无机材料学报 ›› 2024, Vol. 39 ›› Issue (5): 501-508.DOI: 10.15541/jim20230492 CSTR: 32189.14.10.15541/jim20230492

所属专题: 【结构材料】核用陶瓷(202506)

何宗倍1( ), 陈放1, 刘佃光2(

), 陈放1, 刘佃光2( ), 李统业1, 曾强1

), 李统业1, 曾强1

收稿日期:2023-10-23

修回日期:2023-12-30

出版日期:2024-05-20

网络出版日期:2024-01-08

通讯作者:

刘佃光, 副教授. E-mail: dianguang@swjtu.edu.cn作者简介:何宗倍(1985-), 男, 博士. E-mail: hezongbei@126.com

基金资助:

HE Zongbei1( ), CHEN Fang1, LIU Dianguang2(

), CHEN Fang1, LIU Dianguang2( ), LI Tongye1, ZENG Qiang1

), LI Tongye1, ZENG Qiang1

Received:2023-10-23

Revised:2023-12-30

Published:2024-05-20

Online:2024-01-08

Contact:

LIU Dianguang, associate professor. E-mail: dianguang@swjtu.edu.cnAbout author:HE Zongbei (1985-), male, PhD. E-mail: hezongbei@126.com

Supported by:摘要:

全陶瓷微封装弥散(FCM)燃料以其较好的固有安全性而成为核能领域研究的重点。针对SiC基体难以烧结的问题, 本研究利用振荡烧结具有加速传质和降低烧结温度的优势, 开展了模拟核芯FCM燃料振荡烧结行为研究, 重点考察了振荡烧结温度、振荡时间与振荡压力等参数对基体致密化行为的影响, 并与热压烧结结果进行了对比。结果表明, 振荡烧结温度、保温时间以及中值压力对基体致密化有重要影响, 而振荡压力的振幅对基体致密化影响不大。相比于热压烧结, 振荡烧结可以提高材料的致密度, 振荡烧结试样的致密度更高, 1850 ℃振荡烧结试样的致密度为99.99%; 振荡烧结试样的晶粒尺寸更小, 1850 ℃振荡烧结试样的晶粒尺寸为(284±4) nm, 比同等温度下热压烧结试样的晶粒尺寸减小~27%; 振荡烧结试样的硬度更高, 1850 ℃振荡烧结试样的硬度为(26.7±0.4) GPa。借助改进的热压烧结本构方程, 计算得到试样在致密度为90%时的应力指数n=1, 活化能Q=430 kJ/mol, 致密化的主导机制为晶界扩散协调的晶界滑移。

中图分类号:

何宗倍, 陈放, 刘佃光, 李统业, 曾强. 模拟核芯FCM燃料的振荡烧结行为研究[J]. 无机材料学报, 2024, 39(5): 501-508.

HE Zongbei, CHEN Fang, LIU Dianguang, LI Tongye, ZENG Qiang. Sintering Behavior of Simulating Core FCM Fuel via Hot Oscillatory Pressing[J]. Journal of Inorganic Materials, 2024, 39(5): 501-508.

| No. | T/℃ | t/h | σm/MPa | σa/MPa |

|---|---|---|---|---|

| HOP-1 | 1600 | 1 | 20 | 5 |

| HOP-2 | 1600 | 2 | 20 | 5 |

| HOP-3 | 1650 | 1 | 20 | 5 |

| HOP-4 | 1650 | 2 | 20 | 5 |

| HOP-5 | 1700 | 1 | 20 | 5 |

| HOP-6 | 1700 | 2 | 20 | 5 |

| HOP-7 | 1750 | 0 | 20 | 5 |

| HOP-8 | 1750 | 1 | 20 | 5 |

| HOP-9 | 1750 | 2 | 20 | 5 |

| HOP-10 | 1750 | 2 | 10 | 5 |

| HOP-11 | 1750 | 2 | 15 | 5 |

| HOP-12 | 1750 | 2 | 20 | 1 |

| HOP-13 | 1750 | 2 | 20 | 3 |

| HOP-14 | 1800 | 2 | 20 | 5 |

| HOP-15 | 1850 | 2 | 20 | 5 |

| HP-1 | 1700 | 2 | 20 | 0 |

| HP-2 | 1750 | 2 | 20 | 0 |

| HP-3 | 1800 | 2 | 20 | 0 |

| HP-4 | 1850 | 2 | 20 | 0 |

表1 模拟核芯FCM燃料的振荡烧结和热压烧结参数

Table 1 Sintering parameters of simulated core FCM fuel via hot oscillatory pressing and hot pressing

