碳纤维预制体结构对C/C复合材料及其螺栓力学性能的影响

收稿日期: 2019-04-15

修回日期: 2019-05-08

网络出版日期: 2019-06-15

基金资助

国家自然科学基金(U1537204);国家自然科学基金(51802313);国家重点研发计划(2018YFF01013600);装备预研项目(61409220101);青促会优秀会员人才项目(2014171)

Carbon Fiber Preform's Structure on Mechanical Property of C/C Composites and Bolts

Received date: 2019-04-15

Revised date: 2019-05-08

Online published: 2019-06-15

Supported by

National Natural Science Foundation of China(U1537204);National Natural Science Foundation of China(51802313);National Key R&D Program of China(2018YFF01013600);Equipment Research Foundation(61409220101);Research Fund of Youth Innovation Promotion Association of CAS(2014171)

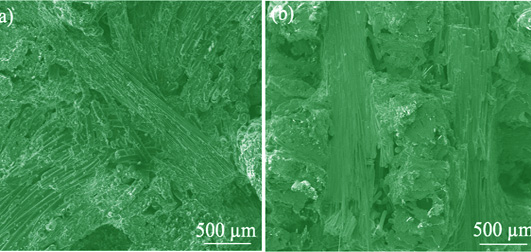

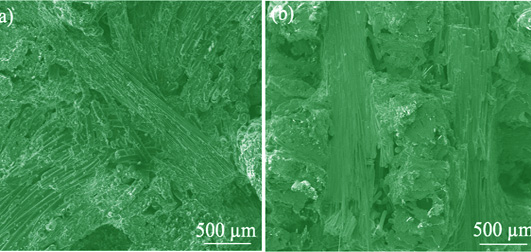

以2D碳纤维预制体为增强体, 采用电耦合和等温化学气相渗联合工艺制备C/C复合材料, 研究不同预制体结构对C/C复合材料及其螺栓力学性能的影响。结果表明, 不同预制体结构增强的C/C复合材料表现出不同的力学行为。对于针刺结构, 随着针刺密度由35 pin/cm 2降至25 pin/cm 2, C/C复合材料的拉伸、弯曲强度分别由60.1、119.9 MPa增大至69.5、176.8 MPa; 随着碳纱丝束由12 K变为3 K, C/C复合材料的拉伸、弯曲强度分别由69.5、176.8 MPa增大至105.5、184.4 MPa。对于12 K双向缝合结构, C/C复合材料的拉伸、弯曲强度分别为68.1、123.7 MPa。不同碳纤维预制体结构增强的C/C复合材料力学性能的差异主要取决于长纤维的完整性、大孔的分布和数量等因素。C/C复合材料的螺栓性能由于体材料性能和加工过程中缺陷的影响, 其拉伸强度略低于其体材料, 并表现出更为明显的脆性断裂模式。

庞生洋 , 王佩瑶 , 胡成龙 , 赵日达 , 汤素芳 . 碳纤维预制体结构对C/C复合材料及其螺栓力学性能的影响[J]. 无机材料学报, 2019 , 34(12) : 1272 -1278 . DOI: 10.15541/jim20190155

The C/C composites reinforced by 2D-preforms were fabricated using an electro-coupling chemical vapor infiltration (E-CVI) technique. The effects of different preform's structure on the mechanical properties of C/C and their bolts were investigated. The results show that the C/C composites reinforced by different preforms parameters exhibit different mechanical behaviors. For needle-punched preforms, as the needle-punched density decreasing from 35 pin/cm 2 to 25 pin/cm 2, the tensile and flexural strengths of C/C composites increased from 60.1, 119.9 MPa to 69.5, 176.8 MPa, respectively. With the carbon yarn tow changing from 12 K to 3 K, the tensile and flexural strengths of C/C composites increased from 69.5, 176.8 MPa to 105.5, 184.4 MPa, respectively. For bidirectional stitched preforms, the tensile and flexural strengths of C/C composites are 68.1 and 123.7 MPa, respectively. The different mechanical behaviors is mainly attributed to structural integrity of long fibers, and the distribution and quantity of large pores. The mechanical properties of bolts are impacted by their bulk materials and surface status, which are slightly lower than those of their counterparts.

