自由基引发活性聚碳硅烷交联及其在制备SiC纤维中的应用

收稿日期: 2020-12-03

修回日期: 2021-01-25

网络出版日期: 2021-03-01

基金资助

宁波市科技创新2025重大专项(2019B10091);宁波“3315计划”创新团队项目(2018A-03-A)

Crosslinking of Active Polycarbosilane Initiated by Free Radical and Its Application in the Preparation of SiC Fibers

Received date: 2020-12-03

Revised date: 2021-01-25

Online published: 2021-03-01

Supported by

Ningbo 2025 Science and Technology Innovation Major Project(2019B10091);Ningbo “3315 Plan” Innovation Team Project(2018A-03-A)

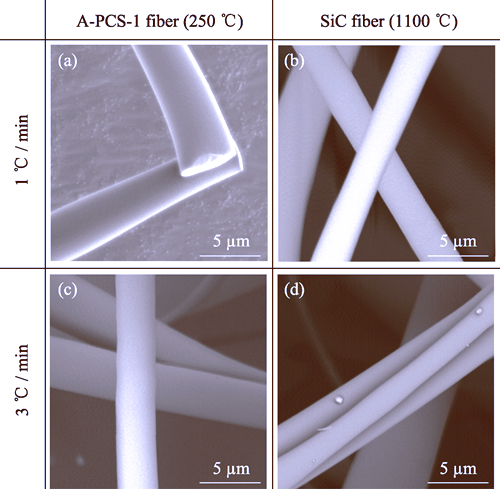

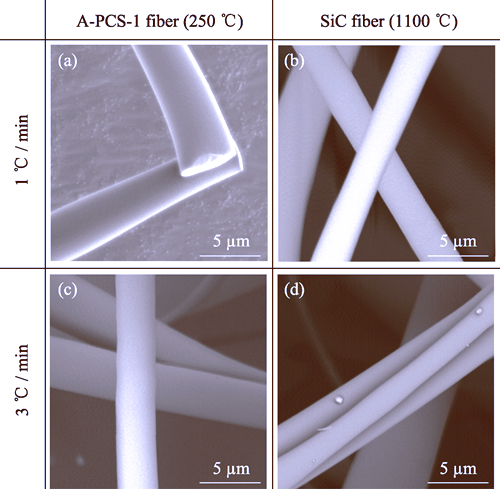

在基于先驱体聚碳硅烷转化制备SiC陶瓷纤维过程中, 交联过程是保持纤维形貌和提高陶瓷产率的必要条件。本研究以含丙烯酸酯基的聚碳硅烷(A-PCS)为原料, 通过引入自由基热引发剂在热解升温过程中实现原料的交联成型。采用红外光谱仪(FT-IR)和差示扫描量热仪(DSC)研究了引发剂含量对A-PCS交联程度、交联速率以及热降解速率的影响规律; 采用热失重(TG)、元素分析仪和X射线衍射仪(XRD)分析了陶瓷产率、陶瓷产物组成以及无定形态随温度的变化。研究结果表明: 加入自由基热引发剂可提高A-PCS中的丙烯酸酯基的交联速率, 减少交联阶段的热失重; 将质量百分比为1%自由基热引发剂的A-PCS以5 ℃/min升至250 ℃时, 丙烯酸酯基反应完全, 1500 ℃的陶瓷产率为69.5%; 通过静电纺丝加工工艺可获得直径介于2~5 μm的A-PCS原丝, 并通过后续升温热解转化为SiC纤维; 所得SiC纤维形貌规整、无熔并现象, 且随着热解温度的升高从无定形态向结晶形态转变。

王袁杰 , 裴学良 , 李好义 , 徐鑫 , 何流 , 黄政仁 , 黄庆 . 自由基引发活性聚碳硅烷交联及其在制备SiC纤维中的应用[J]. 无机材料学报, 2021 , 36(9) : 967 -973 . DOI: 10.15541/jim20200695

