随着脉冲功率技术的快速发展和元件透明化需求的增加, 具有优异储能特性的无铅透明铁电陶瓷作为脉冲功率系统的关键元件, 被广泛应用于航天航空、定向武器和新能源汽车等领域[1,2,3,4]。目前常见的储能材料体系有NaNbO3(NN)体系、K0.5Na0.5NbO3(KNN)体系、BaTiO3(BT)体系与Bi0.5Na0.5TiO3(BNT)体系等。上述材料中, KNN基陶瓷材料具有较高的居里温度、稳定的高压电系数、易固溶、缺陷容忍度高等优点, 是易于实现光学、电学以及机械性能耦合的多功能材料[5,6,7]。纯KNN陶瓷的剩余极化强度Pr较大, 饱和极化强度与剩余极化强度差(Pmax-Pr)小于5 μC/cm2, 且击穿场强Eb<40 kV/cm, 导致其不能作为优良的储能介质材料[8]。此外, KNN陶瓷在室温下为高对称性的正交相结构, 粒径为4~5 μm[9], 难以采用普通的烧结方法制成透明陶瓷[10,11]。

为了改善KNN材料的电学及光学性能, 研究者尝试通过稀土元素掺杂改性基体材料。Lu等[12]通过在Bi0.5Na0.5TiO3-BaTiO3材料中掺杂适量的 La和Zr元素, 最终得到了可利用储能密度Wrec= 1.21 J/cm3。Wang等[13]对BNT基陶瓷改性, 设计了[(Bi0.5Na0.5)0.94Ba0.06]La(1-x)ZrxTiO3储能陶瓷, 其具有高饱和极化强度(Pmax=37.5 μC/cm2), 并表现出双电滞回线形状, 可利用储能密度Wrec提高至1.58 J/cm3。为实现多晶陶瓷材料的透明性, Ren等[14]通过在K0.5Na0.5NbO3中引入SrZrO3作为第二组元, 将晶粒尺寸降至0.19 μm, 从而使(1-x)K0.5Na0.5NbO3-xSrZrO3陶瓷获得较高的光学透明性(T~68%)。Zhang等[15]通过在KNN基陶瓷中固溶第二组元(K0.7Bi0.3)NbO3, 使其在晶界处聚集来抑制晶粒生长, 利用固相反应法制备的0.85KNN-0.15KBN透明陶瓷在近红外光波长范围内透光率达到83.3%。Heartling等[16]通过热压烧结技术, 在锆钛酸铅(PZT)陶瓷基体中掺入La元素, 制备出锆钛酸铅镧(PLZT)透明陶瓷, 大大提高了铅基陶瓷的透明度。Song等[17]在PMN-PT驰豫铁电陶瓷中加入La元素后制备了高透明度的陶瓷, 当掺杂量为4%, 厚度为0.5 mm时, 陶瓷透光率在可见光范围内接近70%。

本研究通过稀土元素异价离子取代方法, 在0.825(K0.5Na0.5)NbO3-0.175Sr(Sc0.5Nb0.5)O3陶瓷中掺入La2O3。采用传统固相反应法制备0.825(K0.5Na0.5)NbO3-0.175Sr1-3x/2Lax(Sc0.5Nb0.5)O3(x= 0, 0.1, 0.2, 0.3)陶瓷, 简称0.825KNN-0.175SLSN陶瓷, 研究掺杂La2O3含量对0.825KNN-0.175SLSN陶瓷相结构、微观形貌、光学、介电、铁电及储能性能的影响规律。

