source for preparation of boron-modified SiC/SiC composites, providing valuable insights for developing high-performance SiC/SiC composite hot-end components.

CHEN Yi , QIU Haipeng , CHEN Mingwei , XU Hao , CUI Heng . SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties[J]. Journal of Inorganic Materials, 2025 , 40(5) : 504 -510 . DOI: 10.15541/jim20240457

| [1] | 成来飞. 陶瓷基复合材料强韧化与应用基础. 北京: 化学工业出版社, 2019. |

| [2] | 邹豪, 王宇, 刘刚, 等. 碳化硅纤维增韧碳化硅陶瓷基复合材料的发展现状及其在航空发动机上的应用. 航空制造技术, 2017(15): 76. |

| [3] | 张立同. 纤维增韧碳化硅陶瓷复合材料:模拟、表征与设计. 北京: 化学工业出版社, 2009. |

| [4] | NASLAIN R R. SiC-matrix composites: nonbrittle ceramics for thermo-structural application. International Journal of Applied Ceramic Technology, 2005, 2(2): 75. |

| [5] | DARZENS S, FARIZY G, VICENS J, et al. High temperature ceramic matrix composites. Hoboken: John Wiley & Sons, Inc., 2001: 211- 217. |

| [6] | KOTANI M, KOHYAMA A, OKAMURA K, et al. Fabrication of high performance SiC/SiC composite by polymer impregnation and pyrolysis method//USTUNDAG E, FISCHMAN G. 23rd Annual Conference on Composites, Advanced Ceramics, Materials, and Structures: B:Ceramic Engineering and Science Proceedings. Hoboken: John Wiley & Sons, Icn., 1999: 309-316. |

| [7] | GOUJARD S R, VANDENBULCKE L, REY J, et al. Process for the manufacture of a refractory composite material protected against corrosion: US5246736A. 1993-09-21. |

| [8] | LAMOUROUX F, BERTRAND S, PAILLER R, et al. A multilayer ceramic matrix for oxidation resistant carbon fibers-reinforced CMCs. Key Engineering Materials, 1999, 164/165: 365. |

| [9] | LAMOUROUX F, BERTRAND S, PAILLER R, et al. Oxidation- resistant carbon-fiber-reinforced ceramic-matrix composites. Composites Science and Technology, 1999, 59(7): 1073. |

| [10] | RUGGLES-WRENN M B, POPE M T, ZENS T W. Creep behavior in interlaminar shear of a Hi-NicalonTM/SiC-B4C composite at 1200 ℃ in air and in steam. Materials Science and Engineering: A, 2014, 610: 279. |

| [11] | 张立同, 成来飞, 徐永东, 等. 自愈合碳化硅陶瓷基复合材料研究及应用进展. 航空材料学报, 2006, 26(3): 226. |

| [12] | CHEN M, QIU H, ZHANG Q, et al. Influence of precursor concentration on the densification efficiency and properties of SiC/SiC composites. International Journal of Applied Ceramic Technology, 2022, 19(6): 3238. |

| [13] | CHEN Y, CHEN M, XIE W, et al. Influence of polycarbosilane composition on the properties of SiC/SiC composite fabricated by precursor infiltration and pyrolysis process. International Journal of Applied Ceramic Technology, 2024, 21(5): 3237. |

| [14] | HU J, LIU C, YE F, et al. A review on high-performance SiCf/SiC composites prepared by PIP process. Journal of Materials Research and Technology, 2024, 33: 7216. |

| [15] | SONG C, YE F, CHENG L, et al. Long-term ceramic matrix composite for aeroengine. Journal of Advanced Ceramics, 2022, 11(9): 1343. |

| [16] | 张立同, 成来飞. 自愈合陶瓷基复合材料制备与应用基础. 北京: 化学工业出版社, 2015. |

| [17] | LUAN X, XU X, ZOU Y, et al. Wet oxidation behavior of SiC/(SiC-SiBCN)x composites prepared by CVI combined with PIOP process. Journal of the American Ceramic Society, 2019, 102(10): 6239. |