| No. | T/℃ | t/h | σm/MPa | σa/MPa |

|---|---|---|---|---|

| HOP-1 | 1600 | 1 | 20 | 5 |

| HOP-2 | 1600 | 2 | 20 | 5 |

| HOP-3 | 1650 | 1 | 20 | 5 |

| HOP-4 | 1650 | 2 | 20 | 5 |

| HOP-5 | 1700 | 1 | 20 | 5 |

| HOP-6 | 1700 | 2 | 20 | 5 |

| HOP-7 | 1750 | 0 | 20 | 5 |

| HOP-8 | 1750 | 1 | 20 | 5 |

| HOP-9 | 1750 | 2 | 20 | 5 |

| HOP-10 | 1750 | 2 | 10 | 5 |

| HOP-11 | 1750 | 2 | 15 | 5 |

| HOP-12 | 1750 | 2 | 20 | 1 |

| HOP-13 | 1750 | 2 | 20 | 3 |

| HOP-14 | 1800 | 2 | 20 | 5 |

| HOP-15 | 1850 | 2 | 20 | 5 |

| HP-1 | 1700 | 2 | 20 | 0 |

| HP-2 | 1750 | 2 | 20 | 0 |

| HP-3 | 1800 | 2 | 20 | 0 |

| HP-4 | 1850 | 2 | 20 | 0 |

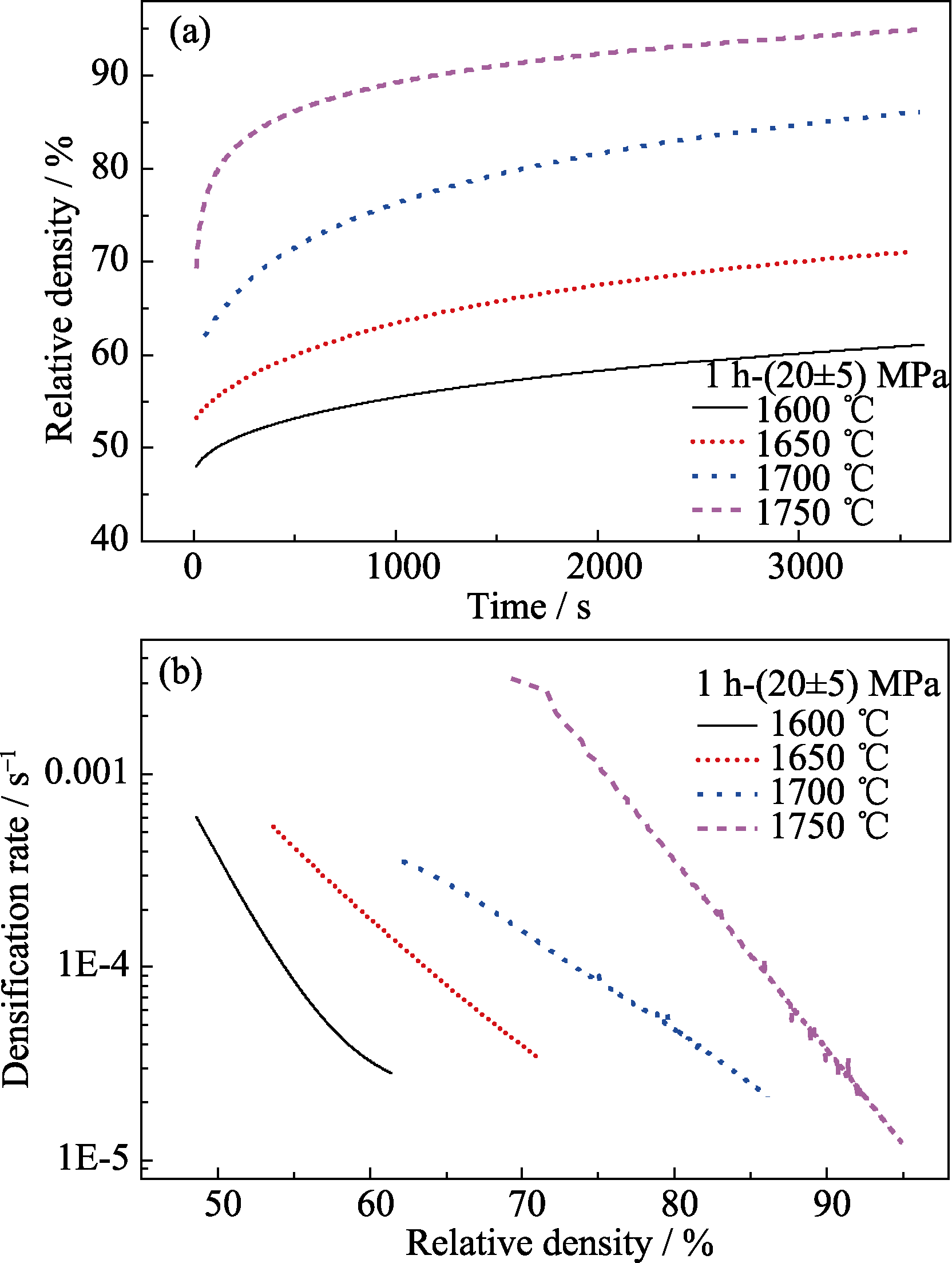

图2 不同烧结温度下振荡烧结试样的致密化曲线

Fig. 2 Densification curves of samples sintered via hot oscillatory pressing at different temperatures (a) Relative density-time curves; (b) Densification rate-relative density curves

