当前氮化硅粉体的一致性评价仍是行业内面临的共性难题。一方面, 粉体性能指标模糊, 常用的指标为高α相含量(>93%, 质量分数), 低氧含量 (< 1.5%, 质量分数), 细粒度 (D50=0.6~0.8 μm), 高纯度(Fe, Al, Ca<100×10-6), 但满足上述指标的粉体烧结制品的性能却存在差异[5-6], 粉体性能指标的评定无据可依; 另一方面, 若从粉体应用效果角度进行评价, 即用陶瓷制品性能作为评价粉体性能的评价依据, 则存在评价周期长、受烧结工艺流程中意外因素、制品性能测试误差等影响性能数据的问题, 难以分辨引起陶瓷产品性能波动的主要原因是否在于粉体原料。粉体产品质量的批次稳定性缺乏有效的评价手段和量化依据已成为亟需解决的问题。

1 实验方法

1.1 粉体数据

采用中国科学院理化技术研究所和齐鲁中科光物理与工程技术研究院在廊坊园区共建的燃烧合成氮化硅粉体中试基地生产的氮化硅粉体为原料, 采集2022年3月17日至11月14日期间生产的Y系列粉体, 共33批次粉体, 批次号为Y220317~ Y221114, 每批次200 kg粉体, 均化处理后随机抽取1 kg进行指标测量。各批号样品按日期顺序标记为0~32号, 详细性能数据表见表S1。

1.2 粉体指标选取

所选取的粉体静态理化指标如表1所示。

表1 氮化硅粉体产品理化指标体系及测量方法

Table 1

| General indicator | Secondary indicator | Symbol | Unit | Method | Test equipment |

|---|---|---|---|---|---|

| Physical property | Particle size | D10 | μm | Laser diffraction method | Particle diameter sizer (Dandong Bettersize Instruments, Bettersiza 2600) |

| D50 | μm | ||||

| D90 | μm | ||||

| Bulk density | ρB | kg/m3 | Weight-volume method | Intelligent integrated powder characterizer (Dandong Bettersize Instruments, BT-1001) | |

| Specific surface area | S | m2/g | Gas adsorption method | Gas absorption powder specific surface tester (MicrotracBEL, Belsorp maxⅡ) | |

| Component property | α phase content | A | % (in mass) | Mean-normalised- intensity method | X-ray diffractometers (Rigaku Corporation, MiniFlex600) |

| O content | O | % (in mass) | Infrared detection method (CO/CO2) | Nitrogen/oxygen analyz (HORIBA, EMGA- 820) | |

| Moisture content | H2O | % (in mass) | Gravimetric method | Rapid moisture tester (Shenzhen Guanya, SZ-GY820FT) |

表2 氮化硅粉体产品流动性指标体系及测量方法

Table 2

| General indicator | Secondary indicator | Symbol | Unit | Definition |

|---|---|---|---|---|

| Stability and variable flow rate | Basic flowability energy | BFE | mJ | The energy required for the rotor to overcome the resistance of the powder to rotate |

| Stability index | SI | — | Repeated measurements of powder flow energy to characterise its stability | |

| Flow rate index | FRI | — | Measurement of flow energy at different speeds | |

| Specific energy | SE | mJ/g | Data measured during the upward movement of the blade through the powder sample | |

| Compressibility | Conditioned bulk density | CBD | g/mL | Loose packing density of pre-treated powders |

| Compressibility | CPSm | % | Compressibility at positive stress m kPa | |

| Shear test | Cohesion | Cm | kPa | Shear strength at zero positive stress for a pre-consolidated positive stress of m kPa |

| Unconfined yield strength | UYSm | kPa | The maximum principal stress corresponding to a molar circle tangent to the yield trajectory at a pre- consolidation stress of m kPa and a minimum principal stress of 0 | |

| Maximum principal stress | MPSm | kPa | Maximum compressive stress calculated from the molar circle at steady state flow under a pre-consolidated positive stress of m kPa | |

| Flow function | FFm | — | Ratio of the above maximum principal stress to the unconfined yield strength | |

| Angle of internal friction | AIF | ° | The angle between the shear linear yield trajectory and the x-axis, characterizing the ease with which the powder particles can slide against each other | |

| Aeration test | Aerated energy | AEn | — | The energy required to move the powder sample when filling the gas at a rate of n mm/s |

| Aeration ratio | AR | — | Ratio of the base flow energy to the filling energy after the powder having reached stability in the filling test | |

| Normalized aeration sensitivity | NAS | s/mm | Sensitivity to the effect of air introduced by the powder, normalized BFE to air velocity ratio | |

| Permeability | Pressure drop | PDm | 100 Pa | Pressure reduction after passing air through a powder sample when a positive stress of m kPa is applied and the air velocity is maintained at 0.5 mm/s |

1.3 指标标准化变换

为了消除指标之间的量纲影响, 使粉体性能的各指标之间具有可比性, 须对数据进行去量纲化和归一处理, 本研究采用线性归一化方法, 将各指标参数值限定在[0,1]之间:

式中,

1.4 一致性评价方法

1.4.1 余弦相似度法

表征粉体性能的指标经过标准化变换后, 形成n个无量纲指标, 将此作为一个n维空间的向量, 余弦相似度法就是通过计算两个向量间夹角的余弦值来评估它们的相似度。基于余弦值的相似度评价判断依据为两个向量是否大致指向相同的方向, 当两个向量趋向相同的指向时, 余弦相似度的值趋近1, 代表两种粉体的指标越相似; 当两个向量夹角趋向于90°时, 余弦相似度趋近于0, 代表两种粉体的差异越大。两个样品

