近年来, 随着科学技术的迅猛发展, 在特定服役环境下, 高性能陶瓷需要满足大尺寸复杂构型的要求。SiC陶瓷作为一种重要的热结构材料, 具有高强高硬、化学稳定性好、导热系数高等独特优良特性[1⇓⇓-4], 被广泛应用在航空航天、空间探测、能源化工等工程领域[5⇓-7]。陶瓷的传统制备路线包括制粉、成型、烧结及后处理等工序, 成型作为至关重要的步骤, 主要包含干压成型、注浆成型以及流延成型等方法[8⇓-10]。采用传统成型工艺制备高性能精细化陶瓷, 难以实现蜂窝状、拓扑状等多孔薄壁的异形复杂成型, 存在制备周期长、生产成本高、加工性差等局限性[11⇓-13], 严重限制了碳化硅陶瓷的进一步推广应用。采用3D打印(3D printing)新技术可以有效解决上述难题, 为制备高性能陶瓷提供新的方案。

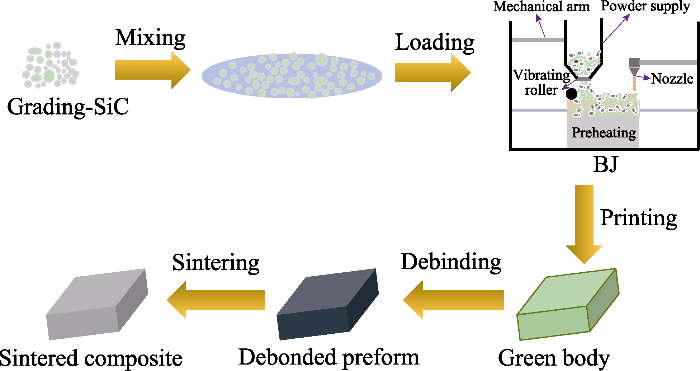

3D打印技术, 亦称为增材制造(Additive Manufacturing, AM), 它是一种基于数字化结合计算机辅助设计制造所需三维对象的技术, 被广泛应用在金属、陶瓷和高分子等材料领域[14]。3D打印技术主要分为浆料式3D打印和铺粉式3D打印, 前者成型需要考虑浆料的固含量、分散性和润湿性等诸多因素, 较为繁琐; 相比之下, 后者的制备操作更加简便。黏结剂喷射(BJ)打印[15]作为铺粉式3D打印的重要技术之一, 主要由铺粉、喷射打印和粉料黏合三个步骤构成, 其中铺粉决定了粉料状态, 喷射打印关系到打印精度, 粉料黏合影响到成型性能。BJ打印的具体过程如下: 通过投料机在成型区域内振动撒上一定厚度的粉料, 反旋转辊子将粉料均匀铺平在成型区, 接着通过计算机控制打印机喷头并根据CAD模型的轮廓信息在需要的区域有选择地喷射黏结剂到粉末床上, 使截面内的粉料与黏结剂溶液粘合, 加热器控制黏结剂/粉末的水分以及固化, 随后将成型缸下降一层, 继续撒料、铺平、喷射, 重复以上过程, 直至打印工作结束, 生成三维立体零件。目前, 国外对BJ打印SiC陶瓷的研究主要集中在打印参数、后处理工艺对SiC陶瓷性能的影响, 粉末特性对打印试件性能影响的研究较少, 而粉末的状态将会影响整个铺粉过程的好坏, 因而亟待开展相关研究。国内由于设备条件相对不成熟, 在BJ打印SiC陶瓷方面鲜有报道, 处于刚起步阶段。Cramer等[16]运用Exone生产的BJ设备, 打印参数设置为: 散粉速度25 mm/s, 振荡器转速2700 r/min, 辊子旋转速度300 r/min, 黏结剂饱和度80%, 加热器横扫速度22 mm/s, 研究了PIP对SiC复合材料性能的影响。研究发现SiC陶瓷的密度由2.05 g/cm3(1次PIP循环)增大到2.33 g/cm3(3次PIP循环), 3次PIP循环后的室温弯曲强度和杨氏模量分别达到(66.8±2.5) MPa和(69.5±2.8) GPa。他们团队[17]还采用PIP和反应熔渗(RMI)结合的技术, 通过两次浸渍酚醛树脂(PR)热解成碳, 结合RMI技术, 最终制备得到的陶瓷孔隙率小于2%, 弹性模量接近300 GPa, 抗弯强度达(517.6±24.8) MPa。Terrani等[18]采用Exone生产的BJ设备, 结合化学气相渗透致密化工艺, 最终打印得到陶瓷的导热系数和抗弯强度分别为37 W·(m·K)-1和297 MPa。

