石墨烯增强铜基复合材料的研究进展

收稿日期: 2018-09-03

修回日期: 2018-11-22

网络出版日期: 2019-05-14

基金资助

国家电网公司科技项目(SGRIDGKJ[2016]795)

Preparation and Mechanical Property of Graphene-reinforced Copper Matrix Composites

Received date: 2018-09-03

Revised date: 2018-11-22

Online published: 2019-05-14

Supported by

Science and Technology Project of State Grid Corporation(SGRIDGKJ[2016]795)

林正得 , 舒圣程 , 李傲 , 吴明亮 , 杨明阳 , 韩钰 , 祝志祥 , 陈保安 , 丁一 , 张强 , 王强 , 戴丹 . 石墨烯增强铜基复合材料的研究进展[J]. 无机材料学报, 2019 , 34(5) : 469 -477 . DOI: 10.15541/jim20180393

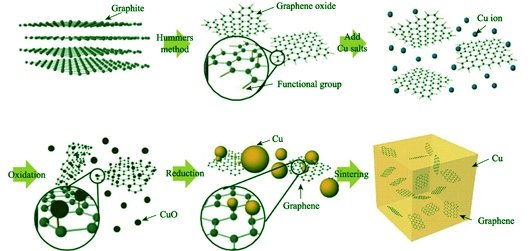

Graphene, which has two-dimensional carbon single atomic layer, attracts great attention due to its superb mechanical, electrical and thermal properties. In addition to its excellent mechanical properties, a large surface area (about 2600 m 2?g -1) makes it an ideal reinforcement for copper-based composites. However, graphene owns a low density (2.2 g?cm -3), while the density of copper is about 8.9 g?cm -3. The traditional powder metallurgy process is difficult to solve the problem of uniform dispersion of graphene in the copper matrix and the poor bonding strength between graphene and copper due to the huge density difference between copper and graphene. With the in-depth exploration in the issue of graphene/copper interface in recent years, some novel preparation processes and strengthening mechanisms were proposed and demonstrated. This review systematically introduces and compares the recently-developed preparation processes of graphene-reinforced copper composites, also summarizes the mechanism of mechanical enhancement in graphene-reinforced copper matrix composites.

| [1] | RAJKOVIC V, BOZIC D, JOVANOVIC M T . Properties of copper matrix reinforced with various size and amount of Al2O3 particles. Journal of Materials Processing Tech., 2008,200(1/2/3):106-114. |

| [2] | IBRAHIM I A, MOHAMED F A, LAVERNIA E J . Paniculate reinforced metal matrix composites—a review. Journal of Materials Science, 1991,26(5):1137-1156. |

| [3] | IZMAILOV V V, USHAKOVA I N, DROZDOVA E I , et al. Electrical and tribological properties of composite material with copper matrix reinforced by superelastic hard carbon. Journal of Friction & Wear, 2016,37(3):253-258. |

| [4] | RAJKOVIC V, BOZIC D, JOVANOVIC M T . Properties of copper matrix reinforced with nano- and micro-sized Al2O3 particles. Materials Characterization, 2008,459(1/2):177-184. |

| [5] | TENG L, CAIJU L I, YUAN Q , et al. Progress of carbon nanotubes reinforced copper matrix composites. Mater. Rev., 2014,28(7):16-19. |

| [6] | BOZIC D, STASIC J, DIMCIC B , et al. Multiple strengthening mechanisms in nanoparticle-reinforced copper matrix composites. Bulletin of Materials Science, 2011,34(2):217-226. |

| [7] | MCDANELS D L, JECH R W, WEETON J W . Stress-strain Behavior of Tungsten-fiber-reinforced Copper Composites. National Aeronautics And Space Administration Cleveland Oh Lewis Research Center, 1963. |

| [8] | MAI Y J, CHEN F X, LIAN W Q , et al. Preparation and tribological behavior of copper matrix composites reinforced with nickel nanoparticles anchored graphene nanosheets. Journal of Alloys and Compounds, 2018,756:1-7. |

| [9] | GUI C X, ZHAO X H, HUA X U , et al. Study and development of carbon fiber reinforced copper matrix coposites. Journal of Hebei University of Technology, 2002,31(6):43-48. |

