热电转换技术能实现热能与电能之间的相互转换, 在热电制冷和温差发电等领域有着巨大应用前景[1⇓⇓-4], 受到广泛关注[5⇓⇓⇓-9]。Bi2Te3基材料是室温附近性能最好的热电材料, 可应用于制冷和低温发电等领域[10⇓⇓-13]。室温下, Bi2Te3材料的带隙为0.15 eV, 它是以Bi和Te原子组成的五原子层状结构为结构单元, 沿c轴方向堆叠而成, 层间以范德瓦尔斯力结合[14⇓-16]。层间作用力较弱导致Bi2Te3基合金易沿层间解离, 加工性能和力学性能较差, 极大限制了其在微型热电器件领域的应用[17⇓-19]。因此, 亟需开发兼具优异热电性能和力学性能的Bi2Te3基热电材料[20⇓-22]。

目前, 一般通过固溶晶体结构相同的Sb2Te3和Bi2Se3来提升Bi2Te3基材料室温附近的热电性能[23-24]。p型Bi2Te3基热电材料中, 与Bi原子相比, Sb原子的电负性和原子半径更接近Te原子。因此在Bi2Te3中固溶Sb2Te3可以有效降低反位缺陷的形成能, 增加反位缺陷浓度, 提高载流子浓度, 从而提升其热电性能[25-26]。目前采用区熔生长工艺制备的Bi2Te3基材料由于较高的取向性导致其力学性能较差[27]。而采用粉末冶金法制备的多晶样品, 虽然力学性能得到明显改善[28⇓-30], 但是制备过程中产生的类施主效应使多晶样品的载流子浓度偏离最优范围, 导致热电性能劣化, 是目前影响多晶Bi2Te3基热电材料性能的主要因素[31⇓⇓⇓-35]。因此揭示类施主效应的产生机制, 并通过制备工艺调控和抑制类施主效应至关重要。前期的研究表明, Bi2Te3基热电材料的类施主效应与材料受机械力作用下非基面滑移产生的表面缺陷和空气中的氧气密切相关[36]。但目前关于类施主效应的缺陷反应机制不清晰, 因此系统研究和探索Bi0.5Sb1.5Te3基多晶合金制备过程中产生类施主效应所涉及的具体缺陷物理化学反应过程, 以及如何有效抑制该反应, 对于有效调控Bi2Te3基热电材料的性能至关重要。

本研究主要以p型Bi0.5Sb1.5Te3基热电材料为研究对象, 采用放电等离子活化烧结技术制备了系列Bi0.5Sb1.5Te3块体样品, 系统研究了不同气氛下破碎、研磨和不同气氛吸附、脱附处理对类施主效应和热电性能的影响规律, 结合第一性原理计算揭示了p型Bi0.5Sb1.5Te3基热电材料类施主效应过程中的物理化学反应机制, 为调控和抑制材料的类施主效应提供一种新途径。

1 实验方法

1.1 材料制备合成方法

将组分为Bi0.5Sb1.5Te3的商业区熔(Zone Melting, ZM)锭体(广东富信科技股份有限公司)用石英管真空密封, 并在673 K下退火48 h, 获得组分均匀的区熔锭体。然后将退火锭体分成两部分: 一部分在手套箱(Ar气氛)中研磨, 将研磨之后的粉体分为两份, 一份在手套箱中放置48 h后烧结, 标记为In-Ar, 另一份在空气中放置48 h后烧结, 标记为In-Air; 另一部分在空气中研磨, 研磨之后的粉体也分为两份, 一份放入手套箱中48 h后烧结, 标记为Out-Ar, 另一份放置在空气中48 h后烧结, 标记为Out-Air。其中烧结温度为733 K, 烧结压力为45 MPa, 并在733 K下保温5 min。制备得到ϕ15 mm×12 mm的圆柱形块体材料, 相对密度达到99%以上。为了表征样品的热稳定性, 将前述制得的样品真空密封于玻璃管内, 在473 K下退火7 d, 进一步测试其电性能。退火后的样品分别标记为In-Ar-TH、In-Air-TH、Out-Ar-TH和Out-Air-TH。