式中,

1.4.2 欧氏距离法

欧氏距离计算的是n维空间中两点之间的真实距离, 基于欧氏距离的相似度来判定个体的相似程度, 距离越近就越相似。两个样品

式中各参数的意义同式(2)。

若基于欧氏距离, 将不同批次粉体分为

其中,

2 结果与讨论

2.1 关键指标分析

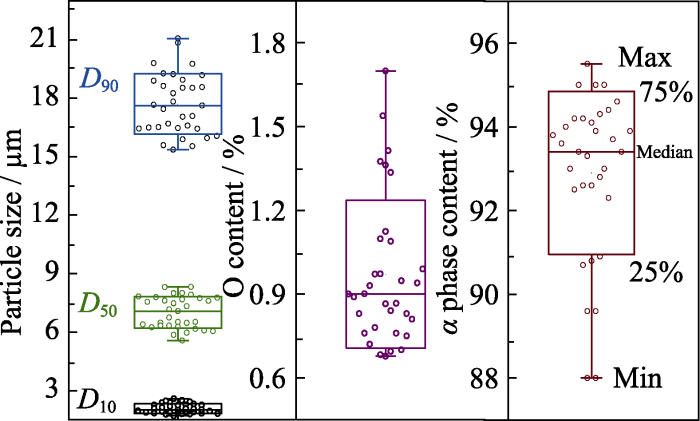

燃烧合成法制备的Y220317~Y221102系列氮化硅粉体的粒度、氧含量分布和α相含量分布情况如图1所示。粒径分布D10, D50, D90均在较窄范围内, 且更集中分布在细粒度范围内。本研究收集的是经过燃烧合成获得的原粉粒径, 而陶瓷烧结使用的亚微米粉体还需经历研磨细化等后处理步骤。原粉粒径的分布波动范围小, 对后处理阶段的工艺稳定有利。氧的含量在0.678%~1.699%(质量分数)范围内波动, 中位数低于0.9%, 属于低氧含量粉体。较高氧含量(>1%)粉体集中在早期3月17日至4月15日期间生产的6批次粉体中, 随着技术进步, 氧含量可控制在1%以下。α相的含量分布在88%~ 95.5%(质量分数)之间, 中位数高于93%, 粉体整体呈现高α相含量的特征。

图1

图1

粒度、氧含量和α相含量分布箱线图

Fig. 1

Box plots of particle size, oxygen content and α phase content distribution

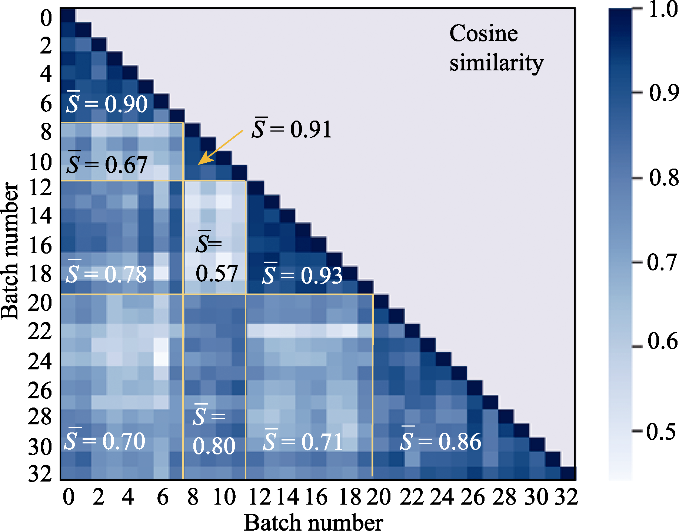

2.2 余弦相似度评价

将Y220317~Y221102批次粉体理化指标和流动性指标数据按照1.3节所述的方法进行归一化, 随后按照1.4.1节所述的余弦相似度计算方法计算每两个批次间的余弦相似度, 计算所得余弦相似度数据表见表S2, 所获得相似度数据绘制成热力图如图2所示。

图2

图2

不同批次氮化硅粉体的余弦相似度热力图

Fig. 2

Heat map of cosine similarity of different batches of silicon nitride powders

在余弦相似度热力图中根据颜色深浅划分为如图2所示的10个区域, 每个区域内标注的数值为该区域中相似度的平均值。由图2可知, 粉体在四个连续时间段内呈现高度相似的特征, 分别为批次0~7(Y220317~Y220415), 批次8~11(Y220503~Y220606), 批次12~19(Y220629~Y220830)和批次20~32(Y220907~ Y221114), 四组粉体组内的批次相似度的平均值分别为0.90, 0.91, 0.93和0.86。在此四个时间段内粉体性质近似, 一致性较好。四个时间段互相间的相似度高低不一, 批次8~11与批次20~32两组粉体之间相似度的平均值为0.80, 批次0~7与批次12~19两组粉体之间相似度的平均值为0.78, 相似度较高, 性质可能相似, 但是批次8~11与批次12~19间的相似度仅为0.57, 表示粉体间存在较大差异。

在氮化硅粉体的生产过程中, 工艺参数与产品质量属性之间的关系较复杂, 使控制产品质量的关键工艺参数难以分辨。上述余弦相似度计算结果说明几个时间段内的生产工艺参数可能发生变化, 造成粉体产品的一致性降低。因此, 对四个时间段内的生产条件进行排查调研, 重点对原材料、制备工艺和工艺参数的差异进行对比分析, 结果发现, 这四个时间段内的原料硅粉分别属于硅粉厂家不同批次的产品, 粒径分布相似但颗粒的微观形貌存在差异, 而原料硅粉的形貌差异导致了不同的氮化硅粉体性质。由余弦相似度分析结合生产条件可以确定, 控制原料硅粉性能的稳定是稳定控制氮化硅粉体性能的关键因素之一。此方法为进一步控制氮化硅粉体的生产工艺提供依据, 使生产过程更加明确且可控。

