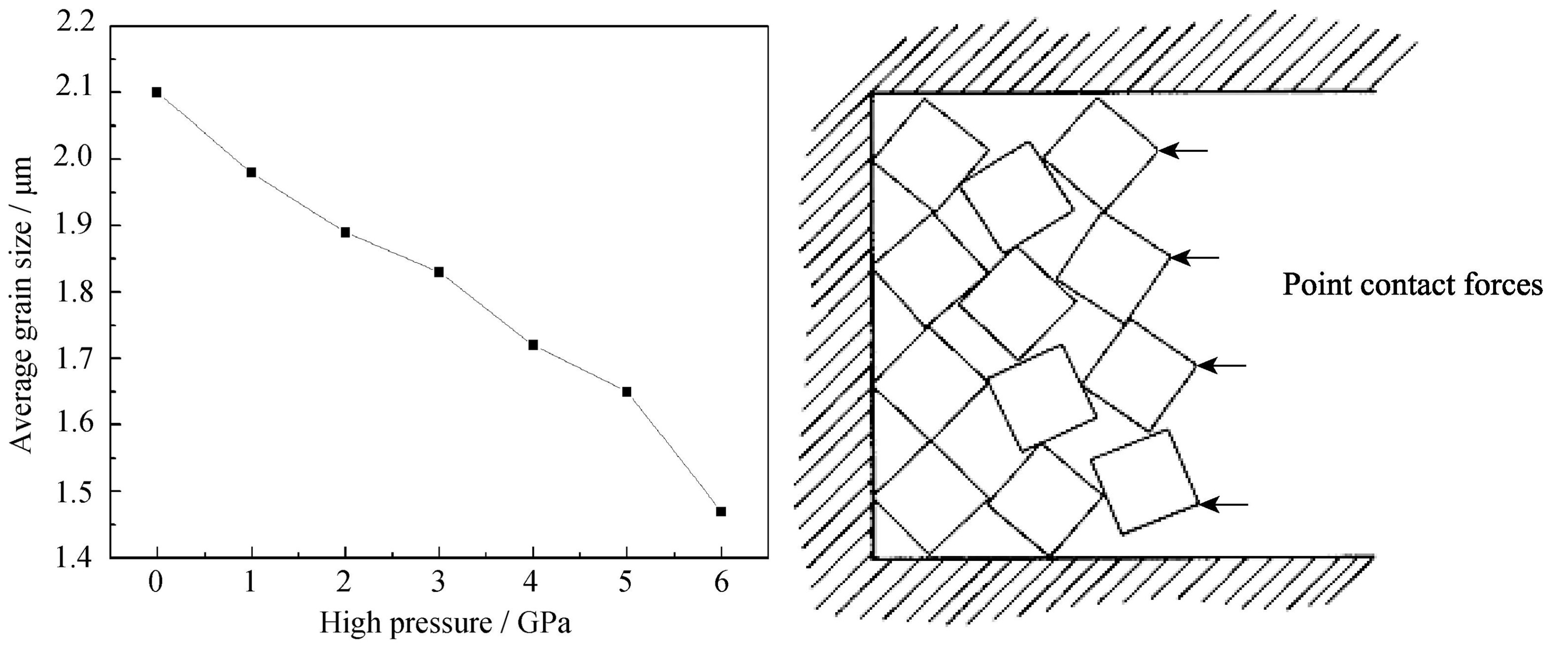

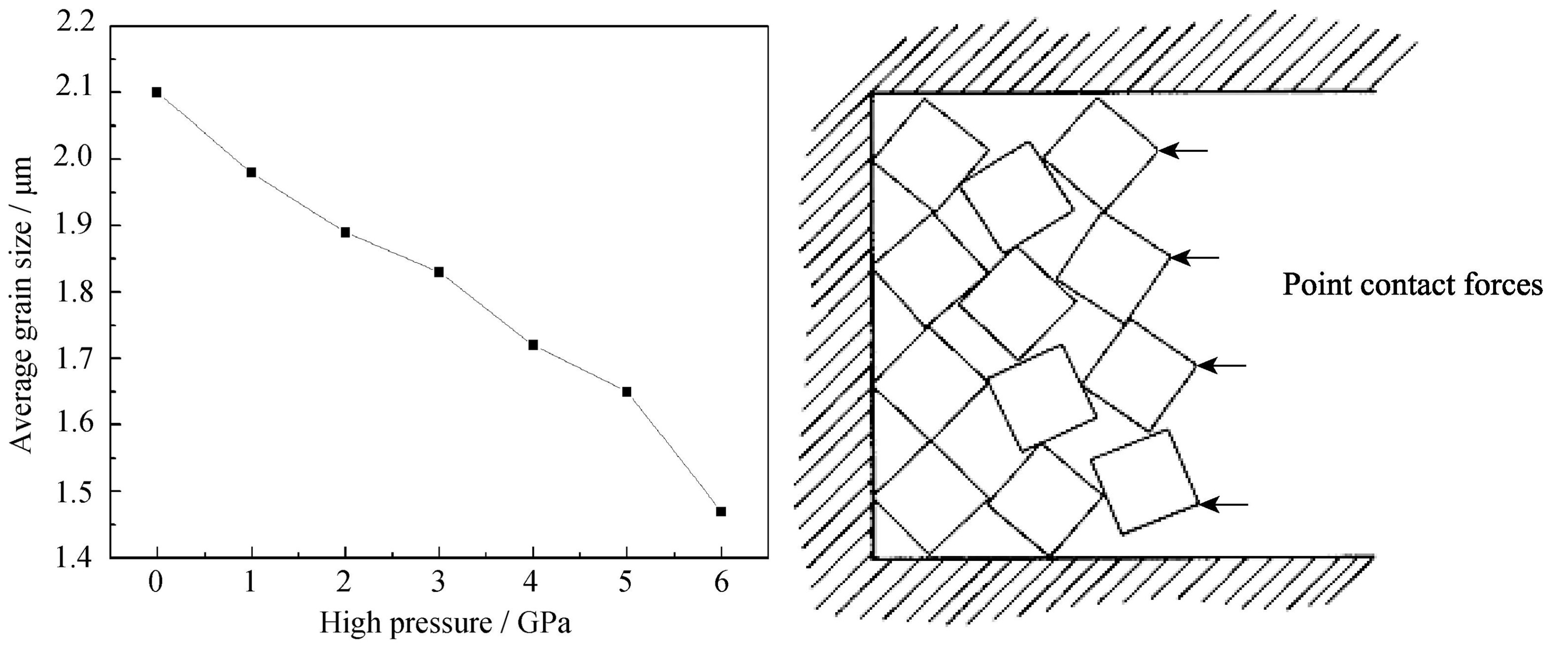

Grain fragmentation of AlN micron?powder under high pressure (2.0–6.0 GPa) was studied on cubic high pressure apparatus. Phase composition, grain size and microstructure of the samples were characterized by X-ray diffraction (XRD) and scanning electron microscope (SEM). The results show that relative density of AlN microcrystal increases and open pore decreases with the rise of high pressure. “Cold-sintering” occurs in the AlN sample pressed at 6.0 GPa because its relative density reaches 88.72%. Obvious pressure-induced grain fragmentation is observed during the compacting of AlN powder under high pressure. The average particle diameter drops to 1.47 μm from 2.10 μm when high pressure is increased to 6.0 GPa from atmospheric pressure. Pressure-induced grain fragmentation can improve the surface free energy of AlN powder and increase sintering driving force. Meanwhile, it can activate sintering to improve AlN sintering rate because of the presence of defects (such as dislocation, crack, etc.) caused by high pressure.

LI Xiao-Lei

,

WANG Hong-Liang

,

ZHANG Qin-Shan

,

WANG Li-Ying

,

LI Shang-Sheng

,

SU Tai-Chao

. Study on Grain Fragmentation of Aluminum Nitride Microcrystal under High Pressure[J]. Journal of Inorganic Materials, 2012

, 27(12)

: 1313

-1316

.

DOI: 10.3724/SP.J.1077.2012.12198

[1] Baik Y, Drew R A L. Aluminum nitride: processing and applications. Key Eng. Mater., 1996, 122-124: 553–570.

[2] BANG Rong, ZHOU He-Beng, NING Xiao-Shan, et al. Bonding strength and mechanism between aluminum and AlN. Journal of Inorganic Materials, 2011, 26(3): 249–253.