| [10] | XIA L, JIA B, ZENG J , et al. Wear and mechanical properties of carbon fiber reinforced copper alloy composites. Materials Characterization, 2009,60(5):363-369. |

| [11] | BAKSHI S R, LAHIRI D, AGARWAL A . Carbon nanotube reinforced metal matrix composites - a review. Metallurgical Reviews, 2010,55(1):41-64. |

| [12] | LIM B, KIM C, KIM B , et al. The effects of interfacial bonding on mechanical properties of single-walled carbon nanotube reinforced copper matrix nanocomposites. Nanotechnology, 2006,17(23):5759-5764. |

| [13] | NOVOSELOV K S, GEIM A K, MOROZOV S V , et al. Electric field effect in atomically thin carbon films. Science, 2004,306(5696):666-669. |

| [14] | KAMALI A R, FRAY D J . Large-scale preparation of graphene by high temperature insertion of hydrogen into graphite. Nanoscale, 2015,7(26):11310-11320. |

| [15] | SUN H, LI X, LI Y , et al. High-quality monolithic graphene films via laterally stitched growth and structural repair of isolated flakes for transparent electronics. Chemistry of Materials, 2017,29(18):7808-7815. |

| [16] | VLASSIOUK I, SMIRNOV S, IVANOV I , et al. Electrical and thermal conductivity of low temperature CVD graphene: the effect of disorder. Nanotechnology, 2011, 22(27): 275716-1-9. |

| [17] | KUMAR R, SINGH R K, DUBEY P K , et al. Pressure-dependent synthesis of high-quality few-layer graphene by plasma-enhanced arc discharge and their thermal stability. Journal of Nanoparticle Research, 2013,15(9):1847-1857. |

| [18] | AKINWANDE D, BRENNAN C J, BUNCH J S , et al. A review on mechanics and mechanical properties of 2D materials—graphene and beyond. Extreme Mechanics Letters, 2017,13:42-77. |

| [19] | DUTKIEWICZ J, OZGA P, MAZIARZ W , et al. Microstructure and properties of bulk copper matrix composites strengthened with various kinds of graphene nanoplatelets. Materials Science & Engineering A, 2015,628:124-134. |

| [20] | WANG S, ZHANG Y, ABIDI N , et al. Wettability and surface free energy of graphene films. Langmuir, 2009,25(18):11078-11081. |

| [21] | DAS S, LAHIRI D, LEE D Y , et al. Measurements of the adhesion energy of graphene to metallic substrates. Carbon, 2013,59(7):121-129. |

| [22] | PONRAJ N V, AZHAGURAJAN A, VETTIVEL S C , et al. Graphene nanosheet as reinforcement agent in copper matrix composite by using powder metallurgy method. Surfaces & Interfaces, 2017,6:190-196. |

| [23] | LI JING-FU, ZHANG L, XIAO J K , et al. Sliding wear behavior of copper-based composites reinforced with graphene nanosheets and graphite. Transactions of Nonferrous Metals Society of China, 2015,25(10):3354-3362. |

| [24] | RHO H, LEE S, BAE S , et al. Three-dimensional porous copper- graphene heterostructures with durability and high heat dissipation performance. Scientific Reports, 2015, 5: 12710-1-7. |

| [25] | CHEN Y, ZHANG X, LIU E , et al. Fabrication of in-situ grown graphene reinforced Cu matrix composites. Scientific Reports, 2016, 6: 19363-1-9. |

| [26] | PAVITHRA C L, SARADA B V, RAJULAPATI K V , et al. A new electrochemical approach for the synthesis of copper-graphene nanocomposite foils with high hardness. Sci. Rep., 2014, 4: 4049- 1-7. |

| [27] | JAGANNADHAM K . Thermal conductivity of copper-graphene composite films synthesized by electrochemical deposition with exfoliated graphene platelets. Metallurgical and Materials Transactions B, 2011,43(2):316-324. |

| [28] | HWANG J, YOON T, JIN S H , et al. Enhanced mechanical properties of graphene/copper nanocomposites using a molecular-level mixing process. Adv. Mater., 2013,25(46):6724-6729. |