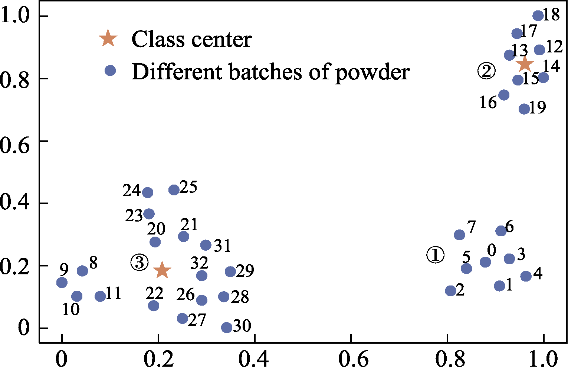

2.3 欧式距离聚类分析

图3

图3

t-SNE法可视化粉体的性能指标

Fig. 3

Performance indicators for the visualization of powders by the t-SNE method

表3 三个类中心处粉体性能指标

Table 3

| General indicator | Secondary indicator | Symbol | Unit | Class ① | Class ② | Class ③ | |

|---|---|---|---|---|---|---|---|

| Physical/ chemical indicator | Physical property | Size | D10 | μm | 1.870 | 1.854 | 2.275 |

| D50 | μm | 6.439 | 6.158 | 7.798 | |||

| D90 | μm | 16.819 | 16.038 | 19.092 | |||

| Bulk density | ρB | kg/m3 | 0.229 | 0.211 | 0.261 | ||

| Specific surface area | S | m2/g | 2.599 | 2.480 | 1.892 | ||

| Component property | α phase content | A | % (in mass) | 92.625 | 94.350 | 92.231 | |

| O content | O | % (in mass) | 1.368 | 0.940 | 0.800 | ||

| Moisture content | H2O | % (in mass) | 1.086 | 1.206 | 1.654 | ||

| Liquidity indicator | Stability and variable flow rate | Basic flowability energy | BFE | mJ | 412.750 | 458.000 | 510.500 |

| Stability index | SI | — | 1.058 | 1.009 | 1.033 | ||

| Flow rate index | FRI | — | 1.840 | 1.659 | 1.731 | ||

| Specific energy | SE | mJ/g | 9.283 | 8.986 | 9.423 | ||

| Compressibility | Conditioned bulk density | CBD | g/mL | 0.295 | 0.287 | 0.403 | |

| Compressibility | CPSm | % | 32.463 | 37.462 | 33.388 | ||

| Shear test | Cohesion | Cm | kPa | 1.609 | 1.949 | 1.711 | |

| Unconfined yield strength | UYSm | kPa | 6.540 | 7.874 | 6.989 | ||

| Maximum principal stress | MPSm | kPa | 28.175 | 28.337 | 28.281 | ||

| Flow function | FFm | — | 4.341 | 3.619 | 4.055 | ||

| Angle of internal friction | AIF | ° | 37.612 | 37.325 | 37.800 | ||

| Aeration Test | Aerated energy | AEn | — | 100.200 | 140.750 | 104.262 | |

| Aeration ratio | AR | — | 4.053 | 3.975 | 6.719 | ||

| Normalized aeration sensitivity | NAS | s/mm | 0.119 | 0.089 | 0.119 | ||

| Permeability | Pressure drop | PDm | mbar | 20.025 | 12.492 | 5.169 |

3 结论和展望

本研究针对燃烧合成氮化硅粉体的一致性评价问题, 构建了以静态理化指标、动态流动性指标为主的粉体性能参数体系, 测试获得氮化硅粉体在该参数体系下的数据后, 使用余弦相似度法、欧氏距离法进行一致性评价, 结果表明:

1) 使用该参数体系计算的余弦相似度和欧氏距离均能反映批次粉体间的相似程度, 两种评价方式的计算结果相互验证;

2) 对余弦相似度法一致性评价中判定为存在差异的粉体, 结合生产工艺的变化, 找到了控制氮化硅粉体性能稳定的关键因素(原料硅粉) ;

3) 使用欧氏距离法对氮化硅粉体进行聚类分析, 实现了粉体组别划分, 以类中心和类间距为判据为新生产粉体批次划分提供了量化依据。

所建立氮化硅粉体评价指标体系为控制氮化硅粉体生产的批次稳定性提供了有效手段和量化依据。

但对于粉体性能一致性评价问题, 仍处于起步阶段, 尚存在以下不足, 相应工作仍需完善。 (1)当前研究对粉体的分类是基于粉体指标数据的聚类分析, 未结合应用粉体后制品的性能。而在实际应用中, 使用粉体制备的制品性能更受关注。在已获得的粉体分类基础上, 进行制品性能评价, 对分类结果进行进一步优化, 合并制品性能相近的类别, 最终获得在应用场景中批次稳定的粉体的指标范围。(2)当前研究中获得的批次划分结果还存在不同批次中指标相近的情况, 原因是数据规模偏小。当数据量扩展之后, 可以使用深度学习等自适应的机器学习方法, 通过自监督学习方式挖掘指标之间的相关性, 使粉体性能体系中的指标获得精简完善, 更好地完成粉体性能一致性评价任务。

补充材料

与本文相关补充材料可以登录

燃烧合成氮化硅粉体的性能一致性评价方法和应用

李宏华1, 东婉茹2, 王良1, 杨增朝1, 李江涛1

(1.中国科学院 理化技术研究所, 低温重点实验室, 北京 100190; 2.齐鲁中科光物理与工程研究院, 济南 250000)

表S1 原粉测量数据

| 批号 | 测试时间 | 相含量 /% | 粒度/µm | 氧含量/% | 水分 /% | 松堆密度 /(g·cm-3) | 比表面 /(m2·g-1) | 稳定性和变流速 | 压缩性 | 剪切性能 | 充气性 | 透气性 PD(压降) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D10 | D50 | D90 | BFE | SI | FRI | SE | CBD | CPS | Cohesion | UYS | MPS | FF | AIF | AE | AR | NAS | |||||||||

| 0 | Y220317 | 2022.3 | 93.9 | 1.864 | 6.57 | 17.1 | 1.362 | 1.46 | 0.24 | 2.590 | 413 | 1.07 | 1.82 | 9.25 | 0.291 | 33.1 | 1.64 | 6.63 | 28.1 | 4.24 | 37.2 | 105 | 3.98 | 0.119 | 22.7 |

| 1 | Y220321 | 2022.3 | 93.3 | 1.865 | 6.798 | 17.88 | 1.414 | 0.98 | 0.24 | 2.770 | 450 | 1.09 | 1.78 | 9.62 | 0.310 | 33.4 | 1.61 | 6.48 | 27.9 | 4.31 | 37.2 | 97.9 | 4.35 | 0.117 | 11.5 |

