Due to the intensive growing application of electronic devices, the harm of EMWs emitted from electronic devices to human health cannot be ignored[1,2,3,4]. Also, electromagnetic interference (EMI) can make electronic devices difficult for normal operation. To reduce the damage of EMI to the human body and electronic devices, materials are designed to shield or weaken EMI[5]. The shielding material can cut down the EMWs emitted by electronic equipments and prevent the EMWs from scattering, which can ensure a relatively independent working environment and prevent the information from leaking by the EMWs. Currently, metal is an optional EMWs absorption material, and the movable electrons can induce current in electromagnetic fields to consume EMWs[6,7]. EMWs are converted and consumed, which results in a considerable EMI SE. However, the properties of high density, easy to be oxidized and corroded significantly limit the application of metal in electromagnetic shielding material.

In recent years, one-dimensional nanomaterials with unique properties have attracted the attention of researchers. Especially, SiCNWs possess many unpaired chemical bonds on the surface than SiCf, which can be polarized in electromagnetic fields to consume the EMWs[8,9,10,11,12]. So SiCNWs with the unique one-dimensional structure own excellent electromagnetic absorption performance, and the construction of a 3D spatial network is expected to further enhance the EMI SE[13,14,15,16]. The introduction of SiCNWs into composites can effectively improve the EMI shielding performance of the composites[10,17-19].

Moreover, the twins SiCNWs possess higher energy and better electromagnetic absorption performance[20,21,22,23]. Compared with the traditional ferromagnetic materials, the one-dimensional structure makes SiCNWs easier to construct a 3D network structure, which can further expand the path of dissipation current and increase electromagnetic absorption loss[24]. For the application of SiCNWs on EMI shielding performance, the main method is the in-situ growth of SiCNWs inside the composite. The purity and mass of SiCNWs cannot be controlled, which makes it difficult to establish a relationship between introducing parameters of the SiCNWs and the improving performance of the composites. Another way for adding SiCNWs into the composite is to introduce the purified SiCNWs, which can avoid the problems of purity and uncertain parameters. However, the agglomeration makes SiCNWs difficult to construct a uniform network, which could result in performance deviation and weakening of enhancement effect.

The shielding efficiency of electromagnetic shielding materials can be expressed by the following formula[25]:

Among them, SET represents the total shielding loss, SER and SEA represent the reflection loss and absorption loss, respectively. SER relates to the structure of the material, and the increase of the specific surface area increases the reflection loss[26,27,28]. SEA depends on the intrinsic properties of the components and different materials possess different absorption loss[29,30,31]. To enhance the EMI shielding performance, improving the reflection and absorption loss are the main ways.

In this work, 3D network preforms with 20% volume fraction of SiCNWs were prepared by vacuum filtration method, and the densified SiCNWs/SiC ceramic matrix composites with PyC interphase were obtained by CVI and PIP process. The PyC has a positive effect on the EMI shielding performance, the SET of the SiCNWs network preforms with PyC mass gain of 21.3% and 29.5% are 45.0 and 64.1 dB at 8 GHz, respectively. The SiCNWs/ SiC ceramic matrix composite with PyC interphase shows a SET of 37.8 dB in X-band. The introduction of the PyC interphase makes EMWs strongly reflect and absorb at the interface of PyC, SiC and air, and the EMWs are repeatedly reflected and absorbed in the 3D network.

1 Experimental

1.1 Construction of a 3D SiCNWs network preform

The uniform SiCNWs suspension was firstly obtained by the ultrasonication of the mixture of commercial SiCNWs (Changsha Sinet Advanced Materials Co., Ltd., China) with the dispersant PVP. The mass ratio of SiCNWs and PVP is controlled at 6:1 and the ultrasonic power is set at 300 W. As for the vacuum filtration method, uniform suspension of SiCNWs with PVP dispersed was poured into vacuum filtration bottle and SiCNWs network preform with a volume fraction of 20% was prepared by vacuum filtration. The size of the preform is about 40 mm in diameter and 0.67 mm in thickness.

1.2 Preparation of PyC interphase and SiC matrix

The PyC interphase and SiC matrix were prepared by the CVI process. CH4 was set at a flow rate of 50 sccm at 1100 ℃ and the PyC interphase was in-situ grown on the preforms through the pyrolysis of CH4. During the preparation of the SiC matrix, hydrogen was selected as both carrier gas and diluent gas. The pyrolysis temperature of MTS is controlled at 1030 ℃ and the flow rate of carrier hydrogen and dilute hydrogen is controlled at 200 and 60 sccm, respectively. The whole reaction is set at 3 kPa for several hours. The PIP process was used for further densification of the porous SiCNWs/SiC ceramic matrix composite for that single CVI process leading to a huge densification difference between surface and internal. The introduction of the PIP process requires the sample high mechanical strength and open pores on the surface, so the further densification of the PIP process was performed after 40 h SiC matrix deposition, and a densified SiCNWs/SiC ceramic matrix composite was obtained after several PIP cycles.