In the preparation of SiC ceramic fibers based on precursor polycarbosilane, the crosslinking treatment is a neccessary process to maintain the fiber morphology and improve the ceramic yield. In this study, polycarbosilane containing acrylate group (A-PCS) was used as raw material, and the thermal free radical initiator was introduced to realize the crosslinking formation during the pyrolysis process. FT-IR and DSC were used to analyze the influence of initiator content on crosslinking degree, crosslinking rate and thermal degradation rate of A-PCS; TG, elemental analysis and XRD were used to analyze the evolution of ceramic yield, composition and amorphous change with temperature. The introduction of free radical thermal initiator can improve the crosslinking rate of acrylate group in A-PCS and reduce the thermal weight loss at the crosslinking stage. When free radical thermal initiator (weight percent 1%) was added, the acrylate group was consumed completely after heating to 250 ℃ at 5 ℃/min and the ceramic yield at 1500 ℃ was 69.5%. A-PCS fibers with diameter of 2-5 μm were obtained by electrospinning process, and then transformed into SiC fibers by subsequent pyrolysis. The morphology of the SiC fibers was regular with no fusion phenomenon. In addition, with the increase of pyrolysis temperature, the amorphous SiC fiber can be transformed into crystalline structure.

| [1] | COLOMBO P, RIEDEL R, SORARÙ G D, et al. Polymer Derived Ceramics: From Nano-structure to Applications. USA: DEStech Publications Inc, 2010. |

| [2] | SHEN G, BANDO Y, YE C, et al. Synthesis, characterization and field-emission properties of bamboo-like β-SiC nanowires. Nanotechnology, 2006, 17(14):3468-3472. |

| [3] | 郝斌. 碳化硅纳米材料制备方法研究进展. 化工新型材料, 2015, 43(8):41-43. |

| [4] | LIU Y W, GAO F M, WANG L, et al. Fabrication of CdS-decorated mesoporous SiC hollow nanofibers for efficient visible-light-driven photocatalytic hydrogen production. J. Mater. Sci., 2019, 30(2):1487-1495. |

| [5] | YAMAMOYO K, KONDO S, SUZUKI K. Filtration and regeneration performances of SiC fiber potentially applied to gasoline particulates. Fuel, 2019, 243:28-33. |

| [6] | LIU Y N, LIU Y, CHOI W C, et al. Highly ?exible, erosion resistant and nitrogen doped hollow SiC fibrous mats for high temperature thermal insulators. J. Mater. Chem. A, 2017, 5(6):2664-2672. |

| [7] | CHEN J J, ZHANG J D, WANG M M, et al. High-temperature hydrogen sensor based on platinum nanoparticle-decorated SiC nanowire device. Sensor. & Actuat. B Chem., 2014, 201:402-406. |

| [8] | AN Z M, YE C S, ZHANG R B, et al. Flexible and recoverable SiC nanofiber aerogels for electromagnetic wave absorption. Ceram. Int., 2019, 45(17):22793-22801. |

| [9] | MAINZER B, LIN C, JEMMALI R, et al. Characterization and application of a novel low viscosity polysilazane for the manufacture of C- and SiC-fiber reinforced SiCN ceramic matrix composites by PIP process. J. Eur. Ceram. Soc., 2018, 39(2/3):212-221. |

| [10] | SU L, WANG H J, NIU M, et al. Ultralight, recoverable, and high- temperature-resistant SiC nanowire aerogel. ACS Nano, 2018, 12(4):3103-3111. |

| [11] | CHIU S C, HUANG C W, LI Y Y. Synthesis of high-purity silicon carbide nanowires by a catalyst-free arc-discharge method. J. Phys. Chem. C, 2007, 111(28):10294-10297. |

| [12] | DONG S M, CHOLON G, LABRUGE C, et al. Characterization of nearly stoichiometric SiC ceramic fibres. J. Mater. Sci., 2001, 36(10):2371-2381. |

