ZrB2-SiC-ZrC复相超高温陶瓷相组成的定量分析

收稿日期: 2012-05-21

修回日期: 2012-07-17

网络出版日期: 2013-03-20

基金资助

国家自然科学基金重点项目(50632070, 51172255) National Natural Science Foundation of China(50632070, 51172255)

Quantitative Analysis for Phase Compositions of ZrB2-SiC-ZrC Ultra-High Temperature Ceramic Composites

Received date: 2012-05-21

Revised date: 2012-07-17

Online published: 2013-03-20

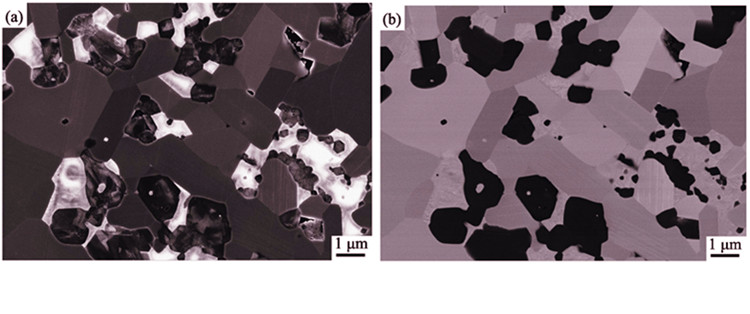

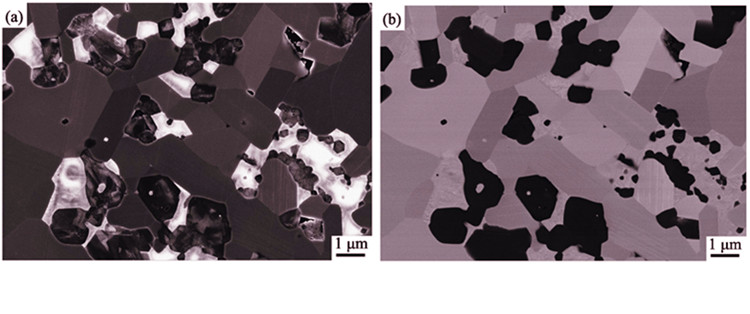

以ZrB2-SiC-ZrC复相超高温陶瓷为研究对象, 对X射线衍射的K值法、二次电子像结合背散射电子像、电子背散射衍射结合能谱面扫描三种相组成的定量分析方法进行了比较, 结果显示K值法使用简单、方便; SEM的两种定量方法不仅可以定量分析相组成, 还能反映相分布与相关系。三种定量方法的结果较一致, 均显示该复相陶瓷实际相组成远远偏离反应烧结设计相组成, 其中, ZrO2杂质相实际含量多于5vol%, ZrC相含量远低于理论值5vol%, K值法显示其含量甚至低于1vol%。相组成的定量分析为进一步开展微结构研究及复合材料设计提供了必要的技术基础。

郑强 , 王贤浩 , 邢娟娟 , 顾辉 , 张国军 . ZrB2-SiC-ZrC复相超高温陶瓷相组成的定量分析[J]. 无机材料学报, 2013 , 28(4) : 358 -362 . DOI: 10.3724/SP.J.1077.2013.12334

Three methods were applied and compared to perform quantitative phase analysis of ZrB2-SiC-ZrC ultra- high temperature ceramic composites: the K value method by powder X-ray diffraction, two SEM methods to combine secondary electron and backscattered electron images, and electron backscatter diffraction and energy dispersive X-ray spectroscope (EDS) mapping. K value method could be applied conveniently and simply, while the two SEM methods could not only be performed quantitative phase analysis but also reveal phase distribution and relationships. Results from the three methods all show significant deviation of phase compositions from the composite designing of reactive sintering, while they are largely consistent with each other. The content of impurity ZrO2 phase is detected more than 5vol%, and in contrast, the content of secondary ZrC phase is found substantially below the theoretical 5vol% level and even below 1vol% as calculated by the more sensitive K value method. These quantitative phase analysis could provide technical supports to study the true composite microstructure and phase designing.

| [1] | 王佩玲,李香庭,陆昌伟,等. 现代无机材料组成与结构表征, 第一版. 北京: 高等教育出版社, 2006: 268-277, 449-490. |

| [2] | Clark G L, Reynolds D H. Quantitative analysis of mine dusts: an X-ray diffraction method. Ind. Eng. Chem., 1936, 8(1): 36-40. |

| [3] | Alexander L, Klug H P. Basic aspects of X-ray absorption in quantitative diffraction analysis of powder mixtures. Anal. Chem., 1948, 20(10): 886-889. |

| [4] | GUO Chang-Lin. X-ray standardless quantitative analysis method for polycrystalline materials. Journal of Inorganic Materials, 1996, 11(1): 1-8. |

| [5] | Davis B L, Walawender M J. Quantitative mineralogical analysis of granitoid rocks: a comparison of X-ray and optical techniques. Am. Mineral., 1982, 67(11/12): 1135-1143. |

| [6] | Goldstein J I, Newbury D E, Joy D C, et al. Scanning Electron Microscopy and X-Ray Microanalysis, third edition. New York: Kluwer Academic / Plenum Publishers, 2003: 1-390. |

| [7] | Fahrenholtz W G, Hilmas G E, Talmy I G, et al. Refractory diborides of zirconium and hafnium. J. Am. Ceram. Soc., 2007, 90(5): 1347-1364. |

| [8] | YAN Yong-Jie, ZHANG Hui, HUANG Zheng-Ren, et al. Synthesis of ultra-fine ZrB2-ZrC composite powders by inorganic Sol-Gel methods. Journal of Inorganic Materials, 2008, 23(4): 815-818. |

| [9] | Wu W W, Zhang G J, Kan Y M, et al. Reactive hot pressing of ZrB2-SiC-ZrC ultra high-temperature ceramics at 1800℃. J. Am. Ceram. Soc., 2006, 89(9): 2967-2969. |

| [10] | Wu W W, Zhang G J, Kan Y M, et al. Reactive hot pressing of ZrB2-SiC-ZrC composites at 1600℃. J. Am. Ceram. Soc., 2008, 91(8): 2501-2508. |

| [11] | Chung F H. Quantitative interpretation of X-ray diffraction patterns of mixtures. I. Matrix-flushing method for quantitative multicomponent analysis. J. Appl. Crystallogr., 1974, 7(6): 519-525. |

| [12] | Chung F H. Quantitative interpretation of X-ray diffraction patterns of mixtures. II. Adiabatic principle of X-ray diffraction analysis of mixtures. J. Appl. Crystallogr., 1974, 7(6): 526-531. |

| [13] | Chung F H. Quantitative interpretation of X-ray-diffraction patterns of mixtures. III. Simultaneous determination of a set of reference intensities. J. Appl. Crystallogr., 1975, 8(1): 17-19. |

| [14] | Zarubova N, Wolf P, Cermak J, et al. Quantitative phase analysis of metastable structure in a laser melted Fe-C alloy: Part I Structural analysis of single melted tracks by SEM and TEM. J. Mater. Sci., 1996, 31(1): 137-143. |

| [15] | Schwartz A J, Kumar M, Adams B L, et al. Electron Backscatter Diffraction in Materials Science, second Edition. New York: Springer, 2009: 1-32. |

| [16] | PDF-2 Data Base: No. 75-1050, 75-0254, 73-0477 and 83-0944. |

/

| 〈 |

|

〉 |