颗粒级配是一种能够很好地改善粉末堆积状态的方式, 可以有效提高素坯致密度, 并且引入粗颗粒可以降低陶瓷烧结时的界面扩散, 抑制晶粒长大, 从而改善陶瓷力学性能[19]。本研究利用颗粒级配改性粉体原料, 采用BJ打印素坯, 运用一次PIP处理并结合液相渗硅致密化烧结制备了SiC陶瓷, 探究颗粒级配对SiC素坯抗弯性能和孔径分布以及陶瓷力学性能的影响。

1 实验方法

1.1 实验材料

实验采用纯度>99.5%的市售SiC粉末(D50 = 5, 10, 20, 50, 80 μm, 上海尚磨机电有限公司)。采用Exone公司生产的型号为PhenolFuse的打印黏结剂, 它是一种水性有机黏结剂, 主要成分为乙二醇(体积分数20%)、乙二醇单丁醚(体积分数10%)和PR。

1.2 颗粒级配SiC粉末的制备

表1 不同中位径SiC粉末的级配比例及流动性指数

Table 1

| Group | Fraction | Carr index/% |

|---|---|---|

| G0 | 20 μm (non-grading) | 37.11 |

| G1 | 5 μm:10 μm:20 μm:50 μm:80 μm =5:6:15:5:5 | 27.80 |

| G2 | 5 μm:10 μm:20 μm:50 μm:80 μm =6:6:15:5:4 | 30.05 |

| G3 | 5 μm:10 μm:20 μm:50 μm:80 μm =6:5:15:4:6 | 34.94 |

Note: “5 μm:10 μm:20 μm:50 μm: 80 μm” refers to mass ratio of SiC powders with different median diameters

1.3 SiC陶瓷的成型与制备

图1

1.4 材料表征

根据阿基米德排水法测得SiC素坯和陶瓷的体积密度(D)和开气孔率(P), 计算公式如式(1)和式(2)所示。采用场发射扫描电子显微镜(Scanning Electron Microscope, SEM, Hitachi SU8220, 日本)观察SiC素坯的断口形貌和陶瓷的抛光面形貌。采用万能材料试验机(Instron-5566, Instron Co. 美国) 测量素坯的抗弯性能和陶瓷的抗弯性能、弹性模量和断裂韧性。采用压汞仪(Quantachrome Instruments, Poremaster60, America)测试SiC素坯的孔径分布。采用X射线衍射(X-ray diffraction, XRD, D8 Advance, Bruker, 德国)进行物相的定性分析。