| [18] | CHEN M, QIU H, XIE W, et al. Influence of precursor composition on oxidation behavior of SiBCN multiphase ceramic and oxidation resistance of SiC/SiBCN composites. Journal of the Australian Ceramic Society, 2022, 58(2): 575. |

| [19] | LUAN X, XU X, WANG L, et al. Self-healing enhancing tensile creep of 2D-satin weave SiC/(SiC-SiBCN)x composites in wet oxygen environment. Journal of the European Ceramic Society, 2020, 40(10): 3509. |

| [20] | CAO F, LI X D, RYU J H, et al. Modification of polycarbosilane by polyborazine as a precursor for oxygen-free SiC fibers. Journal of Materials Chemistry, 2003, 13(8): 1914. |

| [21] | PUERTA A R, REMSEN E E, BRADLEY M G, et al. Synthesis and ceramic conversion reactions of 9-BBN-modified allylhydridopolycarbosilane:? a new single-source precursor to boron-modified silicon carbide. Chemistry of Materials, 2003, 15(2): 478. |

| [22] | YU Z, HUANG M, FANG Y, et al. Modification of a liquid polycarbosilane with 9-BBN as a high-ceramic-yield precursor for SiC. Reactive and Functional Polymers, 2010, 70(6): 334. |

| [23] | VIARD A, FONBLANC D, LOPEZ-FERBER D, et al. Polymer derived Si-B-C-N ceramics: 30 years of research. Advanced Engineering Materials, 2018, 20(10): 1800360. |

| [24] | ANAND R, MADHAVI V, LU K. Effect of boron on phase, nanostructure, and thermal stability of polycarbosilane-derived SiC ceramics. Ceramics International, 2024, 50(24): 53701. |

| [25] | BALESTRAT M, DIZ ACOSTA E, HANZEL O, et al. Additive-free low temperature sintering of amorphous SiBC powders derived from boron-modified polycarbosilanes: toward the design of SiC with tunable mechanical, electrical and thermal properties. Journal of the European Ceramic Society, 2020, 40(7): 2604. |

| [26] | 陶孟, 胡继东, 俸翔, 等. 一种硼改性聚碳硅烷树脂及其制备方法: CN109438712B. 2021-06-11. |

| [27] | 莫高明, 宋育杰, 陈海俊, 等. 一种液态可固化含硼聚碳硅烷及其制备方法: CN110698678A. 2020-01-17. |

| [28] | 裴亚星. 单源聚合物先驱体法制备SiC基超高温纳米复相陶瓷. 厦门: 厦门大学硕士学位论文, 2017. |

| [29] | YU Z, FANG Y, HUANG M, et al. Preparation of a liquid boron-modified polycarbosilane and its ceramic conversion to dense SiC ceramics. Polymers for Advanced Technologies, 2011, 22(12): 2409. |

| [30] | 邵长伟, 王军, 王浩, 等. 一种含硼碳化硅纤维的制备方法: CN104790068A. 2015-07-22. |

| [31] | 董志军, 余汉青, 李轩科, 等. 一种硼掺杂碳化硅纤维及其制备方法: CN108315837A. 2018-07-24. |

| [32] | BILL J, RIEDEL R. Boron carbide nitride derived from amine- boranes. MRS Online Proceedings Library Archive, 1992, 271: 839. |

| [33] | RIEDEL R, BILL J, PASSING G. A novel carbon material derived from pyridine-borane. Advanced Materials, 1991, 3(11): 551. |

| [34] | BILL J, FRIESS M, RIEDEL R. Conversion of amine-boranes to boron carbide nitride. European journal of Solid State and Inorganic Chemistry, 1992, 29: 195. |

| [35] | 王天一. BCN陶瓷制备工艺优化及微结构调控研究. 天津: 河北工业大学硕士学位论文, 2023. |

| [36] | HE L, ZHANG Z, YANG X, et al. Liquid polycarbosilanes: synthesis and evaluation as precursors for SiC ceramic. Polymer International, 2015, 64(8): 979. |

/

| 〈 |

|

〉 |