采用固相反应法制备了Y掺杂 (Ba0.6Sr0.3Ca0.1)1-

(Ba0.6Sr0.3Ca0.1)1-

Barium strontium calcium titanate (Ba,Sr,Ca)TiO3 (BSCT), one of the most important ferroelectric solid solution materials, has attracted much attention because of its interesting ferroelectric, dielectric and pyroelectric properties. Due to the high dielectric constant, low dielectricloss, and concentration-dependent phase transition temperature, BSCT shows its potential in dynamics random access memories, tunable microwave devices, and infrared thermal imaging devices[ 1, 2, 3, 4]. In particular, the large changes in spontaneous polarization and dielectric constant near the ferroelectric-paraelectric phase transition allow the development of BSCT-based high performance infrared thermal imaging devices[ 5]. To achieve good imaging performance, much effort has been devoted to the technology of fabricating hybrid arrays detectors with thin pixel and large array, i.e. 10-20 μm thickness and 384×288 elements[ 5, 6, 7]. So it is required to use a ceramics with a grain size much smaller than the thickness, typically the grain size in the range of 1-3 μm, to avoid poor mechanical properties when thinning and large pixel to pixel variation in crystallite orientation and pyroelectric response[ 6].

However, there seems to be a contradiction between high performance and small grain size. It was reported that, for the pure BSCT, the high pyroelectric response cannot be obtained unless the grain size was greater than 10 μm or so[ 6]. In order to solve this problem, various dopants were introduced. Kulwicki[ 6] doped the material with donor ions such as Nb, Ta, Bi, Sb, Y, La and so on, and obtained the greatly improved pyroelectric response ceramics which had a figure of merit Fd greater than 11×10-5 Pa-1/2 and a small grain size (less than 5 μm). Lee, et al[ 8, 9] reported the effects of Y2O3 and MnCO3 doping on the microstructure and electrical properties of Ba0.6Sr0.3Ca0.1TiO3 ceramics prepared by Sol-Gel method and found that 0.5mol% Y2O3 and 0.1mol% MnCO3 doped BSCT ceramics showed the enhanced figure of merit Fd about 5.91×10-5 Pa-1/2 and small grain size (1-3 μm). Because chemical method is more complicated and expensive, it is desirable to prepare the pyroelectric ceramics by conventional solid-state reaction technique, accounting for the easy and low cost fabrication. The present paper describes the Y doping effects on the microstructure, dielectric and the pyroelectric properties of BSCT-based ceramics prepared by solid-state reaction with the goal of assessing the potential applications for infrared detectors.

The ceramics were prepared according to the formula (Ba0.6Sr0.3Ca0.1)1- xY xTi0.999Mn0.001O3 (BSCY xTM, 0≤ x≤0.007), using the conventional solid-state reaction technique. The raw materials used were 99.0%BaCO3, 99.0%SrCO3, 99.0%CaCO3, 99.44%TiO2, 99.99%Y2O3 and 92.83% MnCO3 powders. They were milled in water with agate balls for 24 h. 0.1mol% MnCO3 was added to maintain sufficiently high resistivity, because the purely Y doped BSCT ceramics may be too conductive. After the mixture was dried, it was calcined at 1150℃ for 2 h in air. Then the powder was mixed with a small amount of poly vinyl acetate (PVA) as adhesive and pressed at 100 MPa in a disk of 15 mm in diameter. The samples were sintered at 1450℃ for 2 h in oxygen after the PVA was burned out at 800℃ for 2 h. The sample disks were machined into 0.2 mm in thickness and silver electrodes were screen printed onto both surfaces of the disks.

The crystallinity and the microstructure of the BSCY xTM specimens (0≤ x≤0.007) were observed using X-ray diffraction (XRD, Rigaku D/MAX-2550V) and scanning electron microscope (SEM, JSM-6700F), respectively. The heat capacite per unit volume Cv at room temperature was determined by a Perkin-Elmer DSC-2C system. The temperature variation of the dielectric properties as a function of DC bias field at 1 kHz was measured by an automatic measuring system based on HP4284 LCR meter. The pyroelectric properties with variation of temperature and DC bias field were studied with a Keithley 6517A electrometer/high-resistance meter using modified Byer and Roundy techniques.