1 实验方法

1.1 样品制备

以分析纯K2CO3(99.5%)、Na2CO3(99.8%)、Nb2O5(99.5%)、Sr2CO3(99%)、Sc2O3(99.9%)和La2O3(99%)为原料, 采用传统固态反应法制备0.825KNN-0.175SLSN陶瓷(x=0, 0.1, 0.2, 0.3)。根据化学计量比进行称料, 将混合粉料进行一次球磨, 以ϕ2~5 mm的锆球为介质, 在酒精中球磨18 h。将料浆置于培养皿中, 在80 ℃烘干后进行筛料。将得到的粉料置于密闭的氧化铝坩埚中在950 ℃保温5 h进行预烧, 再进行10 h二次球磨。干燥后, 将粉料与质量百分比5%的聚乙烯醇水溶液均匀混合。为了使粘结剂充分扩散, 将混合后的粉料压制成坯体后放置12 h。混合粉料在250 MPa下压制成ϕ12 mm×1 mm的圆柱生坯。压制的生坯样品在600 ℃下保温5 h排胶后, 再在1200~1300 ℃烧结5 h。为了获得高的击穿场强, 本研究对烧结后的样品进行打磨抛光处理, 使其表面平行光滑, 厚度约为0.15 mm。采用丝网印刷方法在样品表面涂覆银浆, 800 ℃烧制20 min后得到银电极。

1.2 性能测试

采用Archimedes排水法测试样品密度; 采用X射线衍射仪(XRD, D8 Advance, Bruker, Germany)和扫描电子显微镜(SEM, Quanta 250F, FEI, USA)测试烧结后样品的相结构及微观形貌; 采用LCR电桥(E4980A, Aglient, USA)在-150~150 ℃温度范围以及1~1000 kHz的频率下测试样品的介电常数; 采用分光光度计(UV-2550, Tokyo, Japan)测试样品的透过率, 测试波长范围为400~1200 nm。采用铁电测试仪(Premier II, Radiant, USA)测试样品室温下电滞回线, 测试频率为5 Hz。

2 结果与讨论

2.1 0.825KNN-0.175SLSN陶瓷的结构分析

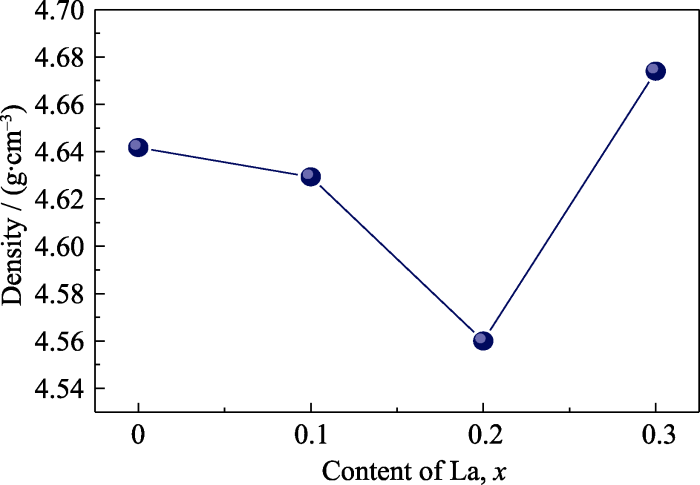

图1

图1

0.825KNN-0.175SLSN陶瓷密度与La含量的关系图

Fig. 1

Variation of density for the 0.825KNN-0.175SLSN ceramics with different content of La