| [13] | CHENG Y L, ZHANG J F, ZHANG Y F, et al. Preparation of hollow carbon and silicon carbide fibers with different cross-sections by using electrospun fibers as templates. Eur. J. Inorg. Chem., 2010, 2009(28):4248-4254. |

| [14] | 钱周琦, 廖欣, 柳兆祥, 等. 碳化硅纳米纤维薄膜的制备及表征. 高科技纤维与应用, 2015, 40(3):33-36, 65. |

| [15] | XIE Z F, GOU Y Z. Polyaluminocarbosilane as precursor for aluminum-containing SiC fiber from oxygen-free sources. Ceram. Int., 2016, 42(8):10439-10443. |

| [16] | YAJIMA S, HAYASHI J, OMORI M, et al. Development of a silicon carbide fibre with high tensile strength. Nature, 1976, 261(5562):683-685. |

| [17] | 谢征芳, 陈朝辉, 肖加余, 等. 先驱体陶瓷. 高分子材料科学与工程, 2000, 16(6):7-12. |

| [18] | CHEN L F, ZHANG L, CAI Z H, et al. Effects of oxidation curing and sintering additives on the formation of polymer-derived near- stoichiometric silicon carbide fibers. J. Am. Ceram. Soc., 2008, 91(2):428-436. |

| [19] | LI Y F, YAN G L, ZHAO Y X, et al. Emulsion-blow spun self-Sustained crystalline β-silicon carbide (SiC) fiber mat and its conductivity property. T. Indian Ceram. Soc., 2017, 76(3):159-164. |

| [20] | HE G M, ZHANG B J, WANG B W, et al. Amorphous fine-diameter SiC-based fiber from a boron-modified polytitanocarbosilane precursor. J. Eur. Ceram. Soc., 2018, 38(4):1079-1086. |

| [21] | 楚增勇, 宋永才, 冯春祥, 等. 电子束辐射交联制备低氧含量SiC纤维的研究. 复合材料学报, 2002, 19(5):22-27. |

| [22] | KANG P H, JEUN J P, SEO D K, et al. Fabrication of SiC mat by radiation processing. Radiat. Phys. Chem., 2009, 78(7/8):493-495. |

| [23] | SU Z M, TANG M, WANG Z C, et al. Processing of silicon carbide fibers from polycarbosilane with polypropylene as the additive. J. Am. Ceram. Soc., 2010, 93(3):679-685 |

| [24] | 余兆菊, 黄木河, 李然, 等. 偶氮二异丁腈引发液态聚碳硅烷的交联研究. 硅酸盐学报, 2009, 37(8):105-109. |

| [25] | 余兆菊, 黄木河, 李然, 等. 过氧化苯甲酰在液态聚碳硅烷交联中的应用. 功能材料, 2009, 40(12):2058-2060. |

| [26] | YU Z J, ZHAN J Y, HUANG M H, et al. Preparation of a hyperbranched polycarbosilane precursor to SiC ceramics following an efficient room-temperature cross-linking process. J. Mater. Sci., 2010, 45(22):6151-6158. |

| [27] | WANG Y J, PEI X L, LI H Y, et al. Preparation of SiC ceramic fiber from a photosensitive polycarbosilane. Ceram. Int., 2020, 46(18):28300-28307. |

| [28] | 潘祖仁. 高分子化学, 4版. 北京: 化学工业出版社, 2007: 73-79. |

| [29] | 李强, 杜华. 橡塑技术实战指南. 北京: 化学工业出版社, 2014: 249. |

| [30] | 张翠丽. 丙烯酸酯类自引发聚合机理理论研究. 湘潭: 湘潭大学博士学位论文, 2008. |

| [31] | POERSCHKE D L, BRAITHWAITEr A, PARK D, et al. Crystallization behavior of polymer-derived Si-O-C for ceramic matrix composite processing. Acta Materialia, 2018, 147(1):329-341. |

/

| 〈 |

|

〉 |