1.2 结构表征

采用粉末X射线衍射技术(Empyrean, 帕纳科, Cu Kα)分析样品的物相组成。采用日本日立公司生产的SU-8020型场发射扫描电子显微镜(Field Emission Scanning Electron Microscope, FESEM)观察样品表面微观结构和背散射测试, 结合德国Bruker公司的能谱仪(Energy Dispersive Spectrometer, EDS)对样品进行组成元素的面分布分析。

1.3 热电性能测试

由德国Linseis公司生产的LSR-3设备, 在He气氛下采用四探针法测得样品的电导率和Seebeck系数。由德国Netzsch公司生产的LFA-457设备在Ar气氛下采用激光闪射法测定样品的热扩散系数。由美国Lake shore公司生产的8400系列霍尔效应测试系统采用范德堡法测试得到室温霍尔系数。考虑到材料电热输运性能的各向异性, 所有样品的热电性能均沿垂直压力方向进行测试。

2 结果与讨论

2.1 相组成与微结构

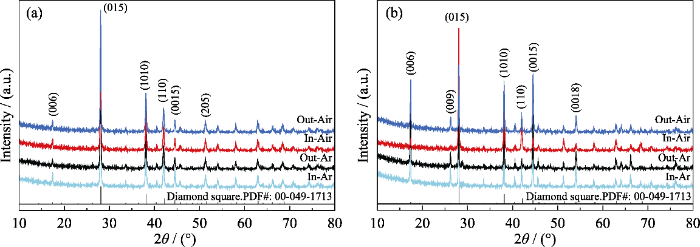

图1(a)是四个采用不同气氛处理的粉体所制备烧结样品的XRD图谱, 所有的衍射峰均与Bi0.5Sb1.5Te3 (JCPDS 00-049-1713)标准卡片相匹配, 在XRD的检测极限范围内未观测到明显的第二相。为了定量描述四个样品的取向性, 测试了烧结样品的块体XRD 图谱, 如图1(b)所示。根据块体X射线强度与粉末X射线衍射峰强度的差别, 可以计算材料的取向性因子F(计算方法见补充材料S1)[37], 当样品内部完全无取向时, 取向因子F为0, 完全取向时, 取向因子F为1。所有样品沿(00l)晶面的取向因子均在0.07左右(如表1), 差别不大, 样品的取向性较弱, 可以忽略取向性差异对热电性能的影响。

图1

图1

(a)不同气氛处理烧结样品的粉体XRD图谱和(b)垂直于烧结压力方向的块体XRD图谱

Fig. 1

(a) Powder XRD patterns of sintered samples with powders treated in different atmospheres, and (b) XRD patterns of bulk samples measured perpendicular to the sintered pressing direction

表1 不同气氛处理粉体烧结样品室温下的取向因子(F)、电导率(σ)、Seebeck系数(S)、载流子浓度(n)、迁移率(μ)、总热导率(κ)、有效质量(m*/m0)、热电优值ZT以及平均热电优值ZTave

Table 1

| Sample | F | σ/(×104, S•m−1) | S/(μV•K−1) | n/(×1019, cm−3) | μ/(cm2•V−1•s−1) | κ/(W•m−1•K−1) | m*/m0 | ZT | ZTave |