| [29] | WANG L D, CUI Y, LI B , et al. High apparent strengthening efficiency for reduced graphene oxide in copper matrix composites produced by molecule-lever mixing and high-shear mixing. RSC Advances, 2015,5(63):51193-51200. |

| [30] | ZHAO C . Enhanced strength in reduced graphene oxide/nickel composites prepared by molecular-level mixing for structural applications. Applied Physics A, 2015,118(2):409-416. |

| [31] | HAUSNER H H. Modern Developments in Powder Metallurgy. New York: Plenum Press, 1973. |

| [32] | ZABIHI M, TOROGHINEJAD M R, SHAFYEI A . Application of powder metallurgy and hot rolling processes for manufacturing aluminum/alumina composite strips. Materials Science & Engineering A Structural Materials Properties Microstructure & Processing, 2013,560:567-574. |

| [33] | ELSAYED A, UMEDA J, KONDOH K . The production of powder metallurgy hot extruded Mg-Al-Mn-Ca alloy with high strength and limited anisotropy. Magnesium Technology, 2011,2016:475-480. |

| [34] | KOZBIAL A, LI Z, CONAWAY C , et al. Study on the surface energy of graphene by contact angle measurements. Langmuir, 2014,30(28):8598-8606. |

| [35] | SEO J, CHANG W S, KIM T S . Adhesion improvement of graphene/copper interface using UV/ozone treatments. Thin Solid Films, 2015,584:170-175. |

| [36] | GAO X, YUE H, GUO E , et al. Mechanical properties and thermal conductivity of graphene reinforced copper matrix composites. Powder Technology, 2016,301:601-607. |

| [37] | CHU K, JIA C . Enhanced strength in bulk graphene-copper composites. Physica Status Solidi, 2014,211(1):184-190. |

| [38] | LI Z, WU P, WANG C , et al. Low-temperature growth of graphene by chemical vapor deposition using solid and liquid carbon sources. ACS Nano, 2011,5(4):3385-3390. |

| [39] | SUN Z, YAN Z, YAO J , et al. Growth of graphene from solid carbon sources. Nature, 2010,468(7323):549-552. |

| [40] | WU T, LIU Z, CHEN G , et al. A study of the growth-time effect on graphene layer number based on a Cu-Ni bilayer catalyst system. RSC Advances, 2016,6(28):23956-23960. |

| [41] | NEGISHI R, HIRANO H, OHNO Y , et al. Thickness control of graphene overlayer via layer-by-layer growth on graphene templates by chemical vapor deposition. Japanese Journal of Applied Physics, 2011,50:1271-1295. |

| [42] | ISMACH A, DRUZGALSKI C, PENWELL S , et al. Direct Chemical Vapor Deposition of Single and Few--graphene Layers on Dielectric Surfaces. APS Meeting Abstracts. 2010. |

| [43] | QU D, LI F Z, ZHANG H B , et al. Preparation of graphene nanosheets/copper composite by spark plasma sintering. Advanced Materials Research, 2014,833:276-279. |

| [44] | LIU X, WEI D, ZHUANG L , et al. Fabrication of high-strength graphene nanosheets/Cu composites by accumulative roll bonding. Materials Science & Engineering A, 2015,642:1-6. |

| [45] | SAITO Y, UTSUNOMIYA H, TSUJI N , et al. Novel ultra-high straining process for bulk materials—development of the accumulative roll-bonding (ARB) process. Acta Materialia, 1999,47(2):579-583. |

| [46] | HU Z, TONG G, LIN D , et al. Graphene-reinforced metal matrix nanocomposites-a review. Materials Science and Technology, 2016,32(9):930-953. |

| [47] | KIM W, RIIKONEN J, ARPIAINEN S , et al. Growth of CVD graphene on copper by rapid thermal processing. MRS Proceedings, 2012,1451:27-32. |

| [48] | KIM W J, LEE T J, HAN S H . Multi-layer graphene/copper composites: preparation using high-ratio differential speed rolling, microstructure and mechanical properties. Carbon, 2014,69(4):55-65. |