| No. | T/℃ | t/h | ρ/(g·cm-3) | Open porosity/% | ρm/(g·cm-3) |

|---|---|---|---|---|---|

| HOP-7 | 1750 | 0 | 2.65 | 26.57 | 2.04 |

| HOP-8 | 1750 | 1 | 3.63 | 3.68 | 3.00 |

| HOP-9 | 1750 | 2 | 3.75 | 1.48 | 3.13 |

表2 不同保温时间下试样致密度及开气孔率

Table 2 Densities and open porosities of samples under different holding time

| No. | T/℃ | t/h | ρ/(g·cm-3) | Open porosity/% | ρm/(g·cm-3) |

|---|---|---|---|---|---|

| HOP-7 | 1750 | 0 | 2.65 | 26.57 | 2.04 |

| HOP-8 | 1750 | 1 | 3.63 | 3.68 | 3.00 |

| HOP-9 | 1750 | 2 | 3.75 | 1.48 | 3.13 |

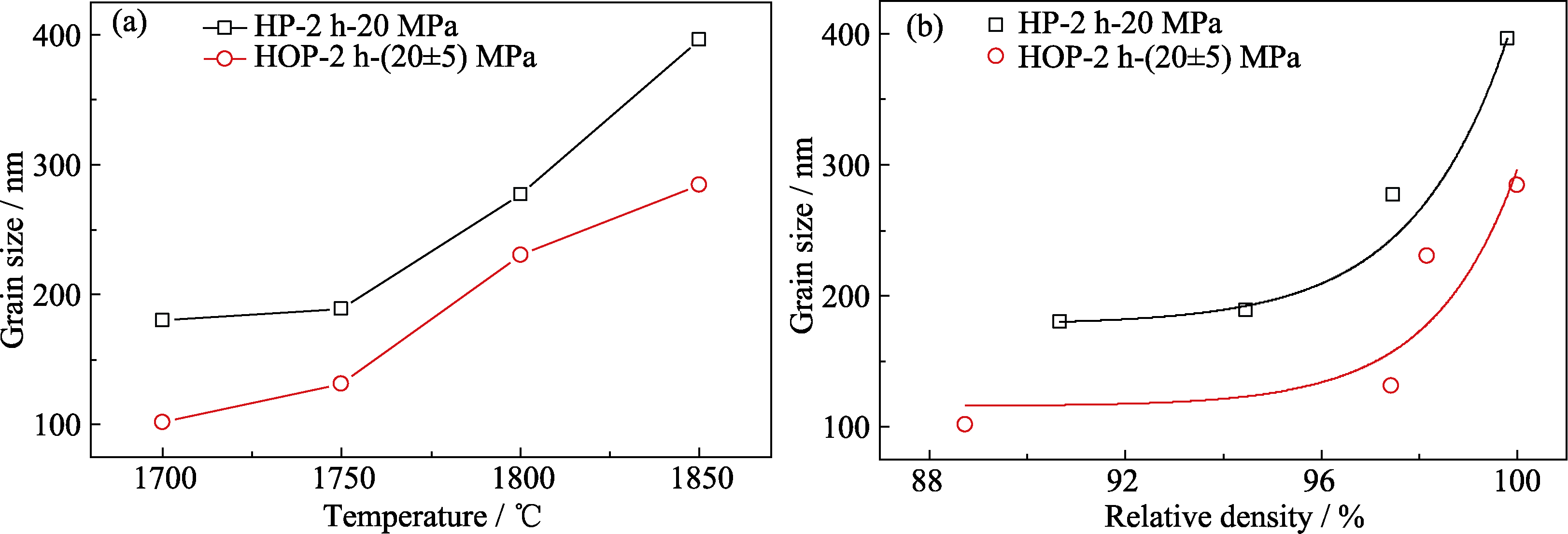

图7 振荡烧结和热压烧结试样的晶粒尺寸随(a)烧结温度和(b)相对密度的变化曲线

Fig. 7 Grain size of samples sintered via hot oscillatory pressing and hot pressing as function of (a) sintering temperature and (b) relative density