| 2 | Y2203172 | 2022.3 | 95.0 | 2.02 | 6.518 | 16.52 | 1.124 | 0.77 | 0.208 | 2.210 | 382 | 1.04 | 1.8 | 8.85 | 0.272 | 32.8 | 1.48 | 6.13 | 28.4 | 4.63 | 38.6 | 94.5 | 3.86 | 0.105 | 19.7 |

| 3 | Y2201141 | 2022.3 | 90.8 | 1.868 | 6.317 | 16.75 | 1.699 | 1.24 | 0.22 | 2.790 | 407 | 1.06 | 1.81 | 9.46 | 0.294 | 32.1 | 1.57 | 6.39 | 28 | 4.39 | 37.6 | 106 | 3.7 | 0.118 | 23.9 |

| 4 | Y2201142 | 2022/4/19 | 90.7 | 1.933 | 6.531 | 17.14 | 1.538 | 0.71 | 0.213 | 2.610 | 418 | 1.02 | 1.92 | 9.5 | 0.289 | 31 | 1.58 | 6.34 | 27.9 | 4.4 | 37.1 | 95.9 | 4.41 | 0.137 | 13.9 |

| 5 | Y2204022 | 2022/4/15 | 93.0 | 1.796 | 6.376 | 16.65 | 1.375 | 0.94 | 0.23 | 2.790 | 375 | 1.03 | 1.86 | 9.03 | 0.28 | 32.7 | 1.71 | 6.97 | 28.8 | 4.12 | 37.8 | 95.3 | 3.82 | 0.111 | 23.2 |

| 6 | Y2204021 | 2022/4/15 | 93.4 | 1.707 | 6.019 | 15.94 | 1.336 | 1.07 | 0.24 | 2.510 | 365 | 1.1 | 1.93 | 9.04 | 0.292 | 31 | 1.37 | 5.58 | 27.8 | 4.99 | 37.7 | 76 | 4.8 | 0.144 | 21.1 |

| 7 | Y220415 | 2022/4/15 | 90.9 | 1.907 | 6.387 | 16.57 | 1.098 | 1.52 | 0.24 | 2.520 | 492 | 1.05 | 1.8 | 9.51 | 0.336 | 33.6 | 1.91 | 7.8 | 28.5 | 3.65 | 37.7 | 131 | 3.5 | 0.103 | 24.2 |

| 8 | Y220503 | 2022/5/4 | 88.0 | 2.496 | 7.73 | 18.58 | 0.678 | 1.65 | 0.268 | 1.720 | 474 | 1.11 | 1.83 | 9.26 | 0.355 | 32.6 | 1.68 | 6.71 | 27.7 | 4.13 | 36.7 | 99.6 | 5.04 | 0.0736 | 2.45 |

| 9 | Y220513 | 2022/5/19 | 88.0 | 2.239 | 7.127 | 17.5 | 0.865 | 1.14 | 0.246 | 2.040 | 482 | 1.07 | 1.86 | 9.7 | 0.337 | 30.2 | 1.59 | 6.41 | 28.1 | 4.23 | 37.3 | 111 | 4.5 | 0.0743 | 1.19 |

| 10 | Y220602 | 2022/6/2 | 89.6 | 2.378 | 7.522 | 17.68 | 0.683 | 0.84 | 0.266 | 1.620 | 495 | 1.06 | 1.85 | 9.64 | 0.355 | 29.1 | 1.55 | 6.28 | 28 | 4.45 | 37.4 | 81.4 | 7.09 | 0.0955 | 4.1 |

| 11 | Y220606 | 2022/6/6 | 89.6 | 2.58 | 7.97 | 18.31 | 0.695 | 1.03 | 0.254 | 1.750 | 531 | 1 | 1.68 | 9.03 | 0.351 | 31.5 | 1.61 | 6.55 | 27.7 | 4.22 | 37.6 | 95.7 | 5.82 | 0.0896 | 5.87 |

| 12 | Y220629 | 2022/6/29 | 93.7 | 1.793 | 6.212 | 16.48 | 1.089 | 1.15 | 0.20 | 2.540 | 508 | 1 | 1.67 | 9.31 | 0.294 | 37.9 | 2.02 | 8.17 | 28.5 | 3.48 | 37.5 | 152 | 3.76 | 0.0965 | 11.7 |

| 13 | Y220630 | 20220/6/30 | 94.1 | 1.836 | 6.294 | 16.55 | 0.972 | 0.89 | 0.204 | 2.470 | 440 | 1.01 | 1.62 | 8.69 | 0.284 | 37.5 | 1.95 | 7.99 | 28.6 | 3.58 | 37.9 | 130 | 3.56 | 0.0634 | 14.7 |

| 14 | Y220715 | 2022/7/15 | 93.0 | 1.779 | 5.617 | 15.42 | 0.841 | 0.84 | 0.228 | 2.720 | 451 | 1 | 1.76 | 9.12 | 0.298 | 38.1 | 1.86 | 7.56 | 28.3 | 3.75 | 37.6 | 135 | 3.87 | 0.0963 | 11.9 |

| 15 | Y220726 | 2022/7/28 | 94.2 | 1.831 | 5.906 | 15.59 | 0.971 | 1.07 | 0.213 | 2.36 | 453 | 1.03 | 1.64 | 8.82 | 0.285 | 35.7 | 1.84 | 7.46 | 28 | 3.76 | 37.4 | 115 | 4.25 | 0.0881 | 14.5 |

| 16 | Y220727 | 2022/7/28 | 95.5 | 1.873 | 6.131 | 16.00 | 0.867 | 1.19 | 0.214 | 2.44 | 424 | 1.02 | 1.73 | 8.88 | 0.291 | 37.3 | 1.78 | 7.17 | 28.1 | 3.91 | 37.2 | 132 | 4.21 | 0.103 | 14.8 |