Key words: C/C composites; preform structure; mechanical properties; bolts

| [1] | ERICH FITZER . The future of carbon-carbon composites. Carbon, 1987,25(2):163-190. |

| [2] | KOWBEL W, HSU T K . Mechanical behavior of carbon-carbon composites made with cold plasma-treated carbon fibers. Composites, 1995,26(11):791-797. |

| [3] | DELHAES P . Chemical vapor deposition and infiltration processes of carbon materials. Carbon, 2002,40(5):641-657. |

| [4] | MA C C M, TAI N H, CHANG W C , et al. Morphologies, microstructure and mechanical properties of 2D carbon/carbon composites during the CVI densification process. Carbon, 1996,34(10):1175-1179. |

| [5] | SAVAGE G . Carbon-Carbon Composites. Springer Netherlands, 1993: 1-389. |

| [6] | LI HE-JUN . Carbon/carbon composites. New Carbon Materials, 2001,16(02):79-80. |

| [7] | GAJIWALA H M, VAIDYA U K, SODAH S A , et al. Hybridized resin matrix approach applied for development of carbon/carbon composites—I. Carbon, 1998,36(7/8):903-912. |

| [8] | VAIDYA U K, MAHFUZ H, JEELANI S . NDE of Structural and Functional Carbon-carbon Composites after First Carbonization. Proceedings of the 18th Annual Conference on Composites and Advanced Ceramic Materials-A: Ceramic Engineering and Science Proceedings, Florida, 2008: 571-578. |

| [9] | WANG JIE, LI KE-ZHI, GUO LING-JUN , et al. Microstructure and mechanical properties of C/C composite bolts. Journal of Solid Rocket Technology, 2012,35(2):248-252. |

| [10] | LIU JIE, LI HAI-BIN, LIU XIAO-YING . Low cost preparation and mechanical property of three-dimensional needled C/SiC bolts. Acta Aeronautica et Astronautica Sinica, 2013,34(7):1724-1730. |

| [11] | HAN HONG-MEI, LI HE-JUN, ZHANG SHOU-YANG , et al. Tensile properties and damage evolution of 3-dimensional braided carbon/carbon composites. Mechanical Science and Technology for Aerospace Engineering, 2002,21(3):451-453. |

| [12] | WEI LIAN-FENG, CUI HONG, JIA LIN , et al. Effects of perform structure on mechanical properties of three-dimensional braided carbon/carbon composites. Carbon, 2017,1:5-9. |

| [13] | 刘文川, 邓景屹, 杜海峰 , 等. 一种高效节能快速沉积制备碳/碳复合材料的方法. 中国, 发明专利, 99122649.6. 1999. 12. 17. |

| [14] | TANG S F, WANG D L, DENG J Y , et al. Ablation properties of C/C composites with various needled preforms prepared by isothermal chemical vapor infiltration. South Univ. Technol, 2007,14(1):13-18. |

| [15] | CHOLLON G, SIRON , TAKAHASHI J , et al. Microstructure and mechanical properties of coal tar pitch-based 2D-C/C composites with a filler addition. Carbon, 2001,39(13):2065-2075. |

| [16] | TANG SU-FANG, ZHOU XING-MING, DENG JING-YI , et al. The preparation of 2D C/C composites by chemical vapor infiltration. New Carbon Materials, 2005,20(02):139-143. |

| [17] | ALY-HASSAN MS, HATTA H, WAKAYAMA S , et al. Comparison of 2D and 3D carbon/carbon composites with respect to damage and fracture resistance. Carbon, 2003,41(5):1069-1078. |

| [18] | CHEN T F, LIAO J Q, LIU G S , et al. Effects of needle-punched felt structure on the mechanical properties of carbon/carbon composites. Carbon, 2003,41(5):993-999. |

/

| 〈 |

|

〉 |