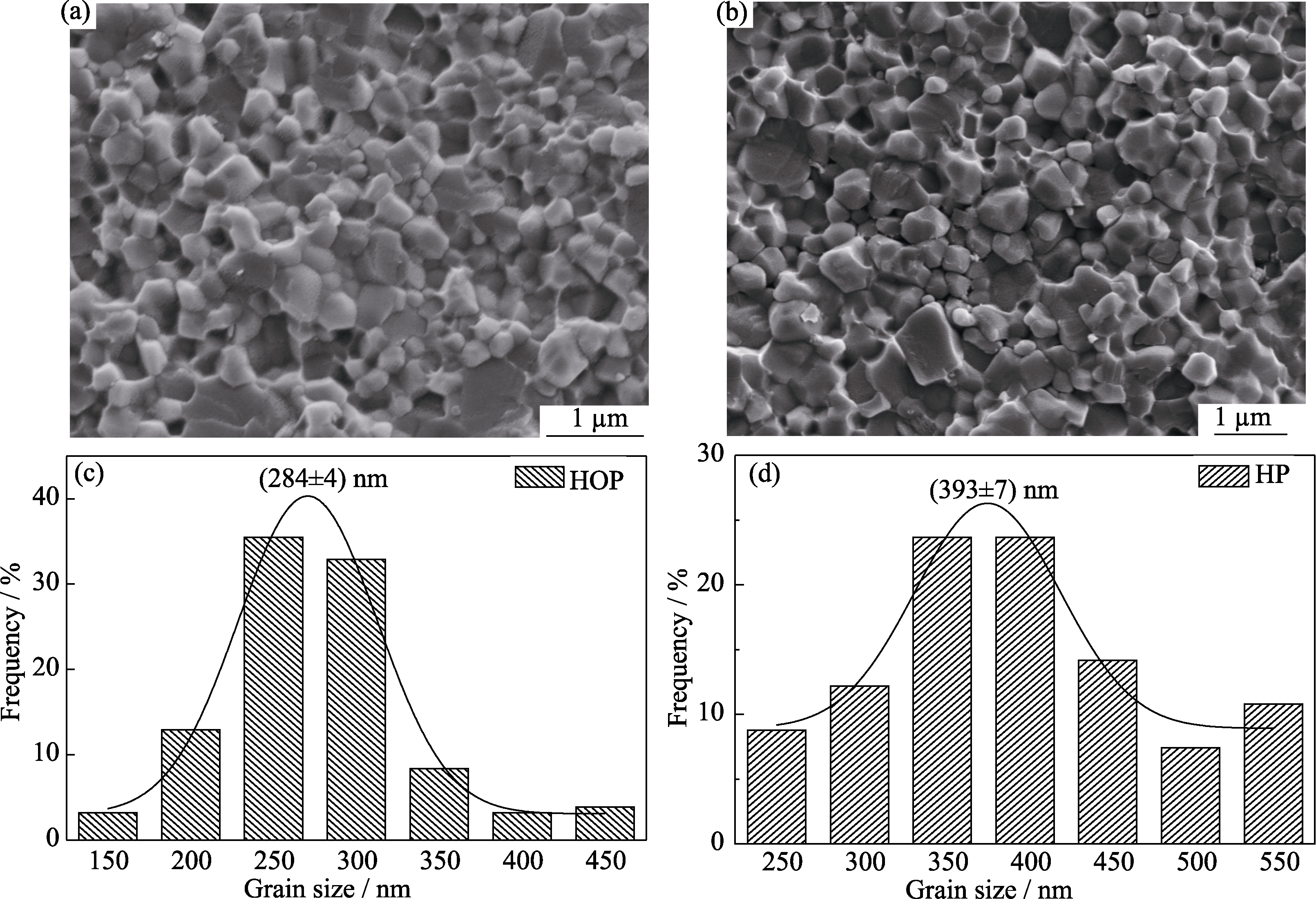

图8 1850 ℃烧结试样断面SEM照片及其晶粒尺寸分布图

Fig. 8 SEM images of fracture surface and grain size distributions of samples sintered at 1850 ℃ (a, c) Hot oscillatory pressing (2 h-(20±5) MPa); (b, d) Hot pressing (2 h-20 MPa)

