亚稳相图研究及其在特种陶瓷涂层中的应用进展

收稿日期: 2019-06-03

修回日期: 2019-07-22

网络出版日期: 2019-10-17

基金资助

国家自然科学基金(51701232);中国科学院率先行动“百人计划”(2017-118)

Review on Metastable Phase Diagrams: Application Roles in Specialty Ceramic Coatings

Received date: 2019-06-03

Revised date: 2019-07-22

Online published: 2019-10-17

Supported by

National Natural Science Foundation of China(51701232);Hundred Talents Program of Taking the Lead of the Chinese Academy of Sciences(2017-118)

相图, 又称相平衡图, 是“材料设计的索骥图”, 而涂层的制备过程中(如物理气相沉积, Physical Vapor Deposition, 简称PVD), 系统一般远离平衡态, 获得的相为亚稳相, 相图计算CALPHAD (CALculation of PHAse Diagrams)方法的应用遇到了挑战。本文概述了模拟涂层材料亚稳相图的研究历程, 重点介绍了近期建立的临界表面扩散亚稳相图模型, 即通过耦合CALPHAD、第一性原理计算和高通量磁控溅射镀膜实验的方法对涂层材料的亚稳相进行表面扩散模拟, 相关计算仅需要一个高通量镀膜实验作为基础数据, 获得的亚稳相图也得到了实验验证。由此, 可以建立相关材料体系的稳定和亚稳相图数据库, 通过组分-制备工艺-组织结构和性能的关系, 指导陶瓷涂层材料的设计, 助推研发时间和成本“双减半”目标的实现。

黄烨琰 , 徐凯 , 吴波 , 李朋 , 常可可 , 黄峰 , 黄庆 . 亚稳相图研究及其在特种陶瓷涂层中的应用进展[J]. 无机材料学报, 2020 , 35(1) : 19 -28 . DOI: 10.15541/jim20190272

Phase diagrams, also known as equilibrium phase diagrams, serve as a road map for materials design. However, preparation process of coatings (such as Physical Vapor Deposition, PVD) is generally far from equilibrium and results in metastable phases. Thus, the CALPHAD (Calculation of Phase Diagrams) approach faces a challenge in calculating the metastable phase diagrams for PVD coating materials. Here we summarized the development of the modeling methodology for the metastable phase diagrams, where the model with critical surface diffusion distance established in recent years were highlighted. The CALPHAD approach, first-principles calculations coupled with high-throughput magnetron sputtering experiments were used to model the atomic surface diffusion, while only one key combinatorial experiment was performed to obtain the basic data for the computation, and the calculated metastable phase diagrams were confirmed by further experiments. Therefore, the database of the stable and metastable phase diagrams can be established, which will be used to guide the design of the ceramic coating materials by the relationship of composition, processing, microstructure, and performance. This model can also help to achieve the goal to shorten the time and reduce the costs of materials research and development.

Key words: metastable phase formation diagram; model; surface diffusion; application; review

| [1] | ENDRINO J C, ?RHAMMAR C, GUTIéRREZ C , et al. Spectral evidence of spinodal decomposition, phase transformation and molecular nitrogen formation in supersaturated TiAlN films upon annealing. Acta Materialia, 2011,59(2):6287-6296. |

| [2] | RACHBAUER R, GENGLER J J, VOEVODIN A A , et al. Temperature driven evolution of thermal, electrical, and optical properties of Ti-Al-N coatings. Acta Materialia, 2012,60:2091-2096. |

| [3] | MAYRHOFER P, RACHBAUER R, HOLEC D , et al. Protective transition metal nitride coatings. Comprehensive Materials Processing, 2014,4:355-387. |

| [4] | NORRBY N, ROGSTR?M L JOHANSSON-J?ESAAR M P , et al. In situ X-ray scattering study of the cubic to hexagonal transformation of AlN in Ti1-xAlxN. Acta Materialia, 2014,73:205-214. |

| [5] | SCHRAMM I C, J?ESAAR M P J, JENSEN J , et al. Impact of nitrogen vacancies on the high temperature behavior of (Ti1-xAlx)Ny alloys. Acta Materialia, 2016,119:218-228. |

| [6] | ZOU H K, CHEN L, CHANG K K , et al. Enhanced hardness and age-hardening of TiAlN coatings through Ru addition. Scripta Materialia, 2019,162:382-386. |

| [7] | RAJAN S T, KARTHIKA M, BENDAVID A , et al. Apatite layer growth on glassy Zr48Cu36Al8Ag8 sputtered titanium for potential biomedical applications. Applied Surface Science, 2016,369:501-509. |