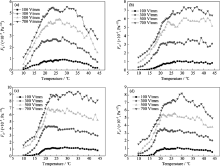

Figure 1 illustrates the XRD patterns of BSCY xTM ceramics (0≤ x≤0.007). All the specimens show a single perovskite structure without second phase. And all peaks move toward high 2 θ with the increase of Y concentration, due to the replacement of Ba2+, Sr2+ and Ca2+ with a smaller Y3+ on the A-site.

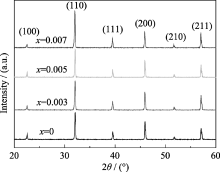

Figure 2 shows the surface SEM micrographs of BSCY xTM ceramics (0≤ x≤0.007). It can be seen that all the specimens exhibit a dense grain structure and the average grain size decreases with Y concentration mono-tonically. When the Y concentration is 0.7mol%, the smallest average grain size of 3.1 μm is obtained, compared with that of 8.5 μm for the undoped specimen. The change in grain size could be attributed to the effect of the donor-dopant incorporation. Drofenik[ 10]proposed that the incorporation behavior of donors played an important role in grain growth and suggested a model for the grain size anomaly. According to this model, the driving force for grain growth of donor doped BaTiO3 consists of the stored energy released during grain growth and the energy consumed during donor incorporation. The more donor dopants added, the more energy consumed for donor incorporation. Therefore, the driving force for grain growth is annihilated, and the grain size decreases.

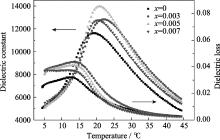

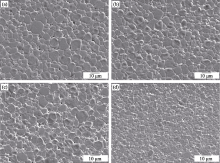

The dielectric constant and dielectric loss as a function of temperature at zero bias field for BSCY xTM ceramics (0≤ x≤0.007) are shown in Fig. 3. Small concentration of Y ions in the ceramics leads to an increase of the dielectric constant (especially the peak dielectric constant), but a further increase of Y concentration causes a decrease of the dielectric constant. Thus, the highest peak dielectric constant was obtained for x=0.005 sample. There are three reasons for the change of the dielectric constant. Firstly, the Y doping in the ceramics leads to the distortion of the crystal lattice, resulting in an increase of internal stress, which is beneficial for the improvement of dielectric constant[ 11]. Secondly, Y ions can inhibit the grain growth and decrease the grain size. With the decrease of grain size, the total 90º domain walls area per volume will increase, giving more contribution to the dielectric constant, which leads to the increase of the dielectric constant[ 12]. Thirdly, as the grain size decreases, the fraction of grain boundary volume increases. Generally, the dielectric constant of grain is larger than that of grain boundary. Therefore, the smaller the grain size is, the more grain boundaries are, and the lower dielectric constant is. As discussed above, the effects of the internal stresses, 90º domain walls and the grain boundary are responsible for the change of the dielectric constant with Y concentration.

| Fig. 3 Dielectric constant and dielectric loss as a function of temperature at zero bias field for BSCY xTM ceramics (0≤ x≤0.007) |

The dielectric loss shows the similar dependence on Y concentration as that of the dielectric constant. The dielectric loss initially increases and then decreases with the increase of Y concentration. The highest dielectric loss was obtained for x=0.003 sample. Obviously, Y doped samples show higher dielectric loss than undoped sample, especially below the transition temperature, which could be attributed to the contributing of the defects to the dielectric loss such as YBa·.

Moreover, it can bee seen that Tc initially increases with Y concentration up to a maximum value of 22.1℃ for x=0.003 before decreasing with increasing Y concentration to a lower value of 20.4℃ for x=0.007. The initial rise in Tc could be attributed to Y, Mn co-doping effect. For x=0 sample, only Mn2+(acceptor) is introduced into the lattice. The replacement of Ti4+ with Mn2+ causes the creation of oxygen vacancy leading to a “break” of the cooperative vibration of the Ti-O chains, and therefore results in the suppression of Tc for the Mn-doped system[ 13, 14]. While for x=0.003 sample, the replacement of Ba2+, Sr2+ and Ca2+ with Y3+ (donor) inhibits oxygen vacancy formation, neutralizing the Mn2+ doping effect on Tc, and therefore results in the initial rise in Tc. Obviously, the decrease in Tc with increasing x from 0.003 to 0.007 can be understood by the A-site cation size effect, in which the smaller Y ion causes a reduction in the average radius of the A-cation size and thereby stabilizes the high temperature cubic structure to lower temperature.