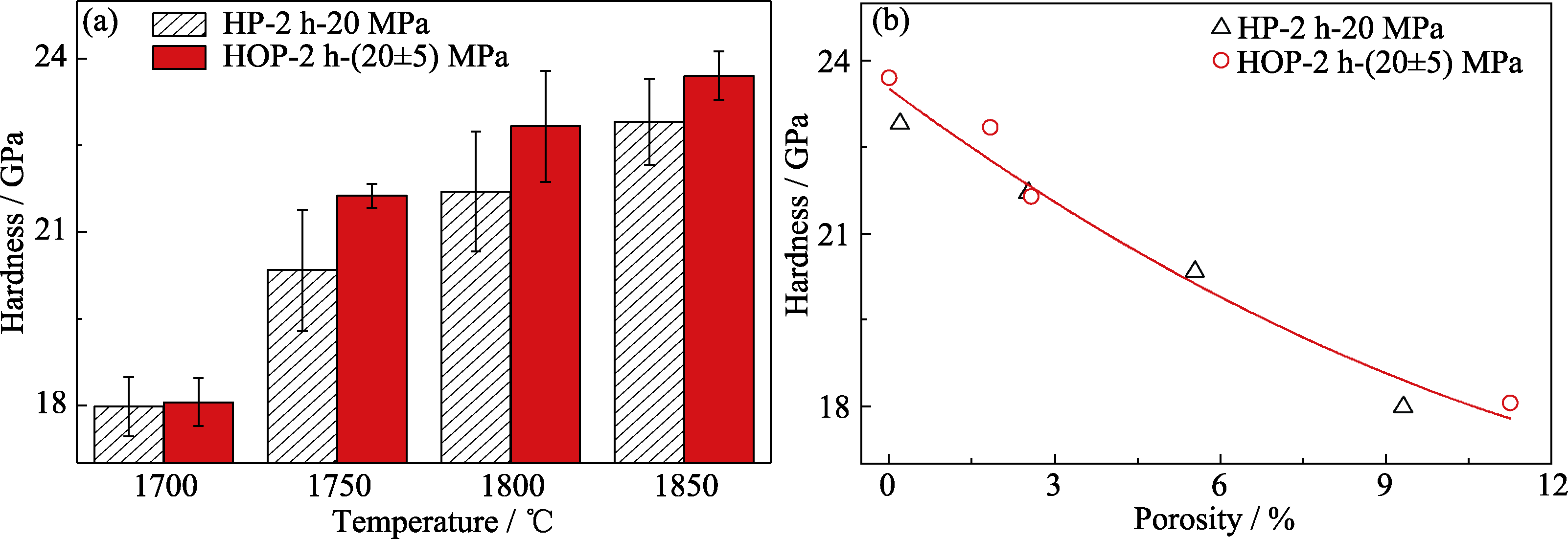

图9 振荡烧结和热压烧结试样的硬度随(a)烧结温度和(b)气孔率的变化曲线

Fig. 9 Hardness of samples sintered via hot oscillatory pressing and hot pressing as function of (a) sintering temperature and (b) porosity