| [8] | CAI C N, ZHANG C, SUN Y S , et al. ZrCuFeAlAg thin film metallic glass for potential dental applications. Intermetallics, 2017,86:80-87. |

| [9] | LEE C M, CHU J P, CHANG W Z , et al. Fatigue property improvements of Ti-6Al-4V by thin film coatings of metallic glass and TiN: a comparison study. Thin Solid Films, 2014,561:33-37. |

| [10] | TSAI P H, LIN Y Z, LI J B , et al. Sharpness improvement of surgical blade by means of ZrCuAlAgSi metallic glass and metallic glass thin film coating. Intermetallics, 2012,31:127-131. |

| [11] | TSAI P H, LI T H, HSU K T , et al. Effect of coating thickness on the cutting sharpness and durability of Zr-based metallic glass thin film coated surgical blades. Thin Solid Films, 2016,618:36-41. |

| [12] | CHU J P, JANG J S C, HUANG J C , et al. Thin film metallic glasses: unique properties and potential applications. Thin Solid Films, 2012,520:5097-5122. |

| [13] | GORDON R G . Criteria for choosing transparent conductors. MRS Bulletin, 2000,25:52-57. |

| [14] | CHENG C H, TING J M . Transparent conducting GZO, Pt/GZO, and GZO/Pt/GZO thin films. Thin Solid Films, 2007,516:203-207. |

| [15] | KIM D . Improved electrical and optical properties of GZO films with a thin TiO2 buffer layer deposited by RF magnetron sputtering. Ceramics International, 2014,40:1457-1460. |

| [16] | WANG H L, SUN Y H, FANG L , et al. Growth and characterization of high transmittance GZO films prepared by Sol-Gel method. Thin Solid Films, 2016,615:19-24. |

| [17] | LU L F, SHEN H L, FENG J , et al. The enhanced conductivity of AZO thin films on soda lime glass with an ultrathin Al2O3 buffer layer. Physica B, 2010,405:3320-3323. |

| [18] | SHEN H L, ZHANG H, LU L F , et al. Preparation and properties of AZO thin films on different substrates. Progress in Natural Science: Materials International, 2010,20:44-48. |

| [19] | SUBRAMANYAM T K, GOUTHAM P, PAVAN KUMAR S , et al. Optimization of sputtered AZO thin films for device application. Materials Today: Proceedings, 2018,5:10851-10859. |

| [20] | Lü K, ZHU B L, LI K , et al. Effect of hydrogen and Cu interlayer on the optical and electrical properties of GZO thin film. Journal of Inorganic Materials, 2014,29(5):494-497. |

| [21] | CHEN D, Lü J G, HUANG J Y , et al. Performances of GaN-based LEDs with AZO films as transparent electrodes. Journal of Inorganic Materials, 2013,28(6):650-652. |

| [22] | QIN X J, HAN S H Z, ZHAO L , et al. Fabrication of transparent conductive Al-doped ZnO thin films by aerosol-assisted chemical vapour deposition. Journal of Inorganic Materials, 2011,26(6):608-611. |

| [23] | AYDOGAN E, WEAVER J S, MALOY S A , et al. Microstructure and mechanical properties of FeCrAl alloys under heavy ion irradiations. Journal of Nuclear Materials, 2018,503:250-262. |

| [24] | DRYEPONDT S, UNOCIC K A, HOELZER D T , et al. Development of low-Cr ODS FeCrAl alloys for accident-tolerant fuel cladding. Journal of Nuclear Materials, 2018,501:59-71. |

| [25] | GUSSEV M N, CAKMAK E, FIELD K G , et al. Impact of neutron irradiation on mechanical performance of FeCrAl alloy laser-beam weldments. Journal of Nuclear Materials, 2018,504:221-233. |

| [26] | HOGGAN R E, HE L F, HARP J M , et al. Interdiffusion behavior of U3Si2 with FeCrAl via diffusion couple studies. Journal of Nuclear Materials, 2018,502:356-369. |

| [27] | JIN D L, NI N, GUO Y , et al. Corrosion of the bonding at FeCrAl/ Zr alloy interfaces in steam. Journal of Nuclear Materials, 2018,508:411-422. |

| [28] | PARK D, MOUCHE P A, ZHONG W C , et al. TEM/STEM study of zircaloy-2 with protective FeAl(Cr) layers under simulated BWR environment and high-temperature steam exposure. Journal of Nuclear Materials, 2018,502:95-105. |

| [29] | TANG C C, JIANU A, STEINBRUECK M , et al. Influence of composition and heating schedules on compatibility of FeCrAl alloys with high-temperature steam. Journal of Nuclear Materials, 2018,511:496-507. |