其中, M1为样品干重, M2为样品充分吸水后在空气中质量(湿重), M3为样品水中质量(浮重)。

2 结果与讨论

2.1 级配对BJ打印SiC素坯性能的影响

表2 BJ打印素坯在PIP处理前后的体积密度和开气孔率

Table 2

| Group | Bulk density/(g•cm-3) | Open porosity/% | ||

|---|---|---|---|---|

| Before PIP | After PIP | Before PIP | After PIP | |

| G0 | 1.236±0.008 | 1.533±0.005 | 61.12±0.47 | 47.48±0.84 |

| G1 | 1.470±0.006 | 1.718±0.009 | 53.19±0.46 | 40.63±0.57 |

| G2 | 1.313±0.007 | 1.598±0.003 | 59.72±0.20 | 46.44±0.63 |

| G3 | 1.284±0.004 | 1.572±0.007 | 59.04±0.13 | 45.85±0.77 |

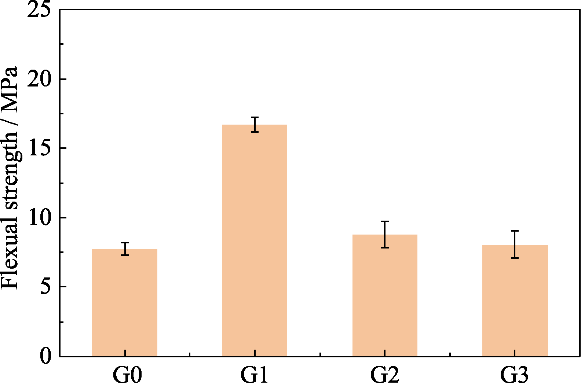

图2

图2

BJ打印素坯经一次PIP后的抗弯强度

Fig. 2

Flexual strength of BJ-printed green body after one PIP

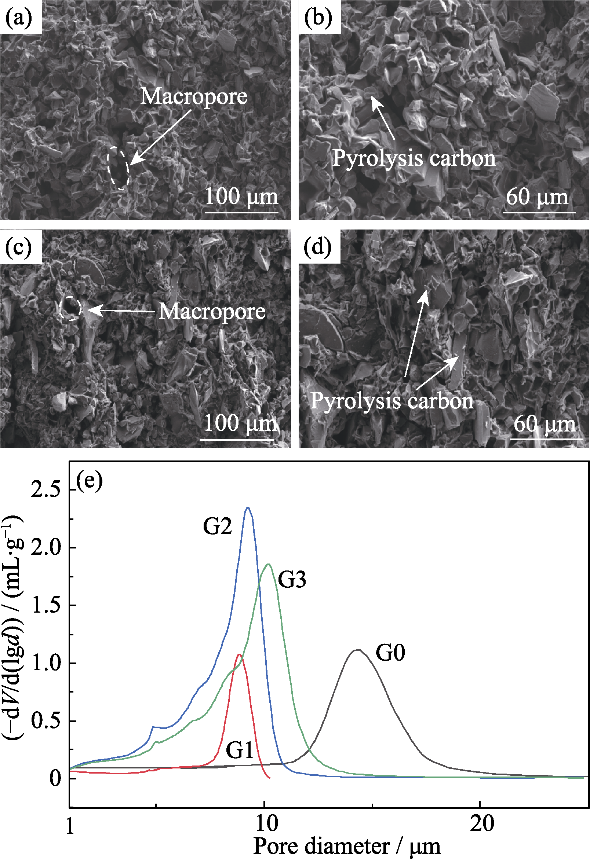

由表2可知, 纯20 μm打印的PIP前素坯体积密度达(1.236±0.008) g/cm3, 开气孔率达(61.12±0.47)%。级配后素坯的密度和气孔率均在一定程度上得到改善, 流动性最好的G1组, 其PIP前素坯体积密度达到(1.470±0.006) g/cm3, 开气孔率达(53.19±0.46)%。级配后的粉体比级配前的粉体流动性在一定程度上得到提升, 同时相同BJ打印参数下PIP后, 素坯性能也有一定改善。特别是通过颗粒级配调控后的 G1组, 抗弯强度达到(16.70±0.53) MPa, 强度比未级配20 μm SiC((7.74 ± 0.99) MPa)), 提升了约8.96 MPa。从级配后三种粉体打印的素坯性能可以发现, 级配后复合粉体的流动性与PIP后的素坯性能之间呈正相关, 即级配后流动性越好的粉体BJ打印后的试件, 经过一次PIP后的素坯性能也越好。由图3(e)可知, 级配之后各组的微分浸汞量峰值位置发生左移, 对应于孔径向小孔偏移。级配之后的各组SiC素坯孔径分布在5~15 μm之间。随着原料流动性由好变差, 最可几孔径分别为8.86、9.21和10.15 μm,中位孔径分别为5.26、7.61和8.35 μm, 而未级配的20 μm打印的SiC素坯最可几孔径为14.29 μm, 中位孔径为9.74 μm。这表明级配有利于减小素坯的孔径, 在某种程度上可以提升素坯的性能。随着原料流动性的变差, 素坯孔径呈现逐渐变大的趋势, 这是由于原料流动性变差, 堆积效果也随之变差, 粉体颗粒之间的间隙变大, 导致素坯的气孔也增大, 与前面的抗弯强度结果一致。

图3

图3

PIP后素坯的断口形貌(a~d)以及PIP后素坯的孔径分布(e)

Fig. 3

Fracture morphologies (a-d), and pore size distributions (e) of green bodies after PIP