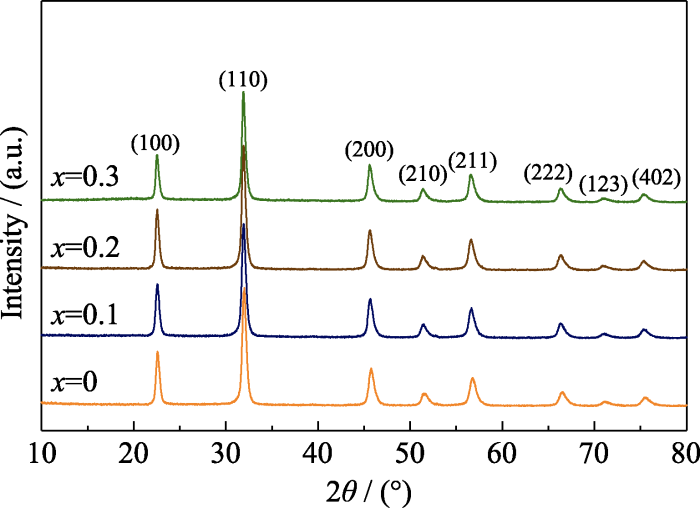

图2

图2

0.825KNN-0.175SLSN陶瓷在室温下2θ的XRD谱图

Fig. 2

XRD patterns of the 0.825KNN-0.175SLSN ceramics at room temperature

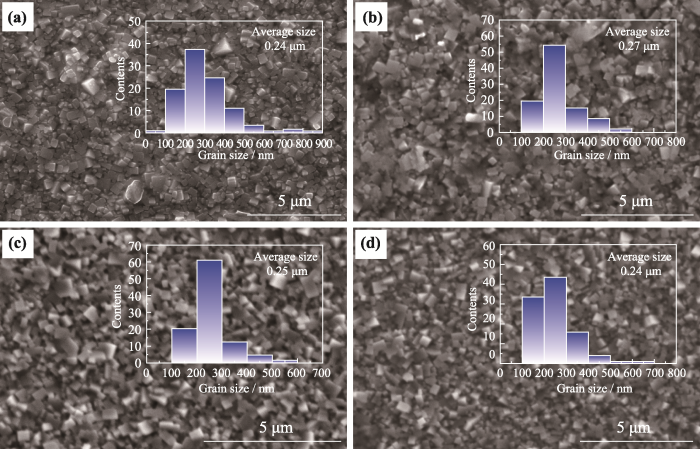

图3为0.825KNN-0.175SLSN陶瓷样品的表面扫描电镜照片。从图中可以观察到各个组分0.825KNN-0.175SLSN陶瓷的晶粒结晶性好, 晶粒堆叠生长, 晶界清晰。当x=0.2时, 晶粒间具有较明显的气孔, 会对样品的致密度产生一定影响, 从而导致击穿场强降低以及入射光发生散射, 最终影响样品的储能及透光性能。图3的插图为0.825KNN- 0.175SLSN陶瓷的粒径分布图, 可以发现掺杂La2O3在一定程度上抑制了0.825KNN-0.175SLSN陶瓷的晶粒生长。当x=0.3时, 平均晶粒尺寸为0.24 μm。一般来说, 透明储能陶瓷的晶粒分布均匀, 可降低入射光的损失并提高样品的击穿场强, 从而提高光学透过率及储能密度。

图3

图3

0.825KNN-0.175SLSN陶瓷室温下自然表面的扫描电镜照片

Fig. 3

SEM micrographs of the original surfaces of 0.825KNN-0.175SLSN (a) x=0; (b) x=0.1; (c) x=0.2; (d) x=0.3

2.2 0.825KNN-0.175SLSN陶瓷的光学性能分析

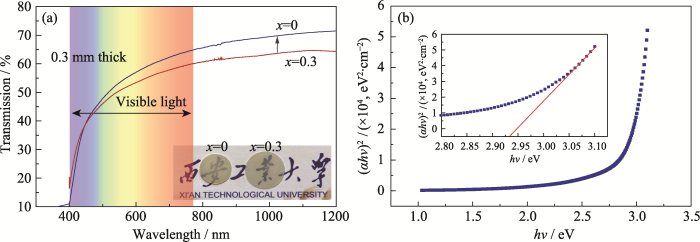

在0.825KNN-0.175SLSN体系样品中, x=0.3的陶瓷的透明度最高。图4(a)为400~1200 nm波长范围内0.825KNN-0.175SLSN陶瓷(x=0, 0.3)的直线透过率光谱图。图4(a)的插图为0.825KNN-0.175SLSN陶瓷(x=0, 0.3)样品的照片。0.825KNN-0.175SLSN陶瓷经打磨至0.3 mm并抛光后, x=0.3陶瓷的光学透过率在可见光波长780 nm处为65.2%(较x=0时的60.2%提升了8.3%), 在近红外波长1200 nm处的透过率达71.5%。与KNN基储能陶瓷的研究报道[23,24,25]比较, 0.825KNN-0.175SLSN (x=0.3)陶瓷具有更优异的透明性, 有望取代铅基透明储能材料。

当入射光进入陶瓷材料内部时, 会激发具有一定能量的电子从价带跃迁到导带, 造成光能量损失。增大材料的禁带宽度会抑制电子发生跃迁, 从而有利于提高材料的透明度。禁带宽度Eg可通过Tauc方程得出, 如下式[26]:

其中, 吸收率α和光子频率v可以根据以下公式获得:

其中, h为普朗克常量(4.1357×10-15 eV), A为常数, t为样品厚度, c为光速(3×108 m/s), T为透过率, λ为波长。

图4

图4

0.825KNN-0.175SLSN陶瓷的透过率图

(a)和0.825KNN-0.175SLSN陶瓷的(αhν)2随hν的变化关系图(b)

Fig. 4

Transmission spectra

(a) of 0.825KNN-0.175SLSN ceramic, with inset showing photographs of the 0.3 mm specimens, and plots (b) of (αhν)2 and hν of the 0.825KNN-0.175SLSN ceramic with x=0.3

2.3 0.825KNN-0.175SLSN陶瓷的介电性能分析

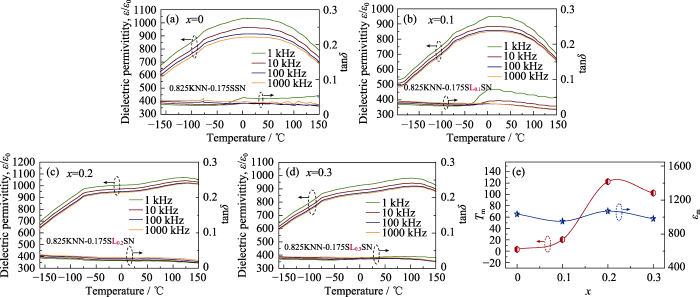

图5(a~d)为0.825KNN-0.175SLSN陶瓷的介电性能-温度关系图。随着x值增大, 介电常数峰逐渐从一个转变为两个。当x=0.2和0.3时, 出现的两个介电常数峰在-75 ℃和100 ℃附近, 分别对应正交相向四方相的相变以及四方相向立方相的相变, 这也印证了XRD的测试结果, 室温下0.825KNN- 0.175SLSN陶瓷均为伪立方的相结构[27]。0.825KNN- 0.175SLSN陶瓷在室温下的介电损耗低于0.03, 有利于获得优异的储能性能。图5(e)为0.825KNN- 0.175SLSN陶瓷在1 kHz下测试的最大介电常数对应的温度(Tm)与介电常数值(εm)的关系曲线, 随着x增大, Tm呈现升高的趋势, εm在950~1100之间。

图5

图5

0.825KNN-0.175SLSN陶瓷样品的介电性能-温度关系图

(a~d)和0.825KNN-0.175SLSN陶瓷的Tm, εm与La掺杂含量关系图(e)

Fig. 5

Temperature dependence of the dielectric properties

(a-d), Tm and εm (e) of 0.825KNN-0.175SLSN ceramics

2.4 0.825KNN-0.175SLSN陶瓷的铁电性能分析

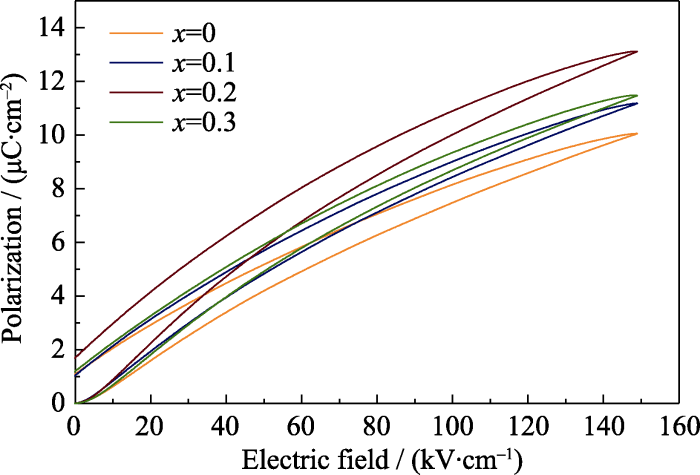

图6

图6

0.825KNN-0.175SLSN陶瓷在150 kV/cm电场下的单极P-E曲线

Fig. 6

P-E loops of 0.825KNN-0.175SLSN ceramics at selected applied electric fields Colorful figures are available on website