|---|---|---|---|---|---|---|---|---|---|

| In-Ar | 0.076 | 17.50 | 150 | 4.49 | 243 | 1.49 | 0.93 | 0.78 | 0.92 |

| Out-Ar | 0.074 | 15.55 | 160 | 3.88 | 249 | 1.45 | 0.91 | 0.82 | 0.86 |

| In-Air | 0.078 | 12.92 | 172 | 3.31 | 243 | 1.28 | 0.89 | 0.90 | 0.81 |

| Out-Air | 0.072 | 12.36 | 177 | 3.21 | 240 | 1.23 | 0.89 | 0.94 | 0.87 |

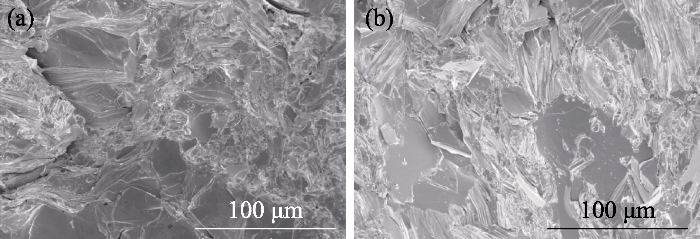

图2

图2

In-Ar样品(a)垂直和(b)平行烧结压力方向的FESEM照片

Fig. 2

FESEM images for In-Ar sample along the direction (a) perpendicular and (b) parallel to sintering pressure

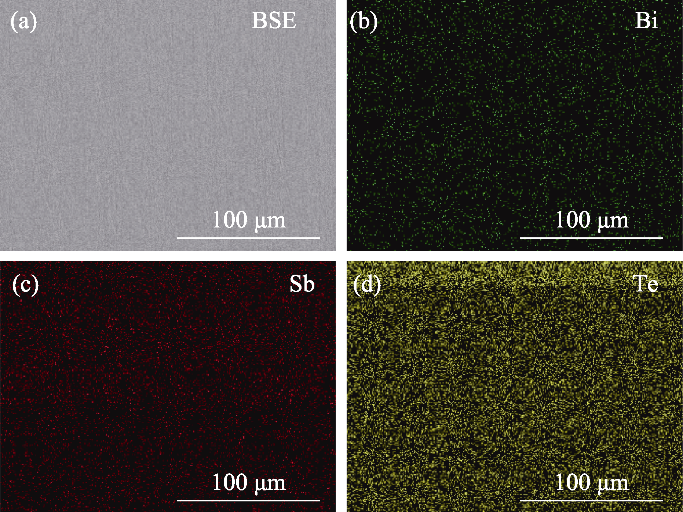

图3

图3

In-Ar样品垂直于烧结压力方向抛光表面的(a)背散射电子像以及(b)Bi、(c)Sb和(d)Te元素的面扫描EDS能谱图

Fig. 3

(a) Backscattered electron images, (b) Bi, (c) Sb, and (d) Te elemental distribution mappings on the polished surface of In-Ar sample via EDS along the direction perpendicular to the sintering pressure

2.2 Bi0.5Sb1.5Te3合金类施主效应

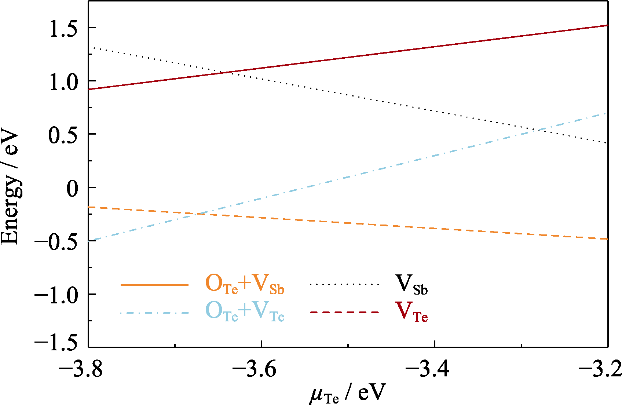

对于p型Bi0.5Sb1.5Te3基热电材料, 为了说明O2诱导产生类施主效应, 计算了Sb2Te3材料中不同形态空位缺陷的形成能, 如图4所示(具体计算方法见补充材料S2), 其中横坐标为Te的化学势大小, 化学势越大, 表明Te的富集程度越高。

图4

图4

不同Te化学势条件下Bi0.5Sb1.5Te3合金中存在的复杂缺陷的形成能

Fig. 4

Formation energy with complex defects presented in Bi0.5Sb1.5Te3 alloys at different Te chemical potentials