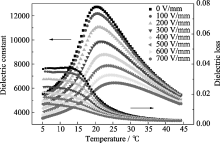

The dielectric constant and dielectric loss as a function of temperature under different DC bias fields for BSCY xTM ceramics ( x=0.007) are illustrated in Fig. 4. With the increase of bias field, the curves display the broadness of peak and the reduction in the dielectric constant and loss, which can be attributed to the domain wall motion under DC bias field[ 15]. Moreover, Tc shifts to a higher temperature as DC bias field increases, which confirms that FE phase can be stabilized by the electric field.

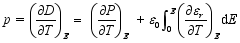

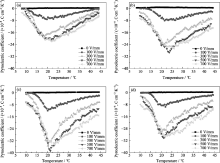

Figure 5 shows the pyroelectric coefficient as a function of temperature under different DC bias fields for BSCY xTM ceramics (0≤ x≤0.007). For each specimen, the maximum pyroelectric coefficient first increases and then decreases with the increase of DC bias field from 0 to 700 V/mm. Generally, the pyroelectric coefficient under DC bias can be obtained as following[ 5]:

| (1) |

where D is the displacement, T is temperature, E is the bias field, P is the polarization, and εr is dielectric constant. According to equation 1, the total pyroelectric coefficient p consists of the spontaneous polarization contribution (the first item on the right side) and the dielectric contribution (the second item). Under zero field, the net decrease of the spontaneous polarization is zero because of the random orientation of dipoles and the dielectric contribution is also zero, and then no pyroelectric current can be detected. As the bias field increases, larger and larger pyroelectric current can be obtained, mainly because more and more dipoles are orientated along the bias field direction. When the bias field continues to increase, the polarization becomes saturated, but the pyroelectric current decreases due to the dielectric contribution. It implies that the polarization plays a more important role in pyroelectric response than dielectric contribution.

| Fig. 5 Pyroelectric coefficient as a function of temperature under different DC bias fields for BSCY xTM ceramics(a) x=0; (b) x=0.003; (c) x=0.005; (d) x=0.007 |

Y doped samples show higher pyroelectric coefficient than undoped sample. The highest pyroelectric coefficient peak of 37.8×10-8 C/(cm2•K) is obtained for x=0.005 sample, which is almost twice than that of undoped sample. The pyroelectric coefficient is mainly dependent on the polarization. Therefore, the enhanced pyroelectric response is mainly due to the enhanced polarization by the Y doping, which could be confirmed by the enhanced dielectric constant as shown in Fig. 3.

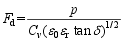

The pyroelectric figure of merit Fd which describes signal to noise can be obtained as following:

| (2) |

where p is pyroelectric coefficient, Cv the heat capacity per unit volume, approximately 2.38 J/(cm3•K), εr dielectric constant and tan δ dielectric loss. Figure 6 shows the figure of merit Fd as a function of temperature and DC bias field for BSCY xTM ceramics (0≤ x≤0.007). Since the dielectric constant and loss are both suppressed by the DC bias field, the figure of merit Fd increases as the DC bias field increases for all specimens. For x=0.007 sample, it shows a maximum Fd value of 8.22×10-5 Pa-1/2 under 700 V/mm near 30℃ with the smallest average grain size of 3.1 μm, while the undoped sample exhibits a maximum Fd value of 5.54×10-5 Pa-1/2 with the largest average grain size of 8.5 μm, which indicates that microstructure and pyroelectric properties of the sample are both improved by the Y doping.

| Fig. 6 The figures of merit Fd as a function of temperature and DC bias field for BSCY xTM ceramics(a) x=0; (b) x=0.003; (c) x=0.005; (d) x=0.007 |