| 17 | Y220808 | 2022/8/10 | 94.3 | 1.946 | 6.571 | 16.5 | 0.931 | 1.13 | 0.196 | 2.71 | 424 | 0.987 | 1.64 | 8.75 | 0.272 | 37.1 | 2.05 | 8.26 | 28.6 | 3.47 | 37.1 | 133 | 3.96 | 0.0814 | 9.44 |

| 18 | Y220816 | 2022/8/16 | 95 | 1.952 | 6.444 | 16.12 | 0.948 | 1.71 | 0.216 | 2.53 | 484 | 0.995 | 1.58 | 8.97 | 0.282 | 38.7 | 2.3 | 9.16 | 28.6 | 3.12 | 36.7 | 187 | 3.82 | 0.0844 | 11.7 |

| 19 | Y220830 | 2022/8/30 | 95 | 1.819 | 6.091 | 15.64 | 0.902 | 1.67 | 0.219 | 2.07 | 480 | 1.03 | 1.63 | 9.35 | 0.291 | 37.4 | 1.79 | 7.22 | 28 | 3.88 | 37.2 | 142 | 4.37 | 0.102 | 11.2 |

| 20 | Y220907 | 2022/9/7 | 94.2 | 2.175 | 7.215 | 17.71 | 0.780 | 1.17 | 0.229 | 1.880 | 471 | 0.968 | 1.8 | 9.54 | 0.308 | 33.8 | 1.75 | 7.09 | 28.4 | 4 | 37.5 | 110 | 6.74 | 0.0579 | 0.735 |

| 21 | Y220921 | 2022/9/21 | 94.4 | 2.264 | 7.661 | 18.58 | 0.830 | 1.29 | 0.274 | 1.75 | 517 | 1.05 | 1.75 | 9.54 | 0.346 | 40 | 1.67 | 6.89 | 28.4 | 4.12 | 38.2 | 161 | 4.44 | 0.0827 | 1.19 |

| 22 | Y220923 | 2022/9/26 | 92.6 | 2.416 | 8.054 | 19 | 0.760 | 2.69 | 0.256 | 1.96 | 509 | 0.995 | 1.74 | 9.59 | 0.341 | 29.7 | 1.53 | 6.34 | 28.3 | 4.46 | 38.6 | 48.5 | 14.9 | 0.0839 | 2.95 |

| 23 | Y220927 | 2022/9/27 | 92.6 | 2.383 | 8.046 | 19.29 | 0.720 | 2.57 | 0.256 | 1.77 | 531 | 0.986 | 1.68 | 9.75 | 0.343 | 34.7 | 1.92 | 7.77 | 28.4 | 3.65 | 37.3 | 94.7 | 5.34 | 0.0873 | 3.81 |

| 24 | Y220928 | 2022/9/28 | 92.8 | 2.468 | 8.37 | 19.82 | 0.700 | 1.69 | 0.259 | 1.87 | 562 | 0.944 | 1.67 | 9.74 | 0.351 | 31.5 | 2 | 8.23 | 29.6 | 3.59 | 38 | 122 | 5.45 | 0.114 | 7.1 |

| 25 | Y220930 | 2022/9/30 | 94 | 2.308 | 7.787 | 18.68 | 0.760 | 2.61 | 0.246 | 1.81 | 600 | 1.07 | 1.74 | 10 | 0.351 | 34.8 | 1.82 | 7.66 | 29.4 | 3.84 | 39.1 | 139 | 4.83 | 0.105 | 5.5 |

| 26 | Y221026 | 2022/10/26 | 92.5 | 2.25 | 7.838 | 19.33 | 0.750 | 1.73 | 0.263 | 1.73 | 497 | 1.03 | 1.7 | 9.13 | 0.332 | 36.2 | 1.72 | 7.02 | 28 | 3.99 | 37.8 | 76.3 | 8.57 | 0.151 | 6.42 |

| 27 | Y221027 | 2022/10/28 | 93.4 | 2.071 | 7.371 | 18.62 | 0.830 | 1.97 | 0.26 | 1.97 | 534 | 1.05 | 1.51 | 9.57 | 0.345 | 35.5 | 1.81 | 7.39 | 28 | 3.78 | 37.7 | 40.3 | 15.8 | 0.14 | 8.3 |

| 28 | Y221103 | 2022/11/2 | 93.6 | 2.127 | 7.65 | 19.24 | 0.810 | 1.86 | 0.288 | 1.86 | 435 | 1.02 | 1.75 | 8.92 | 0.315 | 33.9 | 1.62 | 6.51 | 27.7 | 4.25 | 37.2 | 109 | 5.01 | 0.182 | 6.73 |

| 29 | Y221104 | 2022/11/4 | 93.9 | 2.26 | 8.356 | 21.13 | 0.89 | 1.01 | 0.281 | 2.16 | 471 | 1.04 | 1.75 | 9.13 | 0.321 | 32.3 | 1.56 | 6.47 | 28.2 | 4.35 | 38.4 | 109 | 5.3 | 0.173 | 6.6 |

| 30 | Y221107 | 2022/11/9 | 92.3 | 2.05 | 7.604 | 18.95 | 0.94 | 1.21 | 0.257 | 1.94 | 490 | 1.04 | 1.74 | 9.13 | 1.335 | 35.1 | 1.68 | 6.9 | 28.3 | 4.1 | 38.1 | 97.1 | 6.53 | 0.161 | 7.18 |

| 31 | Y221109 | 2022/11/9 | 94.6 | 2.082 | 7.814 | 19.86 | 0.9 | 1.05 | 0.258 | 2.13 | 547 | 1.05 | 1.73 | 9.44 | 0.34 | 33.9 | 1.77 | 7.16 | 28.3 | 3.95 | 37.3 | 184 | 3.31 | 0.134 | 7.59 |

| 32 | Y221114 | 2022/11/15 | 93.8 | 2.021 | 7.874 | 20.9 | 0.99 | 2.13 | 0.245 | 2.19 | 493 | 1.02 | 1.72 | 9.2 | 0.328 | 33.2 | 1.84 | 7.54 | 28.4 | 3.77 | 38.1 | 99.6 | 5.57 | 0.159 | 5.73 |