由于Sb2Te3材料的带隙非常小, 计算时可以不考虑缺陷形成所带来的电荷变化, 只计算电中性, 缺陷形成能只和原子化学势有关。鉴于本实验原料采用区熔制备工艺, 会造成Te微量缺失, 因此烧结样品内Te的化学势较低, μTe更接近–3.8 eV(图4)。在机械力的作用下, 样品的非基面滑移会产生阴阳离子空位缺陷对。在空气中研磨时, O2会参与反应并占据Te位, 形成

通过缺陷反应方程式可以发现, 产生类施主效应必须同时存在阴、阳离子空位以及O2, 并且此缺陷反应会产生大量自由电子, 从而降低空穴载流子浓度, 这与计算结果一致。

2.3 不同气氛处理过程对类施主效应和电热输运性能的影响

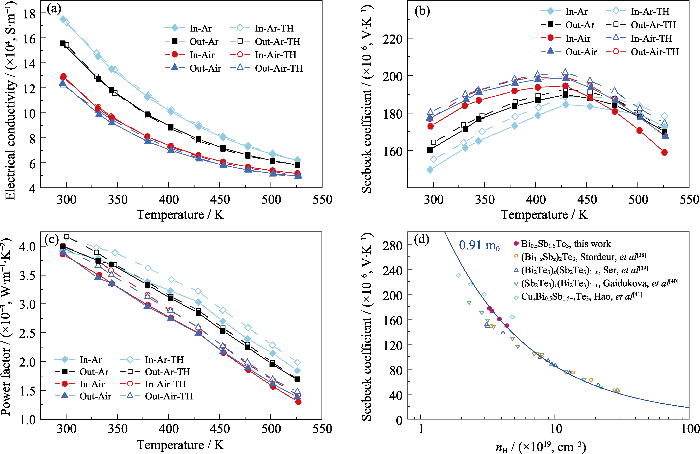

如前所述, 样品的元素组成、微结构基本一致, 取向因子均较小, 可以忽略这些因素对样品电热输运性能的影响。此外, 鉴于样品两个方向的热电性能差异不大, 本实验仅展示烧结样品垂直于烧结压力方向的热电性能, 所有样品的部分物理参数如表1所示。图5(a)为不同气氛下研磨和脱附处理粉末烧结样品的电导率随温度变化的关系曲线, 样品的电导率随温度升高而降低, 表现出金属传导特性。室温下样品的电导率随着研磨气氛和脱附处理气氛由空气(Air)变为Ar气氛不断上升, 在空气中研磨和处理的粉末烧结样品的电导率为1.24×105 S·m–1, 而完全在Ar气氛处理粉末烧结样品的电导率为1.75×105 S·m–1, 表明后续脱附气氛对室温电导率的影响较大。其中当脱附气氛从空气变为Ar气氛后, 样品室温下电导率从1.24×105 S·m–1提高至1.56×105 S·m–1, 提升了26%, 而将研磨气氛从空气变为Ar气氛之后, 样品的室温电导率从1.56×105 S·m–1提高至1.75×105 S·m–1, 提升了12%。样品的电导率主要由材料的载流子浓度和迁移率决定, 样品室温下的载流子浓度和载流子迁移如表1所示, 完全在空气中研磨处理粉体烧结样品的载流子浓度为3.21×1019 cm–3, 经过Ar气氛的脱附处理之后载流子浓度提高到3.88×1019 cm–3, 而完全在Ar保护气氛处理的样品的载流子浓度最高, 达到4.49× 1019 cm–3。总体而言, 样品载流子浓度降低会抑制载流子与载流子之间的散射, 提高迁移率, 但是由于氧气诱导类施主效应产生的

图5

图5

不同气氛处理样品垂直烧结压力方向的(a)电导率、(b)Seebeck系数、(c)功率因子随温度变化的关系曲线, (d) 室温下Bi-Sb-Te合金的Seebeck系数与载流子浓度的关系曲线(Pisarenko曲线)