1.3 Characterization

The microstructures of samples were characterized by scanning electron microscope (SEM; Hitachi SU8220, Japan). The pore parameters were tested by the mercury porosimeter (Micromeritics Instrument Co, Ltd, America). The EMI shielding performance was tested by the vector network instrument (Vector network analyer; ROHDE& SCHWARZ ZVB20; Germany).

2 Results and discussion

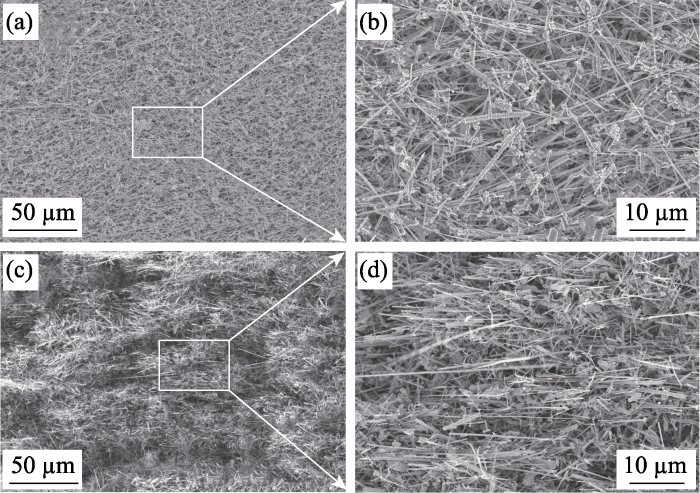

Fig. 1 is the surface and fracture morphologies of the SiCNWs network preforms prepared by the vacuum filtration method. Fig. 1(a-b) are the surface morphologies of the preforms which show a uniform pore size and SiCNWs restrict each other to keep a stable structure. Fig. 1(c-d) are the fracture morphologies of the preforms and SiCNWs almost perpendicular to the fracture which shows a relatively stable structure of the internal. The morphologies of the surface and fracture surface indicate that a 3D network structure with uniform pore size is prepared by vacuum filtration.

Fig. 1

Fig. 1

SEM images of the SiCNWs network preforms prepared by vacuum filtration

(a-b) Surface; (c-d) Section

To solve the problem that the EMI SE of the sample decreases with the increase of frequency, PyC was introduced to cover SiCNWs. The layered structure of PyC owns many free electrons, and the conductivity increases with increasing free electrons. The influence of PyC on EMI shielding performance can be calculated by the following formula[32,33,34,35]:

where f is the frequency of electromagnetic waves, μ is the permeability, d is the thickness of the SiCNWs network preform, and σ is the conductivity. SEA and SER increase with the increase of the conductivity. SEA increases, and SER decrease with the increase of frequency, while the frequency has a greater impact on SEA than SER in X-band. So the deposition of PyC is expected to alleviate the decreasing tendency of EMI SE with the frequency increasing and improve the EMI SE of the preform.

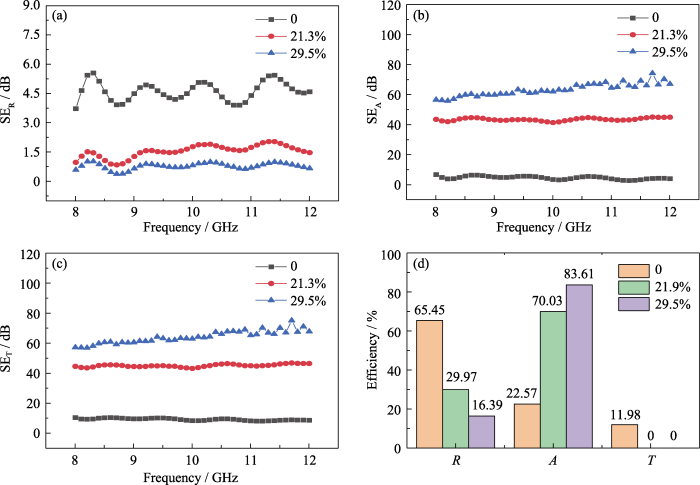

The SiCNWs network preforms with a different amount of PyC were tested to carry out the influence of PyC on EMI shielding performance. As shown in Fig. 2, the SiCNWs preform without PyC deposition shows a higher SER and lower SEA, which indicates that the reflection performance reduces and absorption performance increases after depositing PyC. For the SiCNWs preforms with PyC deposition, SEA shows a monotonously increasing tendency with increasing mass of PyC. Compared to the preform without PyC deposition, SEA of the preforms with 21.3% and 29.5% weight gain of deposited PyC significantly increase from 4.6 dB to 43.5 dB and 63.3 dB in X-band, which results in SET increasing from 9.2 dB to 45.0 dB and 64.1 dB in X-band. SEA and SET are effectively enhanced by the incorporation of PyC.