表S2 余弦相似度计算数据结果

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 0.957 | 0.9 | 0.96 | 0.922 | 0.957 | 0.93 | 0.927 | 0.677 | 0.749 | 0.695 | 0.651 | 0.827 | 0.81 | 0.853 | 0.892 | 0.904 | 0.786 | 0.736 | 0.86 | 0.741 | 0.747 | 0.654 | 0.683 | 0.65 | 0.728 | 0.758 | 0.716 | 0.798 | 0.796 | 0.768 | 0.832 | 0.814 |

| 1 | 0.957 | 1 | 0.843 | 0.937 | 0.938 | 0.9 | 0.89 | 0.883 | 0.718 | 0.822 | 0.75 | 0.686 | 0.82 | 0.765 | 0.835 | 0.847 | 0.854 | 0.758 | 0.697 | 0.836 | 0.774 | 0.786 | 0.676 | 0.699 | 0.66 | 0.742 | 0.769 | 0.746 | 0.788 | 0.827 | 0.788 | 0.865 | 0.824 |

| 2 | 0.9 | 0.843 | 1 | 0.864 | 0.834 | 0.915 | 0.9 | 0.81 | 0.569 | 0.665 | 0.664 | 0.648 | 0.75 | 0.812 | 0.795 | 0.847 | 0.865 | 0.735 | 0.62 | 0.781 | 0.739 | 0.739 | 0.648 | 0.582 | 0.619 | 0.711 | 0.716 | 0.624 | 0.722 | 0.792 | 0.742 | 0.758 | 0.748 |

| 3 | 0.96 | 0.937 | 0.864 | 1 | 0.955 | 0.943 | 0.916 | 0.9 | 0.6 | 0.732 | 0.637 | 0.585 | 0.778 | 0.742 | 0.8 | 0.816 | 0.809 | 0.708 | 0.639 | 0.765 | 0.643 | 0.644 | 0.586 | 0.576 | 0.563 | 0.648 | 0.648 | 0.621 | 0.676 | 0.713 | 0.695 | 0.737 | 0.725 |

| 4 | 0.922 | 0.938 | 0.834 | 0.955 | 1 | 0.906 | 0.897 | 0.848 | 0.641 | 0.791 | 0.716 | 0.636 | 0.752 | 0.676 | 0.778 | 0.758 | 0.78 | 0.684 | 0.596 | 0.724 | 0.709 | 0.662 | 0.606 | 0.595 | 0.599 | 0.637 | 0.678 | 0.61 | 0.715 | 0.758 | 0.722 | 0.771 | 0.744 |

| 5 | 0.957 | 0.9 | 0.915 | 0.943 | 0.906 | 1 | 0.898 | 0.914 | 0.554 | 0.677 | 0.607 | 0.567 | 0.83 | 0.849 | 0.875 | 0.874 | 0.881 | 0.816 | 0.722 | 0.783 | 0.702 | 0.674 | 0.582 | 0.59 | 0.635 | 0.675 | 0.669 | 0.618 | 0.694 | 0.741 | 0.718 | 0.757 | 0.759 |

| 6 | 0.93 | 0.89 | 0.9 | 0.916 | 0.897 | 0.898 | 1 | 0.785 | 0.581 | 0.681 | 0.657 | 0.542 | 0.636 | 0.641 | 0.733 | 0.763 | 0.787 | 0.587 | 0.489 | 0.712 | 0.592 | 0.613 | 0.571 | 0.47 | 0.442 | 0.571 | 0.643 | 0.582 | 0.723 | 0.726 | 0.688 | 0.682 | 0.67 |

| 7 | 0.927 | 0.883 | 0.81 | 0.9 | 0.848 | 0.914 | 0.785 | 1 | 0.695 | 0.785 | 0.703 | 0.684 | 0.902 | 0.858 | 0.898 | 0.896 | 0.876 | 0.826 | 0.826 | 0.874 | 0.768 | 0.773 | 0.653 | 0.758 | 0.763 | 0.818 | 0.758 | 0.732 | 0.73 | 0.747 | 0.767 | 0.844 | 0.817 |

| 8 | 0.677 | 0.718 | 0.569 | 0.6 | 0.641 | 0.554 | 0.581 | 0.695 | 1 | 0.926 | 0.922 | 0.897 | 0.546 | 0.503 | 0.547 | 0.568 | 0.587 | 0.514 | 0.532 | 0.634 | 0.769 | 0.827 | 0.772 | 0.832 | 0.73 | 0.778 | 0.846 | 0.723 | 0.811 | 0.796 | 0.754 | 0.804 | 0.76 |

| 9 | 0.749 | 0.822 | 0.665 | 0.732 | 0.791 | 0.677 | 0.681 | 0.785 | 0.926 | 1 | 0.947 | 0.856 | 0.643 | 0.557 | 0.651 | 0.614 | 0.629 | 0.558 | 0.543 | 0.674 | 0.829 | 0.835 | 0.786 | 0.801 | 0.764 | 0.827 | 0.791 | 0.694 | 0.754 | 0.808 | 0.766 | 0.837 | 0.77 |

| 10 | 0.695 | 0.75 | 0.664 | 0.637 | 0.716 | 0.607 | 0.657 | 0.703 | 0.922 | 0.947 | 1 | 0.914 | 0.538 | 0.476 | 0.556 | 0.553 | 0.576 | 0.46 | 0.447 | 0.622 | 0.827 | 0.831 | 0.835 | 0.802 | 0.783 | 0.806 | 0.848 | 0.749 | 0.806 | 0.853 | 0.792 | 0.822 | 0.762 |

| 11 | 0.651 | 0.686 | 0.648 | 0.585 | 0.636 | 0.567 | 0.542 | 0.684 | 0.897 | 0.856 | 0.914 | 1 | 0.588 | 0.567 | 0.567 | 0.6 | 0.609 | 0.559 | 0.551 | 0.638 | 0.824 | 0.855 | 0.841 | 0.856 | 0.841 | 0.81 | 0.897 | 0.772 | 0.834 | 0.881 | 0.807 | 0.846 | 0.81 |