| [30] | CHANG K K, MENG F P, GE F F , et al. Theory-guided bottom- up design of the FeCrAl alloys as accident tolerant fuel cladding materials. Journal of Nuclear Materials, 2019,516:63-72. |

| [31] | CAIRNEY J M, HARRIS S G, MUNROE P R , et al. Transmission electron microscopy of TiN and TiAlN thin films using specimens prepared by focused ion beam milling. Surface and Coatings Technology, 2004,183:239-246. |

| [32] | RACHBAUER R, STERGAR E, MASSL S , et al. Three-dimensional atom probe investigations of Ti-Al-N thin films. Scripta Materialia, 2009,61:725-728. |

| [33] | WEBER F R, FONTAINE F, SCHEIB M, , et al. Cathodic arc evaporation of (Ti, Al) N coatings and (Ti, Al) N/TiN multilayer-coatings-correlation between lifetime of coated cutting tools, structural and mechanical film properties. Surface and Coatings Technology, 2004,177-178:227-232 |

| [34] | MüNZ W D . A new alternative to TiN coatings. Journal of Vacuum Science and Technology A, 1986,4(6):2717-2725. |

| [35] | WAHLSTR?M U, HULTMAN L, SUNDGREN J E , et al. Crystal growth and microstructure of polycrystalline Ti1-xAlxN alloy films deposited by ultra-high-vacuum dual-target magnetron sputtering. Thin Solid Films, 1993,235:62-70. |

| [36] | ZHOU M, MAKINO Y, NOSE M , et al. Phase transition and properties of Ti-Al-N thin films prepared by rf-plasma assisted magnetron sputtering. Thin Solid Films, 1999,339:203-208. |

| [37] | H?RLING A, HULTMAN L, ODéN M , et al. Mechanical properties and machining performance of Ti1-xAlxN-coated cutting tools. Surface and Coatings Technology, 2005,191:384-392. |

| [38] | KUTSCHEJ K, MAYRHOFER P, KATHREIN M , et al. Structure, mechanical and tribological properties of sputtered Ti1-xAlxN coatings with 0.5≤x≤0.75. Surface and Coatings Technology, 2005,200:2358-2365. |

| [39] | RAFAJA D, POKLAD A, SCHREIBER G , et al. On the preferred orientation in Ti1-xAlxN and Ti1-x-yAlxSiyN thin films. Zeitschrift für Metallkunde, 2005,96:738-742. |

| [40] | GRECZYNSKI G, LU J, JOHANSSON M , et al. Role of Tin + and Aln + ion irradiation(n=1, 2) during Ti1-xAlxN alloy film growth in a hybrid HIPIMS/magnetron mode. Surface and Coatings Technology, 2012,206:4202-4211. |

| [41] | GROSSMANN B, SCHALK N, CZETTL C , et al. Phase composition and thermal stability of arc evaporated Ti1-xAlxN hard coatings with 0.4≤x≤0.67. Surface and Coatings Technology, 2017,309:687-693. |

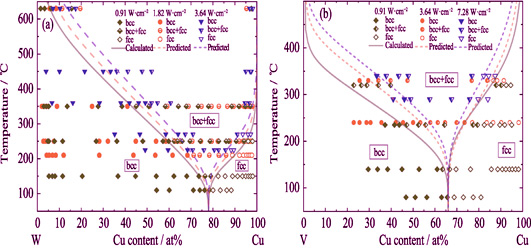

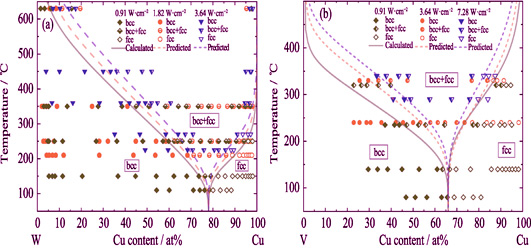

| [42] | HANS M, MUSIC D, CHEN Y T , et al. Crystallite size-dependent metastable phase formation of TiAlN coatings. Scientific Reports, 2017,7(16096):1-7. |

| [43] | SPENCER P, HOLLECK H . Application of a thermochemical data-bank system to the calculation of metastable phase formation during PVD od carbide, nitride and boride coatings. High Temperature Science, 1990,27:295-309. |

| [44] | STOLTEN H, SPENCER P, NEUSCHüTZ D , et al. Estimation of formation enthalpies for transition metal mono nitrides, carbides and oxides. Journal de Chimie Physique, 1993,90:209-219. |