(a) G0; (b) G1; (c) G2; (d) G3

2.2 级配对BJ打印SiC陶瓷性能的影响

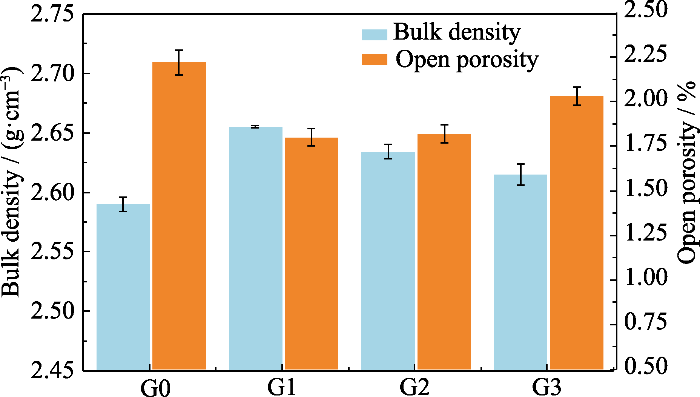

图4

图4

BJ打印SiC陶瓷的体积密度和开孔率

Fig. 4

Bulk densities and open porosities of BJ-printed SiC ceramics

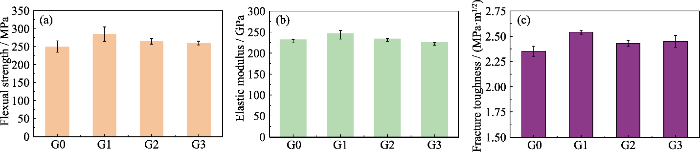

由图5可知, 随着级配后SiC颗粒的流动性提升, 抗弯强度和弹性模量均呈现一定程度的上升, 粉体流动性最好的G1组的抗弯强度达到(285±30) MPa, 弹性模量达到(243±12) GPa, 断裂韧性达到(2.54± 0.02) MPa·m1/2。以20 μm粉体为基准级配后的BJ打印的各组陶瓷力学性能均有所提高, 一定程度上来说, 原料级配有利于提高陶瓷的抗弯性能、弹性模量和断裂韧性等力学性能。

图5

图5

BJ打印SiC陶瓷的力学性能

Fig. 5

Mechanical properties of BJ-printed SiC ceramics

(a) Flexural strength; (b) Elastic modulus; (c) Fracture toughness

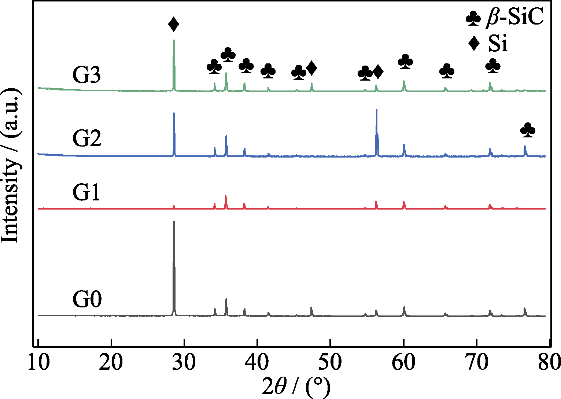

值得一提的是, Si的弹性模量为113 GPa, 低于单相SiC陶瓷的475 GPa[3], 根据基于加权平均值方法的复合材料的混合定律, BJ打印的SiC陶瓷相应的弹性模量随残余硅含量的增加而减小。残余硅的理论体积含量为53%, SiC陶瓷的理论弹性模量应该为283 GPa, 但G1组的实测弹性模量为(243±12) GPa, 这是由于孔隙和残余碳的存在使弹性模量低于理论值。

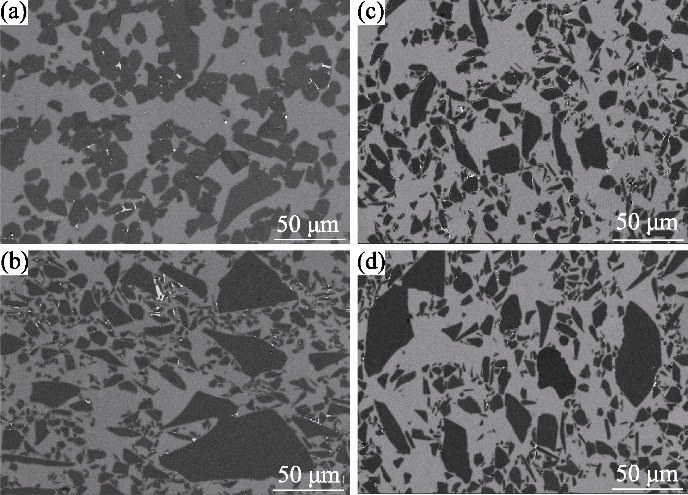

图6

图6

BJ打印SiC陶瓷的抛光面形貌

Fig. 6

Polished surface morphologies of BJ-printed SiC ceramics

(a) G0; (b) G1; (c) G2; (d) G3

图7

3 结论

级配后的粉体比未级配的粉体流动性有一定程度上的提升, 在相同BJ打印参数下的素坯性能均有一定改善。特别是颗粒级配调控后的粉体G1组, 通过BJ打印并经一次PIP 处理后的素坯抗弯强度达到(16.70±0.53) MPa, 此种粉体在流动性达到最佳的同时, 强度比未级配的素坯提高了8.96 MPa。