Fig. 5

Temperature dependence of (a) electrical conductivity, (b) Seebeck coefficient, (c) power factor for samples treated with different atmospheres along the direction perpendicular to the sintering pressure, (d) relationship between Seebeck coefficient and carrier concentration (Pisarenko curve) at room temperature for Bi-Sb-Te alloy

图5(b)为不同气氛下研磨和脱附处理粉末烧结样品的Seebeck系数随温度变化的曲线, 在测试温度范围内, 所有样品的Seebeck系数为正值, 表现为p型传导。受本征激发带来的双重载流子的影响, 所有样品的Seebeck系数均随温度升高呈现先增大后减小的变化趋势。室温下, 样品的Seebeck系数随着研磨和脱附气氛从空气转变为Ar气氛而下降, Out-Air样品在室温下Seebeck系数为177 μV·K−1, 而In-Ar样品的Seebeck系数为150 μV·K−1。

根据实测的电导率和Seebeck系数计算了样品随温度变化的功率因子。如图5(c)所示, 样品的功率因子随着温度升高而减小, 与空气中处理的粉体烧结样品相比, In-Ar样品和Out-Ar样品在整个测试温度区间内均具有更优异的功率因子, 在室温下, Out-Ar样品获得最大功率因子为4.0 W·m-1·K-2。

对比退火前后四个样品的电传输性能可以发现, 各样品的电导率与Seebeck系数经过7 d的退火处理后基本不变, 计算得到的功率因子变化也很小, 表明不同气氛处理的样品均具有较高的热稳定性。

为了进一步揭示样品电性能差异的机制, 假定样品的电子能带结构中价带顶可以采用简单的单抛物线模型进行描述, 考虑载流子受到的主要散射为声学支声子散射, 样品的Seebeck系数可表示为:

其中, S为Seebeck系数(V•K−1), kB为玻尔兹曼常数(1.38×10−23 J·K−1), h为普朗克常数(6.63×10−34 J·s), n为载流子浓度(m-3), m*为载流子有效质量, T为温度(K)。图5(d)为本研究和文献报道的p型BixSb2-xTe3样品室温下载流子浓度与Seebeck系数的关系曲线, 即Pisarenko曲线。样品的载流子有效质量约为0.91m0, 说明在p型BixSb2-xTe3合金中, 尽管类施主效应降低了载流子浓度, Seebeck系数增大, 但是样品的载流子有效质量基本不变。类施主效应对Bi0.5Sb1.5Te3样品的价带顶结构的影响较小, 可以通过单抛物线模型进行描述, 因此材料电传输性能主要由载流子浓度决定。