| [45] | CHEN Q, SUNDMAN B . Thermodynamic assessment of the Ti-Al-N system. Journal of Phase Equilibria, 1998,19(20):146-160. |

| [46] | ZENG K J, SCHMID-FETAER R . Thermodynamic Modeling and Applications of the Ti-Al-N Phase Diagram. Thermodynamics of Alloy Formation, 1997, 275-293. |

| [47] | SPENCER P . Thermodynamic prediction of metastable coating structures in PVD processes. Zeitschrift für Metallkunde, 2001,92:1145-1150. |

| [48] | HUGOSSON H W, H?GBERG H, ALGREN M , et al. Theory of the effects of substitutions on the phase stabilities of Ti1-xAlxN. Journal of Applied Physics, 2003,93(8):4505-4511. |

| [49] | MAYRHOFER P, MUSIC D, SCHNEIDER J , et al. Influence of the Al distribution on the structure, elastic properties, and phase stability of supersaturated Ti1-xAlxN. Journal of Applied Physics, 2006,100:1-5. |

| [50] | HOLEC D, ROVERE F, MAYRHOFER P H , et al. Pressure- dependent stability of cubic and wurtzite phases within the TiN-AlN and CrN-AlN systems. Scripta Materialia, 2010,62:349-352. |

| [51] | EUCHNER H, MAYRHOFER P . Vacancy-dependent stability of cubic and wurtzite Ti1-xAlxN. Surface and Coatings Technology, 2015,275:214-218. |

| [52] | SHULUMBA N, HELLMAN O, RAZA Z , et al. Lattice vibrations change the solid solubility of an alloy at high temperatures. Physical Review Letters, 2016,117(11):1-6. |

| [53] | SANGIOVANNI D, EDSTR?M D, HULTMAN L , et al. Dynamics of Ti, N, and TiNx (x= 1-3) admolecule transport on TiN (001) surfaces. Physical Review B, 2012,8:1-10. |

| [54] | SANGIOVANNI D, EDSTR?M D, HULTMAN L , et al. Ab initio.and classical molecular dynamics simulations of N2 desorption from TiN (001) surfaces. Surface Science, 2014,624:25-31. |

| [55] | SANGIOVANNI D, ALLING B, STENETEG P , et al. Self- interstitial diffusion, and Frenkel-pair formation/dissociation in B1 TiN studied by ab initio and classical molecular dynamics with optimized potentials. Physical Review B, 2015,91:1-17. |

| [56] | ALLING B, STENETEG P, THOLANDER C , et al. Configurational disorder effects on adatom mobilities on Ti1-xAlxN (001) surfaces from first principles. Physical Review B, 2012,85(24):1-5. |

| [57] | CHANG K K, TO BABEN M, MUSIC D , et al. Estimation of the activation energy for surface diffusion during metastable phase formation. Acta Materialia, 2015,98:135-140. |

| [58] | CHANG K K, MUSIC D, TO BABEN M , et al. Modeling of metastable phase formation diagrams for sputtered thin films. Science and Technology of Advanced Materials, 2016,17:210-219. |

| [59] | CANTOR B, CAHN R . Metastable alloy phases by co-sputtering. Acta Materialia, 1976,24:845-852. |

| [60] | SAUNDERS N, MIODOWNIK A P . Phase formation in co-deposited metallic alloy thin flms. Journal of Materials Science, 1987,22:629-637. |

| [61] | LIU S D, CHANG K K, MRáZ S , et al. Modeling of metastable phase formation for sputtered Ti1-xAlxN thin films. Acta Materialia, 2019,165:615-625. |

| [62] | KIM K H, LEE S H . Comparative studies of TiN and Ti1-xAlxN by plasma-assisted chemical vapor deposition using a TiCl4/AlCl3/N2/ H2/Ar gas mixture. Thin Solid Films, 1996,283:165-170. |

| [63] | LEE S H, KIM B J, KIM H H , et al. Structural analysis of AlN and (Ti1-xAlx) N coatings made by plasma enhanced chemical vapor deposition. Journal of Applied Physics, 1996,80(3):1469-1473. |

| [64] | PRANGE R, CREMER R, NEUSCHüTZ D , et al. Plasma- enhanced CVD of Plasma- enhanced CVD of (Ti,Al) N films from chloridic precursors in a DC glow discharge. Surface and Coatings Technology 2000, 133-134:208-214. |

| [65] | ENDLER I, H?HN M, HERRMANN M , et al. Novel aluminum- rich Ti1-xAlxN coatings by LPCVD. Surface and Coatings Technology, 2008,203:530-533. |