| T/℃ | n=1 | n=2 | n=3 |

|---|---|---|---|

| 1700 | 0.9994 | 0.9740 | 0.9476 |

| 1750 | 0.9773 | 0.9986 | 0.9874 |

| 1800 | 0.9904 | 0.9647 | 0.9528 |

| 1850 | 0.9858 | 0.9742 | 0.9695 |

表3 不同应力指数(n)下致密化速率-有效应力的相似度

Table 3 Similarity between densification rate and effective stress at different stress exponents (n)

| T/℃ | n=1 | n=2 | n=3 |

|---|---|---|---|

| 1700 | 0.9994 | 0.9740 | 0.9476 |

| 1750 | 0.9773 | 0.9986 | 0.9874 |

| 1800 | 0.9904 | 0.9647 | 0.9528 |

| 1850 | 0.9858 | 0.9742 | 0.9695 |

| [1] | KIM H J, KANG E S, KIM Y W, et al. Effects of starting powder on microstructure and thermal conductivity of pressureless-sintered fully ceramic microencapsulated fuels. Journal of the European Ceramic Society, 2023, 43: 783. |

| [2] | KIM H M, KIM Y W, LIM K Y. Pressureless sintered silicon carbide matrix with a new quaternary additive for fully ceramic microencapsulated fuels. Journal of the European Ceramic Society, 2019, 39: 3971. |

| [3] | ZHAO K, FENG P, TAN J, et al. A new route to fabricate high- performance binderless tungsten carbide: dynamic sinter forging. Journal of the American Ceramic Society, 2023, 106: 3343. |

| [4] | LIU D, FAN J, ZHAO K, et al. Preparation of super-strong ZrO2 ceramics using dynamic hot forging. Journal of the European Ceramic Society, 2023, 43: 733. |

| [5] | FAN L, SONG X, ZHAO P, et al. Super strong B4C ceramics prepared by dynamic sinter forging. Journal of the European Ceramic Society, 2023, 43: 4209. |

| [6] | FAN J, LIU D, ZHAO K, et al. Densification kinetics and mechanism of zirconia ceramics via hot oscillating pressing. Open Ceramics, 2023, 13: 100323. |

| [7] | HE H, ZHAO R, TIAN H, et al. Sintering behavior of alumina whisker reinforced zirconia ceramics in hot oscillatory pressing. Journal of Advanced Ceramics, 2022, 11: 893. |

| [8] | LIU D, ZHANG X, FAN J, et al. Sintering behavior and mechanical properties of alumina ceramics exposed to oscillatory pressure at different sintering stages. Ceramics International, 2021, 47: 23682. |

| [9] | HE H, SHAO G, ZHAO R, et al. Oscillatory pressure-assisted sinter forging for preparation of high-performance SiC whisker reinforced Al2O3 composites. Journal of Advanced Ceramics, 2023, 12: 321. |

| [10] | ZHU T, XIE Z. Ultrastrong tough zirconia ceramics by defects- engineering. Journal of the American Ceramic Society, 2022, 105: 1617. |

| [11] | TERRANI K A, KIGGANS J O, KATOH Y, et al. Fabrication and characterization of fully ceramic microencapsulated fuels. Journal of Nuclear Materials, 2012, 426: 268. |

| [12] | SNEAD L L, TERRANI K A, KATOH Y, et al. Stability of SiC-matrix microencapsulated fuel constituents at relevant LWR conditions. Journal of Nuclear Materials, 2014, 448: 389. |

| [13] | CAO F, FAN X, LIU B, et al. Microstructure and thermal conductivity of fully ceramic microencapsulated fuel fabricated by spark plasma sintering. Journal of the American Ceramic Society, 2018, 101: 4224. |

| [14] | COLOGNA M, TYRPEKL V, ERNSTBERGER M, et al. Sub-micrometre grained UO2 pellets consolidated from sol gel beads using spark plasma sintering (SPS). Ceramics International, 2016, 42: 6619. |

| [15] | LI J, FAN J, YUAN Y, et al. Effect of oscillatory pressure on the sintering behavior of ZrO2 ceramic. Ceramics International, 2020, 46: 13240. |