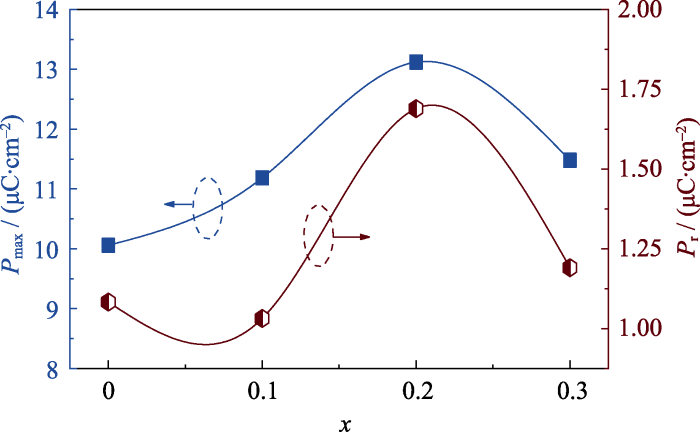

图7为0.825KNN-0.175SLSN陶瓷的Pmax和Pr与掺杂含量的关系曲线。由图可知, 陶瓷样品的Pr均小于2 μC/cm2, Pr越小, 越有利于提高储能效率。随着La含量增大, Pmax呈增大趋势。当x从0增至0.2时, 0.825KNN-0.175SLSN陶瓷Pmax值逐渐从10.06 μC/cm2增大至13.12 μC/cm2, 可见掺杂适量的La元素可以使0.825KNN-0.175SLSN陶瓷Pmax提高, 有利于提高材料的储能密度。

图7

图7

不同La掺杂含量陶瓷的Pmax和Pr

Fig. 7

Pmax and Pr of 0.825KNN-0.175SLSN ceramics as a function of x

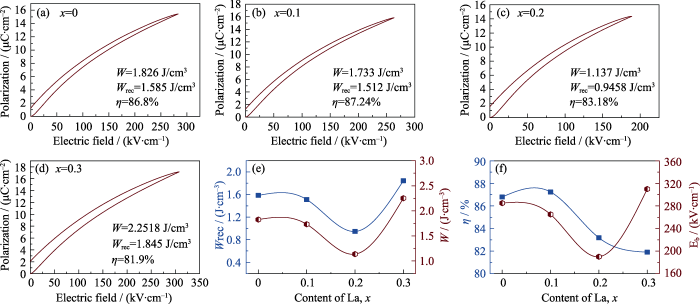

其中, Wrec、W、Pmax、Pr、E、η分别表示陶瓷样品可利用储能密度、储能密度、饱和极化强度、剩余极化强度、外加电场和储能效率。通过对图8(a~d)所得的单极电滞回线进行积分计算, 得到图8(e)所示的W、Wrec随x值的变化曲线, 图8(f)为Eb、η随x值的变化曲线。随着La含量增大, 不同组分陶瓷的Wrec和W值呈现逐渐减小之后再增大的趋势。由于气孔和击穿场强的限制, 在x=0.2时储能密度最低, W=1.14 J/cm3及Wrec=0.95 J/cm3。0.825KNN- 0.175SLSN(x=0.3)陶瓷具有最优的储能密度W= 2.25 J/cm3及Wrec=1.85 J/cm3。

图8

图8

0.825KNN-0.175SLSN陶瓷在击穿场强下的单极P-E曲线

(a~d), 0.825KNN-0.175SLSN陶瓷的W、Wrec 与x的关系曲线(e), 0.825KNN-0.175SLSN陶瓷的η和Eb与x的关系曲线(f)

Fig. 8

Unipolar P-E hysteresis loops

(a-d) of 0.825KNN-0.175SLSN ceramics under different electric fields, variation (e) of W and Wrec, for the 0.825KNN-0.175SLSN ceramics with different x, and variation (f) of η and Eb for the 0.825KNN-0.175SLSN ceramics with different x