Fig. 2

Fig. 2

Influence of the different amount of PyC on the EMI shielding performance of the SiCNWs network

(a) SER; (b) SEA; (c) SET; (d) Shielding efficiency

The shielding efficiency can be calculated by the following formula, and the value of R and A represents the different shielding mechanism:

Fig. 2(d) is the shielding efficiency of the preform. The preform without PyC deposition takes reflection loss as the main shielding mechanism. After deposition PyC, the shielding mechanism converts to absorption loss and the value of A increases with the increasing amount of PyC.

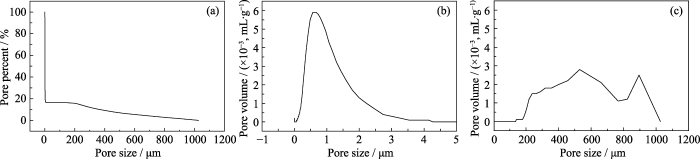

The densification of the preform is achieved by CVI and PIP process, and the densified sample with a small size pore possesses a large surface area, which presents a high strength and increases the reflection of EMWs at the interface, so that EMWs are reflected and absorbed multiple times in the 3D space constructed by SiCNWs. The SiCNWs/SiC ceramic matrix composite shows a high density after CVI and PIP process, and the pore parameters are shown in Fig. 3. The pores of the SiCNWs/SiC ceramic matrix composites mainly distribute in small pores with size less than 3 μm, and the proportion of the small pores reaches almost 82%. Small pores account for a larger proportion of the total pore volume, so the composite has a high pore-specific surface area.

Fig. 3

Fig. 3

Pore percentage (a) of different pore sizes, and pore volume of (b) 0-5 μm and (c) 5-1200 μm

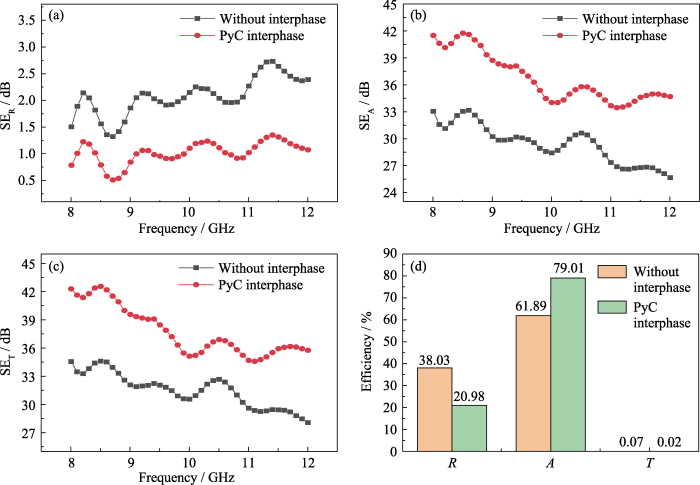

The EMI shielding performance of the densified SiCNWs/SiC ceramic matrix composite is shown in Fig. 4. The EMI shielding performance of the two samples decreases with increasing frequency. The reason is that the insufficient introduction of PyC interphase makes little balance for offsetting the frequency dependence. The large specific surface area of the small pores allows a considerable SER. The SiCNWs/SiC ceramic matrix composite without PyC interphase possesses higher SER than that with PyC interphase in X-band, while the SEA is much lower than the sample with PyC interphase, which results in higher SET of the sample with PyC interphase than the one without interphase. The SET of the SiCNWs/SiC ceramic matrix composite without interphase is 31.5 dB in X-band, and the composite with PyC interphase reaches 37.8 dB. EMWs are reflected at the interface of air, SiC and PyC, which leads to multiple reflection and absorption of EMWs inside the composite. Both of two samples take absorption loss as the main shielding mechanism, and the a value of the sample with PyC interphase equals 79%, which shows that EMWs are heavily absorbed. SET over 30 dB indicates that 99.9% of the incident power is blocked or only 0.1% incident power is transmitted, so the SiCNWs/SiC ceramic matrix composite with PyC interphase shows SET higher than 30 dB in X-band, and the composite is a potential military EMI shielding material.