[3] Jackson T B, Virkar A V, More K L, et al. High thermal conductivity aluminum nitride ceramics: the effect of thermodynamic, kinetic and microstructural factors. J. Am. Ceram. Soc., 1997, 80(6): 1421–1435.

[4] LI Xiao-Lei, LI De-You, WANG Li-Ying, et al. Effect of high pressure annealing on microstructure and thermal conductivity of aluminum nitride ceramics. Journal of Inorganic Materials, 2010, 25(5): 537–540.

[5] QIN Bing-Ke, LI Xiao-Lei, LI Shang-Sheng, et al. High pressure synthesis and thermoelectric properties of the Ba-filled skutterudites. Journal of Inorganic Materials, 2010, 25(1): 23–26.

[6] XIE Mao-Lin, LUO De-Li, XIAN Xiao-Bin, et al. Nano-SiC ceramic sintering at ultra-high pressure and high temperature. Journal of Inorganic Materials, 2008, 23(4): 811–814.

[7] GAO Lian, LI Wei, WANG Hong-Zhi, et al. Preparation of Y-TZP nanoceramics by superhigh pressure compaction. Journal of Inorganic Materials, 2000, 15(6): 1005–1008.

[8] 邓福铭, 陈启武. 金刚石粉末超高压挤压破碎规律研究. 超硬材料工程, 1998(4): 9–15.

[9] 邵光杰, 秦秀娟, 刘日平, 等(SHAO Guang-Jie, et al). 氧化锌纳米晶高压下的晶粒演化和性能. 物理学报(Acta Phys. Sin.), 2006, 55(1): 472– 475.

[10] Dopita Milan,?Janecek Milo?, Kuzel Radomír, et al. Microstructure evolution of CuZr polycrystals processed by high-pressure torsion. J. Mater. Sci., 2010, 45(17): 4631–4644.

[11] LI Xiao-Lei, MA Hong-An, ZUO Gui-Hong, et al. High pressure sintering of AlN ceramics. Journal of Inorganic Materials, 2008, 23(1): 104–108.

[12] Hahn H, Logas J, Averback R S. Sintering characteristics of nanocrystalline TiO2. J. Mater. Res., 1990, 5(3): 609–614.

[13] Gutmanas E Y, Rabinkin A, Roitberg M. Cold sintering under high pressure. Scripta Mater., 1979, 13(1): 11–15.