| 12 | 0.827 | 0.82 | 0.75 | 0.778 | 0.752 | 0.83 | 0.636 | 0.902 | 0.546 | 0.643 | 0.538 | 0.588 | 1 | 0.949 | 0.949 | 0.946 | 0.929 | 0.951 | 0.947 | 0.932 | 0.8 | 0.786 | 0.556 | 0.733 | 0.742 | 0.787 | 0.71 | 0.704 | 0.654 | 0.675 | 0.717 | 0.838 | 0.796 |

| 13 | 0.81 | 0.765 | 0.812 | 0.742 | 0.676 | 0.849 | 0.641 | 0.858 | 0.503 | 0.557 | 0.476 | 0.567 | 0.949 | 1 | 0.929 | 0.959 | 0.935 | 0.964 | 0.921 | 0.878 | 0.752 | 0.757 | 0.519 | 0.657 | 0.687 | 0.729 | 0.676 | 0.648 | 0.62 | 0.665 | 0.685 | 0.779 | 0.751 |

| 14 | 0.853 | 0.835 | 0.795 | 0.8 | 0.778 | 0.875 | 0.733 | 0.898 | 0.547 | 0.651 | 0.556 | 0.567 | 0.949 | 0.929 | 1 | 0.948 | 0.951 | 0.917 | 0.882 | 0.903 | 0.766 | 0.77 | 0.526 | 0.647 | 0.654 | 0.714 | 0.684 | 0.652 | 0.67 | 0.678 | 0.707 | 0.794 | 0.735 |

| 15 | 0.892 | 0.847 | 0.847 | 0.816 | 0.758 | 0.874 | 0.763 | 0.896 | 0.568 | 0.614 | 0.553 | 0.6 | 0.946 | 0.959 | 0.948 | 1 | 0.979 | 0.931 | 0.907 | 0.945 | 0.755 | 0.769 | 0.558 | 0.67 | 0.65 | 0.731 | 0.724 | 0.714 | 0.705 | 0.698 | 0.722 | 0.814 | 0.77 |

| 16 | 0.904 | 0.854 | 0.865 | 0.809 | 0.78 | 0.881 | 0.787 | 0.876 | 0.587 | 0.629 | 0.576 | 0.609 | 0.929 | 0.935 | 0.951 | 0.979 | 1 | 0.929 | 0.89 | 0.948 | 0.791 | 0.794 | 0.578 | 0.687 | 0.659 | 0.731 | 0.748 | 0.699 | 0.757 | 0.732 | 0.74 | 0.835 | 0.787 |

| 17 | 0.786 | 0.758 | 0.735 | 0.708 | 0.684 | 0.816 | 0.587 | 0.826 | 0.514 | 0.558 | 0.46 | 0.559 | 0.951 | 0.964 | 0.917 | 0.931 | 0.929 | 1 | 0.959 | 0.866 | 0.767 | 0.725 | 0.519 | 0.69 | 0.706 | 0.702 | 0.672 | 0.645 | 0.635 | 0.65 | 0.663 | 0.781 | 0.764 |

| 18 | 0.736 | 0.697 | 0.62 | 0.639 | 0.596 | 0.722 | 0.489 | 0.826 | 0.532 | 0.543 | 0.447 | 0.551 | 0.947 | 0.921 | 0.882 | 0.907 | 0.89 | 0.959 | 1 | 0.897 | 0.747 | 0.734 | 0.495 | 0.739 | 0.726 | 0.726 | 0.671 | 0.667 | 0.634 | 0.596 | 0.637 | 0.788 | 0.746 |

| 19 | 0.86 | 0.836 | 0.781 | 0.765 | 0.724 | 0.783 | 0.712 | 0.874 | 0.634 | 0.674 | 0.622 | 0.638 | 0.932 | 0.878 | 0.903 | 0.945 | 0.948 | 0.866 | 0.897 | 1 | 0.822 | 0.852 | 0.638 | 0.781 | 0.714 | 0.825 | 0.788 | 0.781 | 0.767 | 0.718 | 0.753 | 0.864 | 0.808 |

| 20 | 0.741 | 0.774 | 0.739 | 0.643 | 0.709 | 0.702 | 0.592 | 0.768 | 0.769 | 0.829 | 0.827 | 0.824 | 0.8 | 0.752 | 0.766 | 0.755 | 0.791 | 0.767 | 0.747 | 0.822 | 1 | 0.925 | 0.838 | 0.901 | 0.888 | 0.893 | 0.852 | 0.781 | 0.782 | 0.824 | 0.789 | 0.887 | 0.852 |

| 21 | 0.747 | 0.786 | 0.739 | 0.644 | 0.662 | 0.674 | 0.613 | 0.773 | 0.827 | 0.835 | 0.831 | 0.855 | 0.786 | 0.757 | 0.77 | 0.769 | 0.794 | 0.725 | 0.734 | 0.852 | 0.925 | 1 | 0.785 | 0.885 | 0.845 | 0.912 | 0.906 | 0.801 | 0.85 | 0.875 | 0.847 | 0.927 | 0.862 |

| 22 | 0.654 | 0.676 | 0.648 | 0.586 | 0.606 | 0.582 | 0.571 | 0.653 | 0.772 | 0.786 | 0.835 | 0.841 | 0.556 | 0.519 | 0.526 | 0.558 | 0.578 | 0.519 | 0.495 | 0.638 | 0.838 | 0.785 | 1 | 0.869 | 0.824 | 0.857 | 0.871 | 0.869 | 0.782 | 0.82 | 0.763 | 0.739 | 0.84 |

| 23 | 0.683 | 0.699 | 0.582 | 0.576 | 0.595 | 0.59 | 0.47 | 0.758 | 0.832 | 0.801 | 0.802 | 0.856 | 0.733 | 0.657 | 0.647 | 0.67 | 0.687 | 0.69 | 0.739 | 0.781 | 0.901 | 0.885 | 0.869 | 1 | 0.936 | 0.928 | 0.909 | 0.857 | 0.83 | 0.814 | 0.792 | 0.865 | 0.901 |