3 结论

本研究采用稀土元素La掺杂改性0.825(K0.5Na0.5)NbO3-0.175Sr(Sc0.5Nb0.5)O3陶瓷。掺杂后0.825(K0.5Na0.5)NbO3-0.175Sr1-3x/2Lax(Sc0.5Nb0.5)O3 (x=0, 0.1, 0.2, 0.3)陶瓷均具有单一的纯钙钛矿结构, 掺杂La元素并未改变基体材料的相结构, 均为高对称性的伪立方相, 并在一定程度上抑制晶粒生长, 减小晶粒尺寸。随着La掺杂量增大, 0.825KNN-0.175SLSN陶瓷饱和极化强度Pmax呈现增大的趋势。在x=0.3时, 0.825KNN-0.175SLSN陶瓷具有优异的透明性, 在可见光波长780 nm及近红外波长1200 nm处透过率分别达65.2%及71.5%, 同时实现了最佳的储能特性: W=2.25 J/cm3、Wrec= 1.85 J/cm3、η=81.9%。0.825KNN-0.175SLSN陶瓷是有望取代铅基材料作为透明储能介质材料。

参考文献

Homogeneous/inhomogeneous- structured dielectrics and their energy-storage performances

Perovskite lead-free dielectrics for energy storage applications

Ultrahigh energy-storage density in antiferroelectric ceramics with field-induced multiphase transitions

High-performance relaxor ferroelectric materials for energy storage applications

Direct and indirect characterization of electrocaloric effect in (Na, K)NbO3 based lead-free ceramics

Enhanced electrocaloric effect near polymorphic phase boundary in lead-free potassium sodium niobate ceramics

Grain size engineered lead-free ceramics with both large energy storage density and ultrahigh mechanical properties

Lead-free nonlinear dielectric ceramics for energy storage applications: current status and challenges

Significantly enhanced recoverable energy storage density in potassium-sodium niobatebased lead free ceramics

Fabrication of transparent electrooptic PLZT ceramics by atomosphere sintering

The effect of domain structures on the transparency of PMN-PT transparent ceramics

Energy storage properties of (Bi0.5Na0.5)0.93Ba0.07TiO3 lead-free ceramics modified by La and Zr co-doping

High energy-storage properties of [(Bi1/2Na1/2)0.94Ba0.06]La (1-x)ZrxTiO3 lead-free anti-ferroelectric ceramics

Regulation of energy density and efficiency in transparent ceramics by grain refinement

Excellent energy density and power density achieved in K0.5Na0.5NbO3-based ceramics with high optical transparency

Improved hot-pressed electrooptic ceramics in the (Pb,La)(Zr,Ti)O3 system

Fabrication and ferroelectric/ dielectric properties of La-doped PMN-PT ceramics with high optical transmittance

Transmission physics and consequenees for materials seleetion, manufacturing, and applications

Light scattering by pores in poly- crystalline materials

Transparent sintered corundum with high hardness and strength

Investigations of domain switching and lattice strains in (Na,K)NbO3-based lead-free ceramics across orthorhombic-tetragonal phase boundary

Dielectric, ferroelectric, and piezoelectric properties in potassium sodium niobate ceramics with rhombohedral-orthorhombic and orthorhombic-tetragonal phase boundaries

Optical, luminescent and optical temperature sensing properties of (K0.5Na0.5)NbO3-ErBiO3 transparent ceramics

Effect of Sr and Ba-doping in optical and electrical properties of KNN based transparent ceramics

Enhancement of optical transparency in Bi2O3-modified (K0.5Na0.5)0.9Sr0.1Nb0.9Ti0.1O3 ceramics for electro-optic applications

Lead-free (K,Na)NbO3- based ceramics with high optical transparency and large energy storage ability

Lead-free relaxor ferroelectric ceramics with high optical transparency and energy storage ability

Improved energy storage density and efficiency of (1-x)Ba0.85Ca0.15Zr0.1Ti0.9O3-xBiMg2/3Nb1/3O3 lead-free ceramics

An effective strategy to achieve excellent energy storage properties in lead-free BaTiO3 based bulk ceramics

Enhanced energy storage properties and stability in Sr(Sc0.5Nb0.5)O3 modified 0.65BaTiO3- 0.35Bi0.5Na0.5TiO3 ceramics