| [16] | YUAN Y, FAN J, LI J, et al. Oscillatory pressure sintering of Al2O3 ceramics. Ceramics International, 2020, 46: 15670. |

| [17] | FENG B, ZHOU Y, PENG C, et al. Vibration assisted hot-press sintering of AlN ceramics. Journal of the American Ceramic Society, 2015, 98: 1711. |

| [18] | GUBERNAT A, STOBIERSKI L, LABAJ P. Microstructure and mechanical properties of silicon carbide pressureless sintered with oxide additives. Journal of the European Ceramic Society, 2007, 27: 781. |

| [19] | FAN J, YUAN Y, LI J, et al. Densification and grain growth in oscillatory pressure sintering of alumina toughened zirconia ceramic composites. Journal of Alloys and Compounds, 2020, 845: 155644. |

| [20] | GAO Y, GAO K, FAN L, et al. Oscillatory pressure sintering of WC-Fe-Ni cemented carbides. Ceramics International, 2020, 46: 12727. |

| [21] |

GAO K, XU Y, TANG G, et al. Oscillating pressure sintering of W-Ni-Fe refractory alloy. Journal of Alloys and Compounds, 2019, 805: 789.

DOI |

| [22] | XIE Z, LI S, AN L. A novel oscillatory pressure-assisted hot pressing for preparation of high performance ceramics. Journal of the American Ceramic Society, 2014, 97: 1012. |

| [23] | LI S, XIE Z, XUE W. Microstructure and mechanical properties of zirconia ceramics consolidated by a novel oscillatory pressure sintering. Ceramics International, 2015, 41: 10281. |

| [24] | GAO K, ZHAO J, SUN D, et al. W-Ni-Fe refractory alloy sintered by hot oscillating pressure under different amplitudes. Advanced Engineering Materials, 2023, 25: 2201899. |

| [25] | PARK H S, RUDD R E, CAVALLO R M, et al. Grain-size- independent plastic flow at ultrahigh pressures and strain rates. Physical Review Letters, 2015, 114: 065502. |

| [26] | LIU D, DU X, ZHAO K, et al. Sintering behavior and mechanical properties of β-SiC ceramics under oscillatory pressure. Ceramics International, 2024, 50: 1231. |

| [27] |

LI W, LIU D, WANG K, et al. High entropy oxide ceramics (MgCoNiCuZn)O: flash sintering synthesis and properties. Journal of Inorganic Materials, 2022, 37: 1289.

DOI |

| [28] | RAHAMAN M N. Ceramics processing and sintering, 2nd edition. New York: Marcel Dekker Inc., 2003. |

| [29] | LIU D, WANG K, ZHAO K, et al. Creep behavior of zirconia ceramics under a strong DC field. Scripta Materialia, 2022, 214: 114654. |

| [30] | BIND J M, BIGGERS J V. Hot-pressing of silicon carbide with 1% boron carbide addition. Journal of the American Ceramic Society, 2010, 58: 304. |

| [31] | RAY D A, KAUR S, CUTLER R A, et al. Effect of additives on the activation energy for sintering of silicon carbide. Journal of the American Ceramic Society, 2010, 91: 1135. |

| [32] | YANG X, JIANG D L, TAN S H, et al. Densification kinetics and mechanism of β-SiC pressureless sintering. Journal of Inorganic Materials, 1992, 7(1): 25. |

| [33] | HASE T, SUZUKI H. Initial-stage sintering of β-SiC with concurrent boron and carbon additions. Journal of the Ceramic Association of Japan, 1980, 88: 258. |

| [34] | JANA D C, SUNDARARAJAN G, CHATTOPADHYAY K. Effective activation energy for the solid-state sintering of silicon carbide ceramics. Metallurgical and Materials Transactions A, 2018, 49: 5599 |

| [35] | MALINGE A, COUPÉ A, PETITCORPS Y L, et al. Pressureless sintering of beta silicon carbide nanoparticles. Journal of the European Ceramic Society, 2012, 32: 4393. |

| [1] | 阮景, 杨金山, 闫静怡, 游潇, 王萌萌, 胡建宝, 张翔宇, 丁玉生, 董绍明. 三维碳化硅纳米线增强碳化硅陶瓷基复合材料的电磁屏蔽性能[J]. 无机材料学报, 2022, 37(5): 579-584. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||