| 24 | 0.65 | 0.66 | 0.619 | 0.563 | 0.599 | 0.635 | 0.442 | 0.763 | 0.73 | 0.764 | 0.783 | 0.841 | 0.742 | 0.687 | 0.654 | 0.65 | 0.659 | 0.706 | 0.726 | 0.714 | 0.888 | 0.845 | 0.824 | 0.936 | 1 | 0.92 | 0.86 | 0.796 | 0.774 | 0.834 | 0.792 | 0.869 | 0.887 |

| 25 | 0.728 | 0.742 | 0.711 | 0.648 | 0.637 | 0.675 | 0.571 | 0.818 | 0.778 | 0.827 | 0.806 | 0.81 | 0.787 | 0.729 | 0.714 | 0.731 | 0.731 | 0.702 | 0.726 | 0.825 | 0.893 | 0.912 | 0.857 | 0.928 | 0.92 | 1 | 0.88 | 0.832 | 0.782 | 0.828 | 0.82 | 0.879 | 0.9 |

| 26 | 0.758 | 0.769 | 0.716 | 0.648 | 0.678 | 0.669 | 0.643 | 0.758 | 0.846 | 0.791 | 0.848 | 0.897 | 0.71 | 0.676 | 0.684 | 0.724 | 0.748 | 0.672 | 0.671 | 0.788 | 0.852 | 0.906 | 0.871 | 0.909 | 0.86 | 0.88 | 1 | 0.922 | 0.945 | 0.936 | 0.899 | 0.896 | 0.941 |

| 27 | 0.716 | 0.746 | 0.624 | 0.621 | 0.61 | 0.618 | 0.582 | 0.732 | 0.723 | 0.694 | 0.749 | 0.772 | 0.704 | 0.648 | 0.652 | 0.714 | 0.699 | 0.645 | 0.667 | 0.781 | 0.781 | 0.801 | 0.869 | 0.857 | 0.796 | 0.832 | 0.922 | 1 | 0.819 | 0.814 | 0.815 | 0.8 | 0.872 |

| 28 | 0.798 | 0.788 | 0.722 | 0.676 | 0.715 | 0.694 | 0.723 | 0.73 | 0.811 | 0.754 | 0.806 | 0.834 | 0.654 | 0.62 | 0.67 | 0.705 | 0.757 | 0.635 | 0.634 | 0.767 | 0.782 | 0.85 | 0.782 | 0.83 | 0.774 | 0.782 | 0.945 | 0.819 | 1 | 0.941 | 0.867 | 0.893 | 0.913 |

| 29 | 0.796 | 0.827 | 0.792 | 0.713 | 0.758 | 0.741 | 0.726 | 0.747 | 0.796 | 0.808 | 0.853 | 0.881 | 0.675 | 0.665 | 0.678 | 0.698 | 0.732 | 0.65 | 0.596 | 0.718 | 0.824 | 0.875 | 0.82 | 0.814 | 0.834 | 0.828 | 0.936 | 0.814 | 0.941 | 1 | 0.893 | 0.923 | 0.934 |

| 30 | 0.768 | 0.788 | 0.742 | 0.695 | 0.722 | 0.718 | 0.688 | 0.767 | 0.754 | 0.766 | 0.792 | 0.807 | 0.717 | 0.685 | 0.707 | 0.722 | 0.74 | 0.663 | 0.637 | 0.753 | 0.789 | 0.847 | 0.763 | 0.792 | 0.792 | 0.82 | 0.899 | 0.815 | 0.867 | 0.893 | 1 | 0.867 | 0.883 |

| 31 | 0.832 | 0.865 | 0.758 | 0.737 | 0.771 | 0.757 | 0.682 | 0.844 | 0.804 | 0.837 | 0.822 | 0.846 | 0.838 | 0.779 | 0.794 | 0.814 | 0.835 | 0.781 | 0.788 | 0.864 | 0.887 | 0.927 | 0.739 | 0.865 | 0.869 | 0.879 | 0.896 | 0.8 | 0.893 | 0.923 | 0.867 | 1 | 0.922 |

| 32 | 0.814 | 0.824 | 0.748 | 0.725 | 0.744 | 0.759 | 0.67 | 0.817 | 0.76 | 0.77 | 0.762 | 0.81 | 0.796 | 0.751 | 0.735 | 0.77 | 0.787 | 0.764 | 0.746 | 0.808 | 0.852 | 0.862 | 0.84 | 0.901 | 0.887 | 0.9 | 0.941 | 0.872 | 0.913 | 0.934 | 0.883 | 0.922 | 1 |

参考文献

High-temperature structural ceramics

The unique properties of ceramics based on silicon carbide and silicon nitride make them prime candidates for use in advanced energy conversion systems. These compounds are the bases for broad families of engineering materials, whose properties are reviewed. The relationships between processing, microstructure, and properties are discussed. A review and assessment of recent progress in the use of these materials in high-temperature engineering systems, and vehicular engines in particular, is presented.

Silicon nitride and related materials

Effect of Si particle size and NH4Cl additive on combustion synthesis of α-Si3N4

Combustion synthesis of α-Si3N4 powders using in-situ nano-SiO2 coated Si and Si3N4 reactants

Measuring the flow properties of consolidated, conditioned and aerated powders — a comparative study using a powder rheometer and a rotational shear cell

Analysis of the dynamics of the FT 4 powder rheometer

Using a freeman FT 4 rheometer and electrical capacitance tomography to assess powder blending

Analysis of powder rheometry of FT4: effect of air flow

A tough silicon nitride ceramic with high thermal conductivity

A silicon nitride ceramic is prepared by a modified sintering of reaction bonded silicon nitride method (SRBSN). This ceramic has a very high thermal conductivity, high fracture toughness, and a high strength. It is expected to be used as the next-generation insulating substrate material for high-power electronic devices and other new applications.

Formation of tough interlocking microstructures in silicon nitride ceramics by dynamic ripening

Visualizing data using t-SNE