| [49] | PAVITHRA C L P, SARADA B V, RAJULAPATI K V , et al. Process optimization for pulse reverse electrodeposition of graphene- reinforced copper nanocomposites. Advanced Manufacturing Processes, 2015,31(11):1439-1446. |

| [50] | ZHANG D, ZHAN Z . Strengthening effect of graphene derivatives in copper matrix composites. Journal of Alloys & Compounds, 2016,654:226-233. |

| [51] | BARTOLUCCI S F, PARAS J, RAFIEE M A , et al. Graphene- aluminum nanocomposites. Materials Science & Engineering A, 2011,528(27):7933-7937. |

| [52] | ZHU W, CHANG Q, CHEN L , et al. Preparation and properties of reduced graphene oxide reinforced copper matrix composites. Journal of Wuhan University of Science & Technology, 2018,41(1):37-43. |

| [53] | PENG Y, HU Y, HAN L , et al. Ultrasound-assisted fabrication of dispersed two-dimensional copper/reduced graphene oxide nanosheets nanocomposites. Composites Part B, 2014,58(3):473-477. |

| [54] | CHEN X, TAO J, YI J , et al. Strengthening behavior of carbon nanotube-graphene hybrid in copper matrix composite. Materials Science & Engineering A, 2018,718:427-436. |

| [55] | CUI YE, WANG LIDONG, CAO GUOJIAN , et al. Effect of ball milling on the defeat of few-layer graphene and properties of copper matrix composites. Acta Metallurgica Sinica, 2014,27(5):937-943. |

| [56] | LI M X, XIE J, LI Y D , et al. Reduced graphene oxide dispersed in copper matrix composites: facile preparation and enhanced mechanical properties. Physica Status Solidi, 2015,212(10):2154-2161. |

| [57] | XIONG D B, CAO M, GUO Q , et al. Graphene-and-copper artificial nacre fabricated by a preform impregnation process: bioinspired strategy for strengthening-toughening of metal matrix composite. ACS Nano, 2015,9(7):6934-6943. |

| [58] | ZHANG X, SHI C, LIU E , et al. Achieving high strength and high ductility in metal matrix composites reinforced with a discontinuous three-dimensional graphene-like network. Nanoscale, 2017,9(33):11929-11938. |

| [59] | TU J, WANG N, YANG Y , et al. Preparation and properties of TiB2 nanoparticle reinforced copper matrix composites by in situ processing. Materials Letters, 2002,52(6):448-452. |

| [60] | BAIG Z, MAMAT O, MUSTAPHA M . Recent progress on the dispersion and the strengthening effect of carbon nanotubes and graphene-reinforced metal nanocomposites: a review. Critical Reviews in Solid State and Materials Sciences, 2018,43(1):1-46. |

| [61] | TAYA M, ARSENAULT R . A comparison between a shear lag type model and an eshelby type model in predicting the mechanical properties of a short fiber composite. Scripta Metallurgica, 1987,21(3):349-354. |

| [62] | ZHAO P, JI S . Refinements of shear-lag model and its applications. Tectonophysics, 1997,279(1-4):37-53. |

| [63] | TANG Y, YANG X, WANG R , et al. Enhancement of the mechanical properties of graphene-copper composites with graphene- nickel hybrids. Materials Science and Engineering: A, 2014,599:247-254. |

| [64] | TJONG S C . Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Materials Science and Engineering: R: Reports, 2013,74(10):281-350. |

| [65] | ZHANG D, ZHAN Z . Preparation of graphene nanoplatelets- copper composites by a modified semi-powder method and their mechanical properties. Journal of Alloys and Compounds, 2016,658:663-671. |

| [66] | MILLER W S, HUMPHREYS F J . Strengthening mechanisms in particulate metal matrix composites. Scripta Metallurgica et Materialia, 1991,25(1):33-38. |

| [67] | MOCKO J L SARRAO, et al. Microhardness of the YbxY1-xInCu4 alloy system: the influence of electronic structure on hardness. Journal of Physics: Condensed Matter, 15(50):8719-8723. |

/

| 〈 |

|

〉 |