| [66] | TODT T, ZALESAK J, DANIEL R , et al. Al-rich cubic Al0. 8Ti0. 2N coating with self-organized nano-lamellar microstructure: thermal and mechanical properties. Surface and Coatings Technology, 2016,291:89-93. |

| [67] | GROVENOR C R M, HENTZELL H T G, SMITH D A , et al. The development of grain structure during growth of metallic films. Acta Materialia The development of grain structure during growth of metallic films. Acta Materialia, 1984,32(5):(5):773-781. |

| [68] | PETROV I, BARNA P B, HULTMAN L , et al. Microstructural evolution during film growth. Journal of Vacuum Science & Technology A, 2003,21(5):S117-S128. |

| [69] | EINSTEIN A . Elementare teorie der brownschen bewegung. Z Elektrochem, 1908,14:371-381. |

| [70] | SUNDMAN B, OHNUMA I, DUPIN N , et al. An assessment of the entire Al-Fe system including D03 ordering. Acta Materialia, 2009,57:2896-2908. |

| [71] | LIANG S M, SCHMID-FETZER R . Thermodynamic assessment of the Al-Cu-Zn system, part II: Al-Cu binary system. CALPHAD, 2015,51:252-260. |

| [72] | ZHOU C Y, CUI J X, GUO C P , et al. Thermodynamic description of the Al-Ge-Ni system over the whole composition and temperature ranges. CALPHAD, 2017,58:138-150. |

| [73] | LI M, DU Z M, GUO C , et al. Thermodynamic optimization of the Cu-Sn and Cu-Nb-Sn systems. Journal of Alloys and Compounds, 2009,477:104-117. |

| [74] | SUBRAMANINA P R, LAUGHLIN D E . Cu-W (copper tungsten). Indian Institute of Metals, 1991,12:76-79. |

| [75] | ZHAO J R, DU Y, ZHANG L J , et al. Thermodynamic reassessment of the Cu-V system supported by key experiments. CALPHAD, 2008,32:252-255. |

| [76] | WEILAND R, LUPTON D F, FISCHER B , et al. High-temperature mechanical properties of the platinum group metals. Platinum Metals Review, 2006,50(4):158-170. |

| [77] | GANSKE G, SLAVCHEVA E, VAN OOYEN A , et al. Sputtered platinum-iridium layers as electrode material for functional electrostimulation. Thin Solid Films, 2011,519:3965-3970. |

| [78] | TSENG S F, LEE C T, Huang K C , et al. Mechanical properties of Pt-Ir and Ni-Ir binary alloys for glass-molding dies coating. Journal of Nanoscience and Nanotechnology, 2011,11(10):8682-8688. |

| [79] | YI A Y, JAIN A . Compression molding of aspherical glass lenses-a combined experimental and numerical analysis. Journal of the American Ceramic Society, 2005,88(3):579-586. |

| [80] | KLOCKE F, DAMBON O, YI A Y , et al. Process Chain for the Replication of Complex Optical Glass Components. Berlin Heidelberg: Springer, 2013: 119-132. |

| [81] | MA K J, CHIEN H H, CHUAN W H , et al. Design of protective coatings for glass lens molding. Key Engineering Materials Design of protective coatings for glass lens molding. Key Engineering Materials, 2008,364-366:655-661. |

| [82] | KLOCKE F, DAMBON O, GEORGIADIS K , et al. Comparison of nitride and noble metal coatings for precision glass molding tools. Key Engineering Materials, 2010,438:9-6. |

| [83] | BOBZIN K, BAGCIVAN N, EWERING M , et al. Influence of interlayer thickness of a thin noble metal MSIP-PVD coating on compound and system properties for glass lens moulding. Production Engineering, 2012,6:311-318. |

| [84] | BOBZIN K, BAGCIVAN N, BR?GELMANN T , et al. Development and qualification of a MSIP PVD iridium coating for precision glass moulding. Materials Sciences and Application, 2013,44(8):673-678. |

| [85] | SAKSENA A, CHIEN Y C, CHANG K K , et al. Metastable phase formation of Pt-X (X=?Ir,?Au)?thin?flms. Scientific Reports, 2018,8(1):10198. |

| [86] | YAMABE-MITARAI Y, AOYAGI T, ABE T , et al. An investigation of phase separation in the Ir-Pt binary system. Journal of Alloys and Compounds, 2009,484:327-334. |

| [87] | XU X N, REN Y P, LI C F , et al. Thermodynamic assessment of Au-Pt system. Transactions of Nonferrous Metals Society of China, 2012,22:1432-1436. |

/

| 〈 |

|

〉 |