Pyroelectric properties of BSCY xTM ceramics prepared by solid-state reaction and Sol-Gel method are given in Table 1. Typical properties of Ba0.67Sr0.33TiO3 ceramics listed are approximate and broadly published. Obviously, BSCY xTM ceramics prepared by solid-state reaction technique exhibit the highest Fd value. And for x=0.007 sample in this work, its maximum Fd is higher than that of ceramics prepared by Sol-Gel method[ 8, 9].

| Table 1 Pyroelectric properties of BSCY xTM ceramics prepared by solid-state reaction and Sol-Gel method |

(Ba0.6Sr0.3Ca0.1)1- xY xTi0.999Mn0.001O3(0≤ x≤0.007) ceramics were prepared by the solid-state reaction technique. The average grain size decreased from 8.5 μm to 3.1 μm with the increase of x from 0 to 0.007, due to the effect of the donor-dopant incorporation. The dielectric and pyroelectric properties measurement results show that the dielectric constant, dielectric loss, Tc and pyroelectric co efficient all initially increase and then decrease with Y concentration. The specimen doped with 0.7mol% Y shows a improved maximum Fd value of 8.22×10-5 Pa-1/2 under 700 V/mm near 30℃ with the smallest average grain size of 3.1 μm, indicating that the smaller grain size and higher pyroelectric properties can be both achieved by Y doping. Thus, the specimen doped with 0.7mol% Y prepared by solid-state technique is very promising for practical use in uncooled infrared imaging arrays detectors.

| [1] |

|

| [2] |

|

| [3] |

|

| [4] |

|

| [5] |

|

| [6] |

|

| [7] |

|

| [8] |

|

| [9] |

|

| [10] |

|

| [11] |

|

| [12] |

|

| [13] |

|

| [14] |

|

| [15] |

|

| [16] |

|

(

(

)1/2}. Such properties are found in ferroelectric perovskite ceramics and a wide range have been explored for their use in pyroelectric arrays. These include materials based on compositions in the PbZrxTi1 – xO3 (PZT) system, for example close to PbZrO3, with Curie temperatures well above ambient. Examples of the ways in which these materials can be modified by doping to optimise their FoM and other important properties such as electrical resistivity are given and the physics operating behind this discussed. The performances and costs of uncooled pyroelectric arrays are ultimately driven by the materials used. For this reason, continuous improvements in materials technology are important. In the area of bulk ceramics, it is possible to obtain significant improvements in both production costs and performance though the use of tape-cast, functionally-gradient materials. Finally, the use of directly-deposited ferroelectric thin films on silicon ASIC

)1/2}. Such properties are found in ferroelectric perovskite ceramics and a wide range have been explored for their use in pyroelectric arrays. These include materials based on compositions in the PbZrxTi1 – xO3 (PZT) system, for example close to PbZrO3, with Curie temperatures well above ambient. Examples of the ways in which these materials can be modified by doping to optimise their FoM and other important properties such as electrical resistivity are given and the physics operating behind this discussed. The performances and costs of uncooled pyroelectric arrays are ultimately driven by the materials used. For this reason, continuous improvements in materials technology are important. In the area of bulk ceramics, it is possible to obtain significant improvements in both production costs and performance though the use of tape-cast, functionally-gradient materials. Finally, the use of directly-deposited ferroelectric thin films on silicon ASIC s is offering considerable potential for low cost high performance pyroelectric arrays. The challenges involved in developing such materials will be discussed, especially from the aspect of low temperature deposition and other fabrication issues, such as patterning. Sol gel deposition provides an excellent technique for thin film growth and Mn-doped PZT films can be grown at 560

s is offering considerable potential for low cost high performance pyroelectric arrays. The challenges involved in developing such materials will be discussed, especially from the aspect of low temperature deposition and other fabrication issues, such as patterning. Sol gel deposition provides an excellent technique for thin film growth and Mn-doped PZT films can be grown at 560 C with a FoM FD exceeding those of many bulk materials.

C with a FoM FD exceeding those of many bulk materials.