Fig. 4

Fig. 4

EMI shielding performance of the SiCNWs/SiC ceramic matrix composite after treatment by CVI and PIP process

(a) SER; (b) SEA; (c) SET; (d) Shielding efficiency

3 Conclusion

3D SiCNWs network preforms with volume fraction of 20% were prepared by vacuum filtration method. PyC interphase and SiC matrix were used to modify the SiC network preforms. As the amount of PyC and SiC increases, the EMI shielding performance of the preforms is enhanced. The amount of the deposited PyC increases from 21.3% to 29.5 %, which makes SET of the SiCNWs network preform increases from 43.5 dB to 63.3 dB in X-band. Compared with the sample without PyC, the SET of the SiCNWs/SiC ceramic matrix composite with PyC interphase increased by 20% in X-band. The densified SiCNWs/SiC ceramic matrix composites with PyC interphase possess a higher SET than 30 dB in X-band, which shows an excellent EMI shielding performance.

参考文献

Electrical properties and electromagnetic interference shielding effectiveness of polypropylene/ carbon fiber composite foams

The effects of temperature and frequency on the dielectric properties, electromagnetic interference shielding and microwave-absorption of short carbon fiber/silica composites

X C, MA C Q,

et al.Lightweight and flexible graphene foam composites for high-performance electromagnetic interference shielding

Anisotropic microwave absorbing properties of oriented SiC short fiber sheets

Microwave absorbing materials

MXene/metal oxides-Ag ternary nanostructures for electromagnetic interference shielding

Stretchable liquid metal-based conductive textile for electromagnetic interference shielding

Simple approach to β-SiC nanowires: Synthesis, optical, and electrical properties

Electromagnetic interference shielding effectiveness of carbon foam containing in situ grown silicon carbide nanowires

Enhanced electromagnetic wave absorption properties of a novel SiC nanowires reinforced SiO2/ 3Al2O3·2SiO2 porous ceramic

Recent progress in some composite materials and structures for specific electromagnetic applications

Research and development of continuous SiC fibers and SiCf/SiC composities

Controlling the heterogeneous interfaces of S, Co co-doped porous carbon nanosheets for enhancing the electromagnetic wave absorption

Excellent electromagnetic wave absorption properties of porous core-shell CoO/Co@C nanocomposites derived from a needle-shaped Co(OH)2@ZIF-67 template

Achieved ultrahigh energy storage properties and outstanding charge-discharge performances in (Na0.5Bi0.5)0.7Sr0.3TiO3-based ceramics by introducing a linear additive

Achieving excellent electromagnetic wave absorption of ZnFe2O4@CNT/polyvinylidene fluoride flexible composite membranes by adjusting processing conditions

Electromagnetic interference shielding performance of alternatively-deposited multilayer SiC/PyC porous ceramics

SiC coating toughened by SiC nanowires to protect C/C composites against oxidation

Absorption properties of twinned SiC nanowires reinforced Si3N4 composites fabricated by 3D-prining

Absorption properties of twinned SiC nanowires reinforced Si3N4 composites fabricated by 3D-printing

Enhanced electromagnetic absorption properties of novel 3D-CF/PyC modified by reticulated SiC coating

Reduced graphene oxides: light-weight and high-efficiency electromagnetic interference shielding at elevated temperatures

Oxidation behavior of SiC whiskers at 600-1400 ℃ in air

Conductivity-dependent dielectric properties and microwave absorption of Al-doped SiC whiskers

Carbon materials and their composites for electromagnetic interference shielding effectiveness in X-band

Efficient high-temperature electromagnetic wave absorption enabled by structuring binary porous SiC with multiple interfaces

Hierarchical porous film with layer-by-layer assembly of 2D copper nanosheets for ultimate electromagnetic interference shielding

Porous carbon/graphite nanosheets/ ferromagnetic nanoparticles composite absorbents with adjustable electromagnetic properties

Morphology-control synthesis of polyaniline decorative porous carbon with remarkable electromagnetic wave absorption capabilities

Optimizing the electromagnetic wave absorption performances of designed Fe3O4@SiO2@MnO2 hybrids

Synthesis of polypyrrole decorated FeCo@SiO2 as a high-performance electromagnetic absorption material

Microwave absorbing properties of carbon black/silicone rubber blend

Microstructure and properties of porous Si3N4 ceramics with a dense surface

Synthesis and electromagnetic shielding property of pyrolytic carbon-silicon nitride ceramics with dense silicon nitride coating

Mechanical and microwave dielectric properties of SiCf/SiC composites with BN interphase prepared by dip-coating process