级配后的G1组的陶瓷密度最佳为(2.655± 0.001) g/cm3, 比纯20 μm的SiC陶瓷密度((2.590± 0.006) g/cm3)提高了约0.065 g/cm3。级配后的各组SiC颗粒, 随着流动性变好, 制备的SiC陶瓷的抗弯强度和弹性模量均呈现一定程度的上升, 粉体流动性最好的G1组BJ打印陶瓷的实测抗弯强度达到(285±30) MPa, 弹性模量达到(243±12) GPa, 断裂韧性达到(2.54±0.02) MPa·m1/2。

参考文献

Progress and challenges towards additive manufacturing of SiC ceramic

Silicon carbide (SiC) ceramic and related materials are widely used in various military and engineering fields. The emergence of additive manufacturing (AM) technologies provides a new approach for the fabrication of SiC ceramic products. This article systematically reviews the additive manufacturing technologies of SiC ceramic developed in recent years, including Indirect Additive Manufacturing (Indirect AM) and Direct Additive Manufacturing (Direct AM) technologies. This review also summarizes the key scientific and technological challenges for the additive manufacturing of SiC ceramic, and also forecasts its possible future opportunities. This paper aims to provide a helpful guidance for the additive manufacturing of SiC ceramic and other structural ceramics.

Tribological behaviour of C/C-SiC composites—a review

Effect of laser power on mechanical properties of SiC composites rapidly fabricated by selective laser sintering and direct liquid silicon infiltration

Selective laser sintering of SiC green body with low binder content

Belonging to the family of SiC-based composites, Al/SiC has excellent mechanical and thermal properties, making it irreplaceable in high-power electronic devices, key cooling components of 5G base station, electric vehicles, high-speed brake pads, space probe operation devices, and other related fields featured by high technologies. The melt infiltration method, which can achieve near-net forming, has been recognized to be a favorable method for preparing Al/SiC composites to overcome the disadvantages of traditional processing. How to obtain a high-quality silicon carbide (SiC) ceramic green body is a key for the perfect melt infiltration method. Selective laser sintering (SLS) technology provides a new opportunity for a top grade ceramic forming process, which is rapid and efficient in realizing large-scale and complicated-shape without cast molding. Here, the SiC green body was obtained by SLS technique with thermoplastic phenolic resin as binder and its content lower than 15% (in volume) for the subsequent procedure to fabricate composite materials. However, low binder content results in low flexural strength. As the resin content increases to 25% (in volume), the strength of the SiC green body reaches 3.77 MPa with a strength increment of 702.1% for the SLS SiC green body. Spray drying was applied to form more spherical powder. Nevertheless, the porosity of the SiC green body is still high (71.18%), due to porous microstructure remaining in spray-dried powder, which leads to deteriorated strength of the green body.

3D printing of ceramics: a review

Along with extensive research on the three-dimensional (3D) printing of polymers and metals, 3D printing of ceramics is now the latest trend to come under the spotlight. The ability to fabricate ceramic components of arbitrarily complex shapes has been extremely challenging without 3D printing. This review focuses on the latest advances in the 3D printing of ceramics and presents the historical origins and evolution of each related technique. The main technical aspects, including feedstock properties, process control, post-treatments and energy source material interactions, are also discussed. The technical challenges and advice about how to address these are presented. Comparisons are made between the techniques to facilitate the selection of the best ones in practical use. In addition, representative applications of the 3D printing of various types of ceramics are surveyed. Future directions are pointed out on the advancement on materials and forming mechanism for the fabrication of high-performance ceramic components.

Significant increase of UV reflectivity of SiC galvanometer mirror scanners for the high-power laser applications

Recent advances in joining of SiC-based materials (monolithic SiC and SiCf/SiC composites): joining processes, joint strength, and interfacial behavior

Effects of die-pressing pressure and extrusion on the microstructures and mechanical properties of SiC reinforced pure aluminum composites

Effect of sintering conditions on microstructure orientation in α-SiC prepared by slip casting in a strong magnetic field

Microstructure and properties of diamond/SiC composites prepared by tape-casting and chemical vapor infiltration process

Microstructural tailoring, mechanical and thermal properties of SiC composites fabricated by selective laser sintering and reactive melt infiltration

Additive manufacturing of structural materials

Binder jetting additive manufacturing of silicon carbide ceramics: development of bimodal powder feedstocks by modeling and experimental methods

Properties of SiC-Si made via binder jet 3D printing of SiC powder, carbon addition, and silicon melt infiltration

Processing and properties of SiC composites made via binder jet 3D printing and infiltration and pyrolysis of preceramic polymer

3D printing of high- purity silicon carbide

Grain composition on solid-state-sintered SiC ceramics