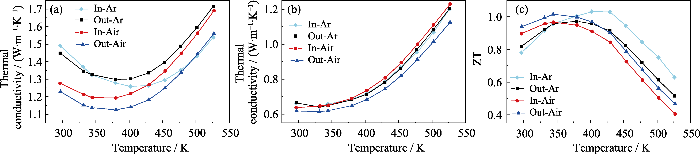

图6(a)为不同气氛处理粉体烧结样品的总热导率随温度变化的关系曲线, 由于U散射和本征激发导致双极扩散的影响, 所有样品的总热导率均随温度升高呈现出先减小后增加的趋势。随着研磨气氛和脱附气氛逐渐向Ar气氛转变, O2逐渐从粉体表面脱附, 样品内的类施主效应得到有效抑制, 空穴载流子浓度增加, 载流子热导率对总热导率的贡献明显增大, 室温总热导率逐渐上升。室温下Out-Air样品的总热导率最低, 为1.23 W·m-1·K-1, 而In-Ar样品的总热导率最高, 为1.49 W·m-1·K-1。此外, 由于载流子浓度增大, 样品双极热导的贡献得到明显抑制, 双极热导的发生温度向高温偏移。图6(b)为不同气氛处理粉体烧结样品的晶格热导率与双极热导率之和随温度变化的关系曲线(具体计算方法见补充材料S3)。从图6(b)中可以看出, 不同气氛处理样品的晶格热导率与双极热导率之和随着温度上升而逐渐增大。各样品之间的晶格热导率与双极热导率之和差异很小, 其中Out-Air样品的室温晶格热导率较小, 为0.62 W·m-1·K-1。图6(c)为不同气氛处理粉体烧结样品的热电优值ZT随温度变化的关系曲线。随着测试温度升高, 所有样品的ZT逐渐升高, 当温度升高至本征温度以上, 由于样品的本征激发增强, ZT开始下降。随着研磨气氛和脱附气氛转变为Ar气氛, 样品的载流子浓度升高, 室温热导率明显增大, 导致室温ZT有所下降。室温下Out-Air样品获得最大的ZT(0.94), 而In-Ar样品的ZT为0.78, 但In-Ar样品在402 K下取得最高ZT为1.03, 且在测试温度范围内的ZTave最高, 达到0.92(表1), 整体性能较为优异。同时由于载流子浓度提升, 与Out-Air样品相比, In-Ar样品的ZT峰向高温偏移。

图6

图6

不同气氛处理样品垂直烧结压力方向的(a)总热导率、(b)晶格热导率与双极热导率之和以及(c)热电优值ZT随温度变化曲线

Fig. 6

Temperature dependence of (a) total thermal conductivity, (b) sum of lattice thermal conductivity and bipolar thermal conductivity, (c) thermoelectric merit ZT for samples treated with different atmospheres along the direction perpendicular to the sintering pressure

3 结论

粉末冶金法制备Bi0.5Sb1.5Te3合金的类施主效应主要是破碎研磨过程中产生表面缺陷$\text{V}_{\text{Te}}^{\cdot \cdot }$和$\text{{V}'''}_{\text{Sb}}^{{}}$, 在放置于空气的过程中物理吸附了空气中的O2, 在烧结过程中吸附的O2与缺陷发生化学反应产生类施主效应, 导致样品的载流子浓度从4.49×1019 cm−3减小至3.21×1019 cm−3。通过将区熔(ZM)锭体的研磨气氛和粉体的脱附气氛逐步从空气转变为Ar保护气氛, 显著提升了烧结样品的热电性能。通过将破碎研磨和脱附的气氛转为Ar气氛, 最终烧结样品的载流子浓度恢复到4.49×1019 cm−3, 在402 K下, 获得最高ZT为1.03, 在整个测试温度范围内平均ZT为0.92。该研究为抑制p型多晶Bi2Te3合金的类施主效应和提升热电性能提供了新方法。

补充材料

本文相关补充材料可登录

补充材料

p型多晶Bi0.5Sb1.5Te3合金类施主效应与热电性能

鲁志强1,2, 刘可可1,2, 李强1,2, 胡芹1,2, 冯利萍1,2, 张清杰2, 吴劲松2,3, 苏贤礼1,2, 唐新峰1,2

(1. 武汉理工大学襄阳示范区, 湖北隆中实验室, 襄阳 441000; 2. 武汉理工大学材料复合新技术国家重点实验室, 武汉 430070; 3. 武汉理工大学 纳微结构研究中心, 武汉 430070)

S1 块体X射线衍射图取向因子的计算

其中, P0为无序粉末(00l)晶面峰值强度I0之和与无序粉末所有晶面峰值强度之和的比值, P为块状样品(00l)晶面峰值强度I之和与块状样品所有晶面峰值强度之和的比值; F为取向因子, 样品内部完全无取向时, 取向因子为0, 样品内部为完全取向时, 取向因子为1。

S2 缺陷形成能的计算

缺陷形成能Ef的计算公式如下:

其中,

S3 晶格热导率与双极热导率的计算

Bi2Te3材料的总热导率主要由晶格热导率、双极热导率以及载流子热导率三部分构成:

其中, κt为样品的总热导率, κL为晶格热导率, κb为双极热导率, κe为载流子热导率(W·m-1·K-1)。样品的载流子热导率可通过Wiedemann-Franz 定律计算得到, 计算公式为:

公式(S6)中的L为洛伦兹常数, 在假定能带结构为单抛物带近似的前提下, 洛伦兹常数可通过下式计算得到:

公式(7)中的kB为波尔兹曼常数(1.38×10−23 J·K−1), e为电子电荷(1.60×10–19 C), r为散射因子。样品内的载流子主要受到声学支声子散射, 因此散射因子r=–1/2, 为简约费米能级, 通过下列公式计算得到

最终通过κL+κb=κt-κe可计算得到样品的晶格热导率与双极热导率。

参考文献:

[1] KRESSE G, FURTHMÜLLER J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Physical Review B, 1993, 54(16): 11169.

[2] KRESSE G, JOUBERT D P. From ultrasoft pseudopotentials to the projector augmented-wave method. Physical Review B, 1999, 59(3): 1758.

[3] BLOCHL P E. Projector augmented-wave method. Physical Review B, 1994, 50(24): 17953.

[4] PERDEW P J, BURKE K E M. Generalized gradient approximation made simple. Physical Review Letters, 1996, 77(18): 3865.

[5] HASHIBON A, ELSÄSSER C. First-principles density functional theory study of native point defects in Bi2Te3. Physical Review B, 2011, 84(14): 144117.

参考文献

Exceptional thermoelectric performance in Mg3Sb0.6Bi1.4 for low-grade waste heat recovery

Structures and thermoelectric properties of (GeTe)nBi2Te3

Ultra-fast synthesis of Cu2S thermoelectric materials under pulsed electric field

Cu2S shows excellent thermoelectric properties as a material with phonon liquid-electron crystal characteristics. However, traditional preparation methods are cumbersome and difficult to afford bulk Cu2S with uniform composition, high density and excellent thermoelectric properties. In this study, a novel method named Pulsed Electric Current Sintering was introduced to synthesize and sinter Cu2S materials in one step consuming only 30 s. The synthesis of Cu2S under intense pulsed electric field includes three steps. A small amount of CuS and Cu2S forms in the first step; most of Cu2S and part of Cu1.96S are produced in the second step; finally, the remained Cu1.96S and Cu react to form completely pure Cu2S. The Cu2S bulk obtained by this method is a dense bulk with homogeneous composition, and contained abundant multi-scale microstructures. The thermoelectric performance is optimized by regulation of Cu-deficient Cu2-xS. The maximum ZT of Cu1.97S bulk at 873 K is 0.72, which is 49% higher than that of the pristine sample.

Effect of Te and In co-doping on thermoelectric properties of Cu2SnSe3compounds

High-performance organic thermoelectric materials: theoretical insights and computational design

Recent progress of thermoelectric nano-composites

Review of development status of Bi2Te3-based semiconductor thermoelectric power generation

Study of thermoelectric generation unit for radiant waste heat

A comprehensive review on Bi2Te3- based thin films: thermoelectrics and beyond

3D printing of shape-conformable thermoelectric materials using all-inorganic Bi2Te3-based inks

Achieving a fine balance in mechanical properties and thermoelectric performance in commercial Bi2Te3 materials

Investigation on a mini-CPC hybrid solar thermoelectric generator unit

Enhanced thermoelectric properties of Bi2Te3 doping Zn4Sb3 by combinatorial approach

Complex band structures and lattice dynamics of Bi2Te3-based compounds and solid solutions

Comprehensive insight into p-type Bi2Te3-based thermoelectrics near room temperature

Use of molecular dynamics simulations to study the effects of nanopores and vacancies on the mechanical properties of Bi2Te3

Development of thermoelectric fibers for miniature thermoelectric devices

Effect of surface treatment of n-type Bi2Te3-based materials on the properties of thermoelectric units

Thermal stability and mechanical response of Bi2Te3-based materials for thermoelectric applications

Effect of nominal Sb2Te3 content on thermoelectric properties of p-type (Bi2Te3)x(Sb2Te3)1-x alloys by MA-HP

Theoretical prediction of the structural, elastic, mechanical and phonon properties of bismuth telluride under pressure

Bismuth telluride (Bi2Te3) is one of the most intricate materials with its semiconducting, insulating and pressure-induced superconducting properties. Although different theoretical works have been carried out to understand the confusing properties of Bi2Te3, information about the high pressure structural, elastic, mechanical and phonon properties of this significant material is still rare. Unlike earlier theoretical approaches, two-body interatomic potentials in the Morse potential form have been employed for the first time to predict the density, phase transition pressure, elastic constants, bulk, shear and Young moduli and elastic wave velocities of Bi2Te3under pressures up to 12 GPa. [Formula: see text] phase transition pressure of Bi2Te3was found to be 10 GPa. The results of above elastic quantities agree well with experiments and are better than some of the published theoretical data. In addition, the effect of pressure on the phonon dispersion and density of states (DOS) were also evaluated with the same potential and their results are satisfactory, especially for the low-frequency acoustic portions of phonons.

Thermoelectric materials based on Sb2Te3-Bi2Te3 solid solutions with optimal performance in the range 100-400 K

High thermoelectric performance in (Bi0.25Sb0.75)2Te3 due to band convergence and improved by carrier concentration control

Plasma screening of the fundamental absorption edge in crystals of Bi2Te3-Sb2Te3 solid solutions with more than 80mol% Sb2Te3

Phase transformation and thermoelectric properties of p-type (Bi2Te3)0.25(Sb2Te3)0.75prepared by mechanical alloying and hot pressing

Investigation of the chemical interaction in the Sb2Te3-InSe system and the properties of the obtained phases

Probing the thermoelectric transport properties of n-type Bi2Te3 close to the limit of constitutional undercooling

Effects of preparation techniques on the thermoelectric properties and pressive strengths of n-type B2Te3 based materials

Strong anisotropic effects of p-type Bi2Te3 element on the Bi2Te3/Sn interfacial reactions

Thermoelectric and mechanical properties of nano-SiC-dispersed Bi2Te3 fabricated by mechanical alloying and spark plasma sintering

Thermoelectric properties of the p-type Bi2Te3-Sb2Te3-Sb2Se3alloys fabricated by mechanical alloying and hot pressing

Thermoelectric properties of p-type antimony bismuth telluride alloys prepared by cold pressing

Thermoelectric properties of 25%Bi2Te3-75%Sb2Te3 solid solution prepared by hot-pressing method

Effects of heavy deformation and annealing on the electrical properties of Bi2Te3

Heavy plastic deformation producing nonbasal slip in Bi2Te3 changes the material from p type to n type and decreases its resistivity. From Hall coefficient measurements, it appears that an excess of about 2×1020 negative carriers can be generated in the lattice. Annealing the deformed samples at different temperatures and in different environments causes large changes in this excess carrier concentration. A simple theoretical model based on point defect generation by the plastic deformation accounts for the results. From this model, it appears that tellurium vacancies are the predominant electrically active point defects. These Te vacancies are annihilated by dislocation climb and array formation during annealing. The effect of dissolved oxygen in Bi2Te3 is to add donor states to the system.

Evolution of the intrinsic point defects in bismuth telluride-based thermoelectric materials

Removing the oxygen-induced donor-like effect for high thermoelectric performance in n-type Bi2Te3-based compounds

Topotactical reactions with ferrimagnetic oxides having hexagonal crystal structures

Investigation of the valence band structure of thermoelectric (Bi1-xSbx)2Te3 single crystals

Energy spectrum of solid solutions of Bi2Te3-Sb2Te3system

Characteristics of the energy spectrum of solid solutions in the SbTe-BiTe system